Glass tile cladding mounting structure

A technology for installing structures and glass bricks, which is applied in building construction, covering/lining, construction, etc. It can solve problems such as difficult load-bearing structures, hard glass bricks, and greater influence of dry-hanging structures, so as to eliminate poor flatness and The effects of falling off, solving common quality problems, and eliminating quality hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

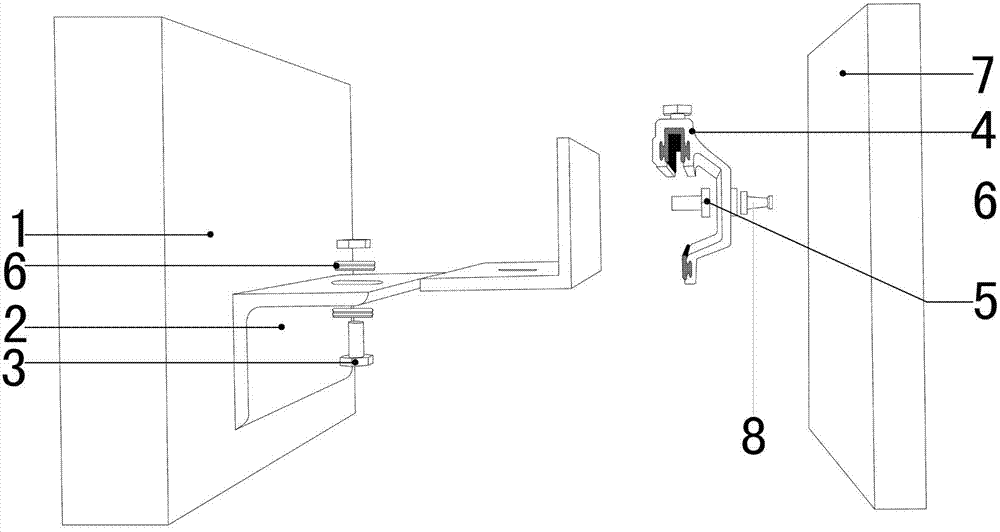

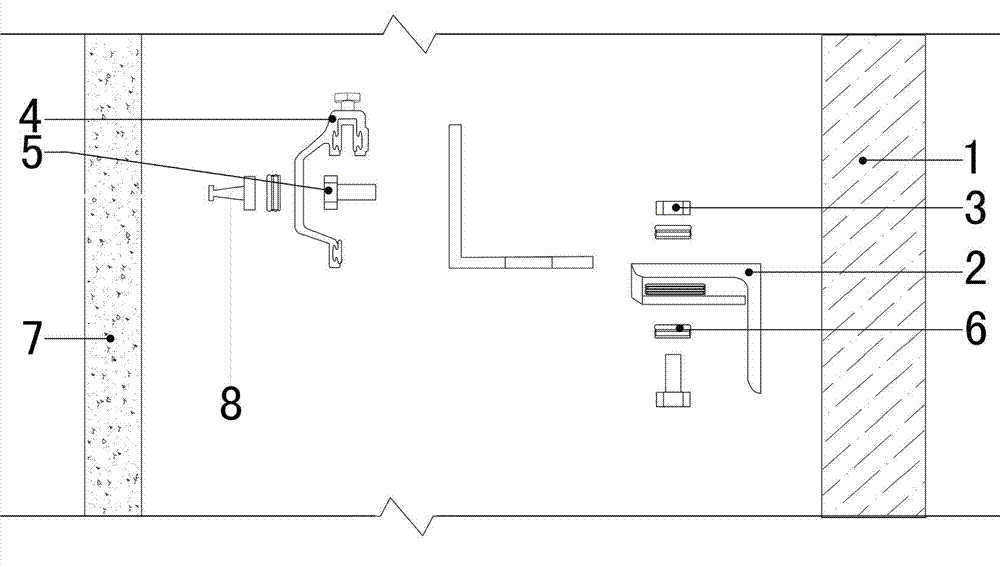

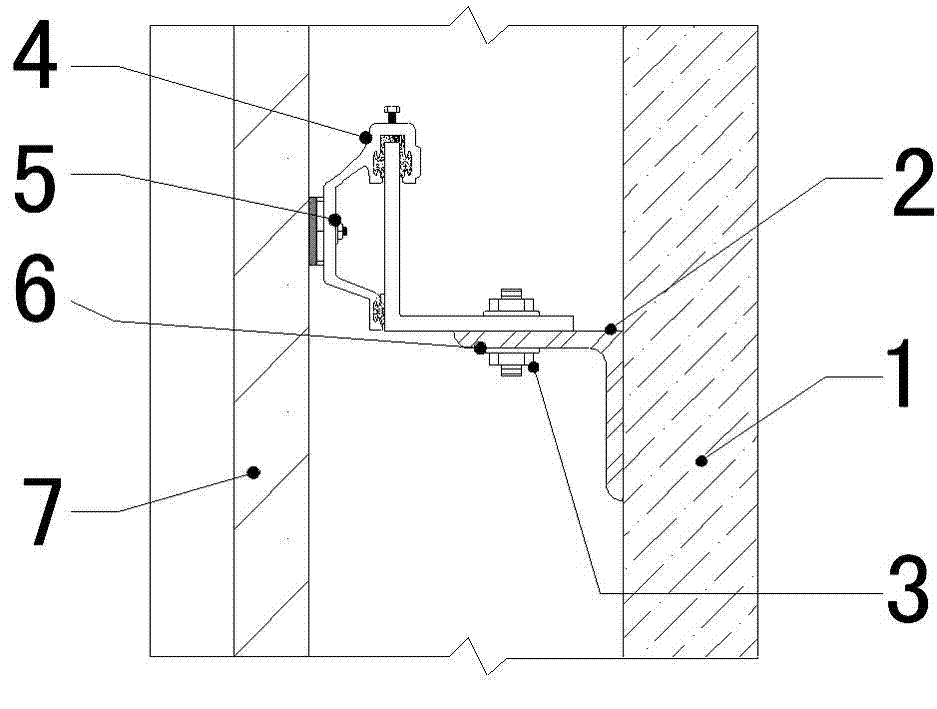

[0024] Example: such as figure 1 , figure 2 As shown, a dry-hanging installation structure for glass bricks includes angle steel 1 , hanging parts, hanging parts 4 , back bolts 5 , gaskets 6 , and glass bricks 7 .

[0025] Such as image 3 As shown, according to the size of the glass brick, the full-scale positioning of the construction site is carried out through three-dimensional sensing, and the opening position of the glass brick 7 is accurately positioned and the precise point is provided for later installation. 5# galvanized angle steel 1 is used to fix the civil wall. The connecting piece is fixed on the angle steel 1 on the wall. The hanging piece has a vertically upward hooking end. The hanging piece is composed of two L-shaped adjusting pieces 2, and the two adjusting pieces 2 are fixed by the fixing piece 3 , forming a Z-shaped hook. The upper end surface of the hook is the hook end, and is fixed with the angle steel 1 downward. The fixing part 3 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com