Simple construction method of screw pile

A construction method and threaded pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of small use range, difficult to achieve process requirements, many mechanical equipment failures, etc., and achieve low drilling and lifting resistance. The effect of simple and easy equipment transformation and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

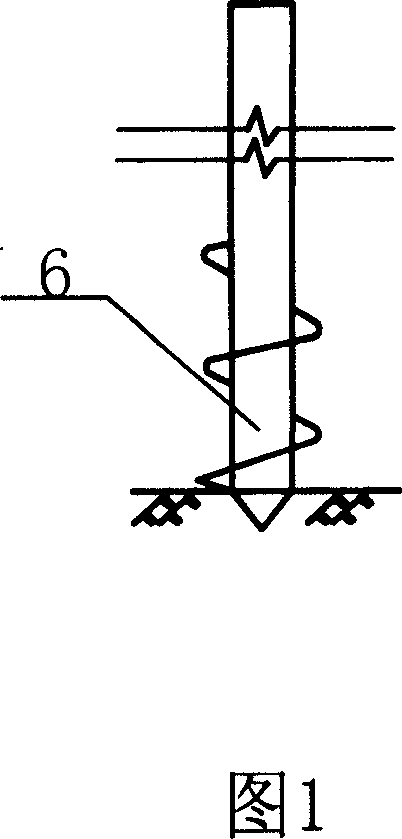

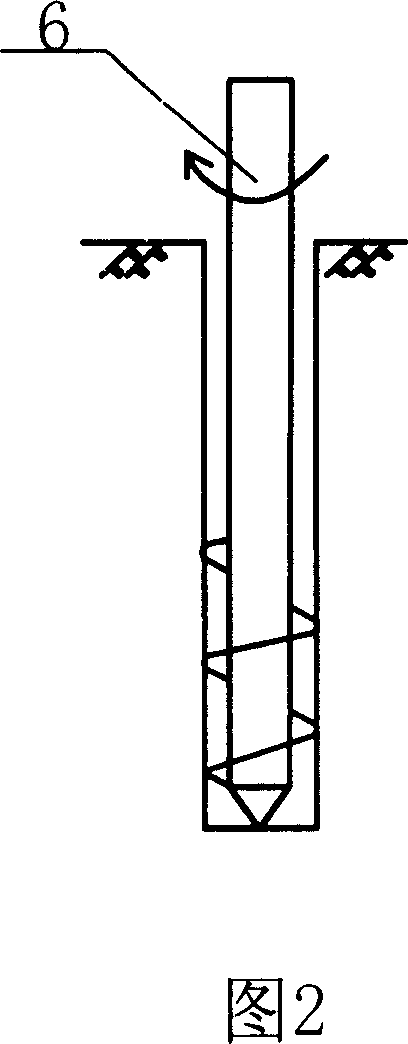

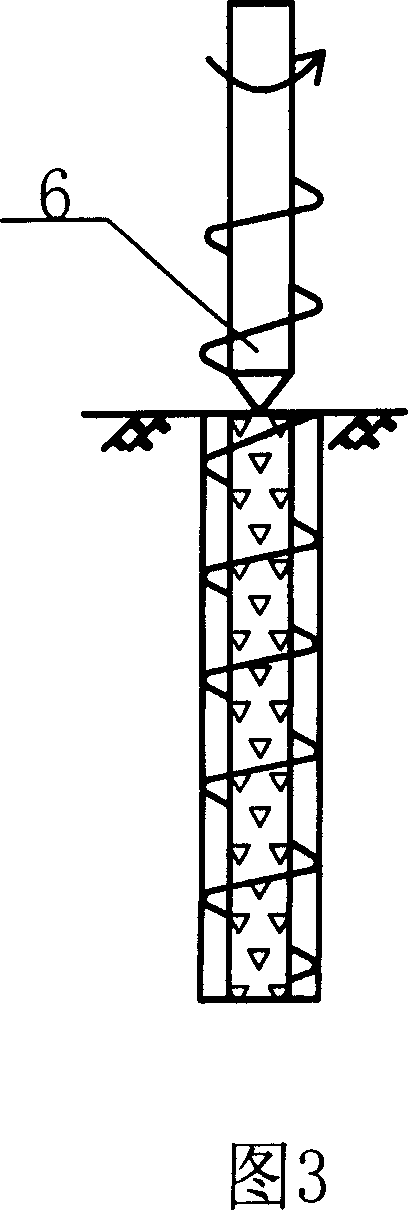

Embodiment 1

[0018] A simple construction method for threaded piles, using the existing auger drilling machine frame, equipped with an electric turntable power head, a non-threaded drill pipe, a threaded drill bit, a hoist wire rope pressurizing device, and a hoist wire rope pressurizing device during drilling to pull the upper end of the drill pipe Drive the threaded drill bit at the lower end of the drill pipe to drill in the forward direction. After drilling to the design depth, reverse the lifting pressure to pour the concrete to the design elevation and place the steel cage to form a pile. When the length and diameter of the threaded pile change, replace the non-threaded drill pipe and the different diameter. The drill bit can meet the construction requirements.

Embodiment 2

[0020] In the simple construction method of threaded piles described in Example 1, when the present invention is pouring concrete with reverse lifting pressure, the wire rope pressurizing device of the hoist should be in the state of free release of the rope, regardless of the matching problem between the drilling and the lifting trajectory, the thread pitch Determined according to lifting speed and rotation speed.

Embodiment 3

[0022] In the simple construction method of threaded piles described in Embodiment 1 or 2, the electric turntable power head used can move on the stalk according to the construction needs, and the threaded drill bit used is not less than two pitches or more, and the cross-section is larger than that of the non-threaded pile. Drill pipe to reduce drag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com