Alkali residue soil hydraulic cofferdam construction process and construction equipment

A technology of construction equipment and construction technology, which is applied in the field of construction technology and construction equipment for alkaline slag soil hydraulic enclosures, can solve problems such as affecting construction, stones are easily stuck on sieve holes, and sieve holes are blocked, so as to achieve a construction that is conducive to construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

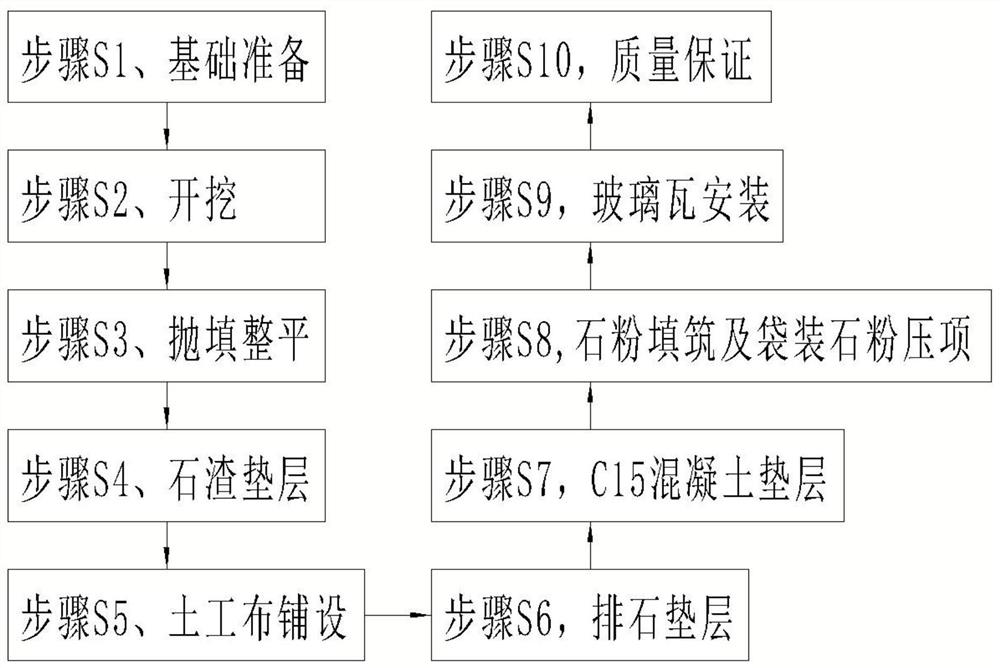

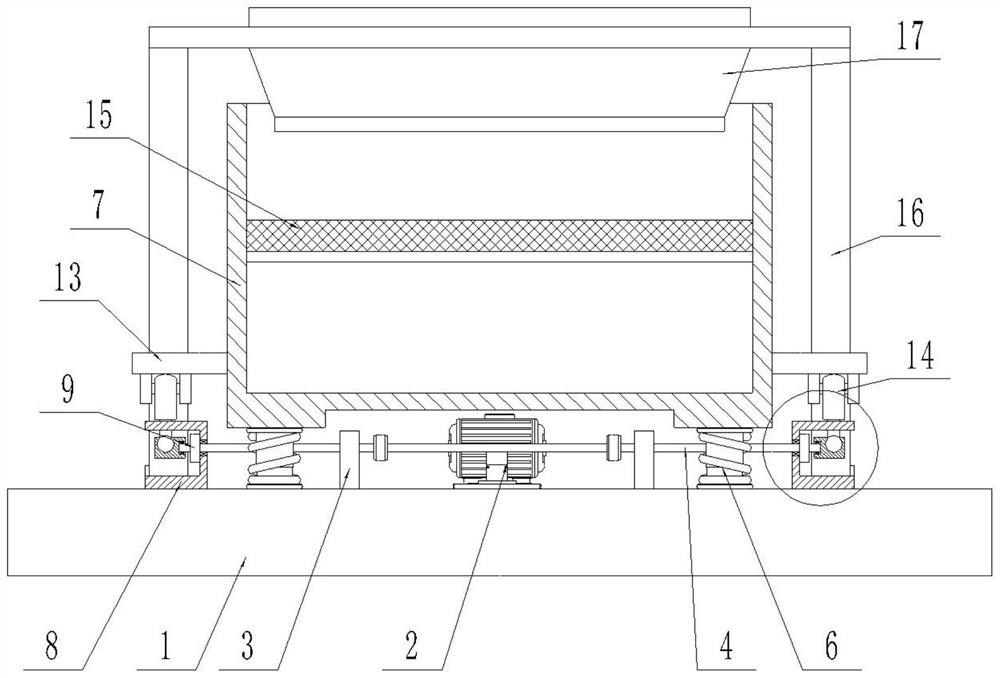

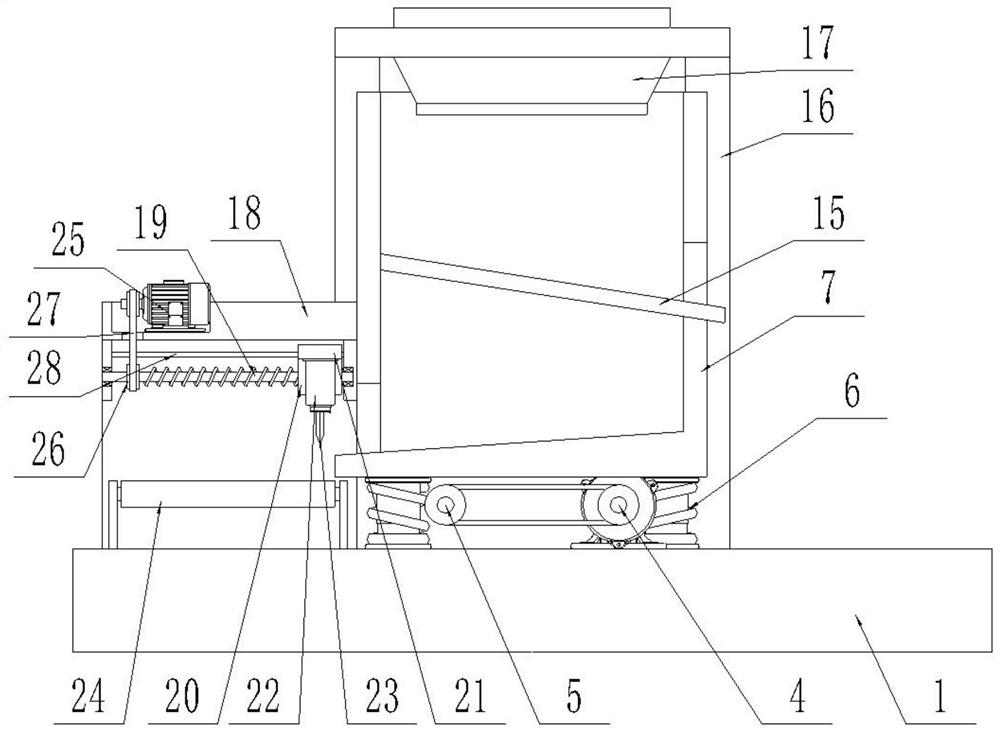

[0064] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, the construction technology and construction equipment of alkali slag soil hydraulic enclosure.

[0065] The construction process of alkali slag soil hydraulic enclosure includes the following operation steps: step S1, foundation preparation, step S2, excavation, step S3, throwing and filling leveling, step S4, gravel cushion, step S5, geotextile laying, Step S6, rock cushion, step S7, C15 concrete cushion, step S8, stone powder filling and bagged stone powder pressing, step S9, glass tile installation and step S10, quality assurance;

[0066] Step S1, technical preparation, material preparation, and equipment preparation; step S2, after step S1 is completed, use the total station to control the plane, perform re-measurement and drawing, calculate the actual required excavation volume, and monitor the excavation machinery regularly. The excavation de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com