Bionic drilling method and drill rod for resistance reduction and heat dissipation of soft coal petrography

A bionic drilling technology for soft coal rocks, applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as low drilling efficiency, many drilling accidents, shallow drilling depth, etc., to improve drilling Efficiency, increasing drilling depth and reducing drilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

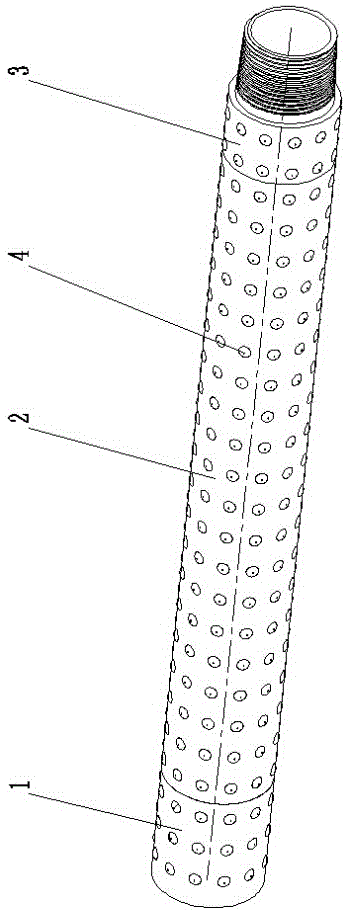

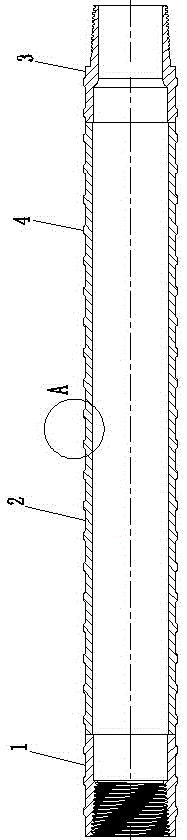

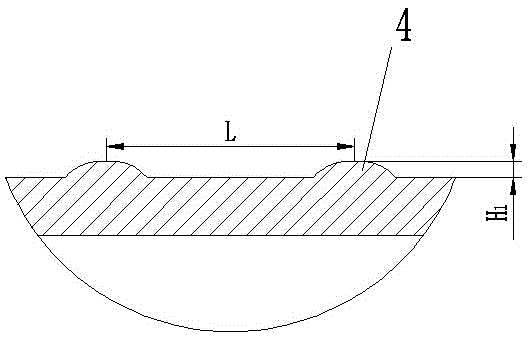

[0032] like Figure 1 ~ Figure 3 As shown, the bionic drilling method for resistance reduction and heat dissipation in soft coal rocks is used to evaluate the drilling shrinkage ratio according to the geological conditions of the coal seam d c And determine the outer diameter of the drill pipe rotation d 1 , Drill pipe surface raised height H 1 , the distance L between the convex shapes on the surface of the drill pipe and the drilling speed, use the bionic drill pipe for reducing resistance and heat dissipation to drill holes, and realize low-resistance and low-temperature integrated drilling, which specifically includes the following steps:

[0033] ①. Take coal or rock samples at the site to be constructed, and evaluate the drilling shrinkage ratio through laboratory tests and theoretical calculations d c (drilling shrinkage ratio d c is the maximum displacement of the borehole wall deformation u p and the ratio of the radius r when the borehole is not contracted);...

Embodiment 2

[0042] Embodiment two: if Figure 4 ~ Figure 6 As shown, the difference from the first embodiment is that the bionic structure on the surface of the bionic drill pipe for reducing resistance and heat dissipation is a square protrusion 5 .

Embodiment 3

[0043] Embodiment three: as Figure 7 ~ Figure 9 As shown, the difference from Embodiment 1 and Example 2 is that the arc-shaped grooves 6 on the surface of the drill pipe in Embodiment 3, the distance L between the arc-shaped grooves 6 is set within the range of 10 mm to 80 mm, and the arc-shaped grooves 6 depth H 2 Set it within the range of 0mm to 5mm. When the drilling shrinkage ratio is 0≤ d c When ≤50%, the surface groove depth H of the drill pipe 2 Set it within the range of 0mm to 3mm; when the drilling shrinkage ratio d c When >50%, the arc-shaped groove 6 depth H on the surface of the drill pipe 2 Set it within the range of 3mm to 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com