Garlic harvesting vibrating shovel with adjustable row spacing

A vibrating shovel and garlic technology, applied in excavating harvesters, harvesters, excavators, etc., can solve the problems of garlic farmers' economic loss, incomplete soil crushing, and leakage of garlic, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

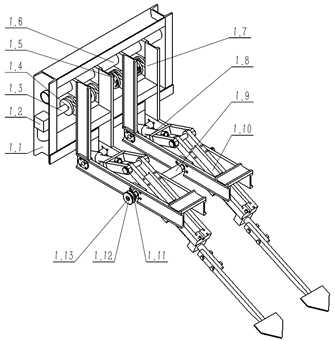

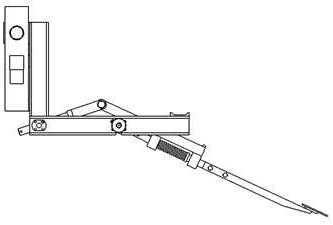

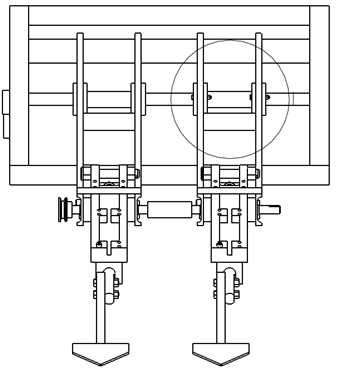

[0033] Such as Figure 1 to Figure 18 As shown, the present invention includes 1.1, frame, 1.2, motor, 1.3, row spacing adjustment screw, 1.4, fixed sleeve, 1.5, row spacing adjustment sleeve, 1.6, row spacing adjustment guide rail, 1.7, vibrating shovel frame, 1.8, depth adjustment device , 1.9, transmission sleeve, 1.10, vibrating shovel mechanism, 1.11 hexagon socket head cap screw, 1.12, driven wheel, 1.13, crankshaft, 1.14, inner angle screw, 1.15, crankshaft frame fixing seat, 1.16 crankshaft fixing seat, 1.17, bolt, 1.18 , Nut. The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Such as figure 1 , image 3 , Figure 4 , Figure 5 As shown in , the motor 1.2 is installed on the vertical channel steel at one end of the frame 1.1; the row spacing adjustment guide rail 1.6 is installed in the installation hole of the row spacing adjustment guide rail of the frame 1.1; the row spacing adjustment screw 1.3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com