Diatomite crushing and drying apparatus and crushing and drying method

A technology of drying device and diatomite, which is applied in the direction of grain processing, etc., can solve the problem that the moisture content of diatomite particle size has not been studied, and achieve the effects of improving yield, reducing adhesion and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

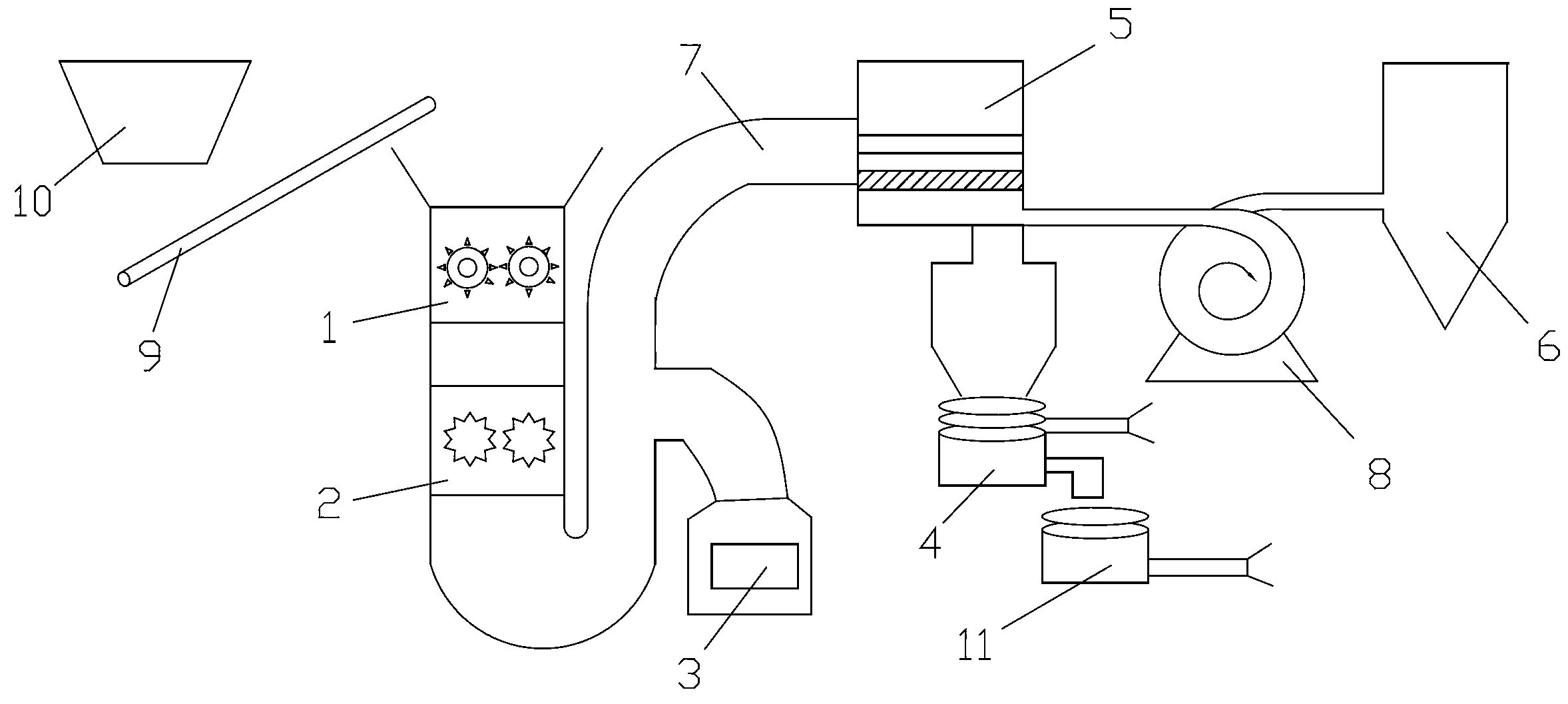

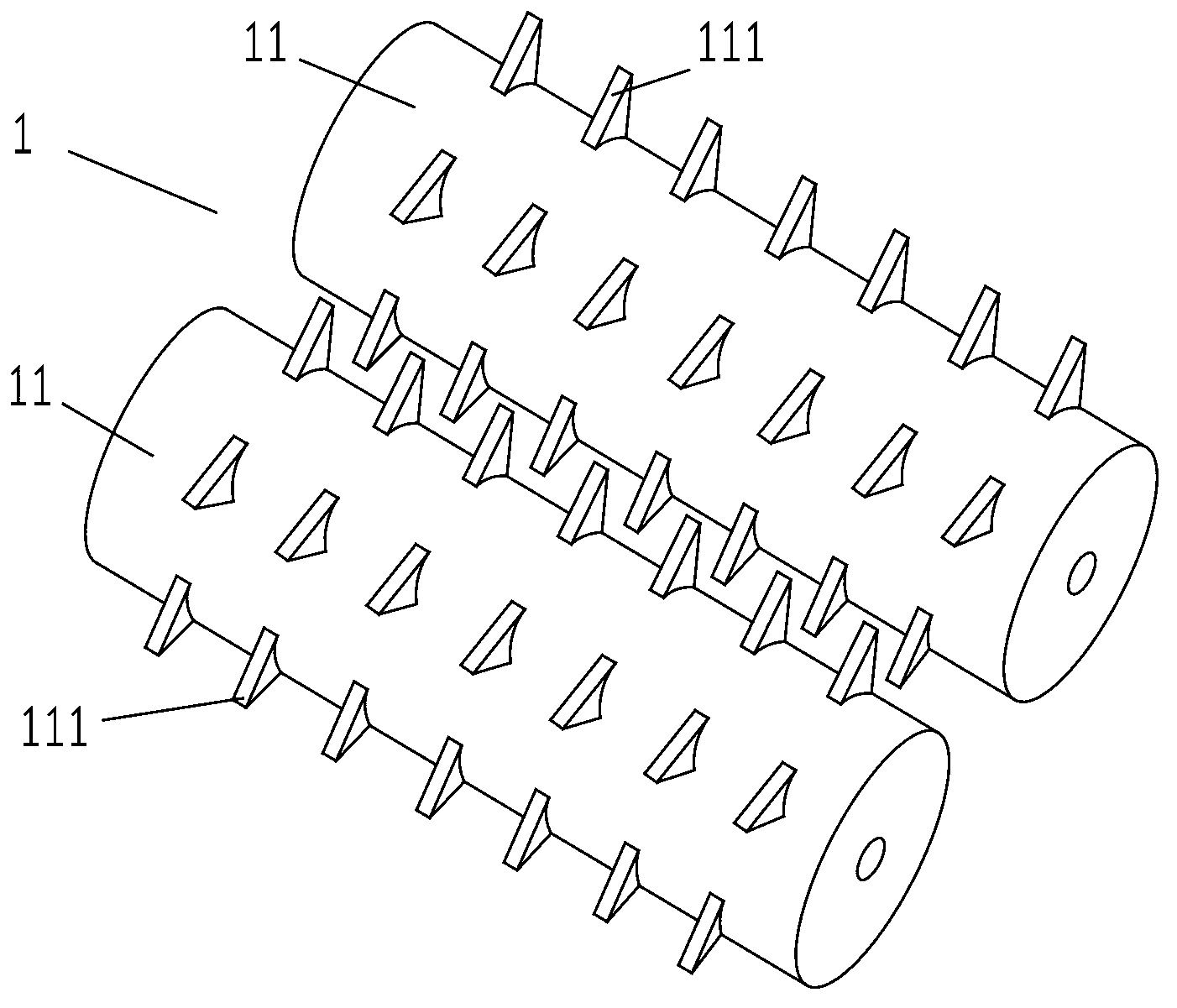

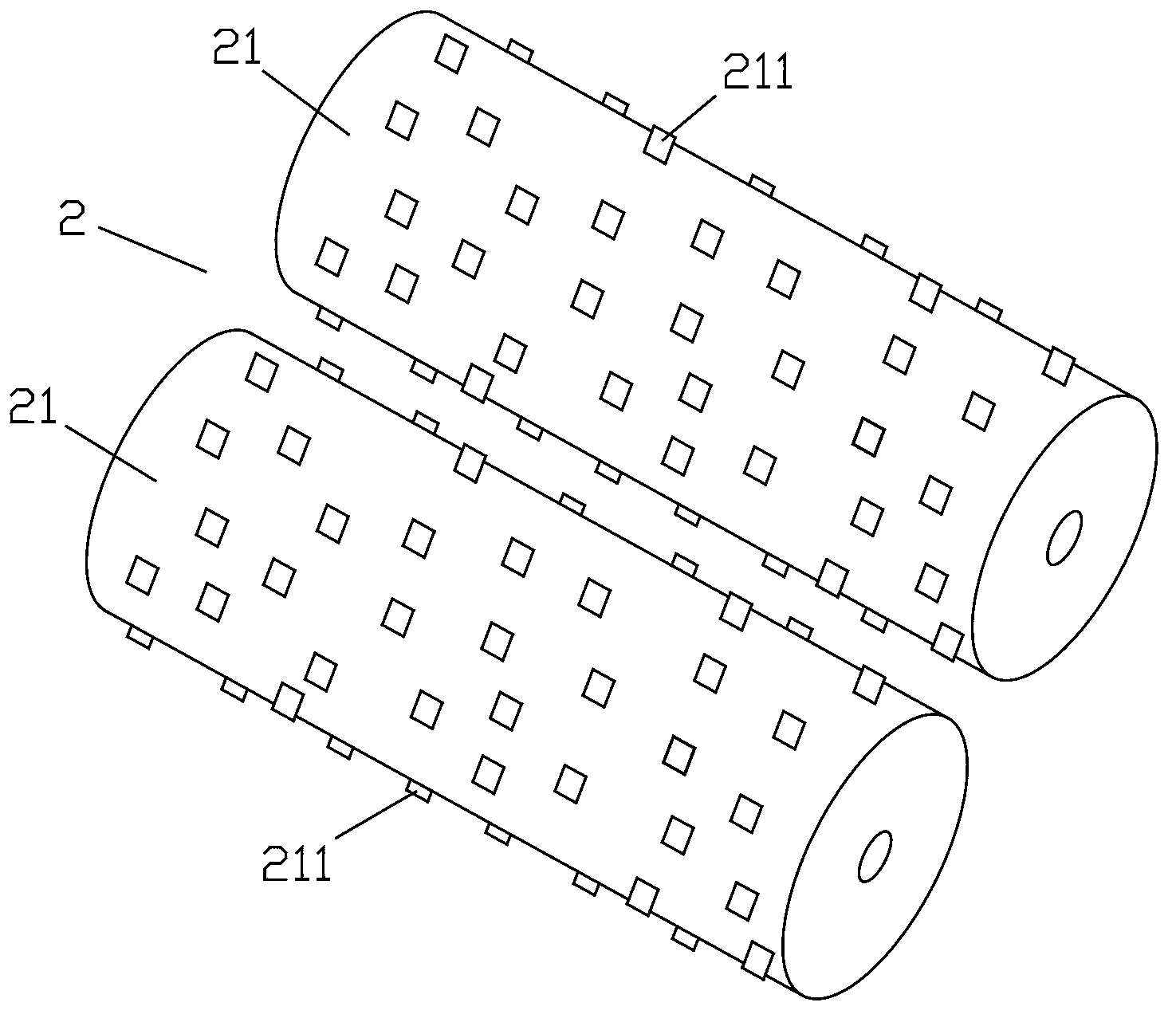

[0038] like figure 1 As shown, a diatomite crushing and drying device includes a storage bin 10, a conveyor belt 9, an air duct 7, a crusher 1, a roller machine 2, a furnace hall 3, a primary vibrating screen 4, a turbo fan 8, Secondary vibrating screen 11, classification device 5 and dust collection storehouse 6. One end of the conveyor belt 9 is located below the storage bin 10, and the other end of the conveyor belt 9 is located above the crusher 1, so the diatomite raw material stored in the storage bin 10 can be conveniently transported to the crusher through the conveyor belt 9 1 above. The turbo blower 8 is arranged between the classification device 5 and the dust collection storehouse 6, and the two ends of the turbo blower 8 communicate with the lower end of the classification device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com