Novel prefabricated threaded tubular pile and construction method thereof

A construction method, threaded pipe technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of small bearing capacity of foundation piles, low friction, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

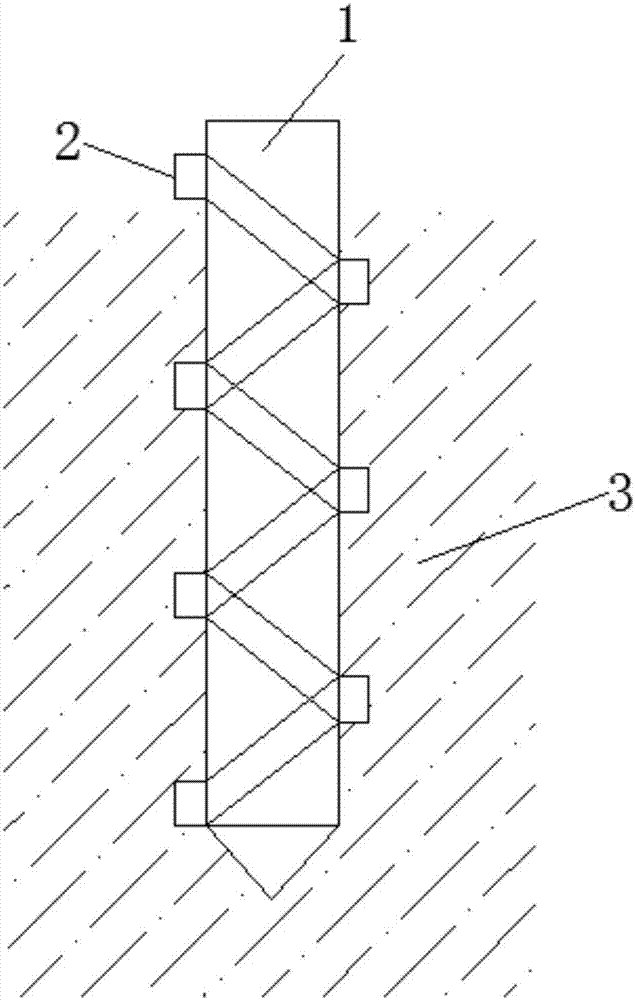

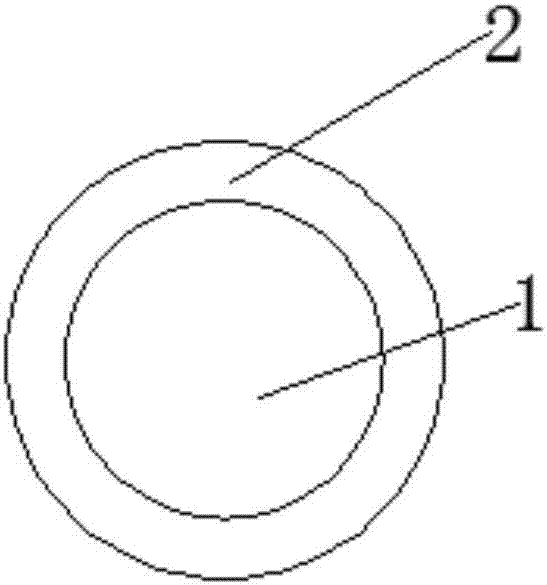

[0022] A new type of prefabricated threaded pipe pile, including a pipe pile body 1 and a thread 2 prefabricated outside the pipe pile body. The thread 2 is a clockwise rotating thread. The width of the thread 2 is 15cm, the thickness is 4cm, and the thread distance is 40cm. The included angle is 25°.

[0023] The pipe pile body 1 adopts ordinary concrete.

[0024] Steel bars are arranged in the pipe pile body 1, and the cross section of the pipe pile is hollow.

[0025] The length of each pipe pile is 14m.

[0026] A new construction method for prefabricated threaded pipe piles, comprising the following steps: (1) prefabricating threaded pipe piles in a factory, and transporting them to the construction site in sections; The pile body is fixed by wrapping method, and it is screwed clockwise into the rock and soil body 3; (3) The welding method is adopted between the lower section pile and the upper section pile, and the welding edge piece is set to ensure 360° full-section ...

Embodiment 2

[0028] A new type of prefabricated threaded pipe pile, including a pipe pile body 1 and a thread 2 prefabricated on the outside of the pipe pile body. The thread 2 is a clockwise rotating thread. The included angle is 10°.

[0029] The pipe pile body 1 is made of high-strength concrete.

[0030] Steel bars are arranged in the pipe pile body 1, and the cross section of the pipe pile is solid.

[0031] The length of each pipe pile is 8m.

[0032] A new construction method for prefabricated threaded pipe piles, comprising the following steps: (1) prefabricating threaded pipe piles in a factory, and transporting them to the construction site in sections; The pile body is fixed by wrapping method, and it is screwed clockwise into the rock and soil body 3; (3) The welding method is adopted between the lower section pile and the upper section pile, and the welding edge piece is set to ensure 360° full-section welding without dead angle; (4) After the piling is completed, the pile ...

Embodiment 3

[0034] A new type of prefabricated threaded pipe pile, including a pipe pile body 1 and a thread 2 prefabricated outside the pipe pile body. The thread 2 is a clockwise rotating thread. The width of the thread 2 is 30cm, the thickness is 6cm, and the thread spacing is 80cm. The included angle is 40°.

[0035] The pipe pile body 1 is made of prestressed concrete.

[0036] A steel wire is arranged in the pipe pile body 1, and the cross section of the pipe pile is hollow.

[0037] The length of each pipe pile is 2m.

[0038] A new construction method for prefabricated threaded pipe piles, comprising the following steps: (1) prefabricating threaded pipe piles in a factory, and transporting them to the construction site in sections; The pile body is fixed by wrapping method, and it is screwed clockwise into the rock and soil body 3; (3) The welding method is adopted between the lower section pile and the upper section pile, and the welding edge piece is set to ensure 360° full-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com