Energy-saving and environment-friendly drying box for chemical raw material production

A chemical raw material, energy saving and environmental protection technology, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of poor drying effect, insufficient drying of chemical raw materials, affecting the normal progress of chemical production, etc., to achieve convenient drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

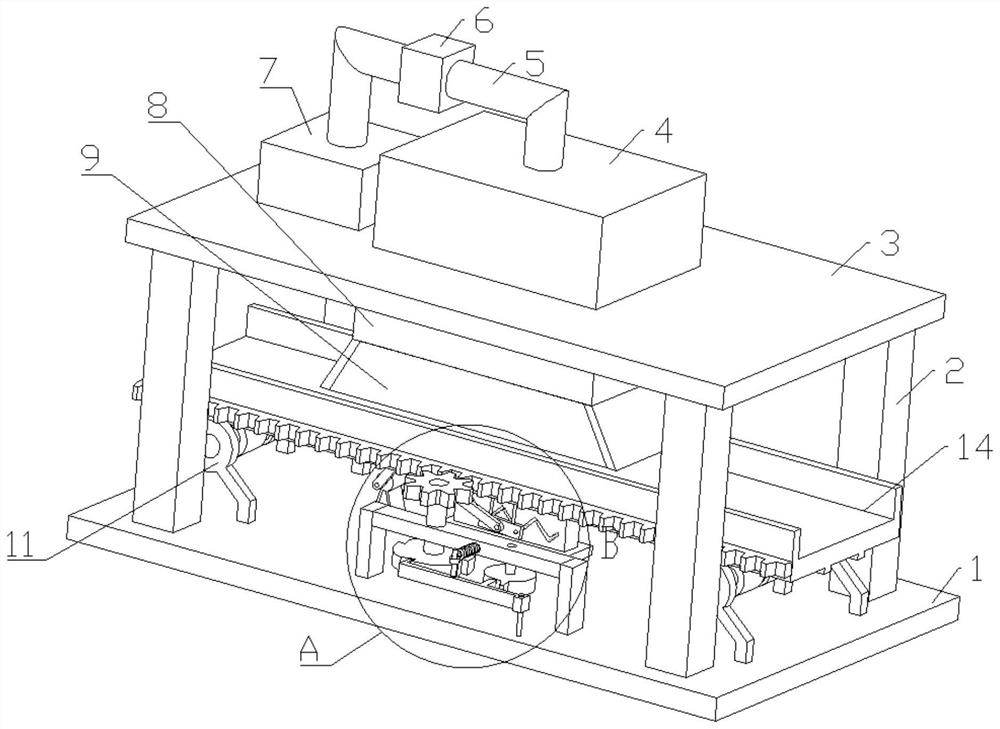

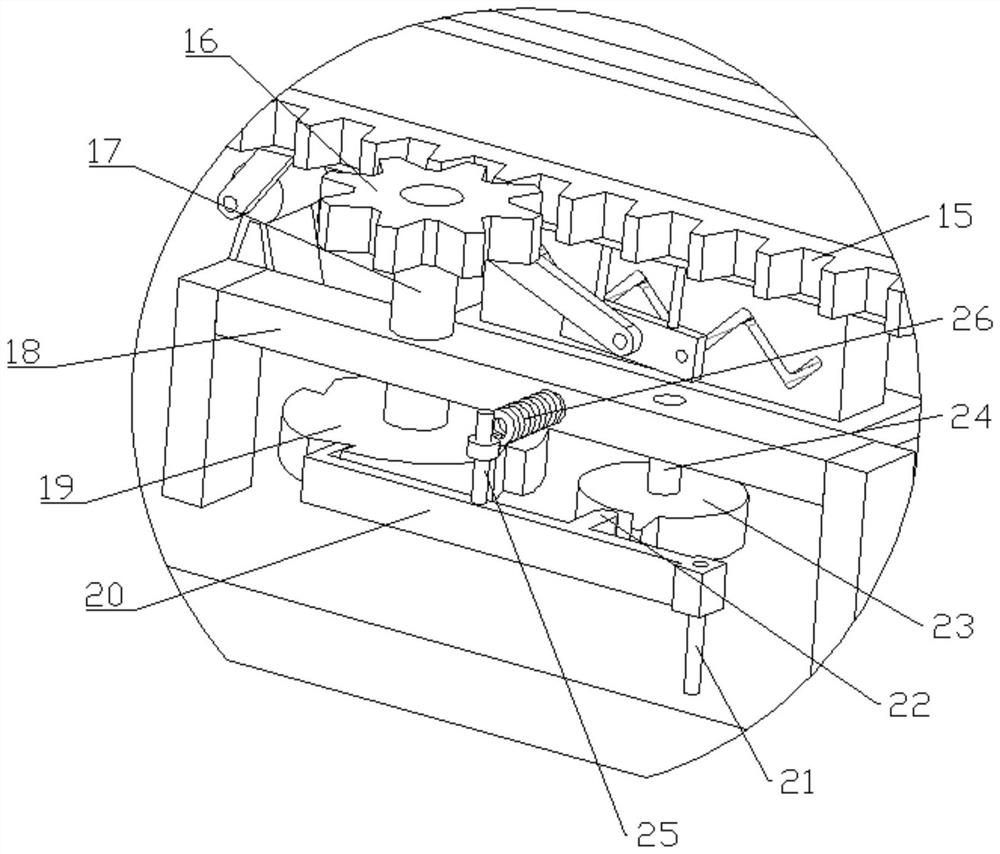

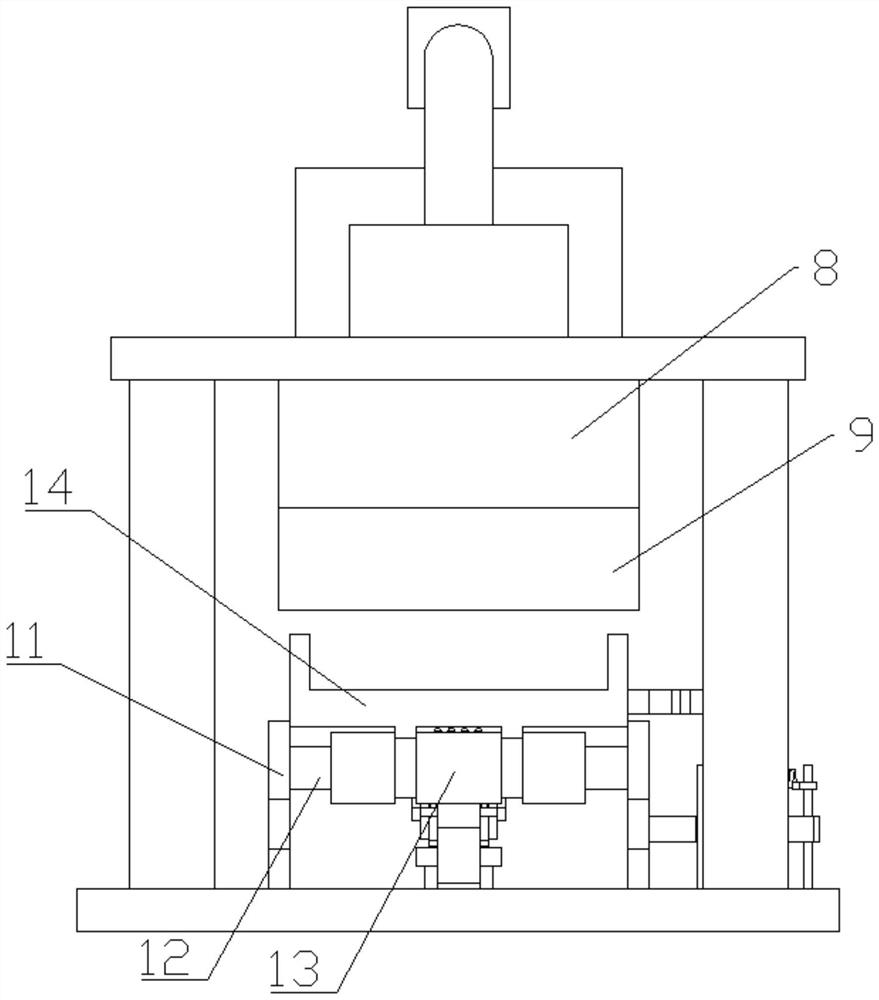

[0029] see Figure 1-6 , in an embodiment of the present invention, an energy-saving and environment-friendly drying box for the production of chemical raw materials includes a base 1 and a box structure, the box structure includes a top plate 3 arranged on one side of the base 1 and a fixed arrangement between the base 1 and the top plate 3 The bracket 2 also includes: a drying mechanism, fixedly installed on the top plate 3, for drying the crushed chemical raw materials; a transmission mechanism, fixed on the side of the base 1 close to the drying mechanism, including a transmission component and a rotation component , for periodically transporting the pulverized chemical raw materials to the bottom of the drying mechanism; the uniform drying mechanism is fixedly arranged in the middle of the base 1, including a vibration component and an elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com