Patents

Literature

95 results about "Glass tile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass tiles are pieces of glass formed into consistent shapes.

LED lighting for glass tiles

InactiveUS20090147504A1Easy to removeEasy to replaceCovering/liningsPoint-like light sourceBrickSurface layer

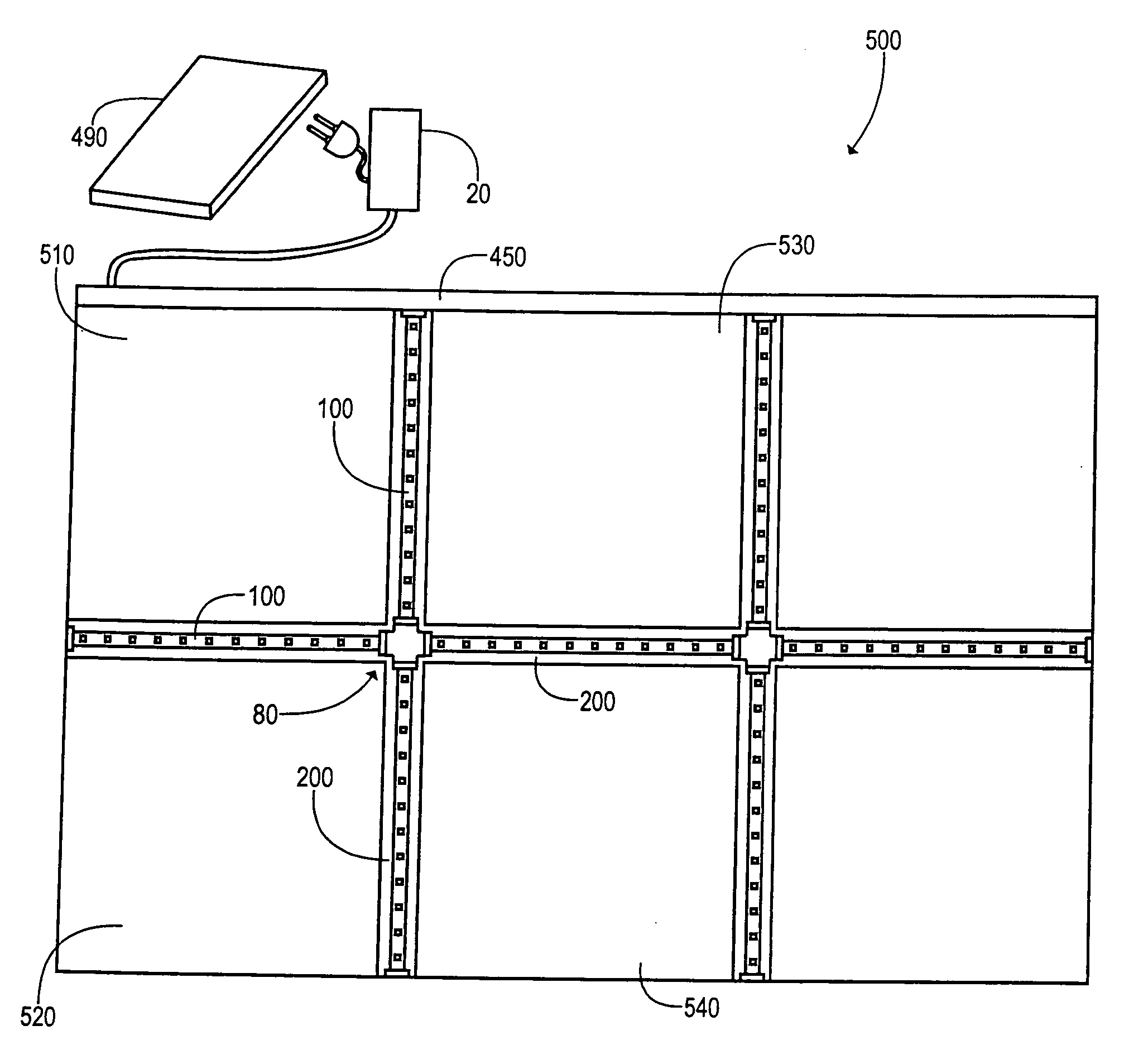

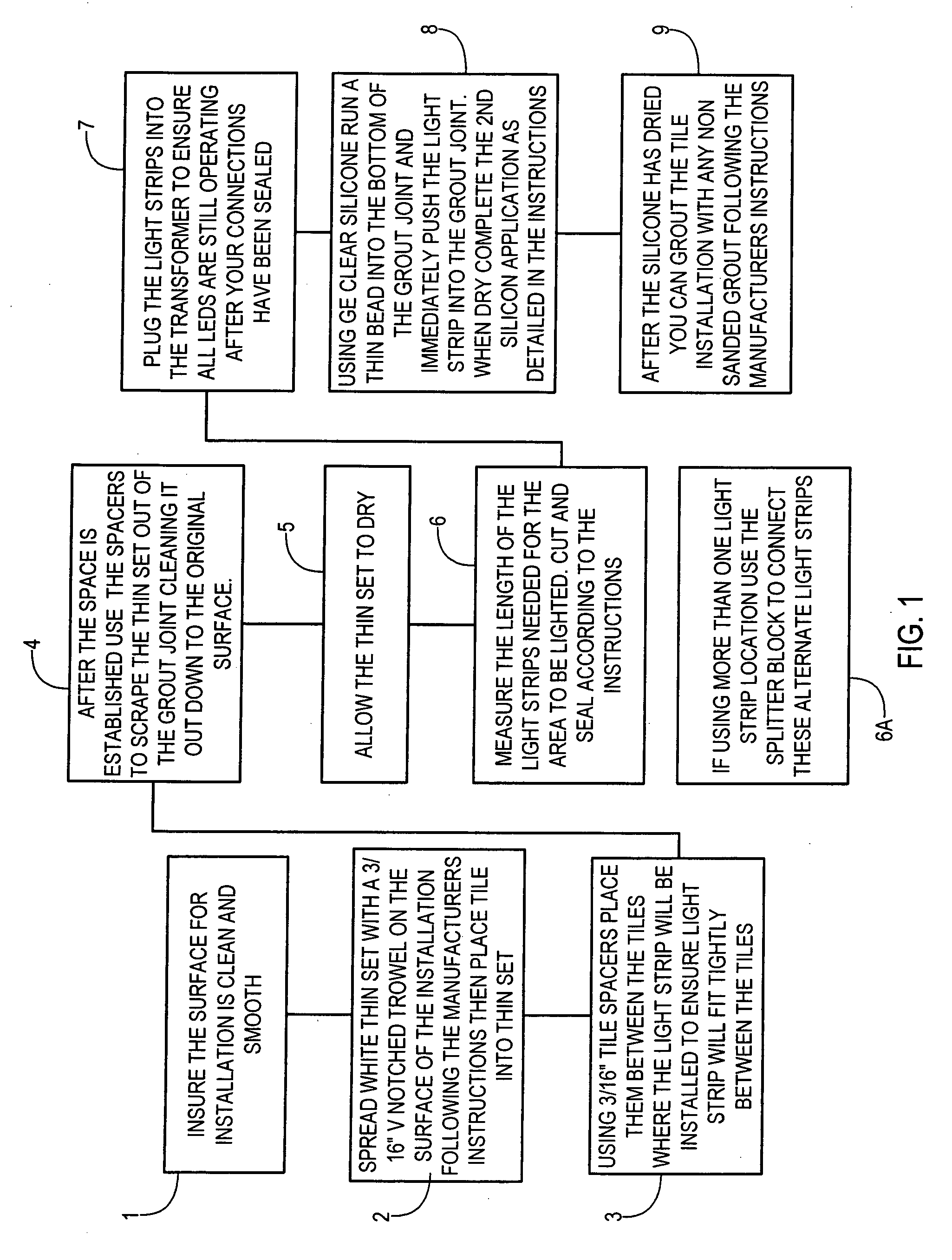

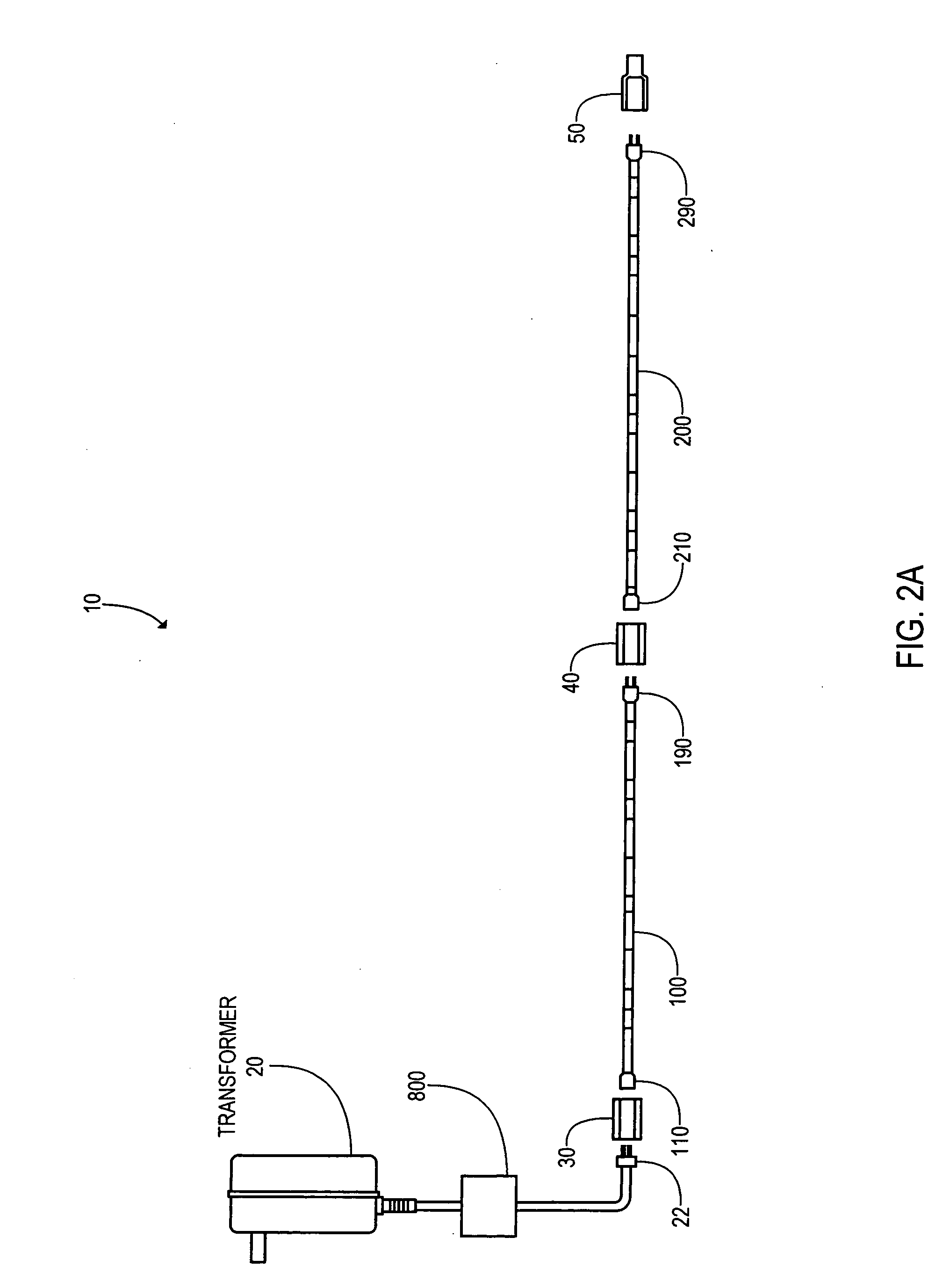

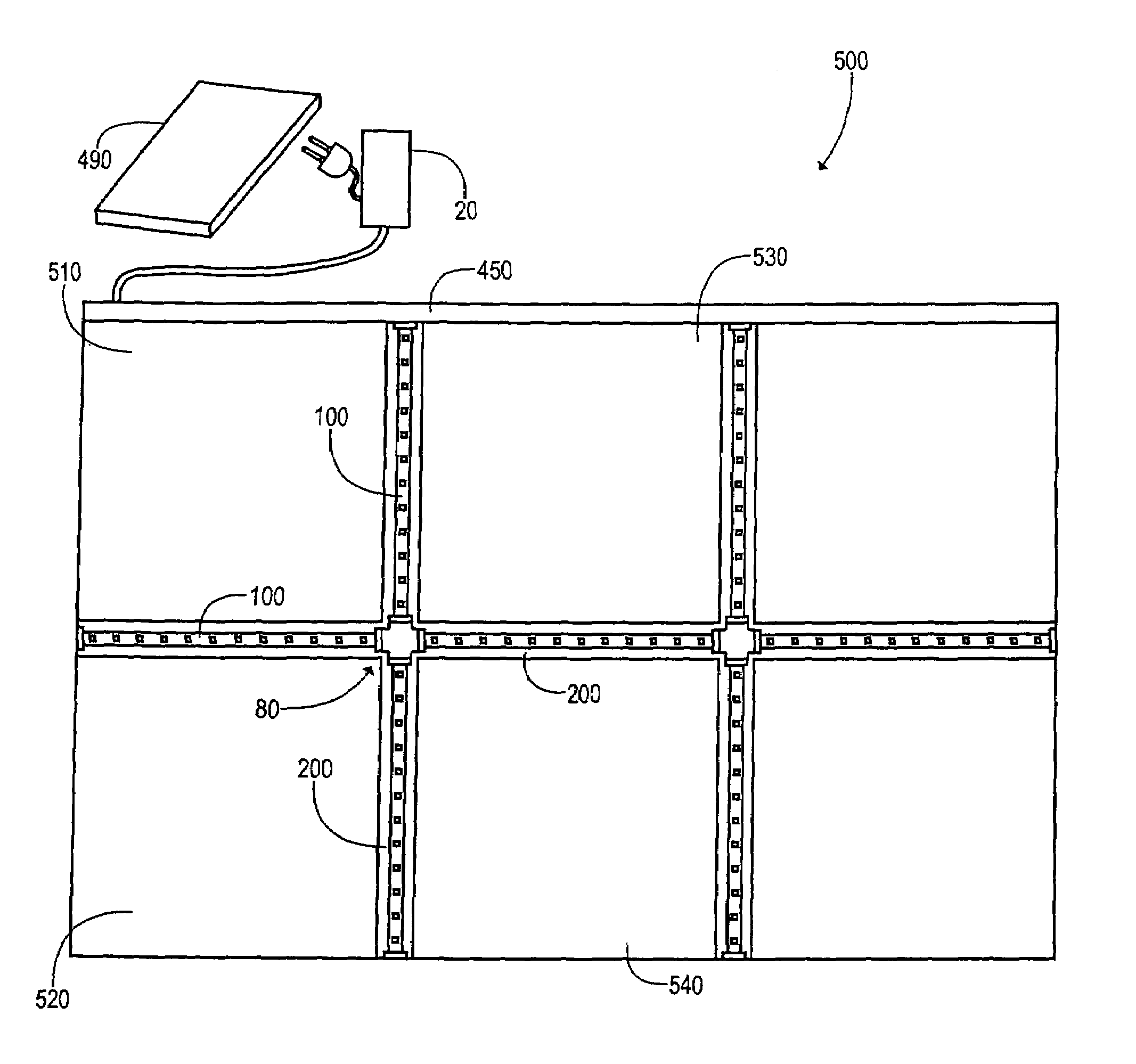

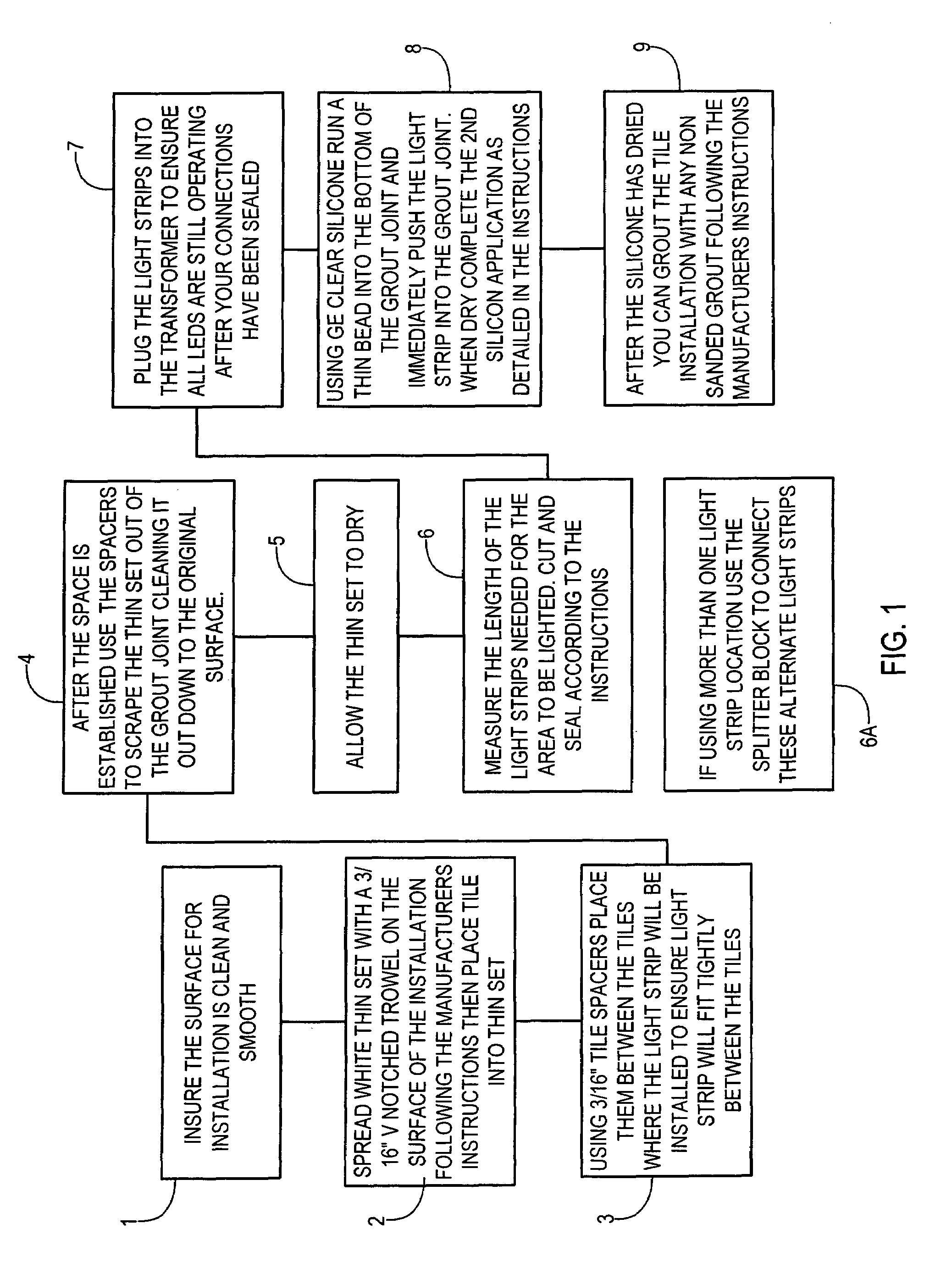

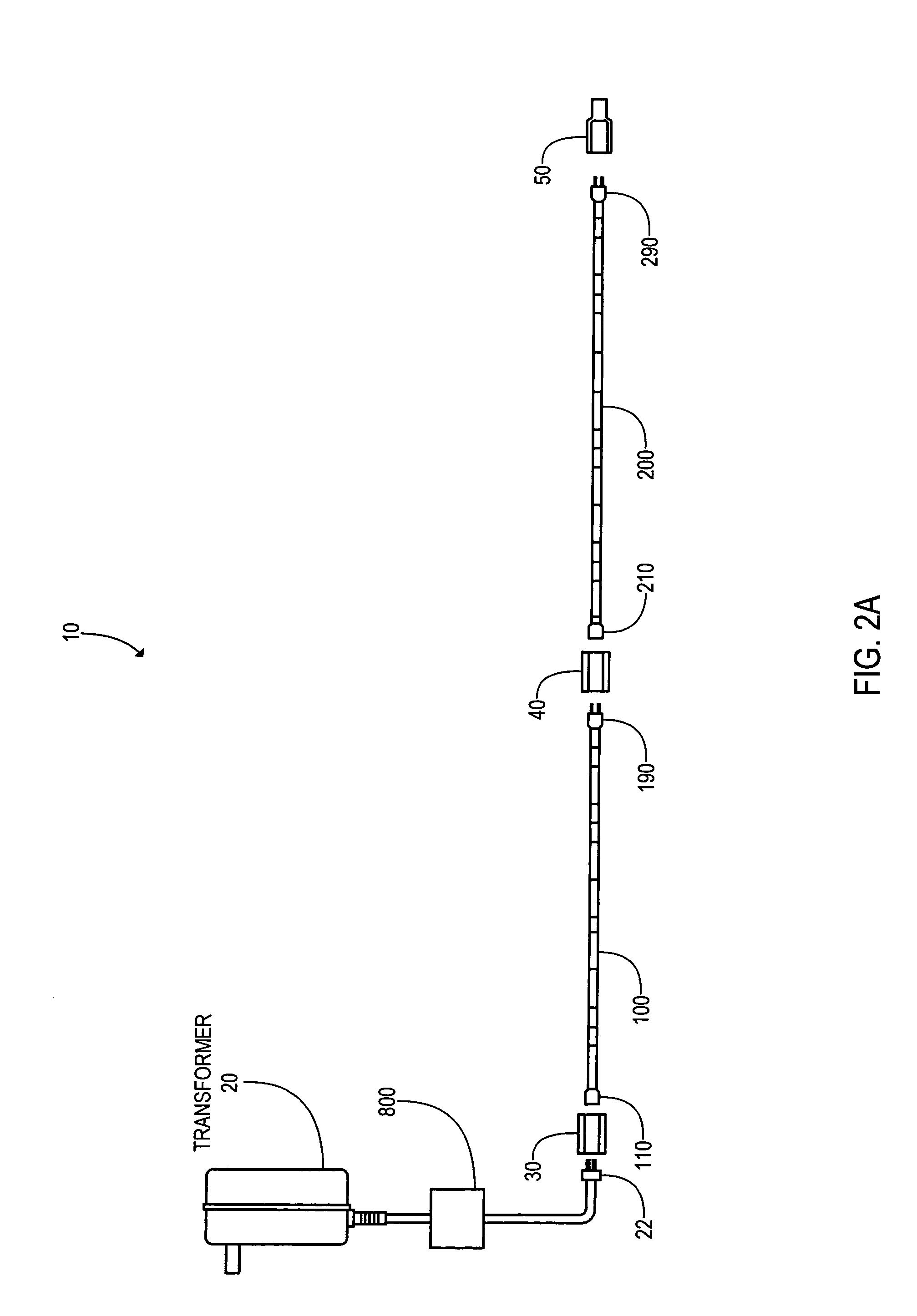

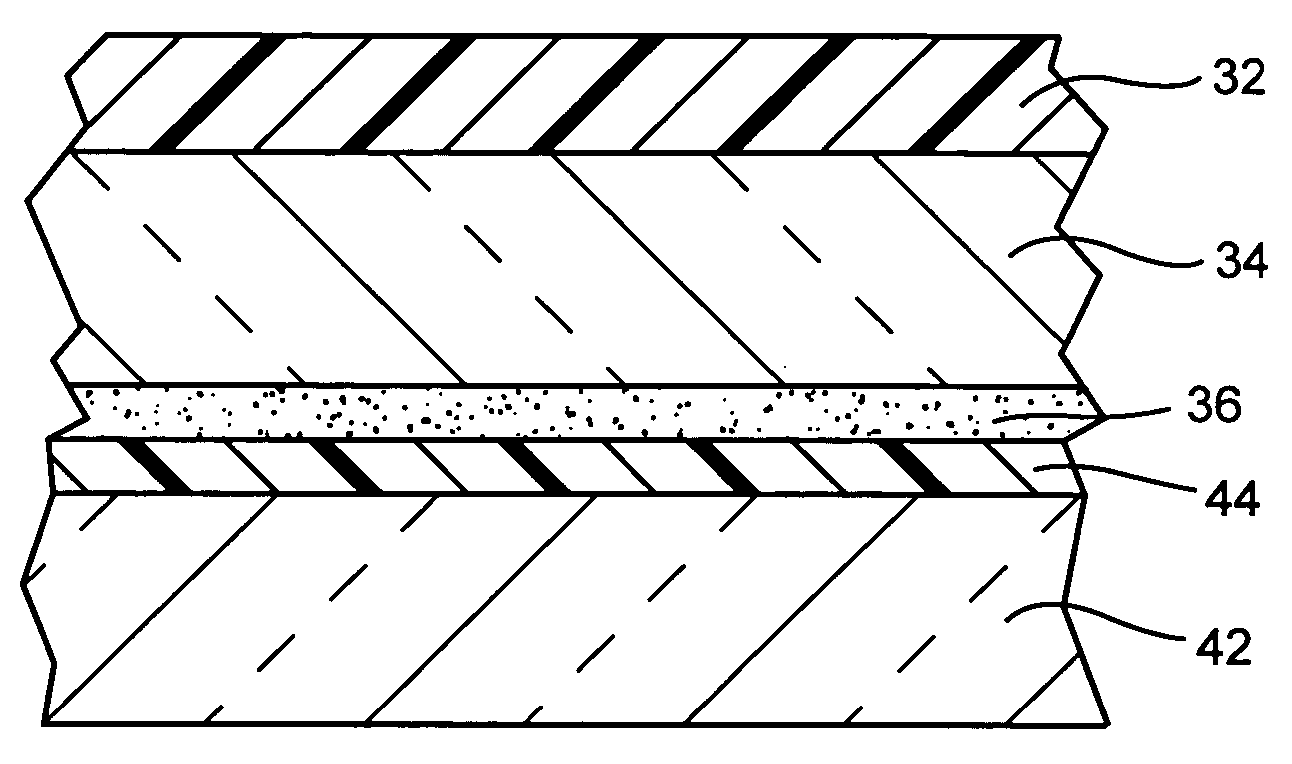

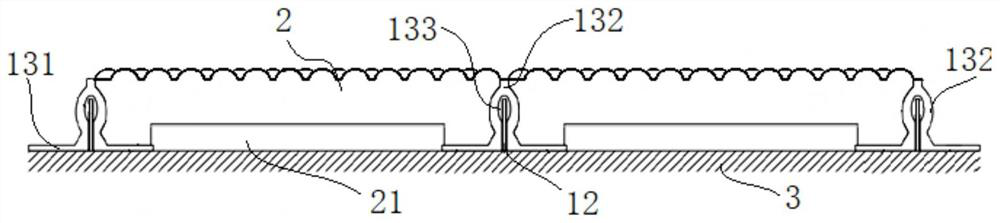

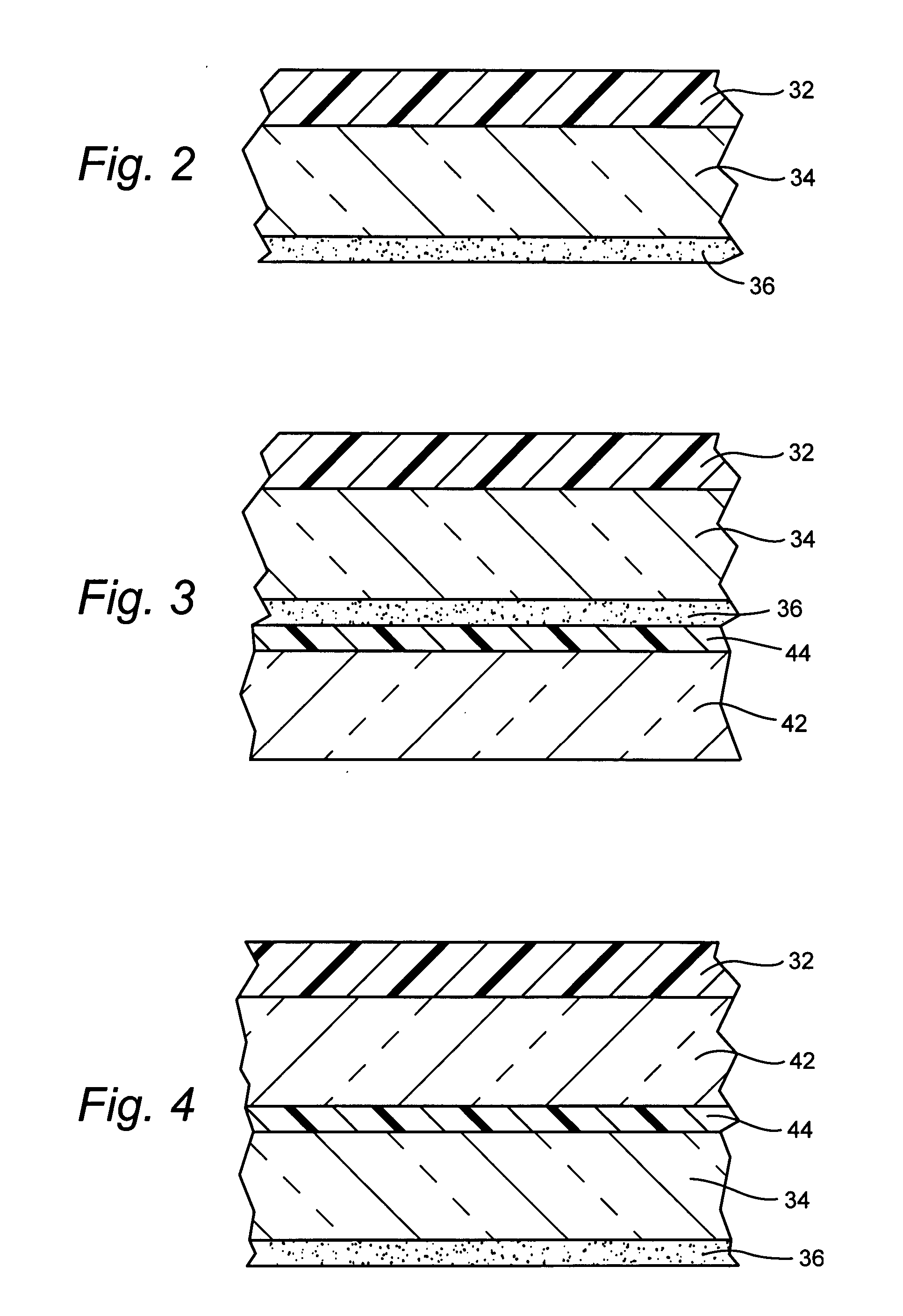

Devices, apparatus, systems, and methods of installing LED (light emitting diodes) for glass tiles and glass blocks. The LEDs can be housed in flexible strips having flexible bendable transparent housing sleeves with ends that can interconnect by male and female ends to one another with various types of interconnectors. Each separate sleeve can house up to 33 LEDs in a transparent plastic sleeve. A transparent connector sleeve can be slid over the interconnected ends and heat shrunk in place. The glass tiles can be laid out to uniform joints spacings between the glass tiles of approximately 3 / 16 of an inch. The LED strips can be placed on a surface layer of transparent grout that has been laid in the joint spacing, followed by a top layer of transparent grout. The transparent grout can be removable grout and include clear Silicon. The LED strips can have peel and stick back layers with adhesive backing that allows mounting to the lower surface. The LED strips can be placed with glass tiles, and other types of tiles such as but not limited to ceramic tiles, stone tiles and the like, as well as with glass blocks. Splitter(s) can be used to run parallel runs of LED strips at different spaced apart locations.

Owner:NEW HORIZON DESIGNS

LED lighting for glass tiles

InactiveUS7549784B1Easy to removeEasy to replaceCovering/liningsPoint-like light sourceInterconnectorBrick

Devices, apparatus, systems, and methods of installing LED (light emitting diodes) for glass tiles and glass blocks. The LEDs can be housed in flexible strips having flexible bendable transparent housing sleeves with ends that can interconnect by male and female ends to one another with various types of interconnectors. Each separate sleeve can house up to 33 LEDs in a transparent plastic sleeve. A transparent connector sleeve can be slid over the interconnected ends and heat shrunk in place. The glass tiles can be laid out to uniform joints spacings between the glass tiles of approximately 3 / 16 of an inch. The LED strips can be placed on a surface layer of transparent grout that has been laid in the joint spacing, followed by a top layer of transparent grout. The transparent grout can be removable grout and include clear Silicon. The LED strips can have peel and stick back layers with adhesive backing that allows mounting to the lower surface. The LED strips can be placed with glass tiles, and other types of tiles such as but not limited to ceramic tiles, stone tiles and the like, as well as with glass blocks. Splitter(s) can be used to run parallel runs of LED strips at different spaced apart locations.

Owner:NEW HORIZON DESIGNS

Fluoropolymer organic lining anticorrosive material for chimney, flue and other pipelines and containers and construction method thereof

ActiveCN101891993AImprove temperature resistanceImprove acid resistanceBio-packagingLarge containersVulcanizationAdhesive

The invention provides an anticorrosive material for a chimney, a flue and other containers and pipelines and an anticorrosive construction process. The construction method of the anticorrosive material comprises the following steps: using crude rubber with higher fluorine content as a raw material, then adding curing agent, stabilizer, special stuffing and other components, and mixing to form precuring gross rubber; dissolving the rubber by using low-molecular weight esters and ketones as the solvent to form a putty type rubber paste; and finally, adding special additives, uniformly mixing, coating to the inner walls of a chimney, a flue and a chemical container, and curing into the polymerized fluororubber organic lining under the room-temperature condition. The material can be independently used as the anticorrosive material, and can also be used for protecting common foam glass bricks (ceramic bricks) and adhesive for anticorrosive purpose in the domestic chimney (flue) at present. The invention well solves the technical problems of fluororubber room-temperature curing and difficult anticorrosive construction, can be used in a high-temperature environment of more than 230 DEG C, and can endure high-concentration sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, corresponding salts and a mixture thereof. The anticorrosive lining material is economically affordable, has extremely high comprehensive anticorrosive properties such as temperature resistance, acid resistance and the like, and is applicable to the anticorrosive treatment of a cured chimney.

Owner:重庆大众防腐股份有限公司

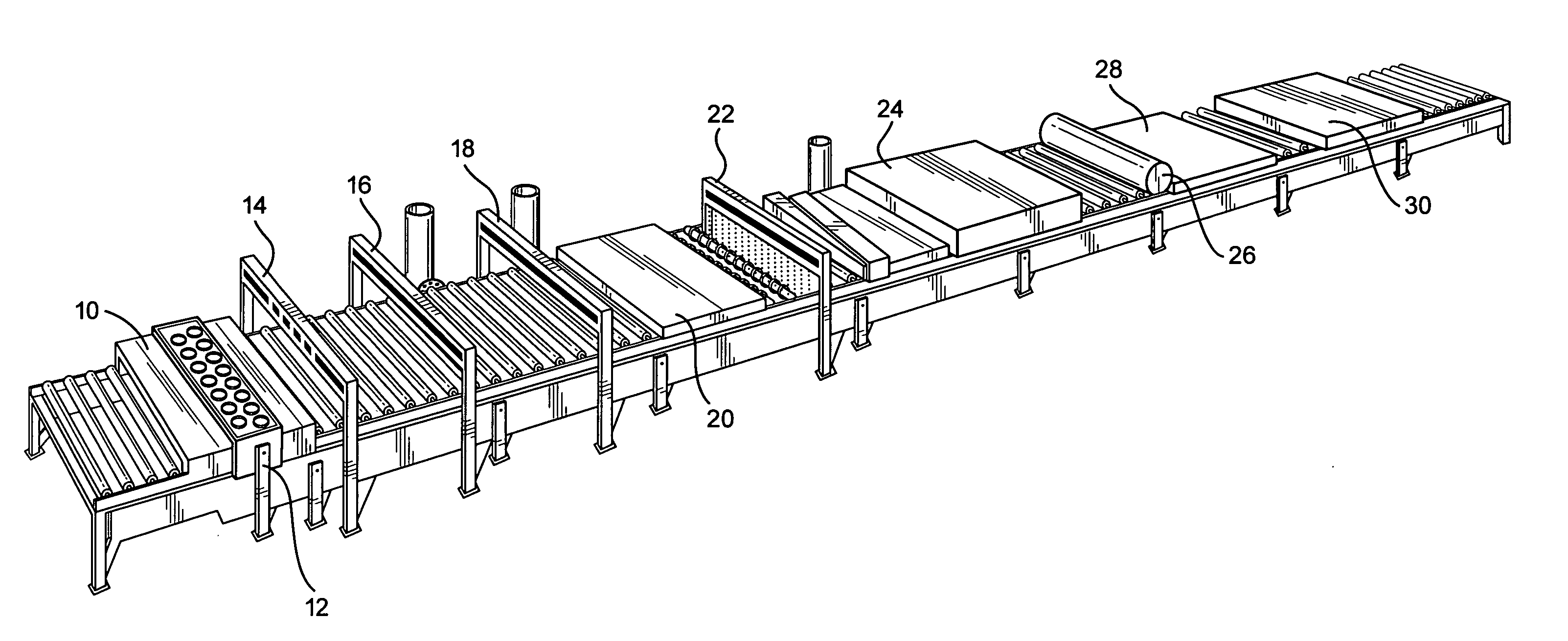

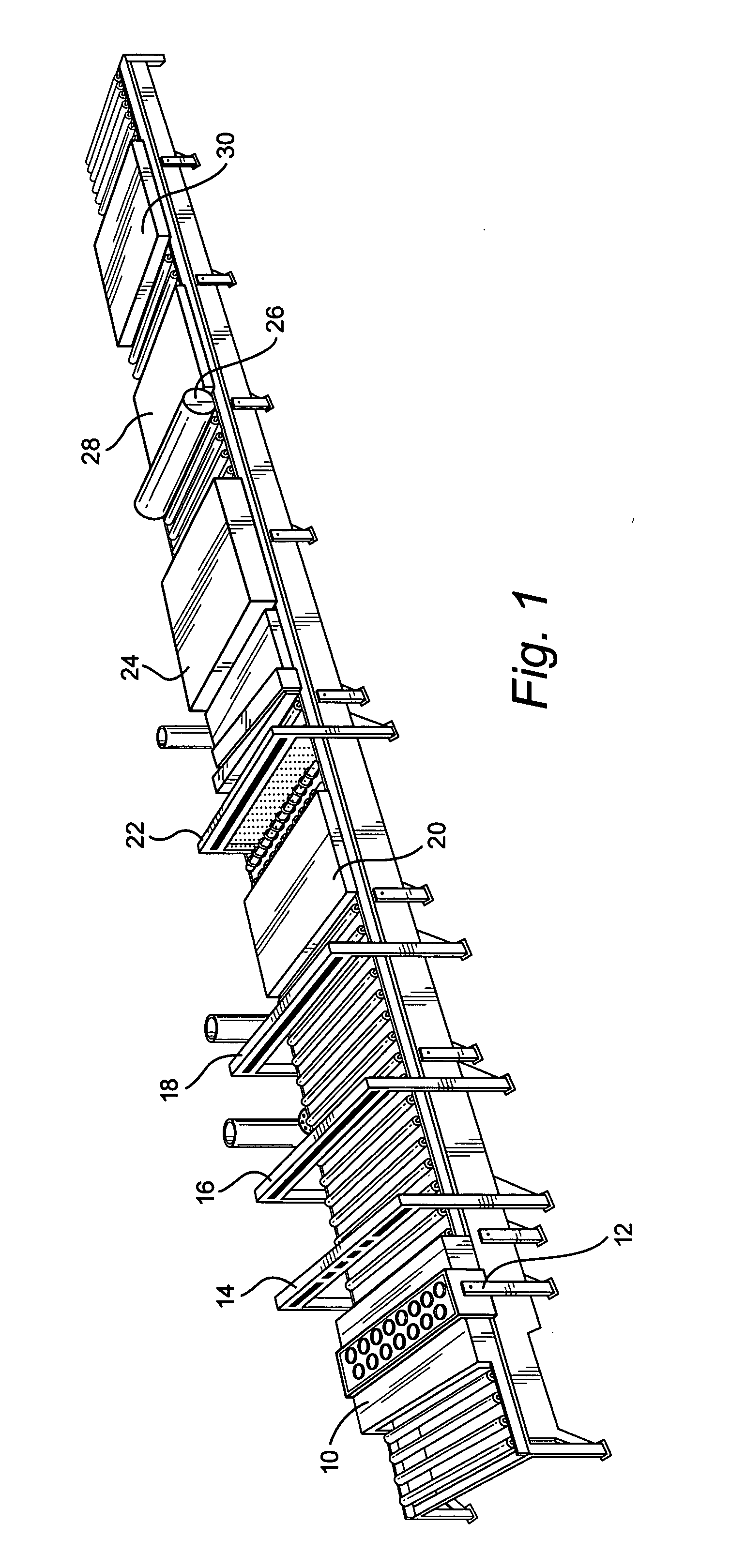

Painted glass tiles, panels and the like and method for producing painted glass tiles and panels

InactiveUS20060115651A1Reduce and minimize corrosionAbrasion resistanceCovering/liningsSpecial ornamental structuresProduction lineBrick

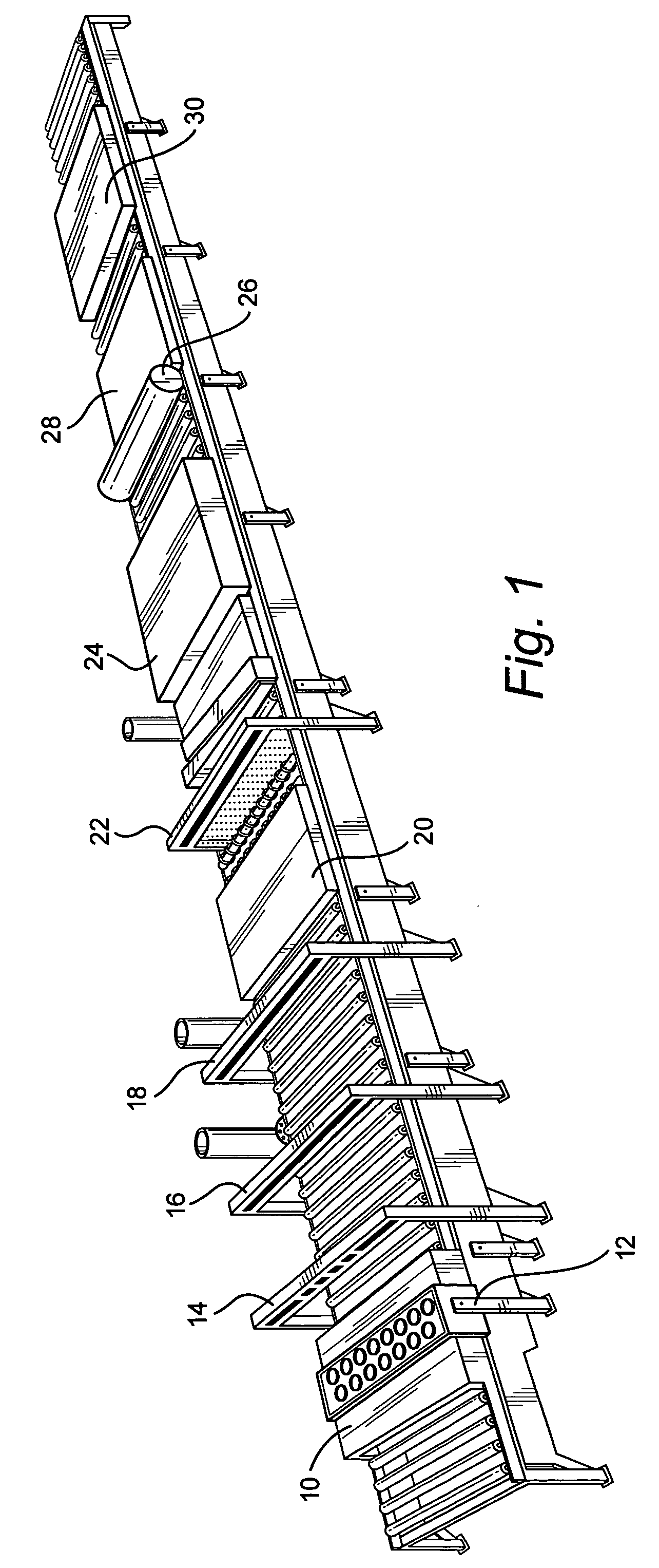

A process and apparatus for painting float glass in particular using a production line that may also be used as or is similar to a mirror line, to produce decorative glass panels. In an embodiment of the invention, painted glass tiles are cut from the glass panels after the paint has dried / cured using a typical glass panel cutter. As such, a mass production technique is provided for making painted glass tiles, particularly for residential use.

Owner:GUARDIAN GLASS LLC

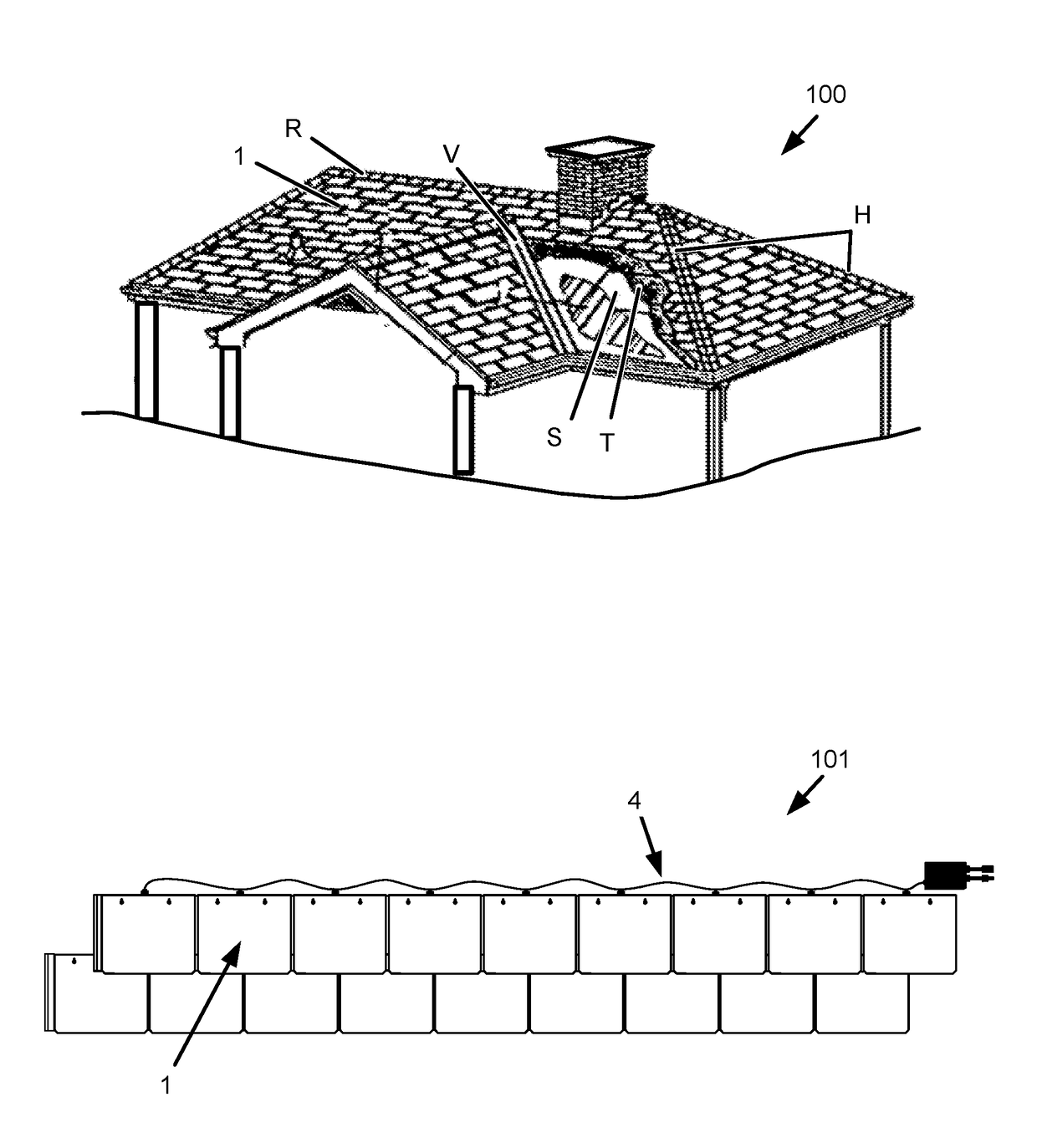

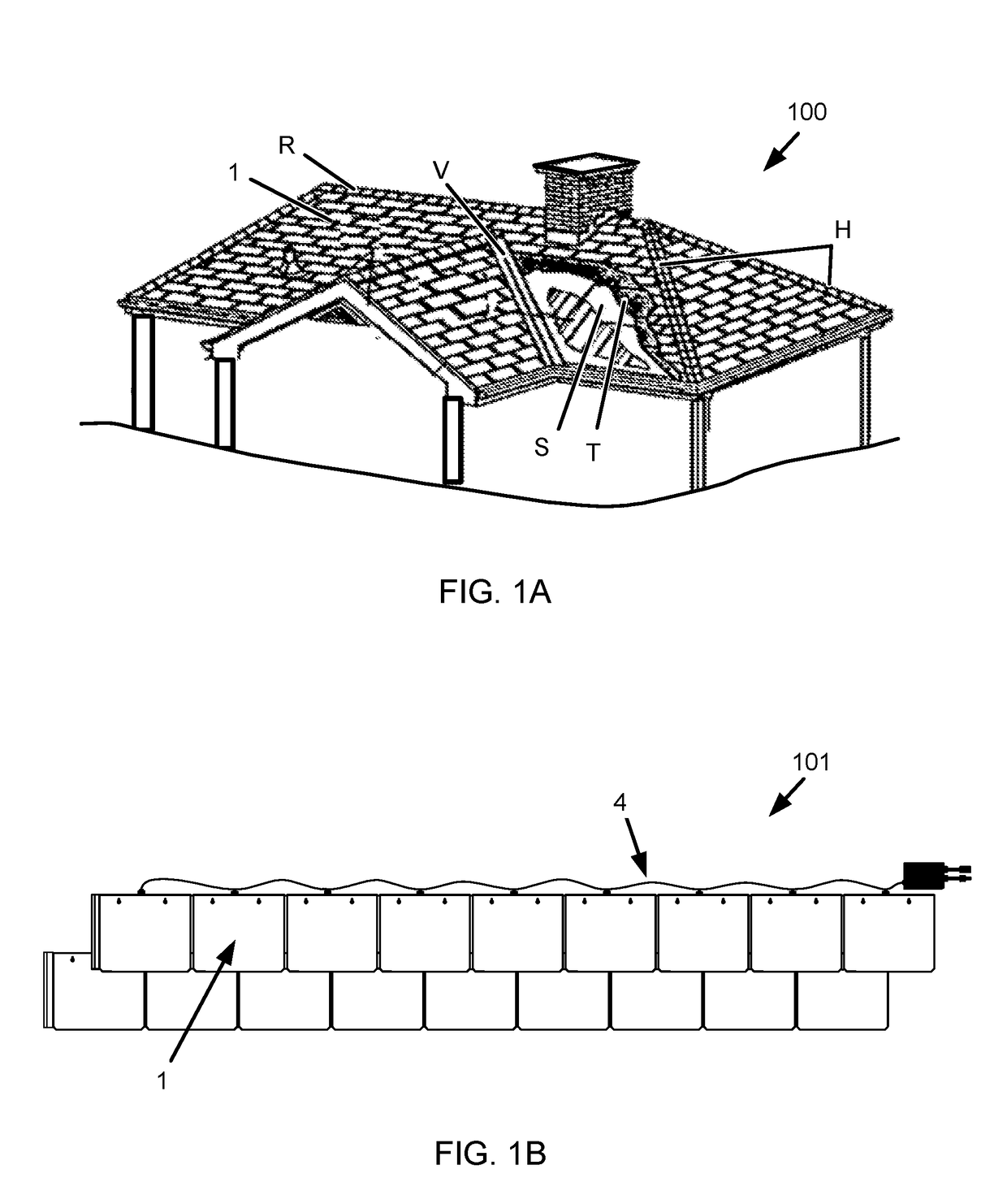

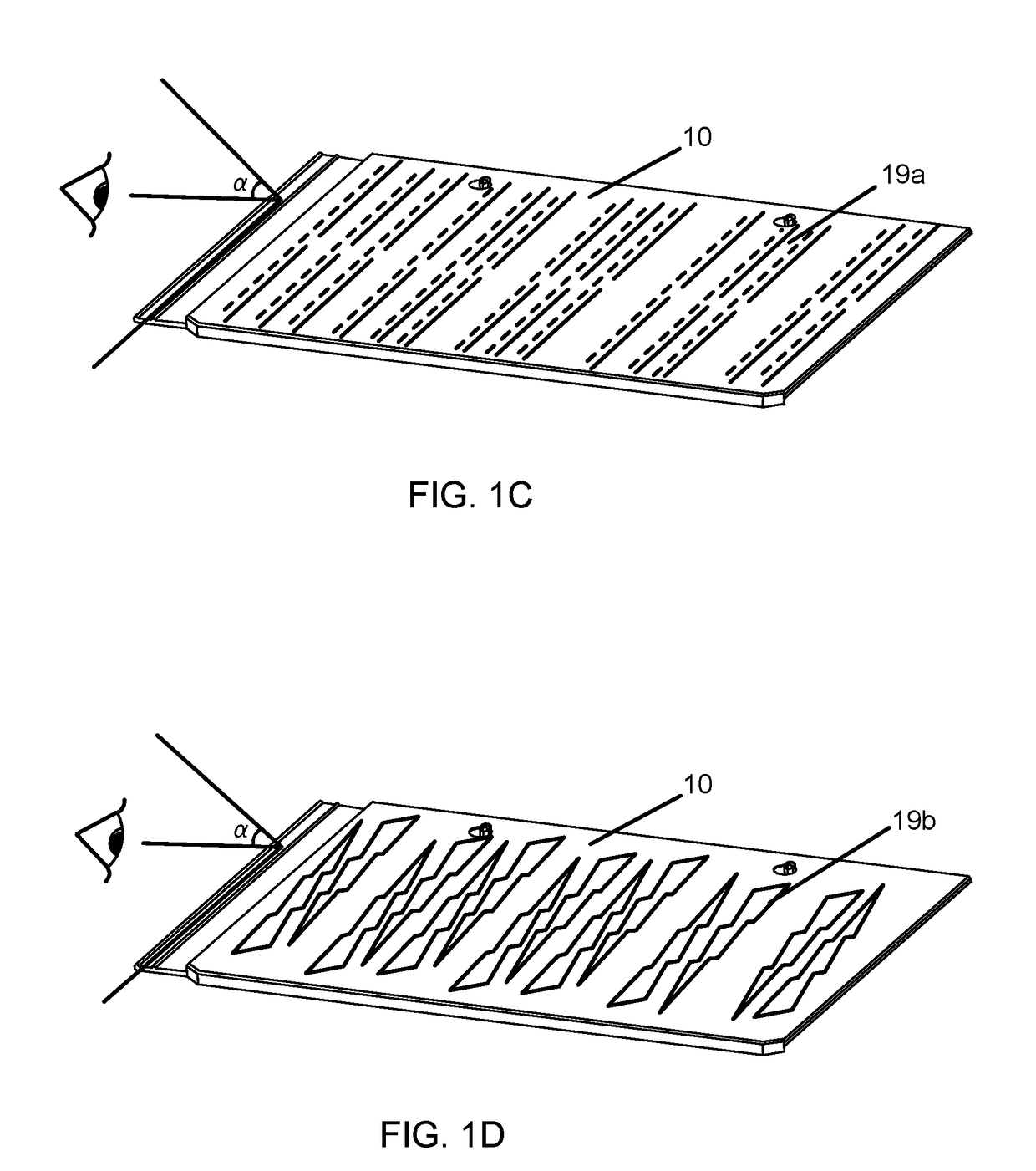

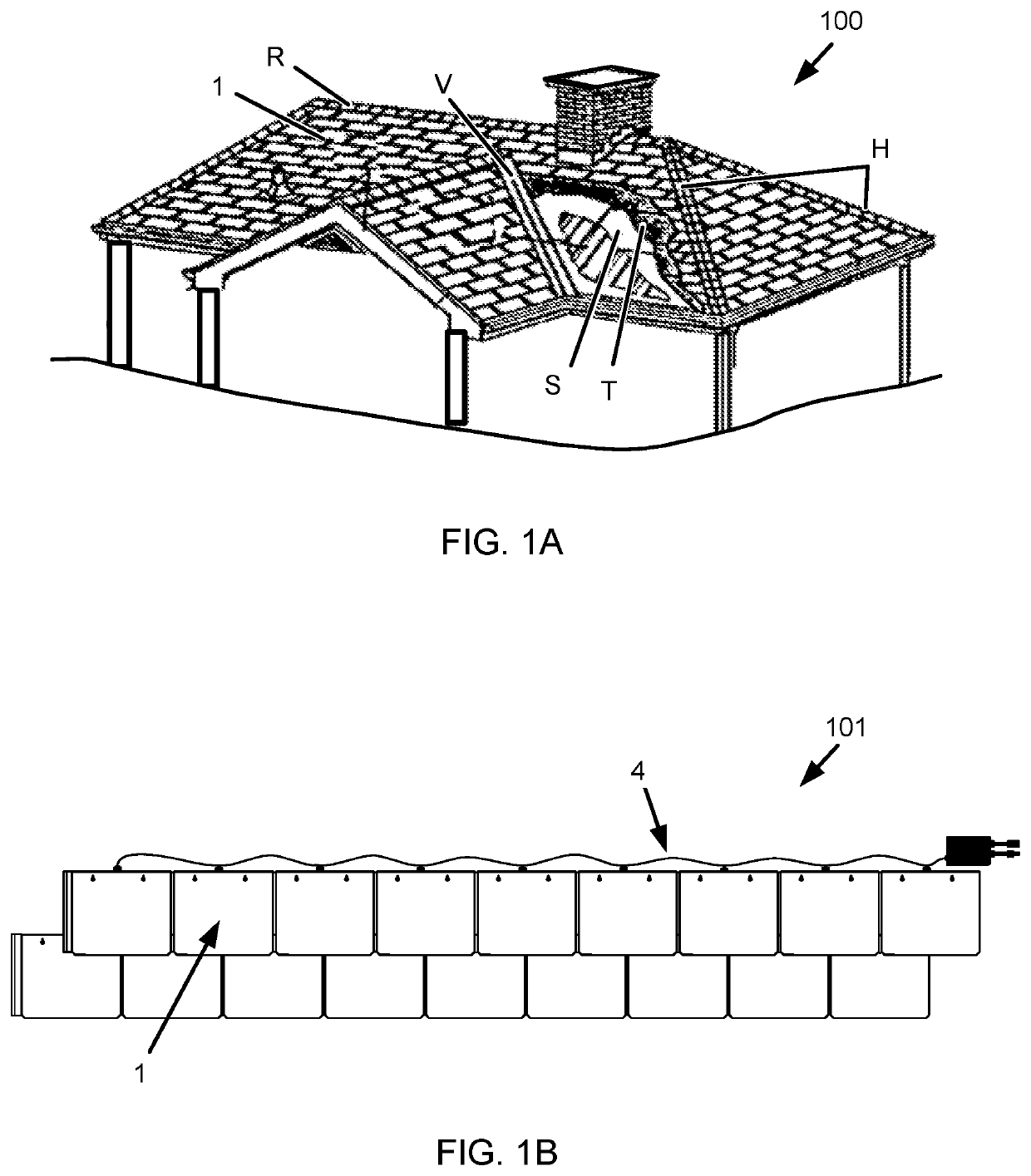

Building integrated photovoltaic system with glass photovoltaic tiles

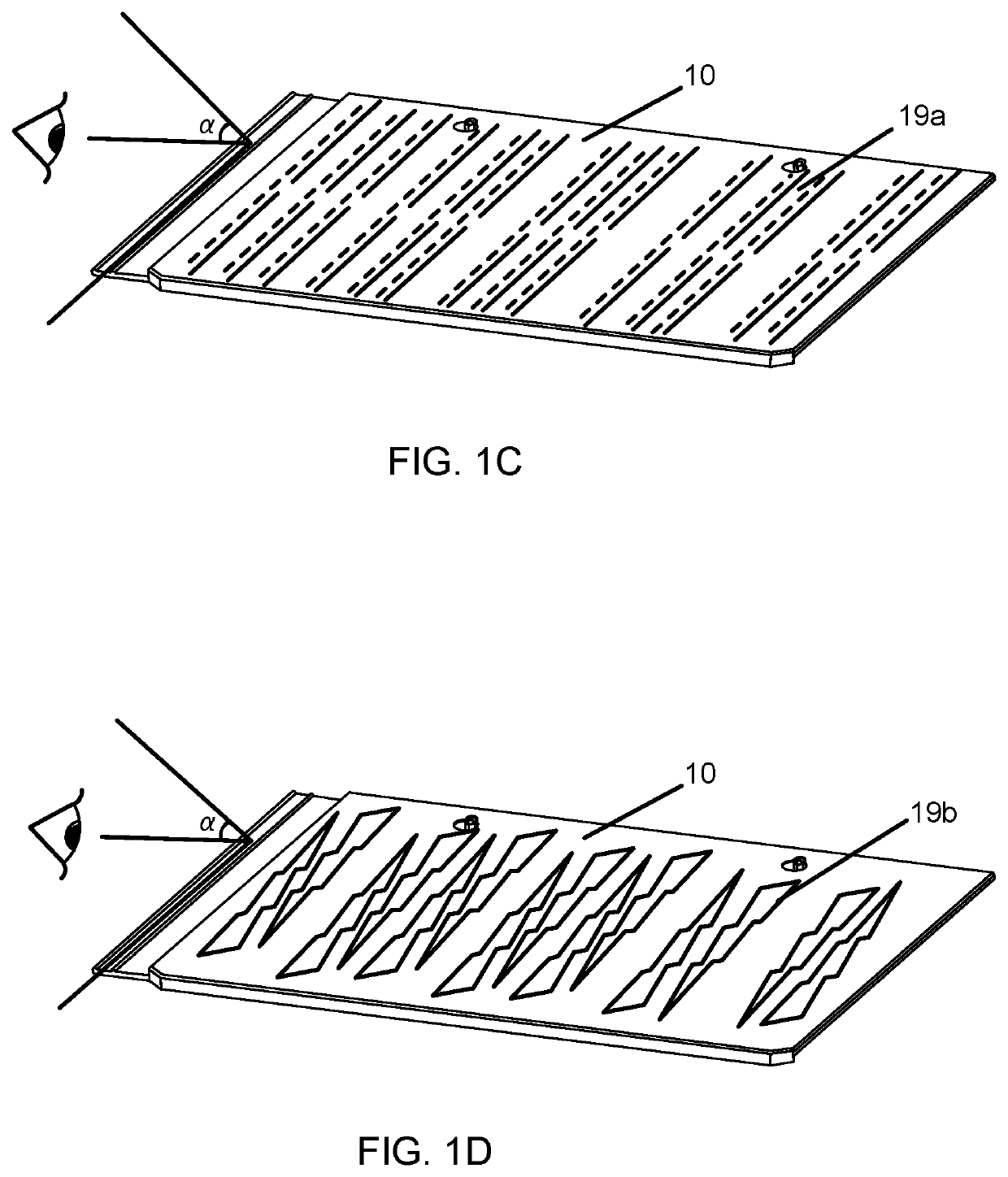

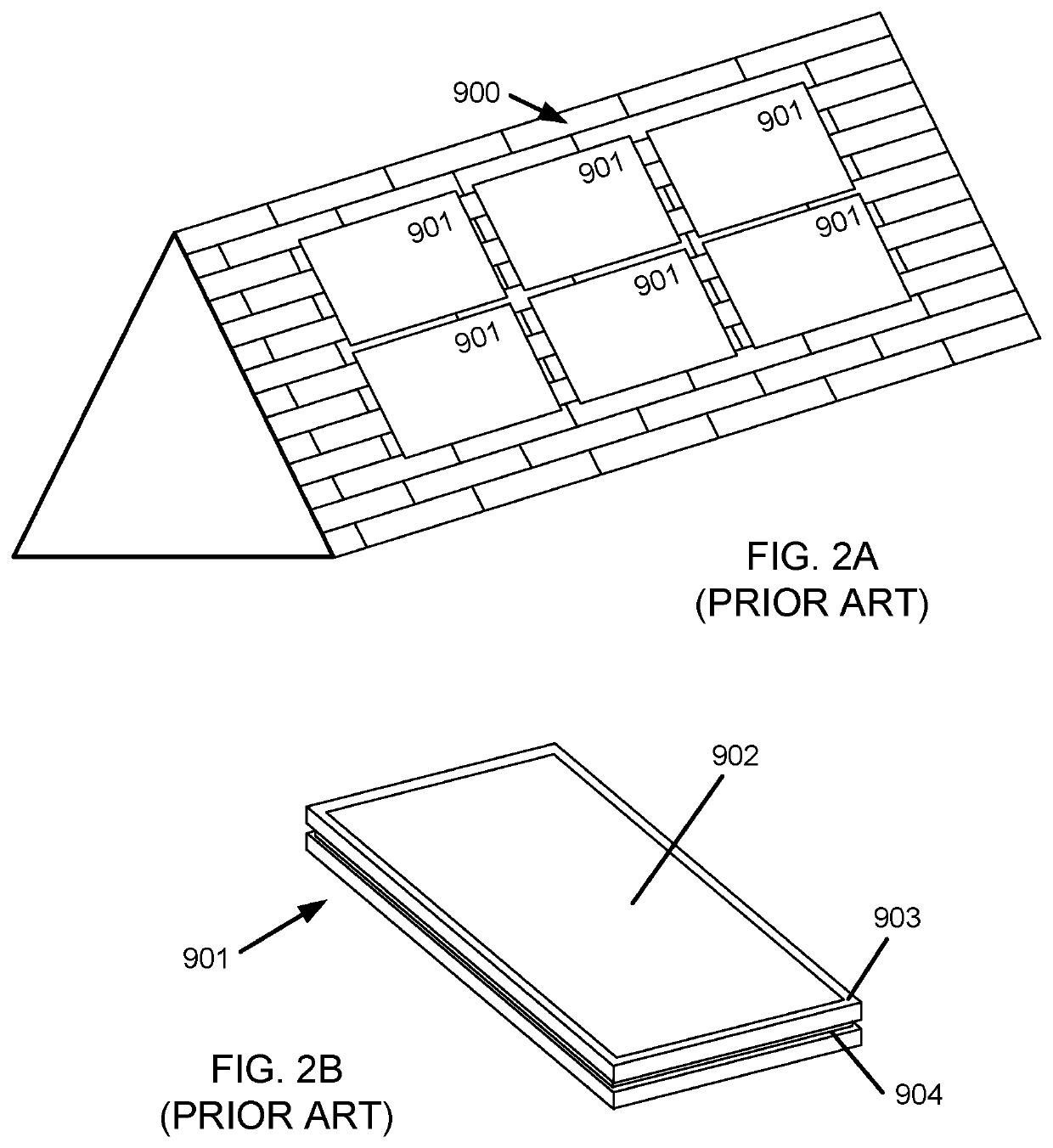

ActiveUS20180123504A1Improve aestheticsImprove efficiencyPhotovoltaic supportsClimate change adaptationVisibilityBuilding integration

Building integrated photovoltaic (BIPV) systems provide for solar panel arrays with improved aesthetics and efficiency that can replace a conventional roof surface structure. These BIPV systems can utilize photovoltaic PV roof tiles defined as glass tiles having photovoltaic elements embedded or incorporated into the body of the roof tile. Such PV roof tiles can include one or more lapping features for interfacing with adjacent tiles and features for electrically connecting multiples tiles within a course to an external power optimizer. Such PV roof tiles can utilize stamped glass that is stamped to define these features within an integrated glass tile and can further include texture, striations on the glass tile and / or color matched back layers or various other components to obscure visibility of any embedded solar cells and provide a more pleasing appearance.

Owner:TESLA INC

Production process of glazed devitrified glass tile

InactiveCN1417166AImprove purification effectUse less clayClaywaresHigh wear resistanceTechnological design

The production process of devitrified glass glazed tile includes the preparation of devitrified glass glaze and the production of tile body. The present invention is characterized by the devitrified glass glaze comprising SiO2, CaO, Al2O3, MgO, Na2O, TiO2, Fe2O3 and BaO; and the tile body raw material includes waste glass, sandstone, clay and binder. Compared with prior art, the present inventionhas reasonable technological design, available raw material, waste utilization, low cost, high wear resistance, fine texture, high pollution resistance, natural beauty similar to natural granite and excellent characteristic.

Owner:UNIV OF JINAN

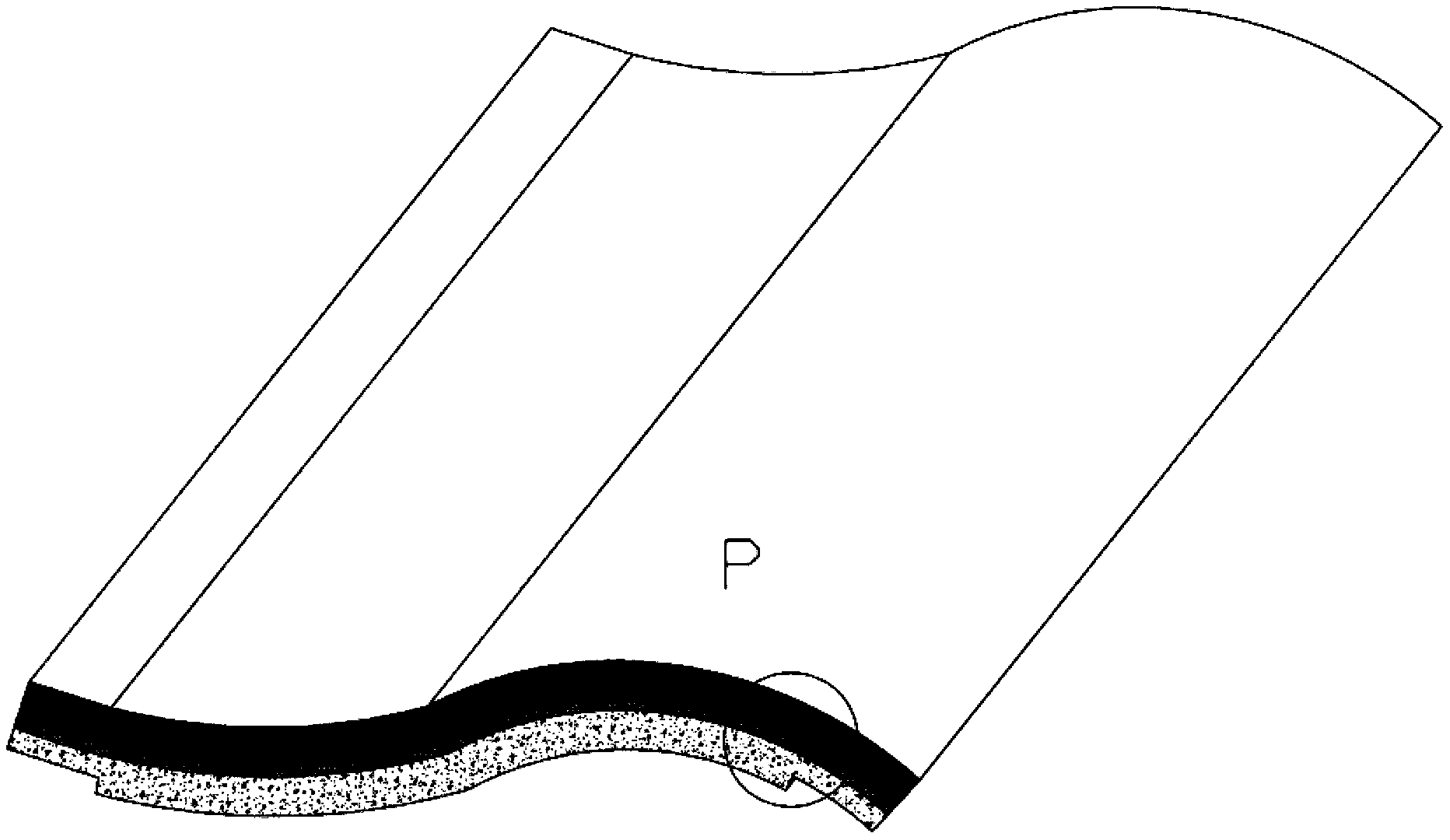

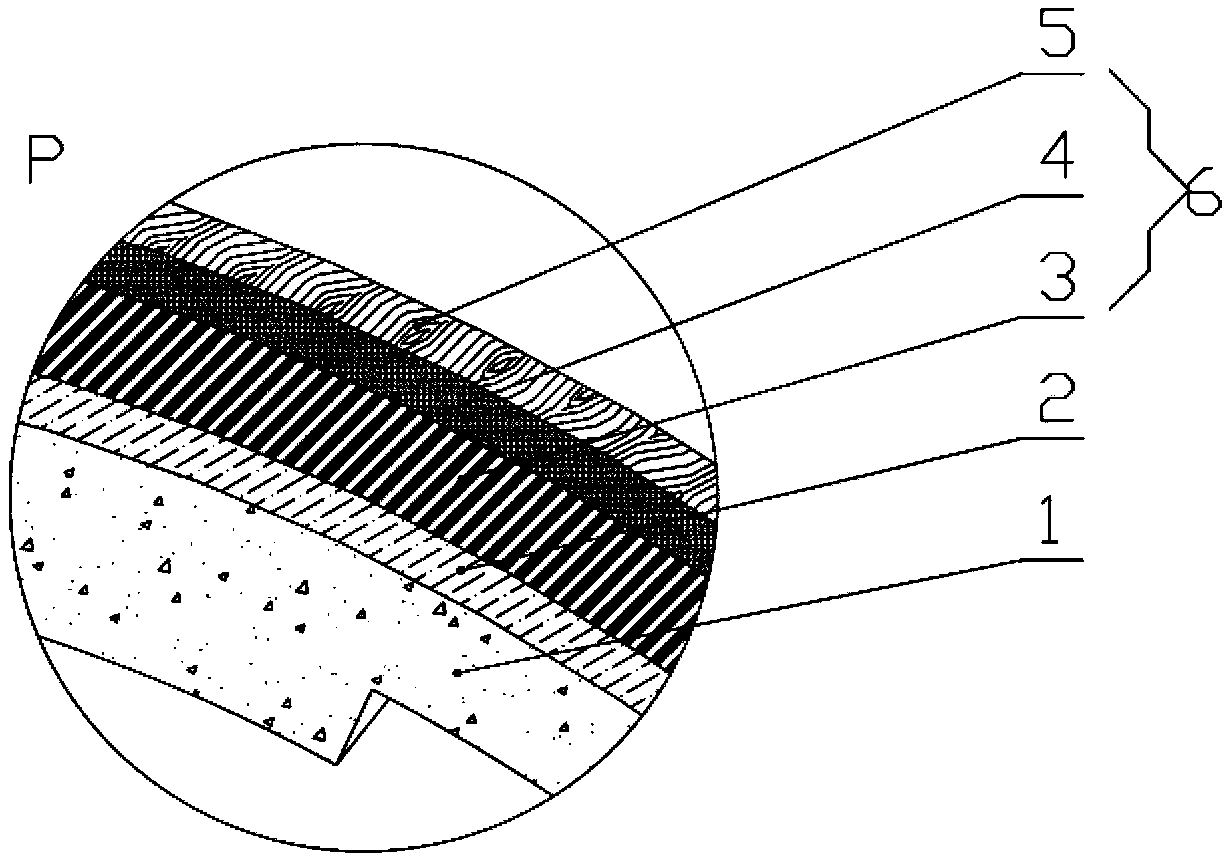

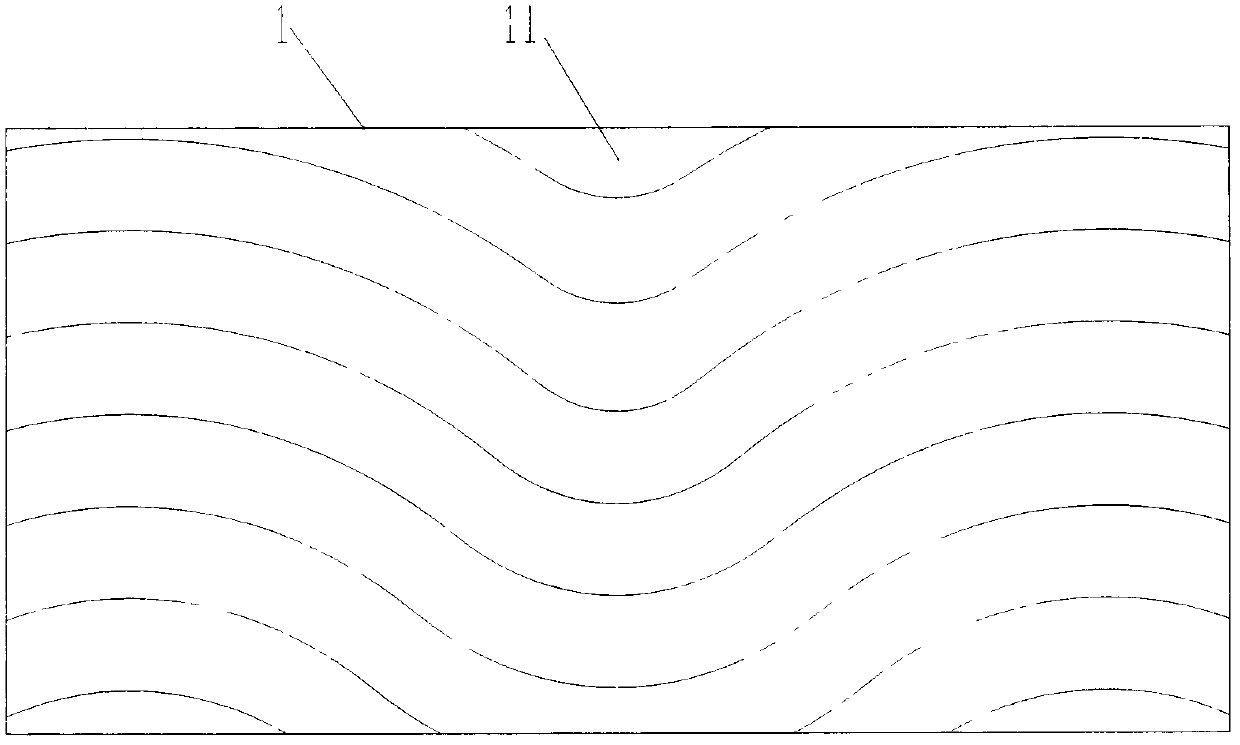

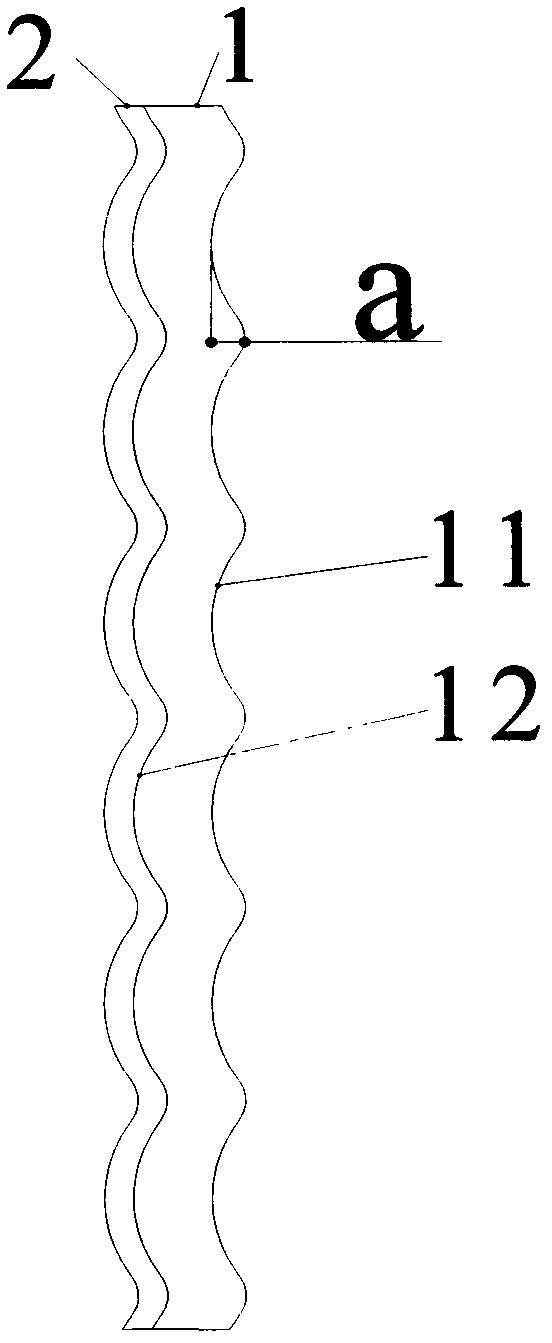

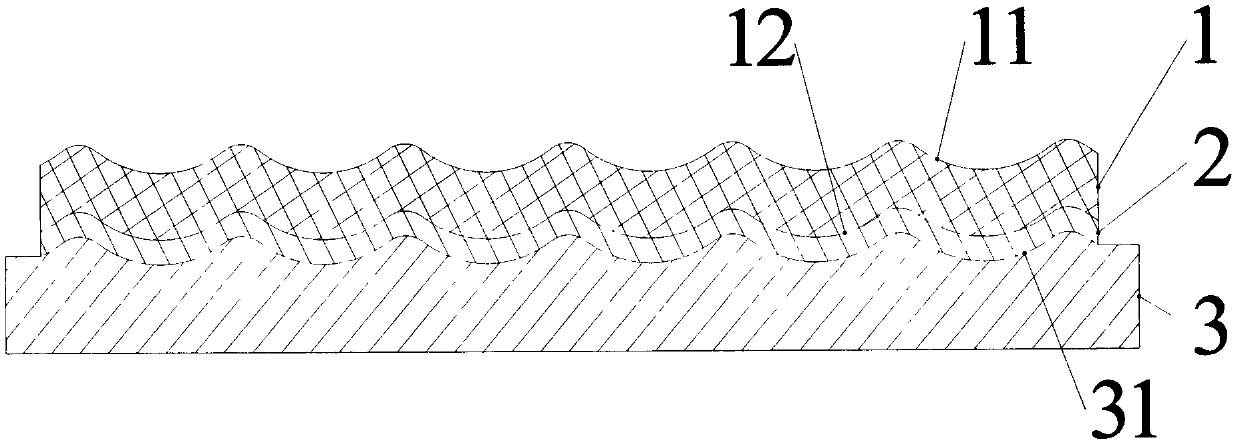

Photovoltaic tile on roof and manufacturing method thereof

ActiveCN103413847AThe function of photovoltaic power generation is soft and beautifulDoes not affect the decorative effectPhotovoltaic energy generationSemiconductor devicesRoof tileEngineering

The invention discloses a photovoltaic tile on a roof and a manufacturing method of the photovoltaic tile on the roof, wherein the photovoltaic tile on the roof integrates the functions of fire prevention, water prevention, decoration and photovoltaic power generation. The photovoltaic tile on the roof comprises a roof tile base material and a photovoltaic decorative layer, wherein the photovoltaic decorative layer and the curved surface of the roof tile base material are bonded into a whole through adhesion agents; the roof tile base material is a clay tile or a ceramic tile or a metal tile or a glass tile or a cement tile; the roof tile base material is coated with high molecular adhesion agents; the photovoltaic decorative layer sequentially comprises a flexible thin film batter assembly, a film layer and a coating layer from interior to exterior. As non-crystalline silicon and other flexible solar photovoltaic thin film batteries are bonded to the surfaces, with the waving feeling, of the ceramic tile, the clay tile, the glass tile and the like through high molecular polymer glue, photovoltaic tiles on roofs which have various complex models, can achieve the function of the photovoltaic power generation and can also keep the shape and color of the tiles on the building roofs can be produced in a factory.

Owner:嘉兴如运建筑科技有限公司

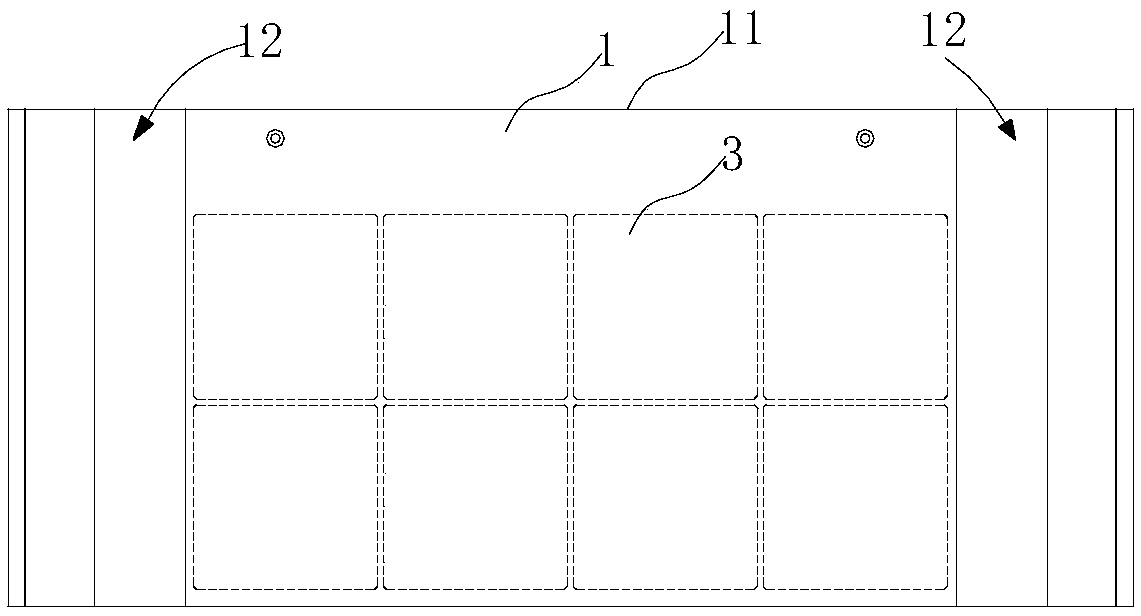

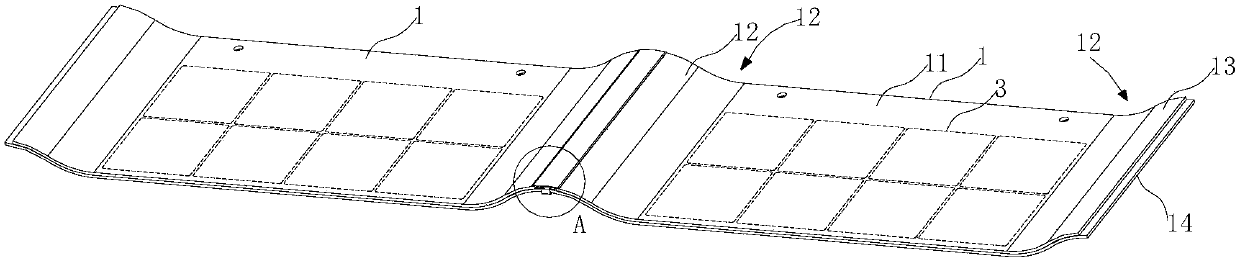

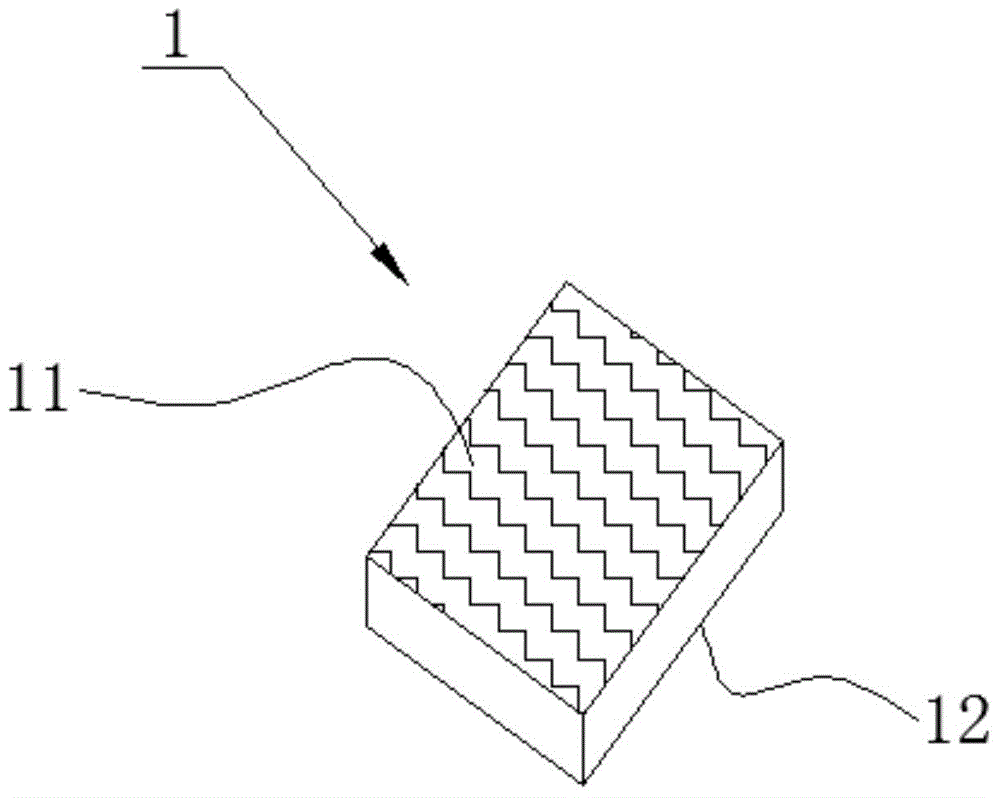

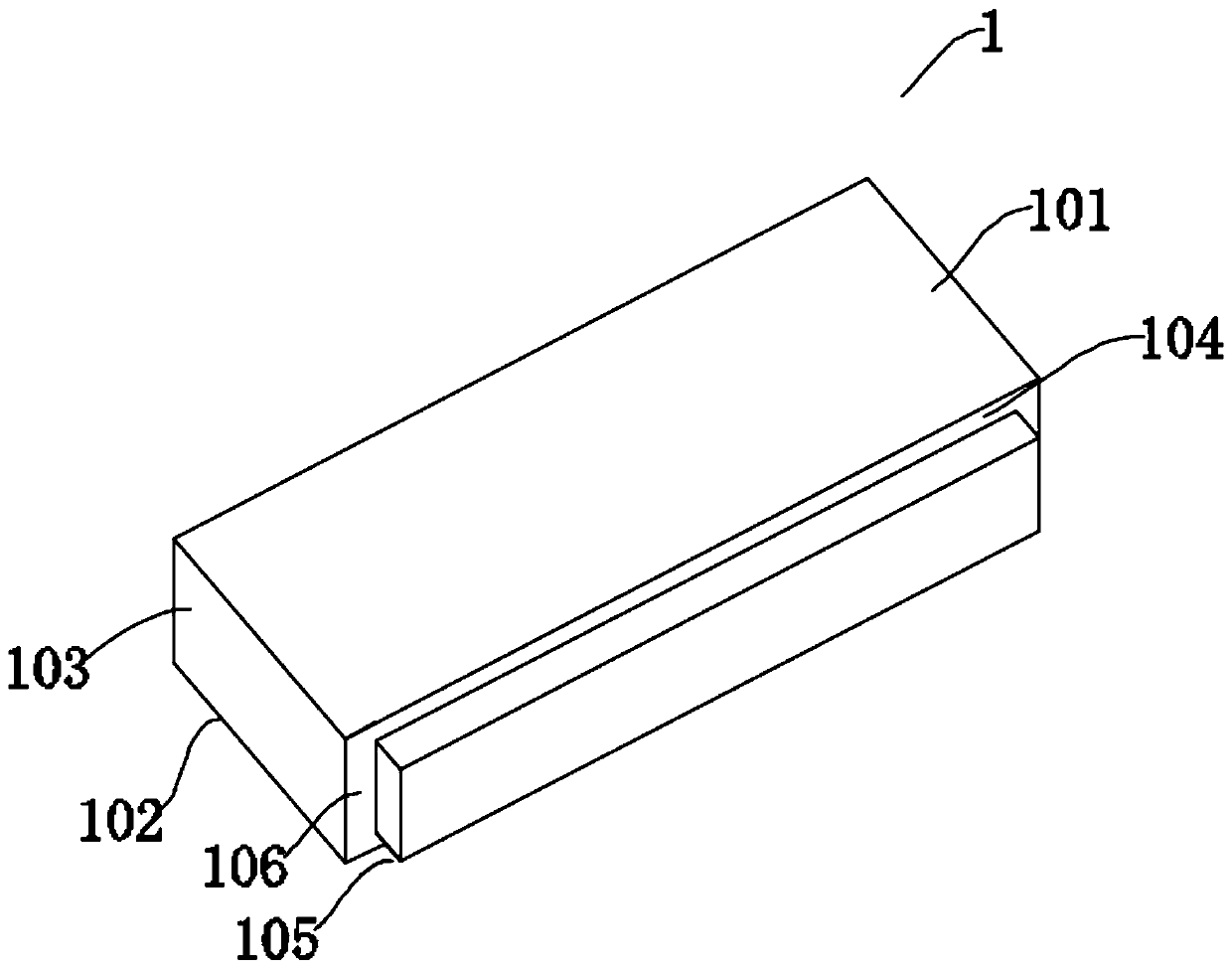

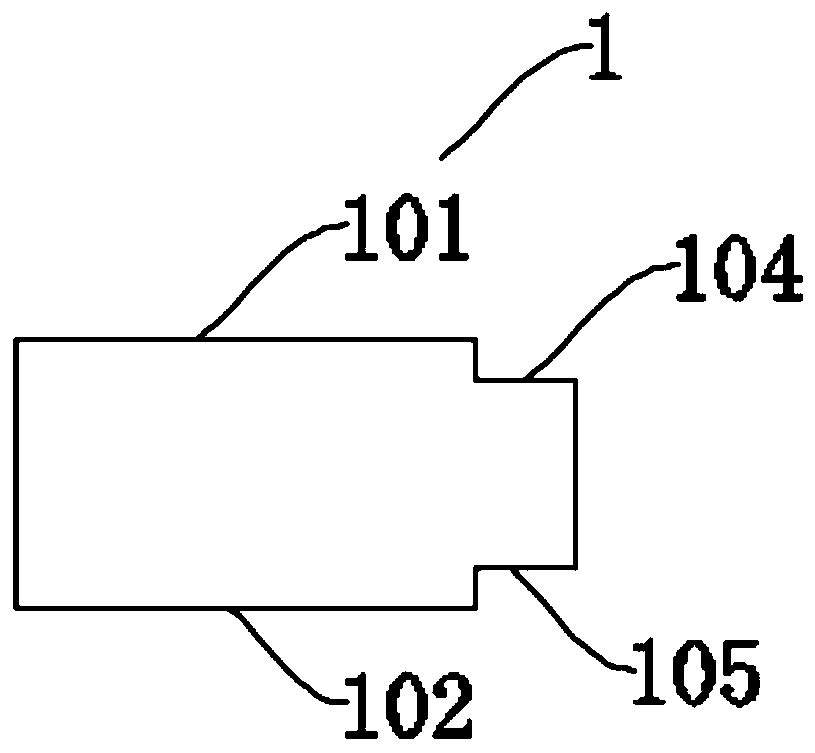

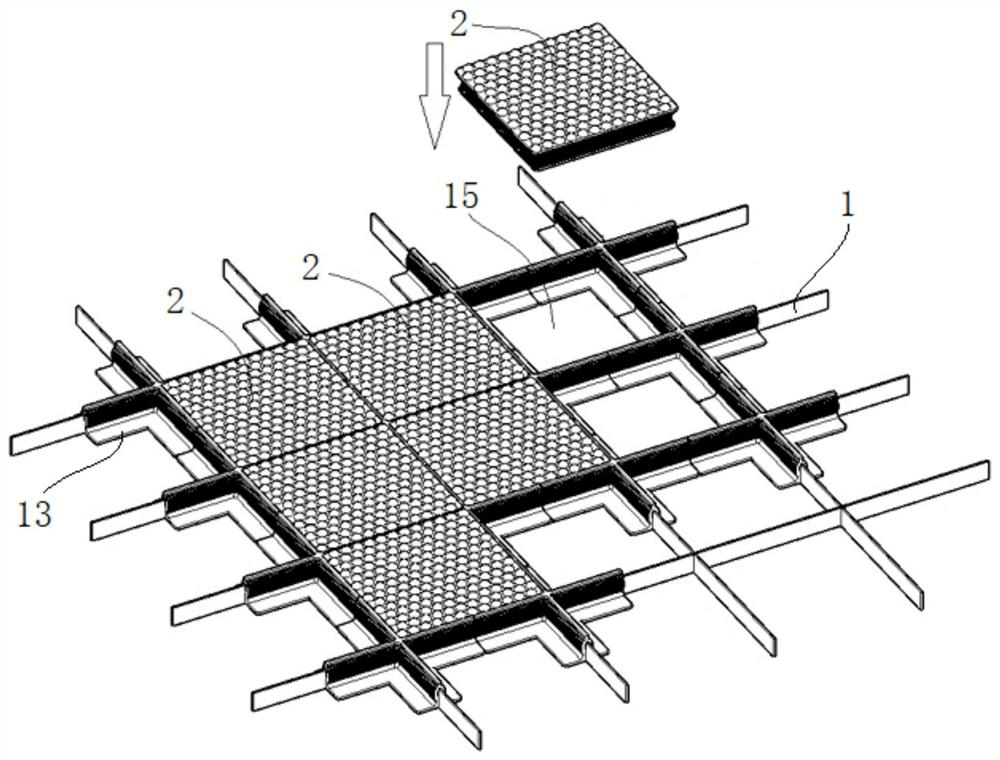

Photovoltaic cell tile, photovoltaic cell installation assembly and roof photovoltaic cell system

PendingCN107612471AAchieve wholenessProtect from direct sunlightPhotovoltaic supportsPhotovoltaic energy generationElectricityGeneration rate

The invention discloses a photovoltaic cell tile, a photovoltaic cell installation assembly and a roof photovoltaic cell system. The photovoltaic cell tile comprises a glass tile body; the glass tilebody comprises a plane installation part used for installing a photovoltaic cell, and reflecting parts which are located on the two sides of the plane installation part and are used for reflecting light rays to the photovoltaic cell at the plane installation part. A wiring box which is electrically connected with the photovoltaic cell is arranged on one side of the back face of the plane installation part. A plurality of photovoltaic cell tiles are sequentially spliced and connected to obtain the photovoltaic cell installation assembly. The reflecting parts on the photovoltaic cell tiles provided by the invention can provide additional light energy, the light energy utilization rate is improved, and the power generation rate of the photovoltaic cell is increased. A new structure installation mode is provided for the combination of the building and photovoltaic power generation in the prior art, the use waste of the product materials can be reduced, and the economic waste caused by secondary construction can be avoided.

Owner:TRINA SOLAR CO LTD

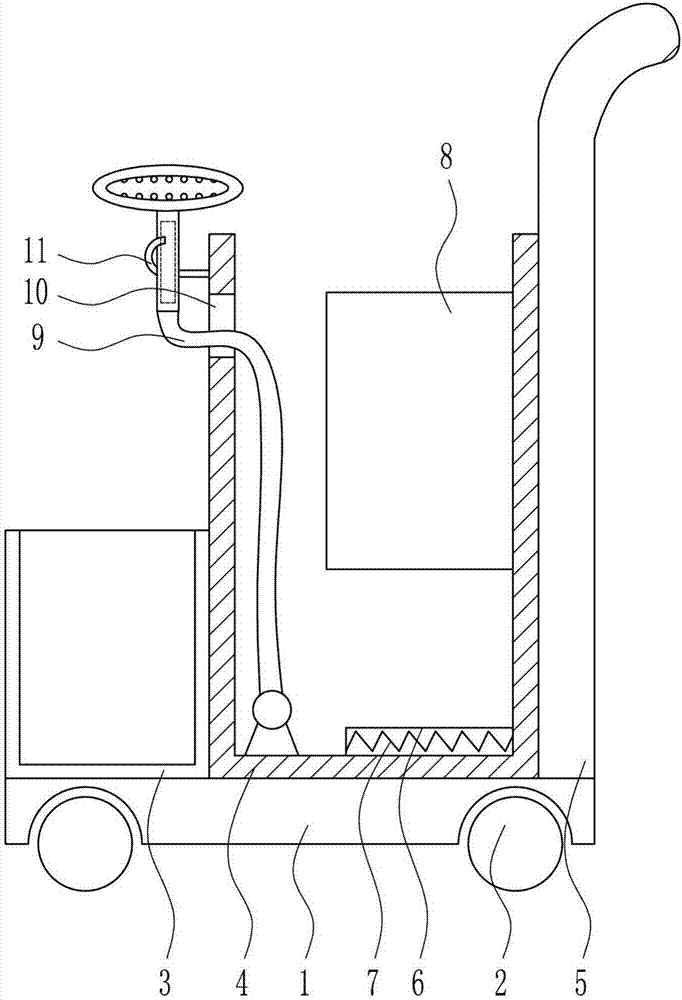

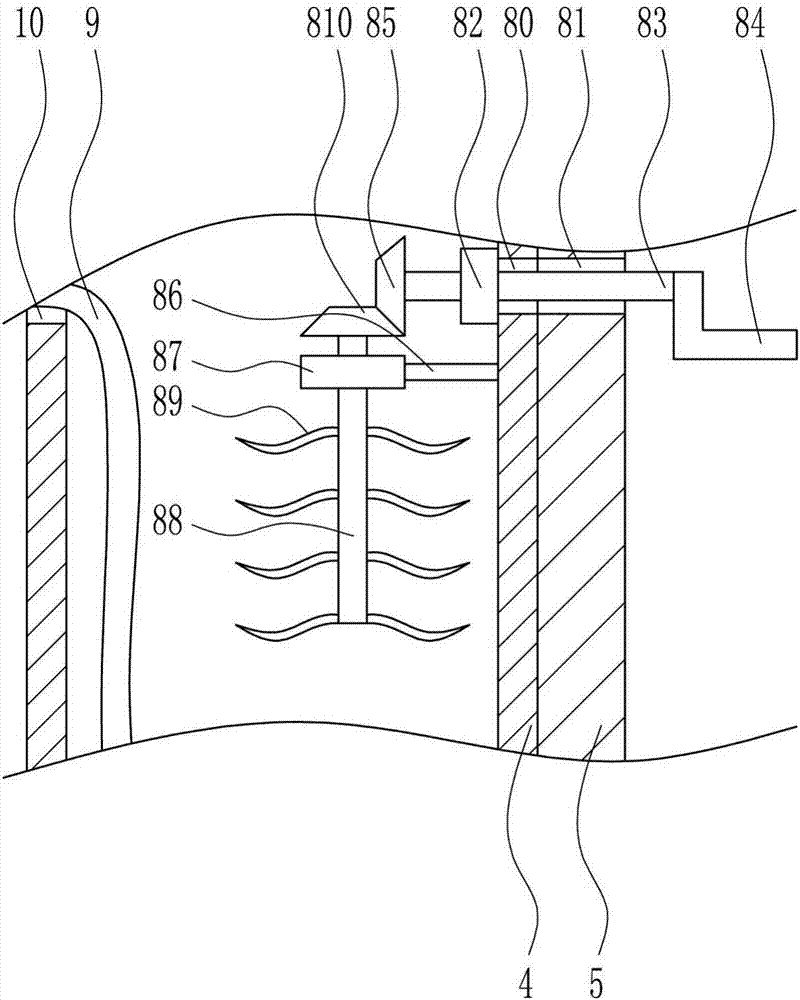

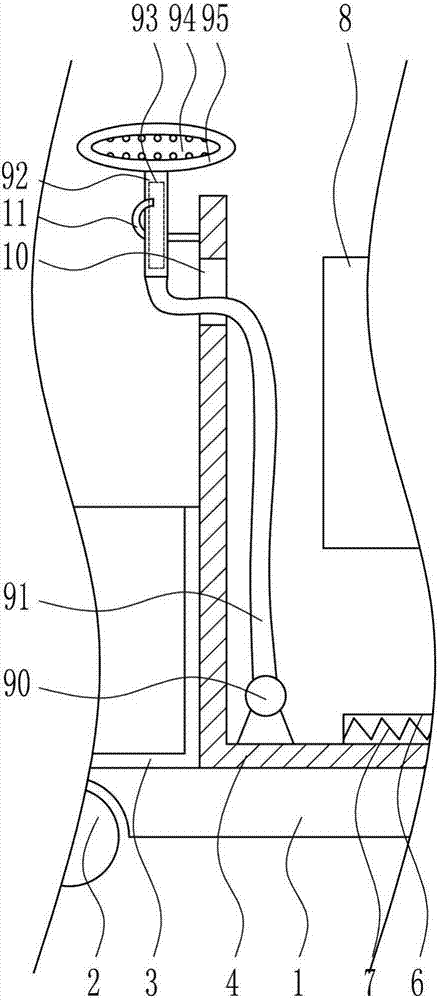

Household cleaning device for glass tiles

InactiveCN106859508AEasy to cleanImprove cleaning efficiencyMachine detailsFloor-scrubbing machinesLeft wallWaste management

Owner:海宁市乔斯特新能源有限公司

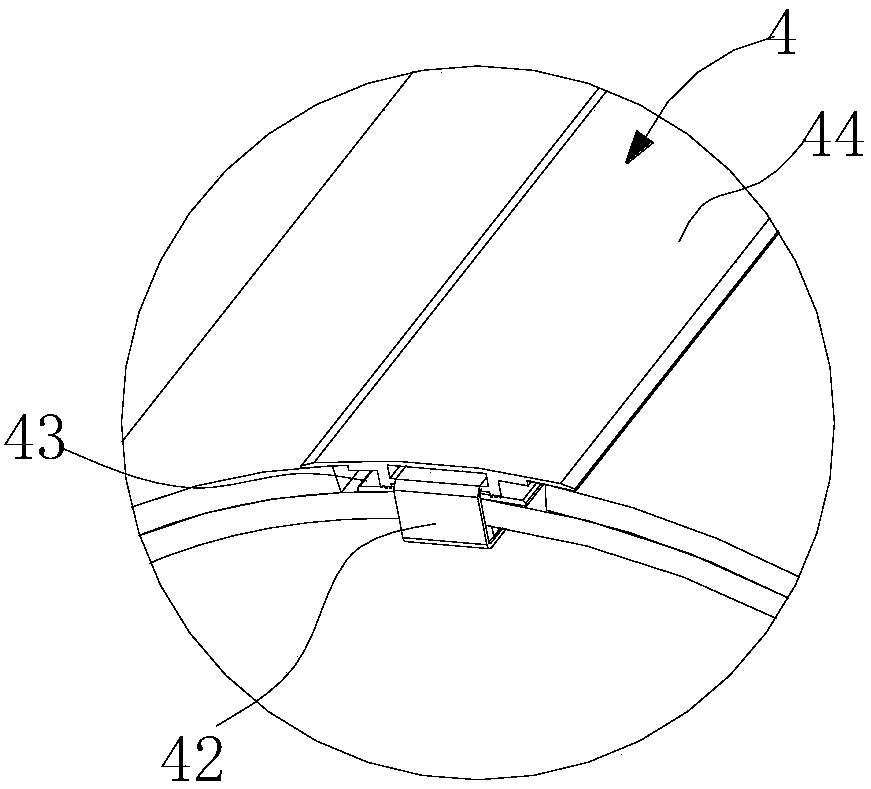

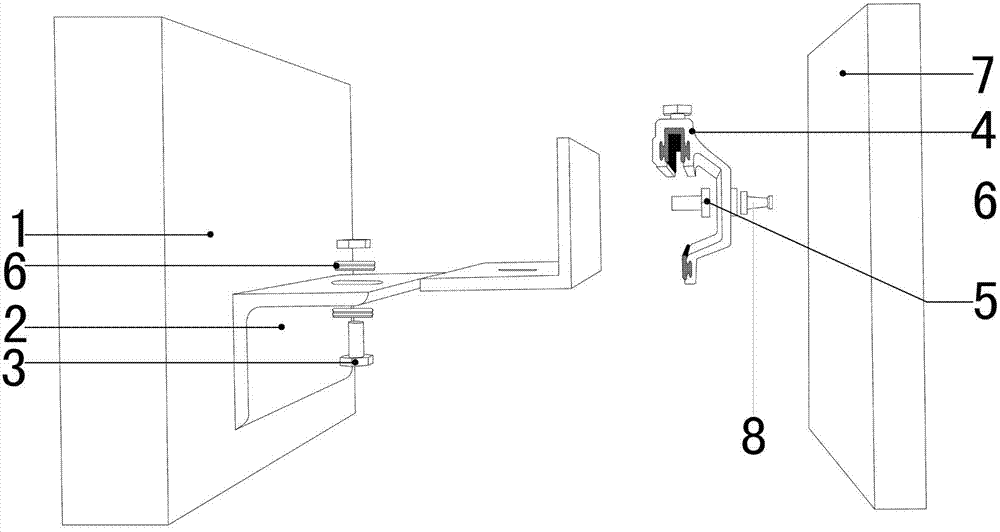

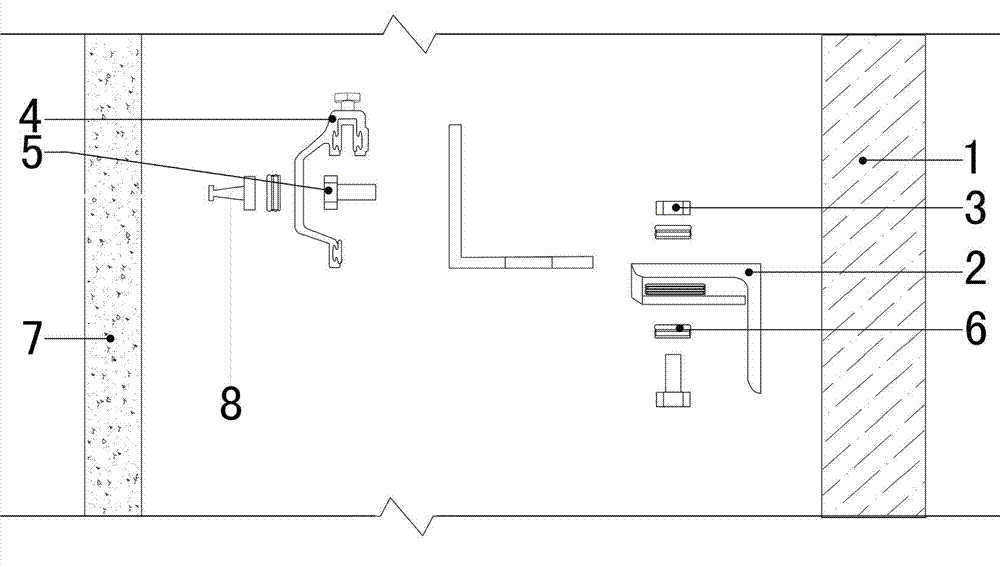

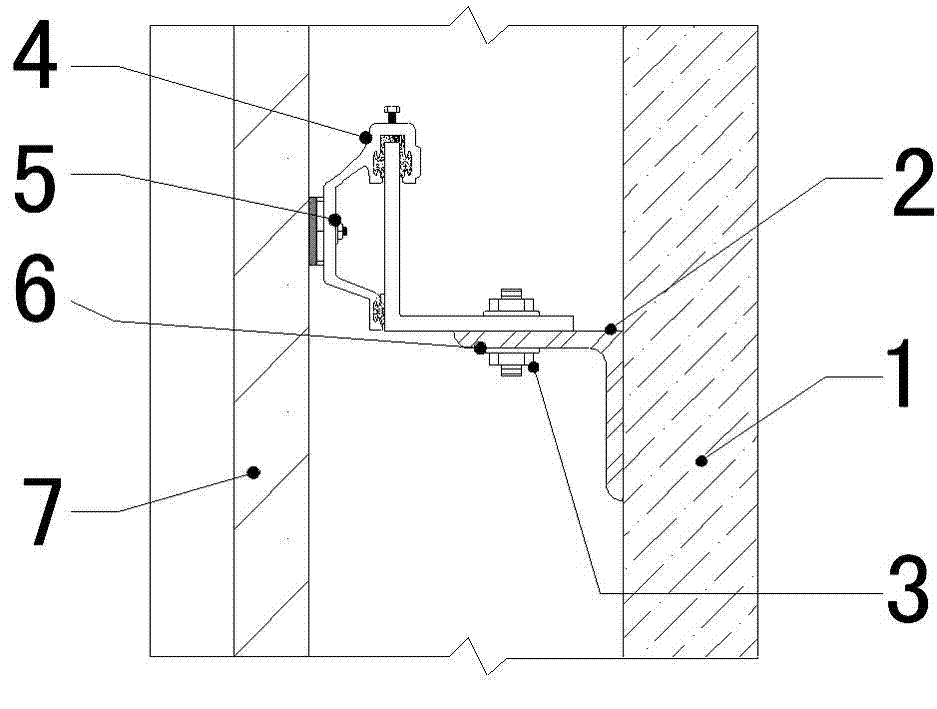

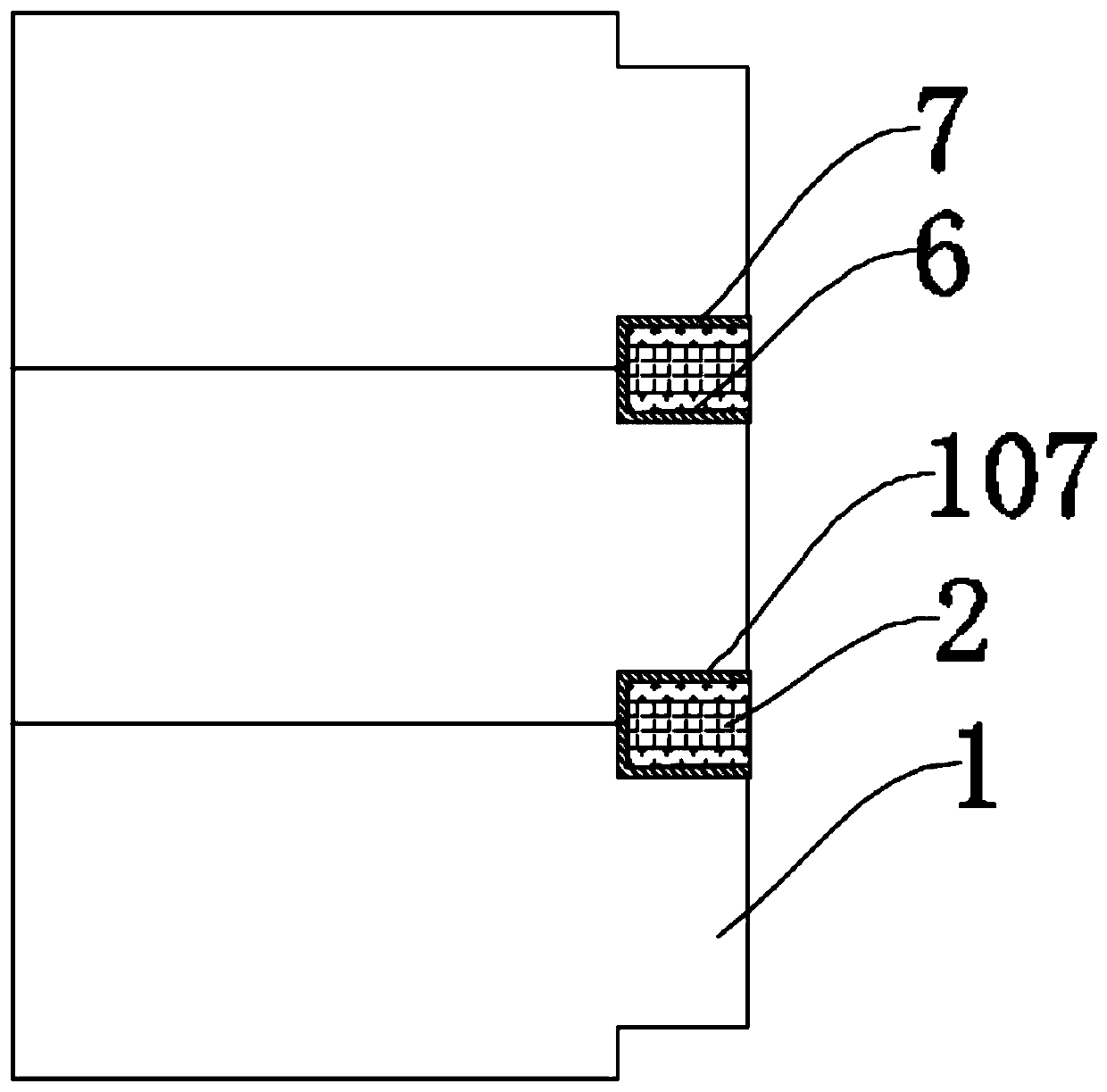

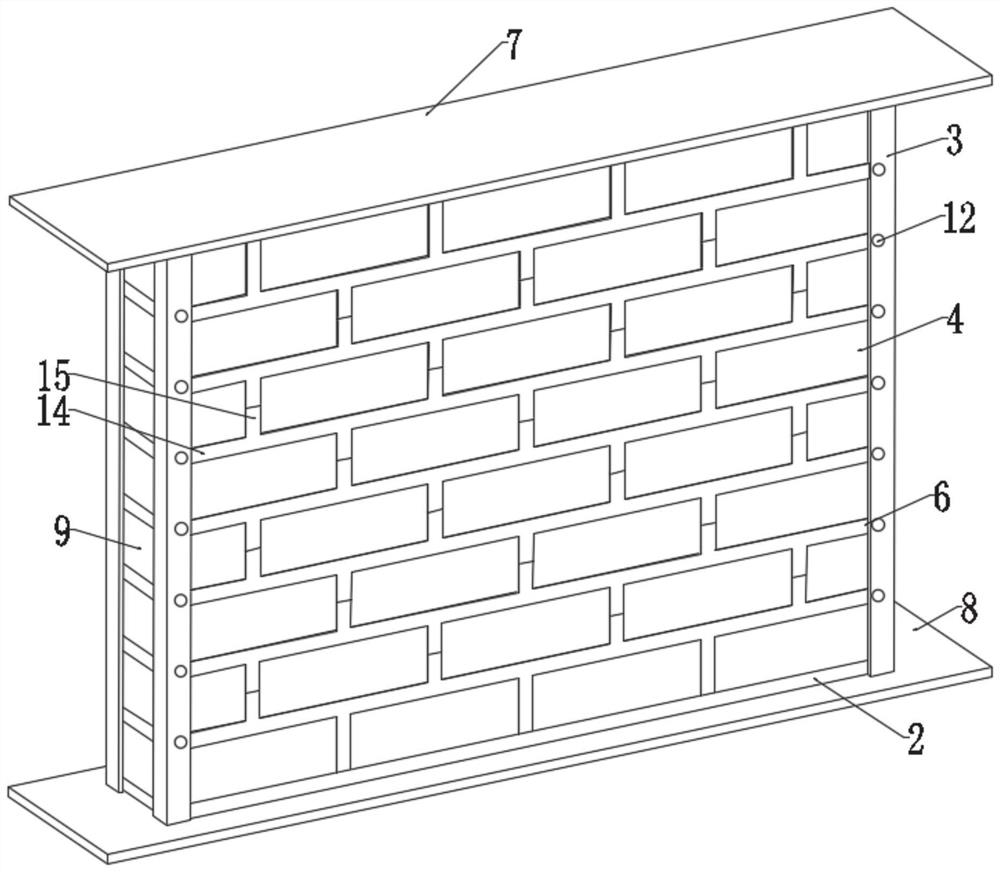

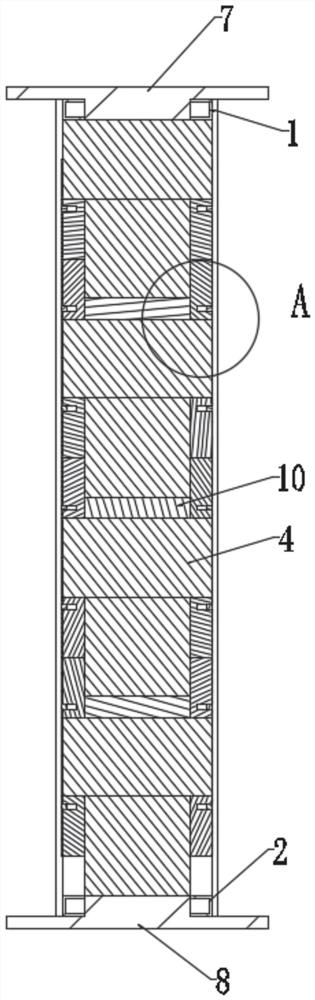

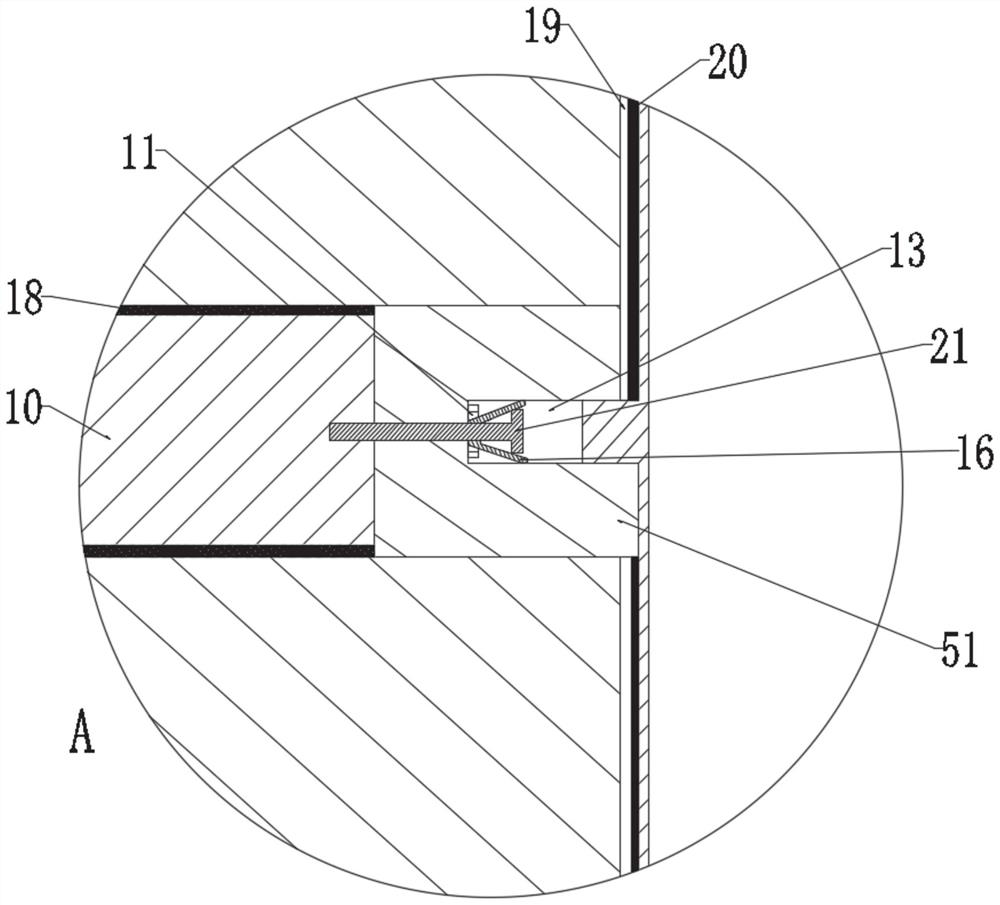

Glass tile cladding mounting structure

The invention discloses a glass tile cladding mounting structure comprising a steel angle (1), a hanger, a cladding member (4), a back bolt (5), and a glass tile (7). The hanger is fixed to the steel angle (1) on a wall. The hanger is provided with an upright hanging end. The back of the glass tile (7) is provided with a reserved duct. An expansion nut (8) is disposed in the duct. The glass tile (7) and the cladding member (4) are fixedly connected through the back bolt (5) to form a cladding portion. The cladding member (4) is provided with a claw channel having a downward opening. The channel is hung to the hanging end to form an integral mounting structure. The glass tile cladding mounting structure has the advantages that the glass tile and a steel frame can be more stabilized through precise positioning and flexible stabilization technique, the common problem with quality of the traditional process construction is solved, and the hidden quality problems such as poor flatness and shedding are eliminated.

Owner:GOLD MANTIS CONSTR DECORATION

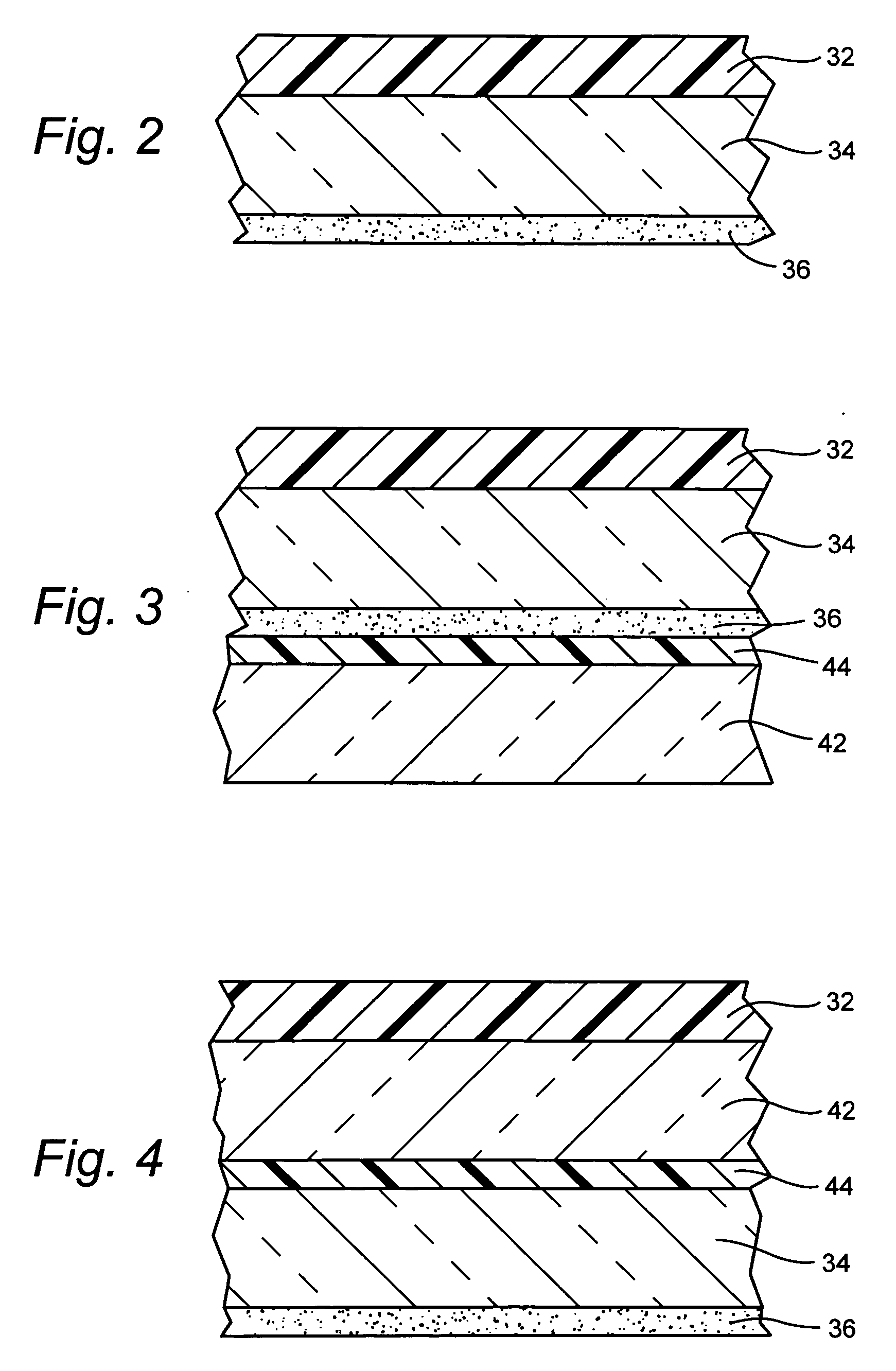

Large high density foam glass tile

InactiveUS20060075704A1High densityHigh strengthCovering/liningsGlass shaping apparatusShock waveHigh density

A large, high density foam glass tile which can be used as a facade on both exterior and interior building walls. The foam glass tile can also be used with other materials to form a panel or a composite. The present invention may be used on the critical surfaces of buildings at high risk for terrorist attacks, in combination with cement, steel or other high strength building materials. The present invention may also be used in surfaces of typical buildings. The present invention has the advantage of absorbing a substantial portion of a shock wave caused by an explosion. The present invention also has the advantage of being more resistant to earthquakes.

Owner:HOJAJI HAMID +1

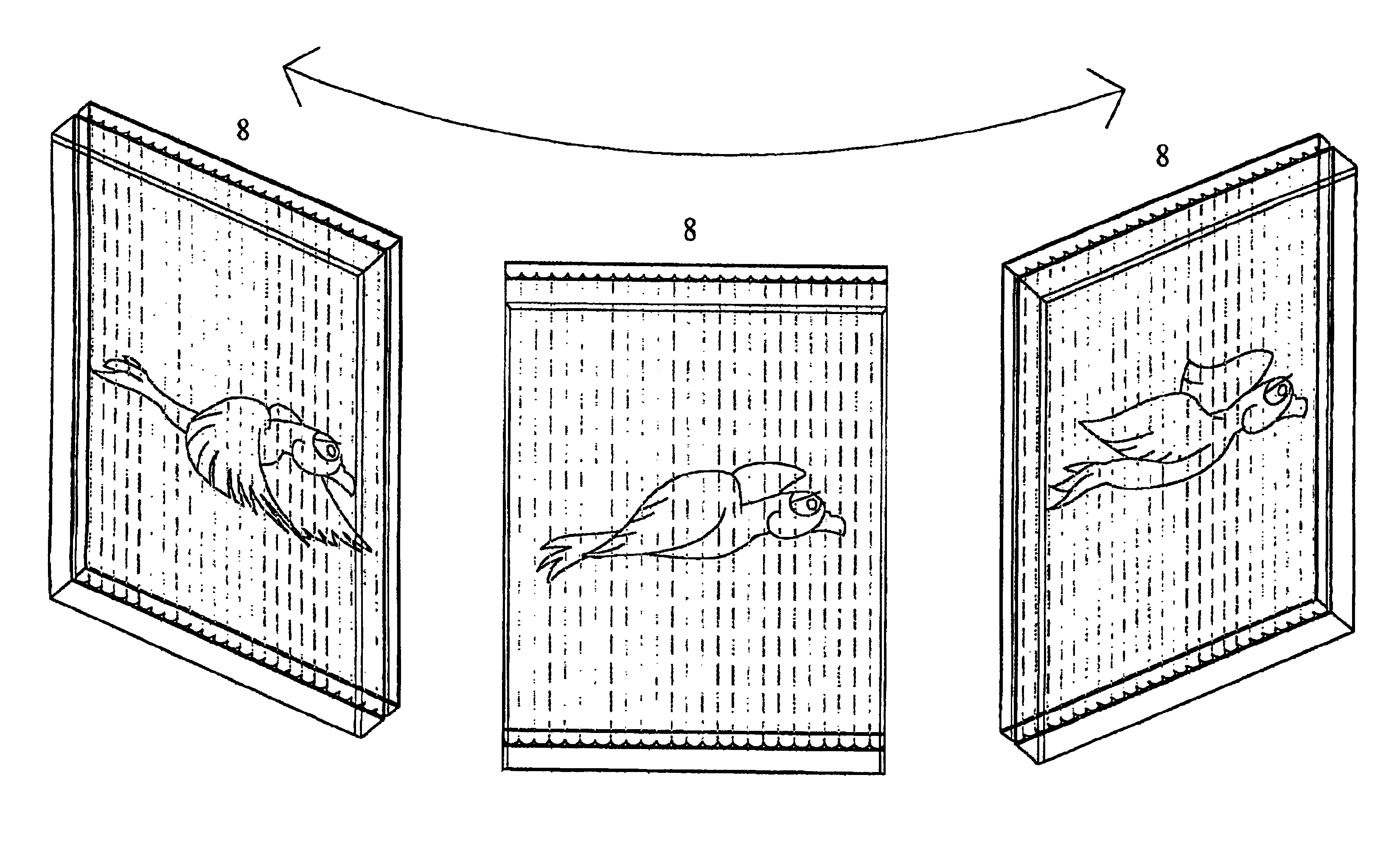

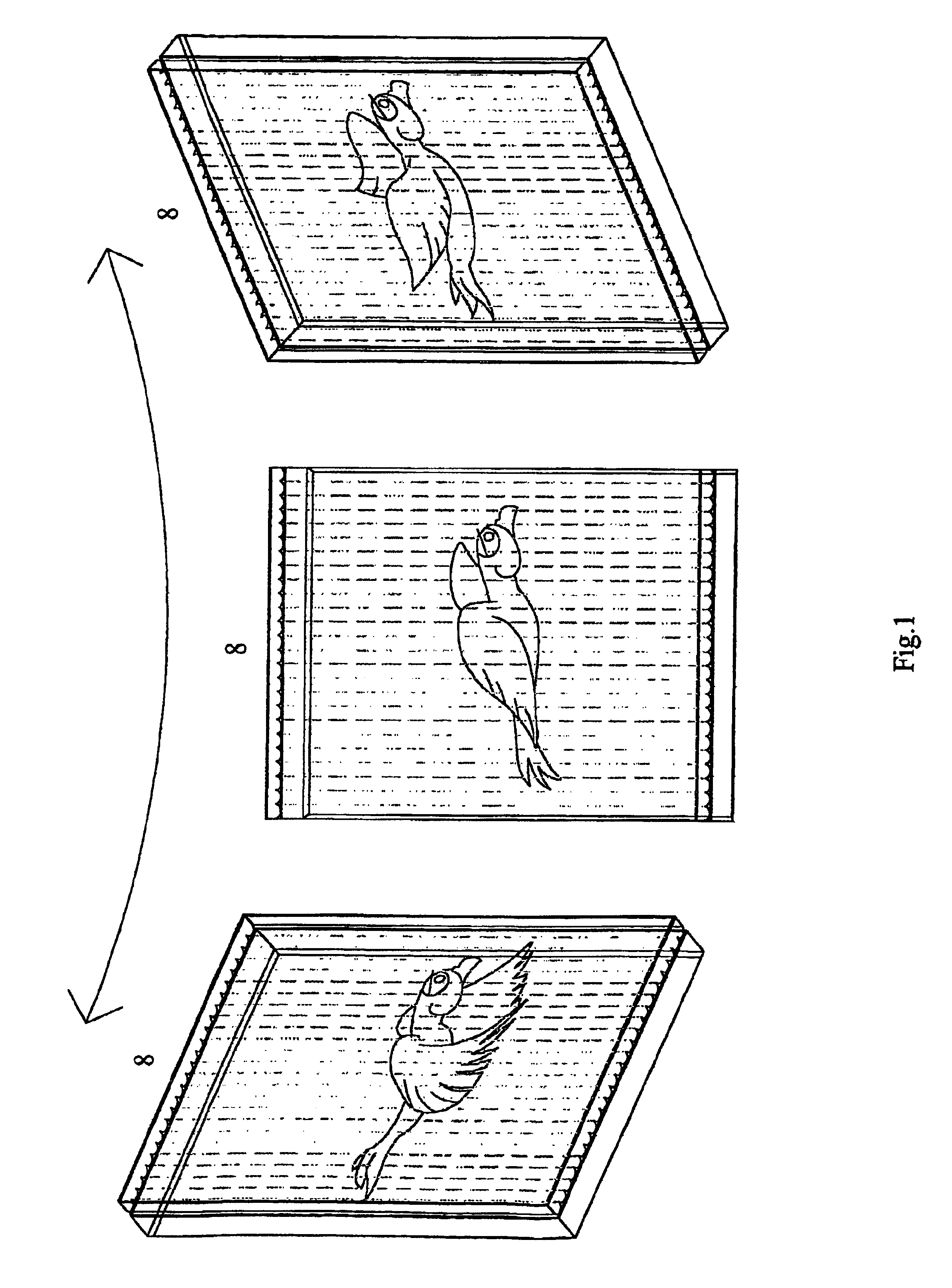

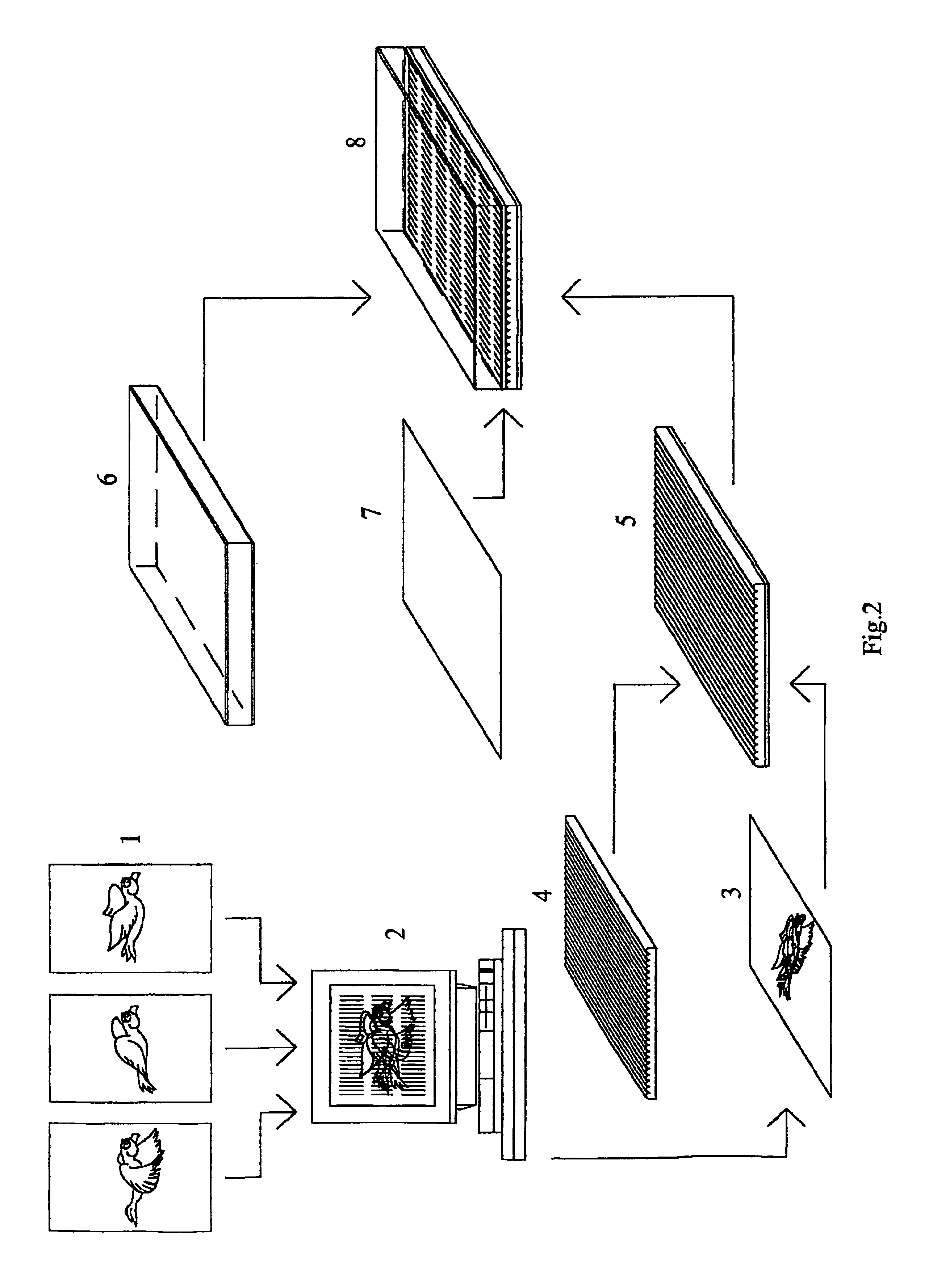

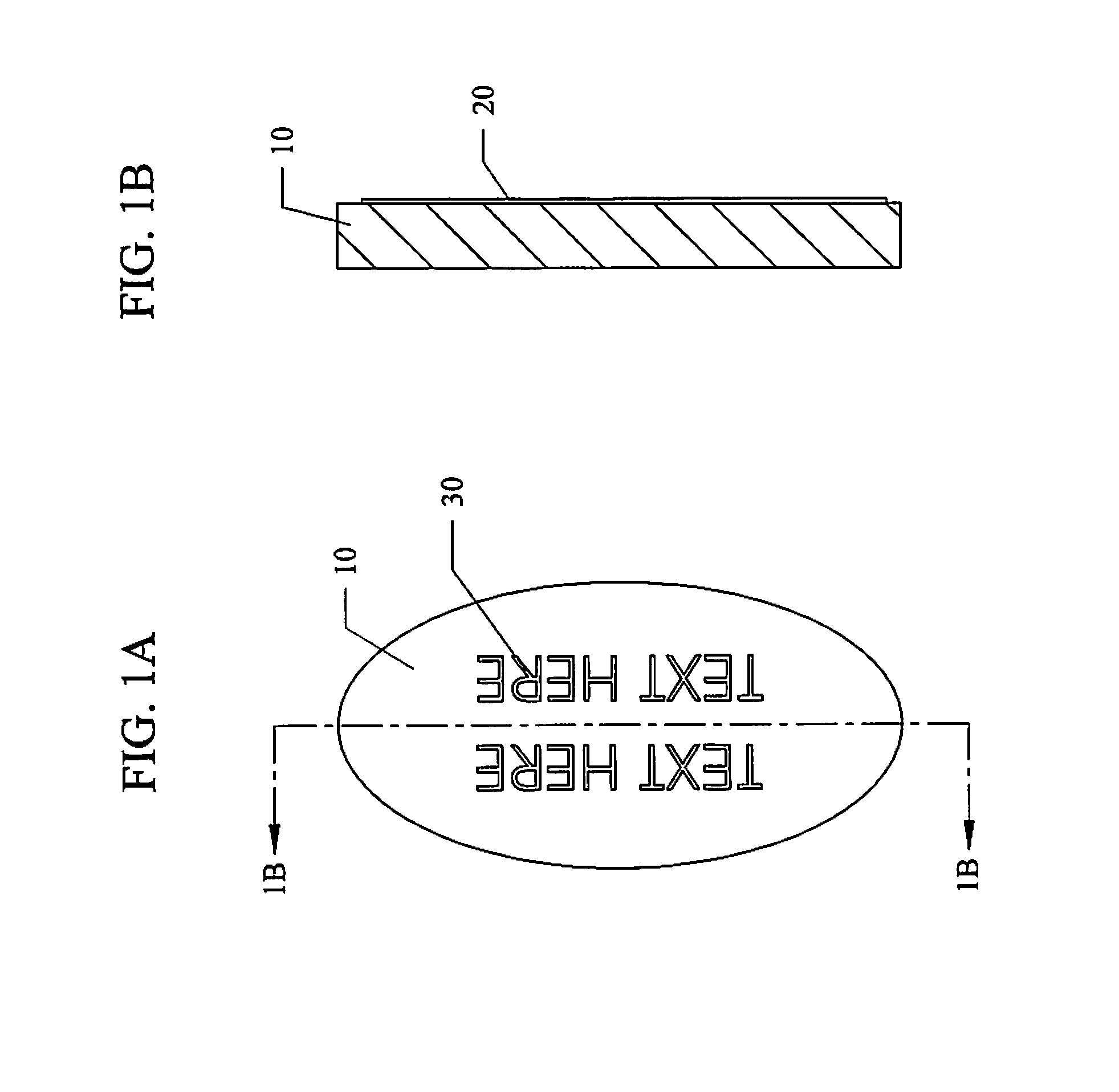

Layered glass tile

This invention is thought as a material for decoration and construction. It can be used in wet areas, walls, floors, and all surfaces. Changing appearance glass tile (8) is made up of colored, non colored, transparent, translucent, or any type, any size, shape, form and thickness of glass (6) laminated with the use of an adhesive material (7) to a lenticular image (5) which is made up of more than one image (1) divided into dozens of strips per cm with the use of special computer programs (2) and are interlaced in to one image (3) which is then printed behind a lenticular film (4) which is a semi cylindrical formed, precisely specified dimensioned, ribbed transparent plastic which allows the viewer to see one image at a time according to the observation angle or printed on a graphic film and then laminated to lenticular film (4).

Owner:KAPKIN KORAY

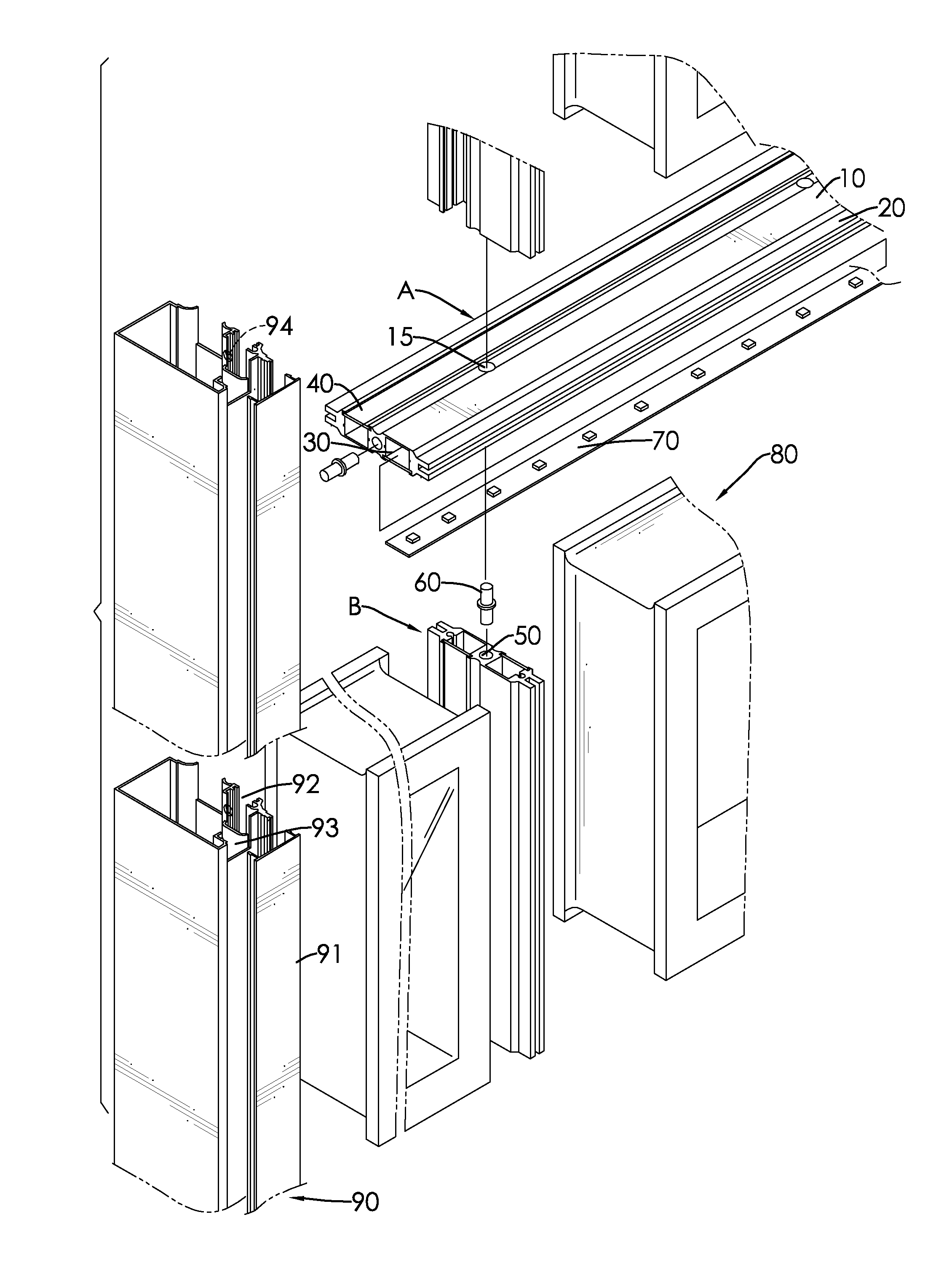

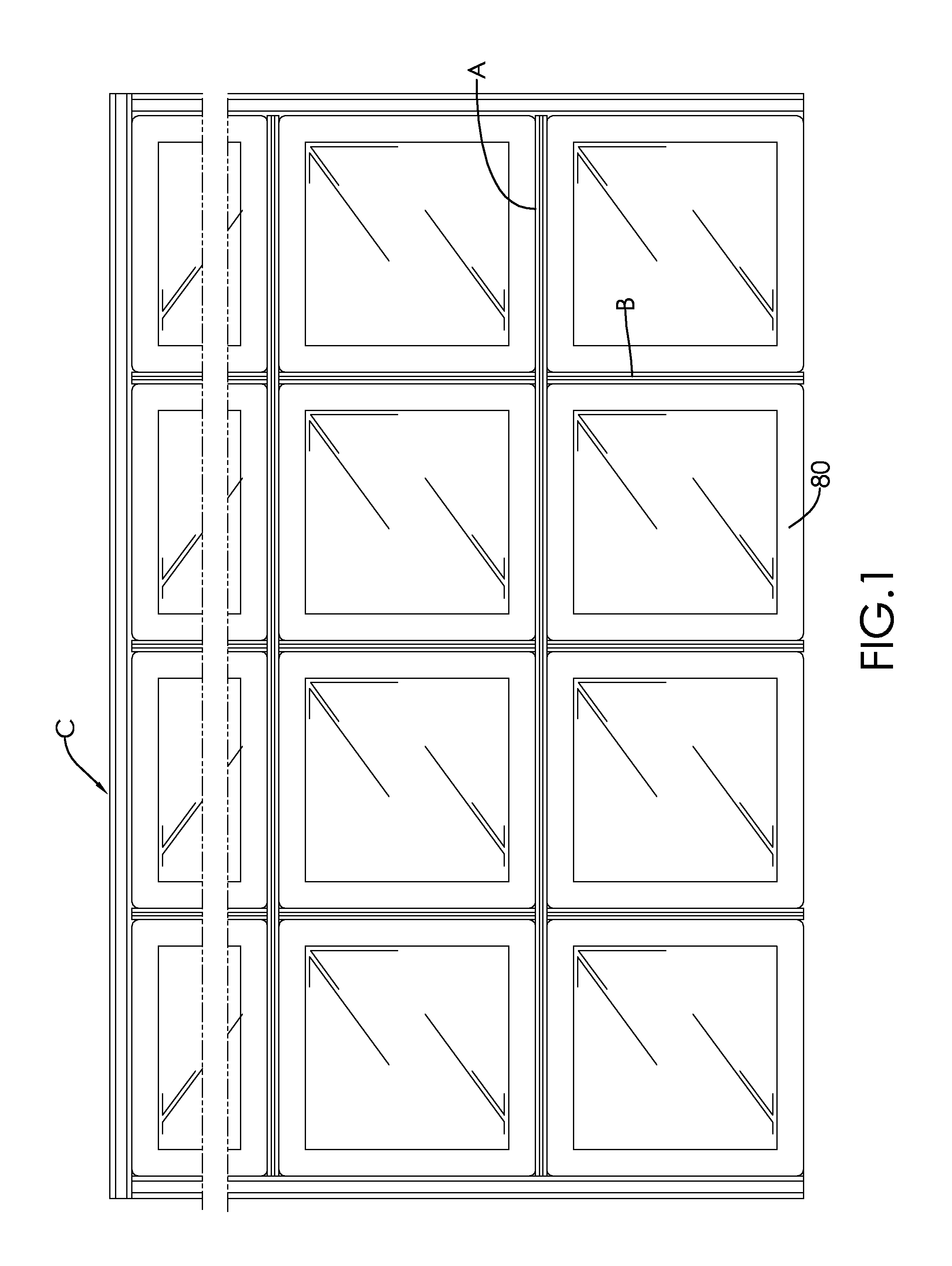

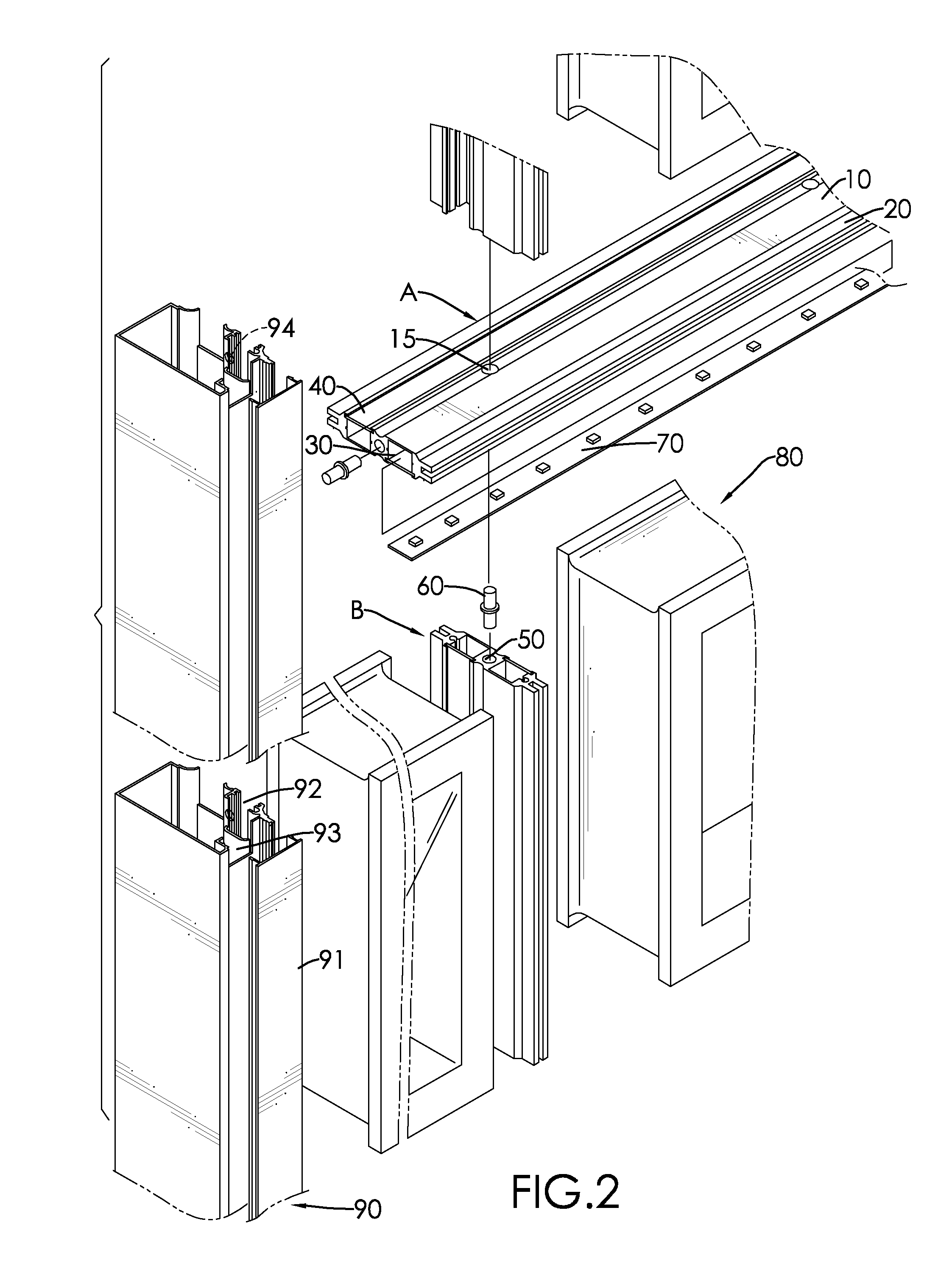

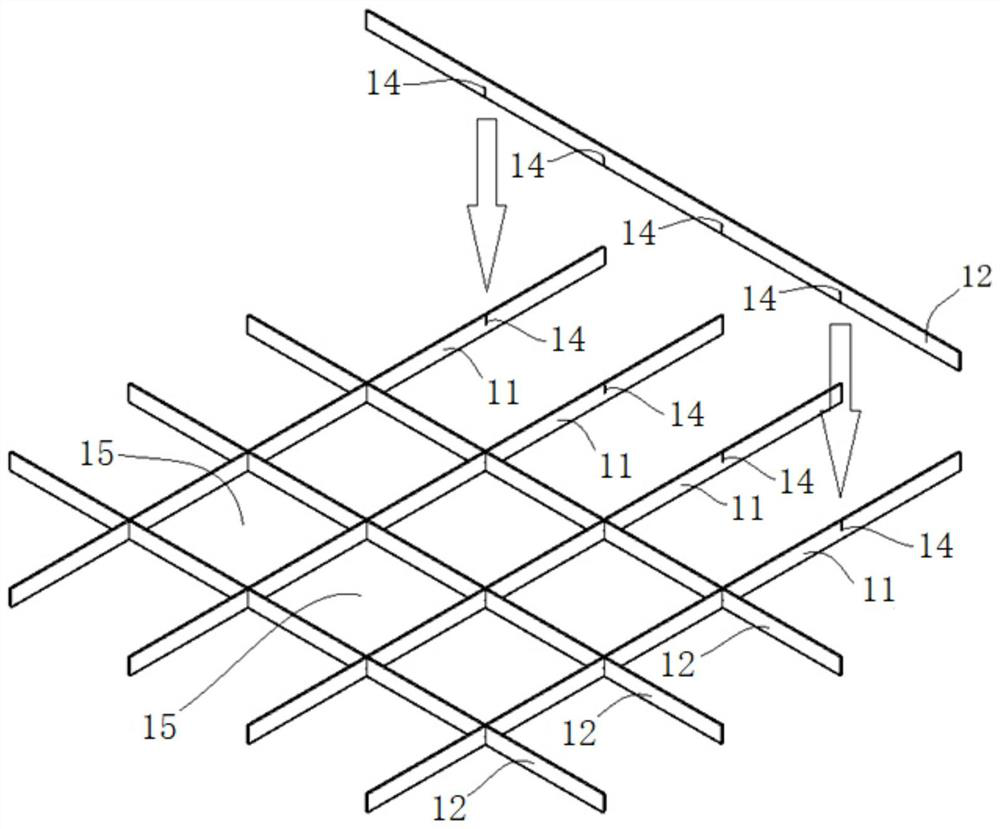

Support Frame of Glass Brick Wall and Method for Mounting the Same

ActiveUS20120124926A1Easy to replaceNot mess up environmentNon-electric lightingConstruction materialBraced frameBrick

A support frame of glass brick wall has multiple horizontal beams, multiple vertical beams and multiple side bars. Each of the horizontal beams and the vertical beams has a body, two side wings respectively and longitudinally formed on and protruding from two edges of the body, and two lamp slots respectively and longitudinally formed on and recessed from two sides of the body. Each of the vertical beams is securely mounted between two adjacent glass bricks in a corresponding row of glass bricks with adhesive. Each of the horizontal beams is securely mounted on a top of a corresponding row of glass bricks with adhesive. Two of the side bars are securely mounted on two edge sides of the glass brick wall. Each of the side bars has openings to replace light strips mounted in the lamp slots. Accordingly, the support frame provides a clean and easy lamp replacement solution.

Owner:KUO YUAN LUN

Method for dexterously getting rid of greasy dirt on the surface of glass tile, etc.

InactiveCN101138765ACleaning using toolsInorganic non-surface-active detergent compositionsCleansers skinAmmonium hydroxide

The present invention discloses a method of removing greasy dirt on a tile or glass. Usually people use detergent to remove the greasy dirt. The present invention is characterized in that an alkali cleanser and a common domestic plastic bag are used for removing the greasy dirt first, and then the glass or the tile is covered with sodium hydroxide or weak aqua ammonia solution of 10 to 20 per cent. After 30 minutes, a piece of cloth is used for cleaning the solution and the glass or the tile will be bright and clean, which is not only effective but also economical with time and effort.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Glass block and method and mold for producing glass block

InactiveCN102677855AHigh surface glossNot easy to fall offCovering/liningsGlass reforming apparatusBrickHeat treated

The invention discloses a glass block and a method and a mold for producing the glass block. The glass block comprises a glass body with an uneven glass surface and a glass laying surface with a shape corresponding to the shape of the glass surface. A high-temperature glass ink coating layer is arranged on the glass laying surface, wherein the sintering temperature t of the high-temperature glass ink coating layer is more than or equal to a first preset threshold and is less than or equal to a second preset threshold. By adopting the structure, the three-dimensional effect is realized; and by adopting a high-temperature physical heat treatment technology, the coating is ensured to be firm and not apt to fall off, the glass block is attractive and stereoscopic, the surface gloss is high, the process flow is simple and the cost is low.

Owner:何登颖

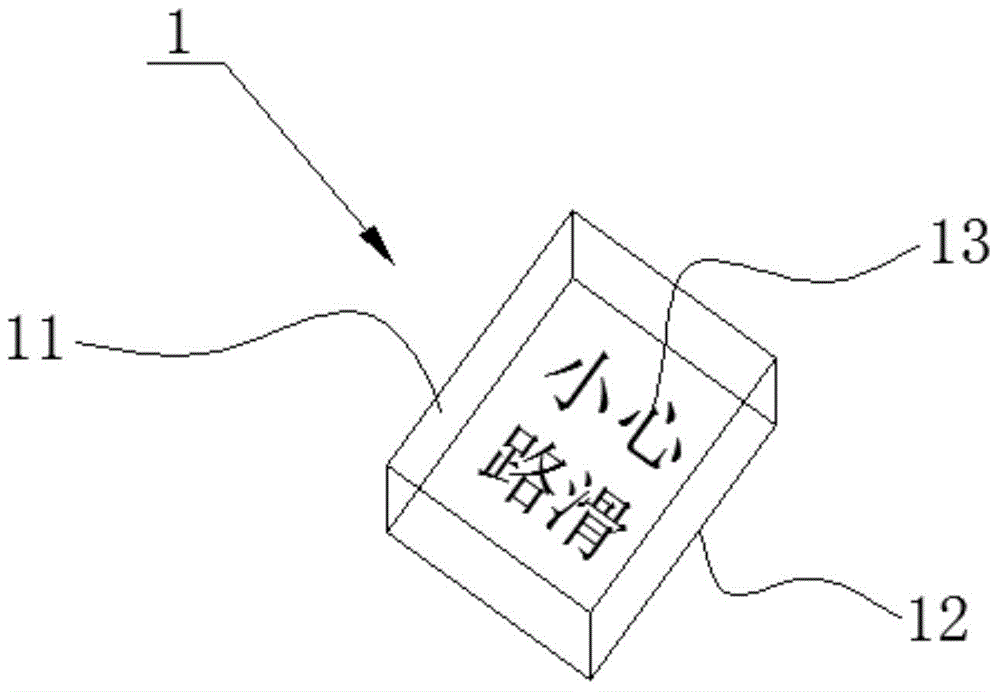

Water-displaying type glass tile

InactiveCN104314280AAvoid wear and tearDoes not affect aestheticsArticle advertisingBoardsRefractive indexWarning label

The invention discloses a water-displaying type glass tile. A tile body is a transparent body, the refraction index of the tile body is the same or similar with the refraction index of water, the upper end surface of the tile body is a frosted surface which is subject to dull polish, the lower end surface of the tile body is a clean transparent surface, and the transparent surface is provided with a warning label; the tile body is made of glass or tempered glass; the warning label is concavely arranged on the transparent surface, and the warning label is coated with a white, yellow or red coating layer; or the warning label is a warning sticker marked with prompting information, and the warning sticker is stuck to the transparent surface. The water-displaying type glass tile has the advantages that the warning label can be displayed when water exists on the frosted surface, and can automatically disappear when the frosted surface is dry; the manual handling is not needed; the warning label can be protected, the easiness in damage is avoided, and the influence on the attractive appearance effect of ground is avoided.

Owner:南宁市第一中学

Solid glass brick wall body structure, and installing and replacing methods thereof

The invention discloses a solid glass brick invisible wall body structure and installing and replacing methods thereof. The installing method is provided, and concretely comprises the following stepsof step A1, bonding the lower end surfaces of bottom layer glass bricks onto a wall body installing surface, and sequentially bonding and connecting the connecting surfaces of a plurality of bottom layer glass bricks in the length direction of the wall body structure; step A2, bonding one sides, bonded to soft buffer cushions, of connecting elements into first square notches formed in the upper end surfaces of the plurality of bottom layer glass bricks, and bonding one sides, bonded to the soft buffer cushions, of support connecting plates onto one sides, parallel to the connecting surface, inside third square notches of the bottom layer glass bricks; and step A3, sequentially bonding the lower end surfaces of a plurality of first glass bricks onto the upper end surfaces of the bottom layer glass bricks so that the second square notches tightly press the connecting elements, and are bonded and connected to the connecting elements. The invention provides the convenient-to-dismount solidglass brick wall body structure and the installing and replacing methods thereof.

Owner:上海晶尔工艺品有限公司

Preparation method of colored glass wall brick or glass tile

The invention relates to a preparation method of colored glass wall bricks or glass tiles, comprising the following steps: (1) preparing raw materials, wherein, the raw materials comprise 74-90 wt% of waste glass, 4-6 wt% of flousper powder, 4-15 wt% of feldspar powder, and 2-6 wt% of soda ash; (2) mixing the ingredients in the step (1), then adding a coloring agent in an amount of 0.1-0.4 wt% based on the total weight of the raw materials, and sintering the mixture into a glass liquid at a temperature of 1050-1100 DEG C; (3) putting the glass liquid obtained in the step (2) in a die for pressing into shape; and (4) annealing the pressed product at a temperature of 400-600 DEG C, and cooling. The preparation method has the advantages of simple process, low cost, and low energy consumption, and the prepared product has abundant color and wide application.

Owner:田长生

Hollow glass brick butt joint process

ActiveCN113716848AAvoid heat softeningAvoid Accidental BurnsGlass reforming apparatusGlass productionBrickEngineering

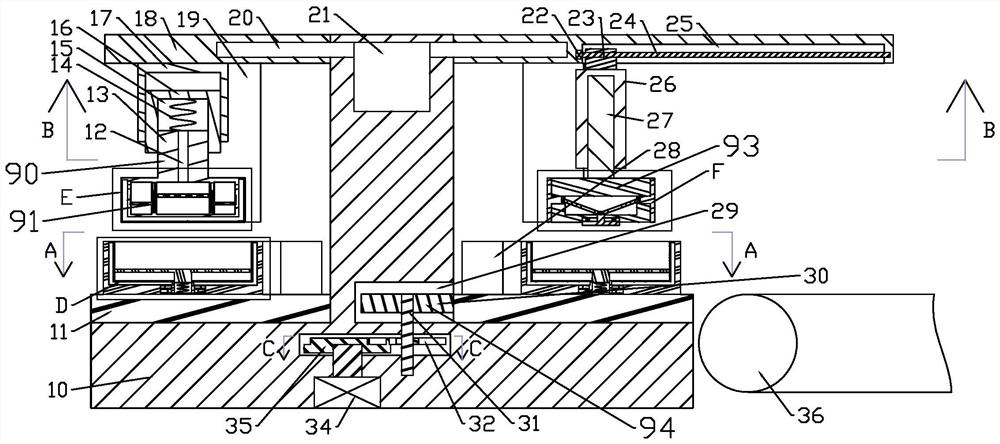

The invention belongs to the field of glass brick processing, and particularly relates to a hollow glass brick butt joint process which is completed by matching with the following hollow glass brick butt joint equipment, the hollow glass brick butt joint equipment comprises a back plate, a heating block is fixedly arranged on the back plate, and the back plate is symmetrically provided with two flat sliding plates relative to the heating block; each flat sliding plate is provided with a clamping mechanism for clamping glass bricks, two heat insulation mechanisms for heat insulation and two melting mechanisms for ignition are arranged in the heating block, and two square-ring-shaped melting grooves with openings facing the two clamping mechanisms are formed in the heating block. Heat on the side of the fire guide spray head in the melting groove is isolated through the second inner heat insulation plate, the first inner heat insulation plate, the second outer heat insulation plate and the first outer heat insulation plate, the non-welding part of the glass brick is prevented from being heated and softened, and the non-welding part of the glass brick can be effectively prevented from deforming in the melting and butt joint process when the hollow glass brick is machined through the technology and equipment.

Owner:佳木斯长城玻璃制品有限公司

Manufacturing process of hollow glass round-hole bricks

InactiveCN101824892AReduce labor intensityIncrease productionCovering/liningsGlass pressing apparatusBrickFusion welding

A manufacturing process of hollow glass round-hole bricks relates to a manufacturing method of building decoration materials. The invention is characterized by adopting the automatic process flow, precisely drawing mold drawings for different round holes, drilling holes and remaking and adjusting the molds according to the drawings. The manufacturing process mainly comprises the following working procedures: mold developing, pressing, molding by fusion welding, annealing and finished product forming. The invention greatly reduces the labor intensity of workers, improves the yield of the round-hole bricks by about 5-6 times, saves a lot of time compared with manual perforating, lowers the production cost and avoids the problems of irregularity of round holes on the glass bricks, burrs and the like in the process of manual manufacturing, thereby improving the product quality.

Owner:德州振华装饰玻璃有限公司

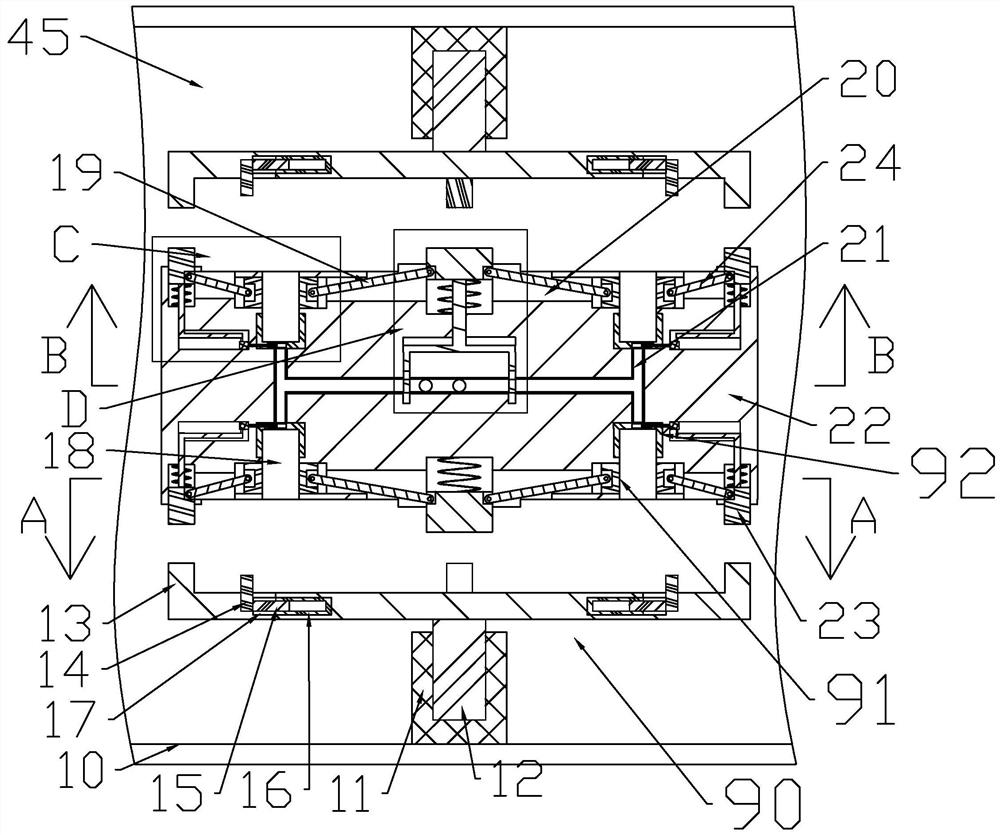

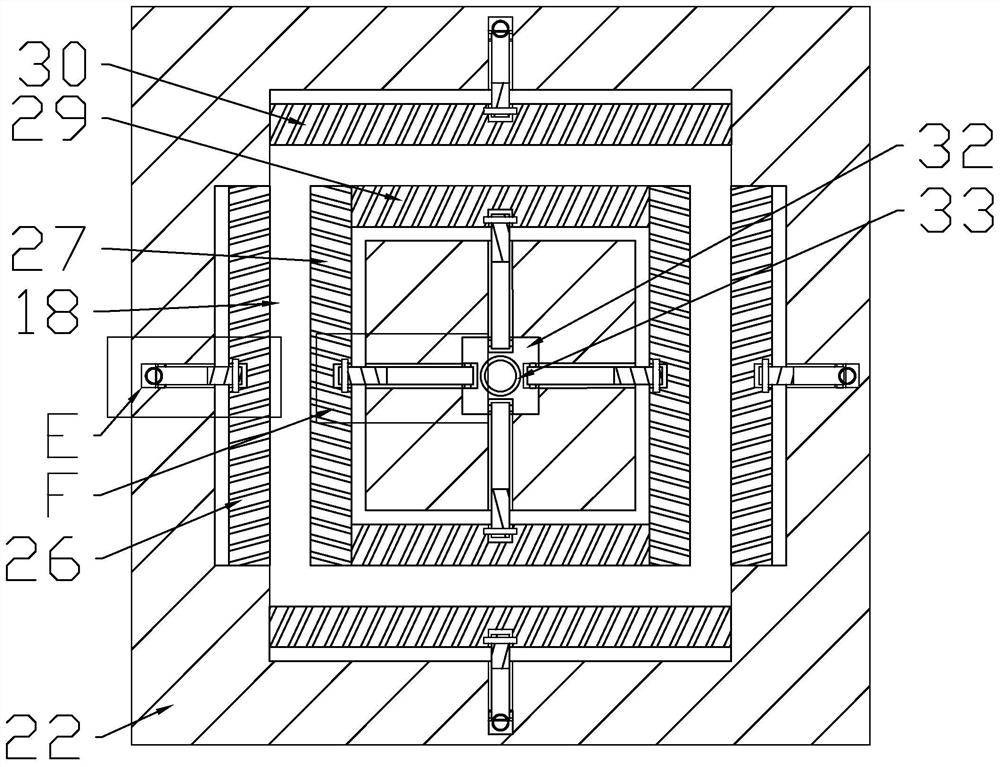

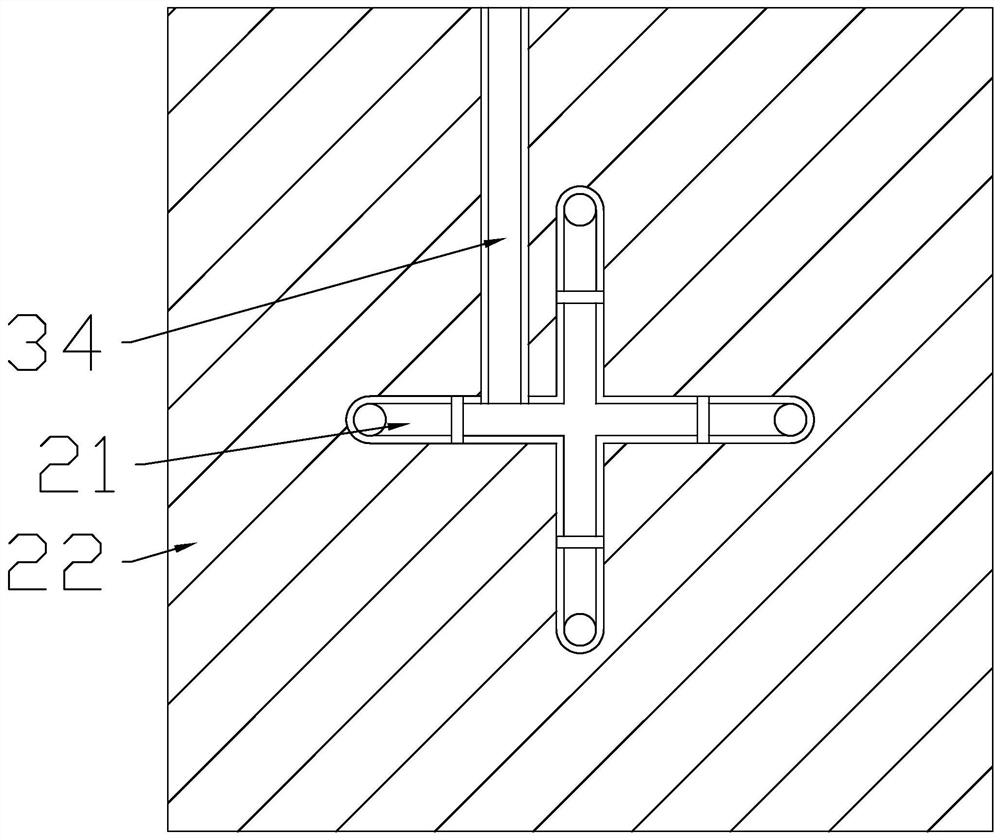

Paving and mounting structure for ultralow-adhesion-coefficient pavement glass bricks in test bed

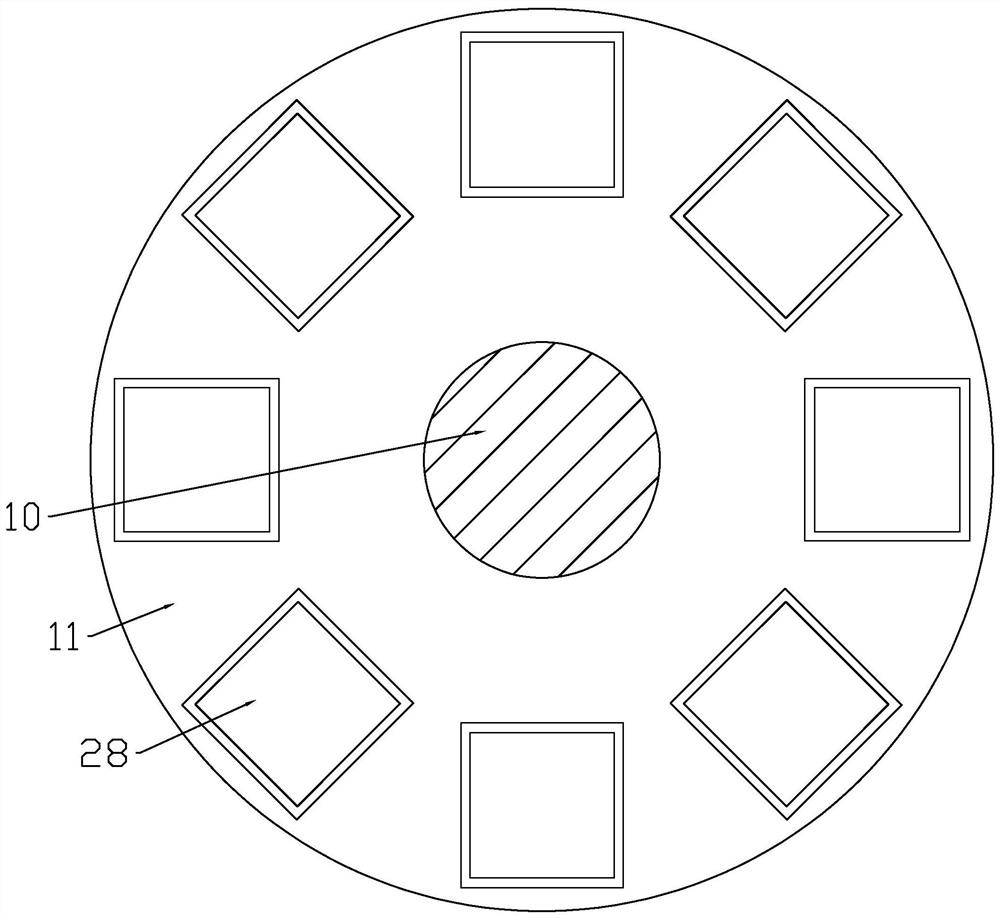

PendingCN112458824APrevent rustHigh strengthSingle unit pavingsPaving gutters/kerbsAdhesion coefficientBrick

The invention discloses a paving and mounting structure for ultralow-adhesion-coefficient pavement glass bricks in a test bed, which comprises a latticed mounting frame and glass bricks embedded intoeach mesh of the mounting frame, the bottom surfaces of the glass bricks are supported in the mounting frame, and the side surfaces of the glass bricks are clamped with rubber clamping pads of the mounting frame, so that an inlaying and fixing structure is formed. According to the invention, the glass bricks only having a building decoration function are enabled to realize pavement performance, the installed glass bricks are combined to form a stable integral pavement, the driving test requirements are met, the problem that glass materials cannot be effectively bonded with other pavement materials is solved, inlaying installation and brick maintenance and replacement are convenient, and the construction and maintenance costs are effectively reduced.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +1

Building integrated photovoltaic system with glass photovoltaic tiles

ActiveUS10778139B2Improve aestheticsImprove efficiencyPhotovoltaic supportsClimate change adaptationBuilding integrationRoof tile

Building integrated photovoltaic (BIPV) systems provide for solar panel arrays with improved aesthetics and efficiency that can replace a conventional roof surface structure. These BIPV systems can utilize photovoltaic PV roof tiles defined as glass tiles having photovoltaic elements embedded or incorporated into the body of the roof tile. Such PV roof tiles can include one or more lapping features for interfacing with adjacent tiles and features for electrically connecting multiples tiles within a course to an external power optimizer. Such PV roof tiles can utilize stamped glass that is stamped to define these features within an integrated glass tile and can further include texture, striations on the glass tile and / or color matched back layers or various other components to obscure visibility of any embedded solar cells and provide a more pleasing appearance.

Owner:TESLA INC

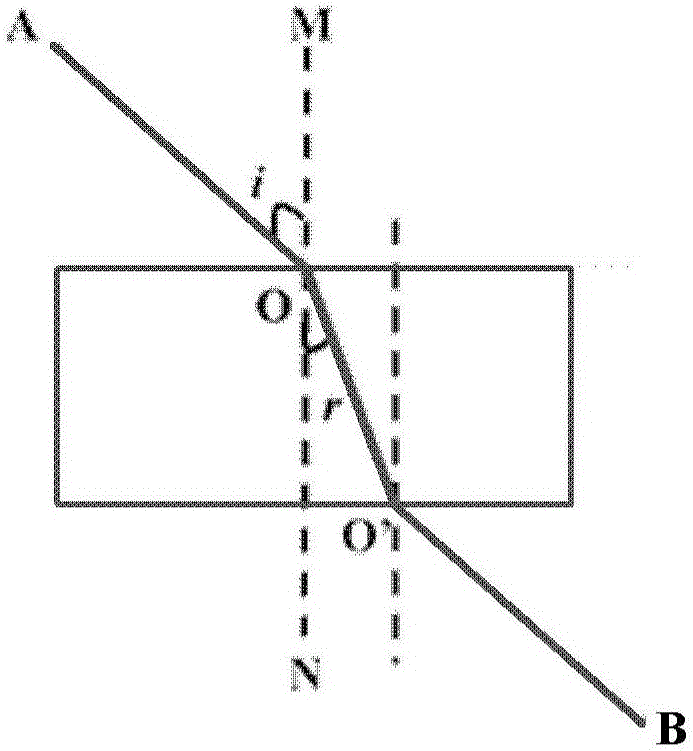

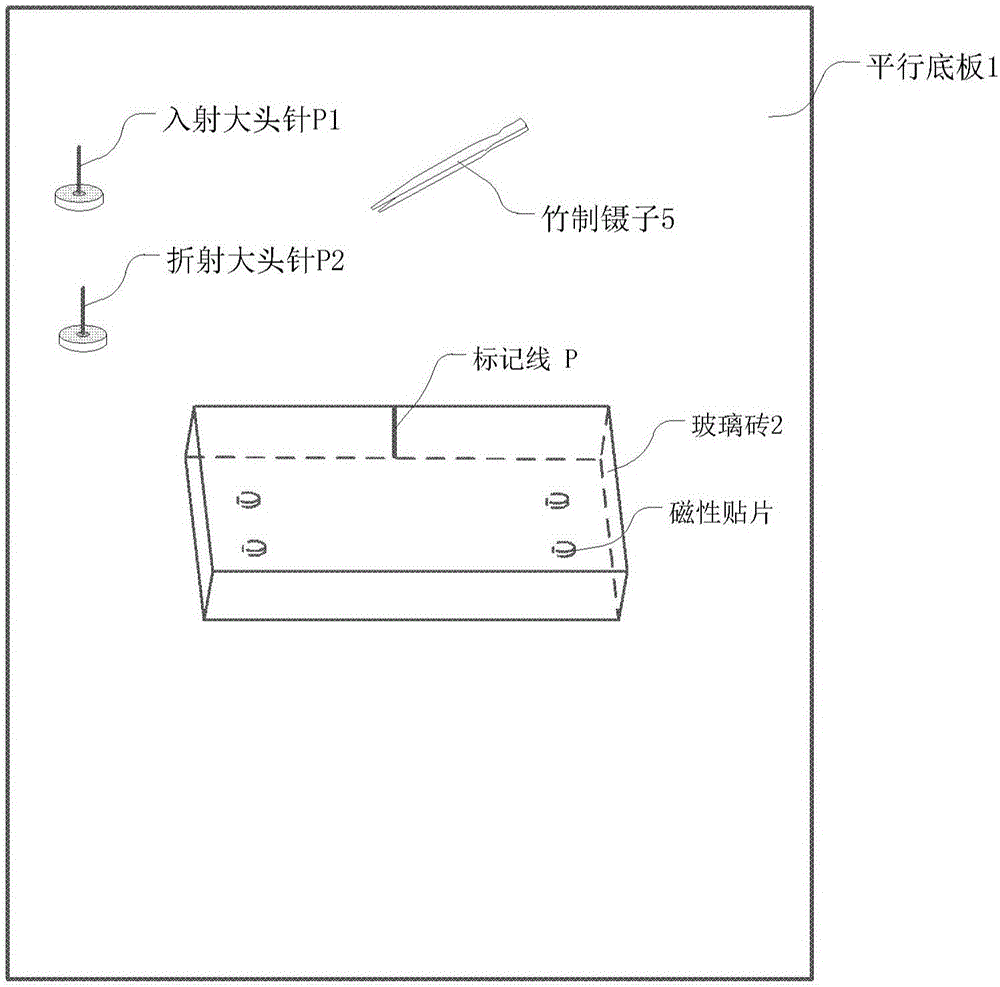

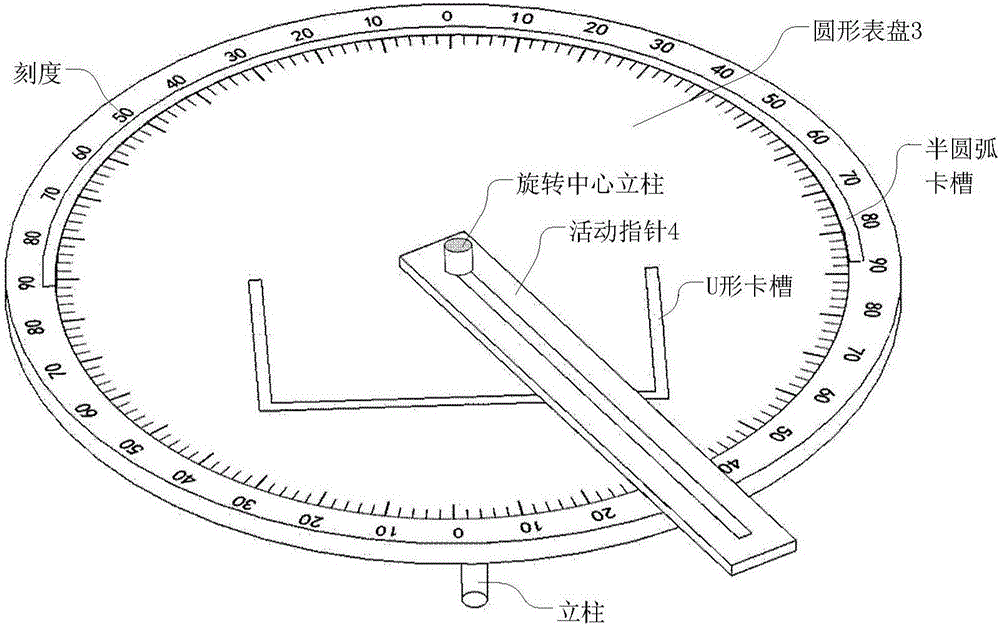

Refractive index measuring instrument

PendingCN106770036APrevent movementEasy to operatePhase-affecting property measurementsMeasuring instrumentRefractive index

The invention discloses a refractive index measuring instrument which comprises a dial, an activity pointer, a glass tile and a marker, wherein the dial is placed above the glass tile, and is provided with at least two slots which are respectively positioned on an incident light side and a refracted light side; the inner edge of the slot positioned on the refracted light side is tangent to the glass tile; the activity pointer is rotationally connected with the dial, and is provided with a hairline; an incident angle is read on the dial according to an incident light position; the direction of refracted light is calibrated by virtue of the marker, the activity pointer and the slots; a refraction angle is read on the dial through the hairline on the activity pointer, so as to calculate the refractive index of glass. When the refractive index measuring instrument provided by the invention is in use, light drawing is not needed, and the incident angle and the refraction angle are read through scales on the dial, thereby avoiding measurement errors introduced by the light drawing, greatly reducing the workload and improving the measurement efficiency.

Owner:裴钊

Fabricated mounting structure of solid glass brick partition

The invention discloses a fabricated mounting structure of a solid glass brick partition, and belongs to the technical field of fabricated buildings. The fabricated mounting structure comprises a sky keel, a ground keel, edge supporting pieces, glass brick bodies, edge plugging strips and edge closing strips, wherein the sky keel and the ground keel are fixedly connected to a top wall base layer and a ground base layer correspondingly; the two ends of each edge supporting piece are fixedly connected with the sky keel and the ground keel correspondingly; the four edge supporting pieces are arranged and define a wall space; and a plurality of glass brick bodies are built into a glass wall in the wall space, and the four edge supporting pieces abut against the four corners of the glass wall correspondingly. According to the fabricated mounting structure, the edge supporting pieces are adopted as a main body frame, a partition plate plays a role in bonding and connecting the glass brick bodies, the partition plate and the edge plugging strips are connected into a fixed frame network and finally fixed to the edge supporting pieces, a special complex reinforcing frame is simplified, building materials are saved, and thus the mounting efficiency is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Hollow glass brick forming process

ActiveCN113501657AReduce the temperatureAvoid deformationGlass pressing apparatusGlass productionCompression moldingBrick

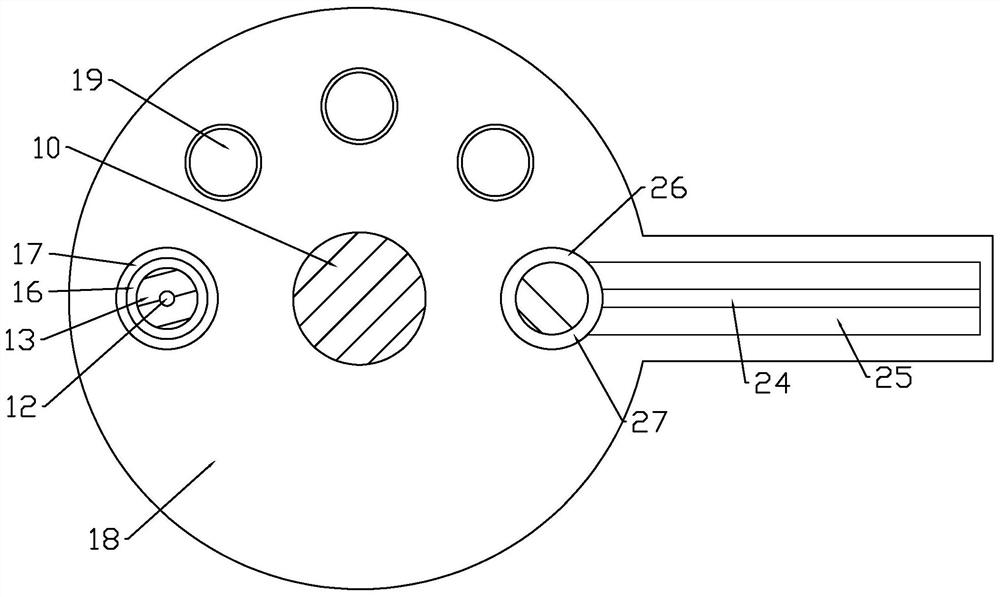

The invention provides a hollow glass brick forming process. The hollow glass brick forming process is completed through cooperation of following hollow glass brick forming equipment; the hollow glass brick forming equipment comprises a working frame, the working frame is in a T shape, and a draught fan is embedded in the narrow end of the working frame; a top disc is fixedly arranged at the narrow end of the working frame; an air guide pipe is arranged in the top disc and connected to the draught fan; a rotating disc is rotationally arranged at the junction of the narrow end and the thick end of the working frame; a pressing mechanism is arranged on the short side of the top disc, a cooling mechanism is arranged in the pressing mechanism, a demolding mechanism is arranged on the long side of the top disc, and a rotating mechanism enabling the rotating disc to rotate intermittently is arranged in the end, away from the top disc, in the working frame; a first refrigerant is cooled when a pressing block is reset, the temperature of the inner surface of molten glass can be reduced through the first refrigerant; meanwhile, a second refrigerant is refrigerated, the outer surface of the glass is cooled, the glass is shaped, and deformation of the glass caused by cooling in the conveying process can be avoided; and deformation of a glass brick in the compression molding and conveying process can be effectively prevented through the process and the equipment for processing the hollow glass brick.

Owner:广西扩展工程机械有限公司

Manufacturing process of cylindrical arc-shaped brick of hollow glass brick

InactiveCN102134898AHigh degree of automationIncrease productivityCovering/liningsGlass pressing apparatusCombustorBrick

The invention discloses a manufacturing process of a cylindrical arc-shaped brick of a hollow glass brick and belonging to the technical field of manufacturing of decorative materials. The process is characterized by manufacturing an arc-shaped glass brick in an automatic process flow, and meanwhile, ensuring that the angle of the arc-shaped surface is 22.5 DEG; drawings of a mould, a clamp and an annular burner are designed precisely; the mould, the clamp and the annular burner are processed in accordance with the drawings; the manufacturing process mainly comprises the steps of developing the mould, the clamp and the annular burner, pressing, welding and moulding, annealing and checking finished products to obtain the cylindrical arc-shaped brick product of the hollow glass brick. The manufacturing process disclosed by the invention has high degree of automation, more diversity of products, high production efficiency, rate of finished products as high as 70% or above, low construction cost and high strength; and through the manufacturing process, expected effects of more attractive arcs and cylinders can be decorated and the selection range of decoration on the decoration of the glass brick can be expanded.

Owner:德州振华装饰玻璃有限公司

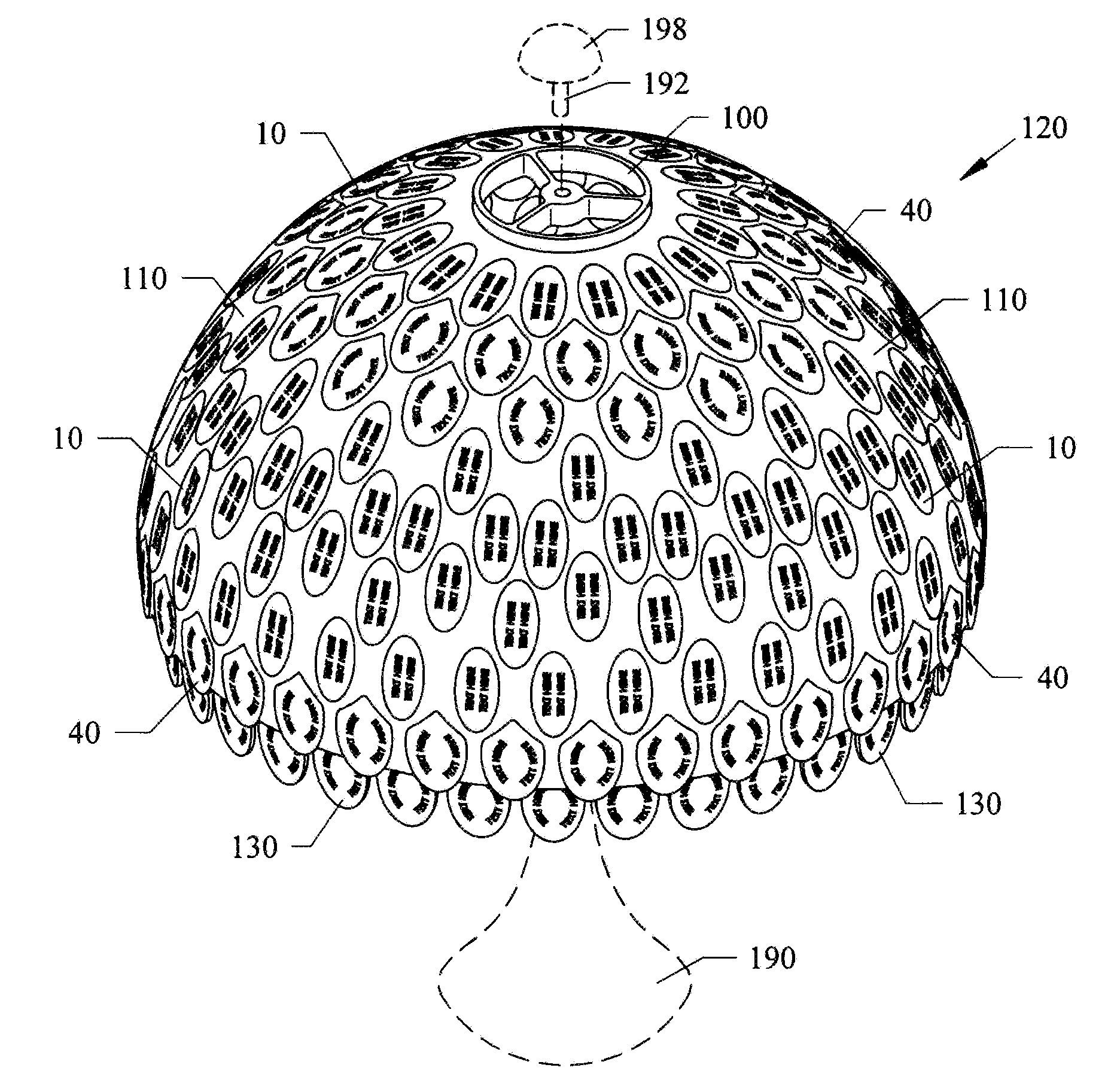

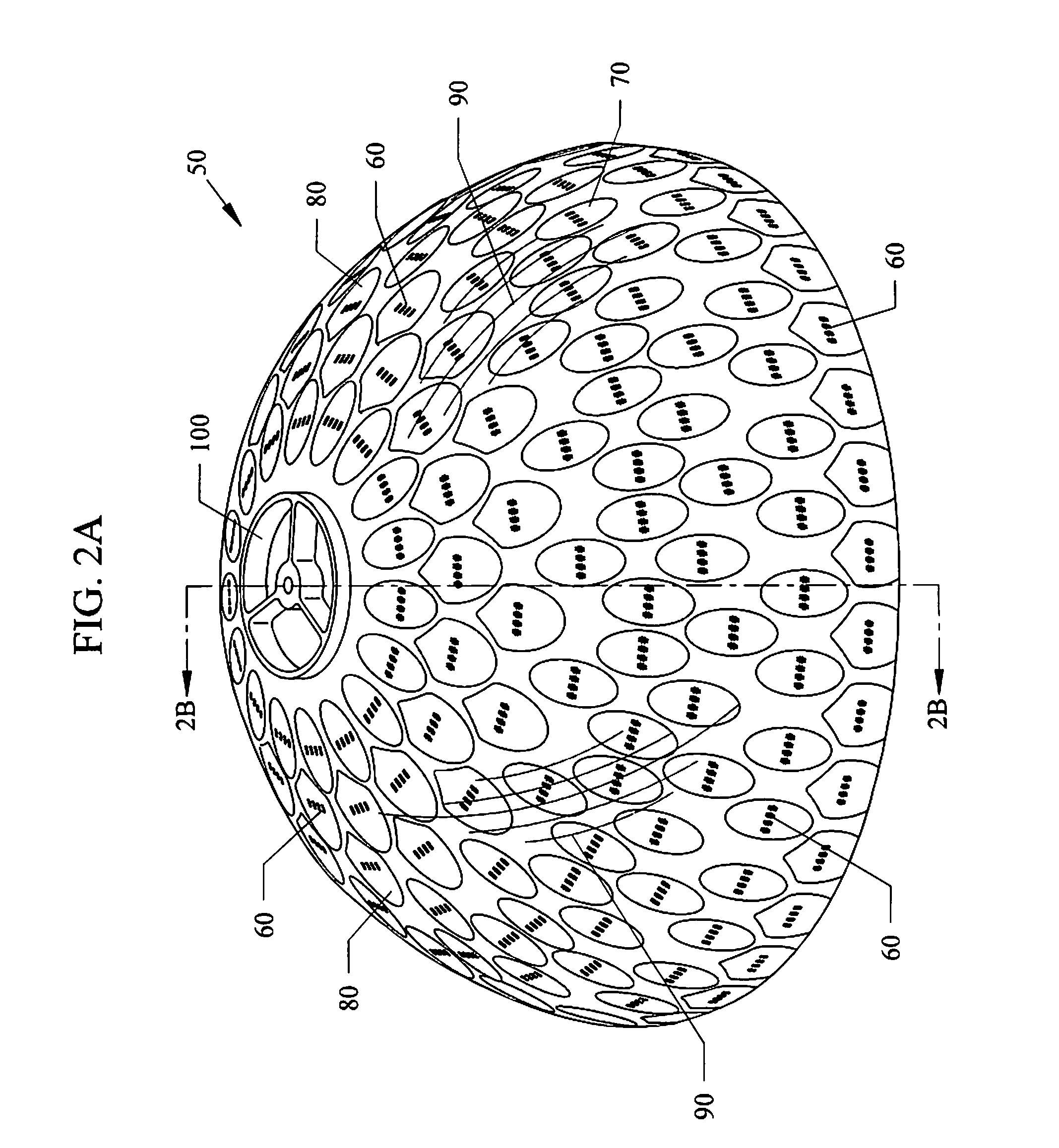

Stained glass lampshade and method of making stained glass lampshade

Stained glass lampshades and decorative lamps and methods of making and fabricating stained glass lampshades and other ornamental shades and decorative articles for lamps, formed from customized glass tiles, that allow for additional glass tiles to be hung from hooks on fixed glass tiles, and allowing for indicia, such as but not limited to names, birthdays, designs, logos and pictures to be customized on selected glass tiles. Water jet cut glass tiles can be attached to one another into a hemi-spherical shape by a cured and hardened grout between each tile.

Owner:TITUS JEFFERY E

Process for manufacturing inner-encaustic brick

InactiveCN101612864AReduce labor intensityIncrease productionSpecial ornamental structuresPaint thinnerBrick

The invention provides a process for manufacturing an inner-encaustic brick, and relates to a method for manufacturing a building material. The process is characterized in that: a flexible process flow is adopted, the blending ratio of the raw materials depends on air temperature and air humidity; when the air temperature is less than or equal to 20 DEG C and the relative air humidity is more than or equal to 40 percent, the blending ratio of glass paint to paint thinner to catalytic type shaping agent is 4.5-5.5:2.5-3.5:0.4-0.6; and when the air temperature is more than or equal to 20 DEG C and the relative air humidity is less than or equal to 40 percent, the blending ratio of glass paint to paint thinner to catalytic type shaping agent is 4.5-55:2-3:0.4-0.6. The manufacturing process mainly comprises the following steps of paint preparation, filling, annealing, air blowing, paint spraying and finished product. The process has the advantages of greatly lowering labor intensity of workers, improving the output of the inner-encaustic brick by nearly 2 to 3 times, saving manual manufacturing time, lowering production cost, solving the problems of unevenly distribution of the glass paint on the inner surface of the glass brick and wet paint surface existing in the manual manufacturing process, and further improving product quality.

Owner:德州振华装饰玻璃有限公司

Epoxy color bead joint mixture, and preparation method and construction method thereof

InactiveCN110723927AGood weather resistanceImprove high temperature resistanceBuilding repairsPolymer scienceBrick

The invention relates to an epoxy color bead joint mixture, and a preparation method and a construction method thereof. The epoxy color bead joint mixture is prepared from epoxy resin, a curing agent,pigment, silicon dioxide and other raw materials through the preparation method including the steps of mixing and low-speed stirring and dispersing. During construction, a rubber spatula is needed and is used for smearing the epoxy color bead joint mixture into a joint in a diagonal direction. The epoxy colored bead joint mixture has the beneficial effects that the epoxy colored bead joint mixture serves as a high-performance halogen-free base material, is suitable for filling in various ceramic tile joints, can release negative oxygen ions for a long time, has excellent weather resistance, high temperature resistance, water resistance and chemical corrosion resistance, is low in viscosity and high in toughness, and can be operated in a humid environment and be used in cold regions; the epoxy colored bead joint mixture is applicable to joints of indoor wall and ground ceramic tiles, and can meet the requirements of various ceramic tiles due to its different colors; and the epoxy colorbead joint mixture is also suitable for beautifying and filling-in of joints of sintered tiles, mosaics, stones, cobblestones, glass bricks and the like.

Owner:栗金超

Painted glass tiles, panels and the like and methods for producing painted glass tiles and panels

InactiveUS20070237960A1Reduce and minimize corrosionAbrasion resistanceCovering/liningsSpecial ornamental structuresProduction linePolymer science

A process and apparatus for painting float glass in particular using a production line that may also be used as or is similar to a mirror line, to produce decorative glass panels. In an embodiment of the invention, painted glass tiles are cut from the glass panels after the paint has dried / cured using a typical glass panel cutter. As such, a mass production technique is provided for making painted glass tiles, particularly for residential use.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com