Patents

Literature

102results about How to "Increase the encounter rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

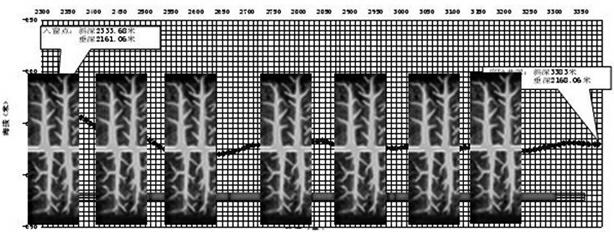

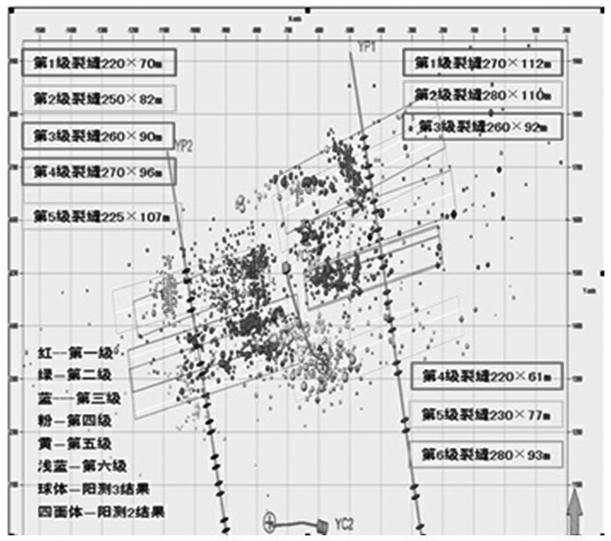

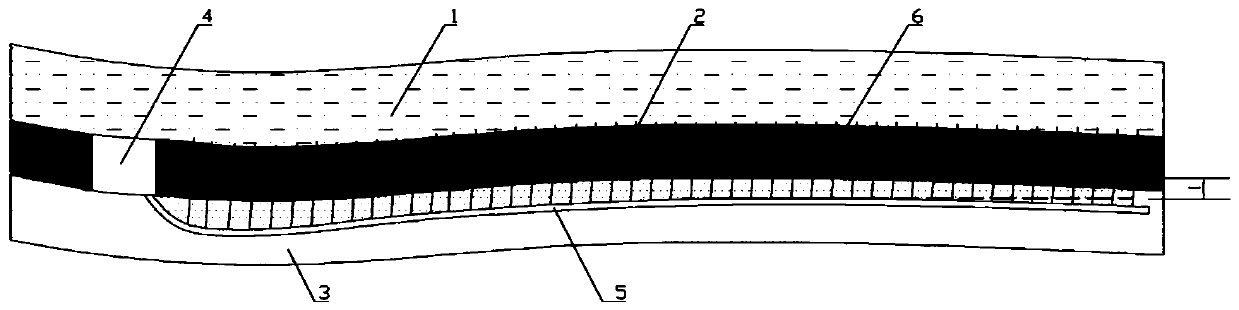

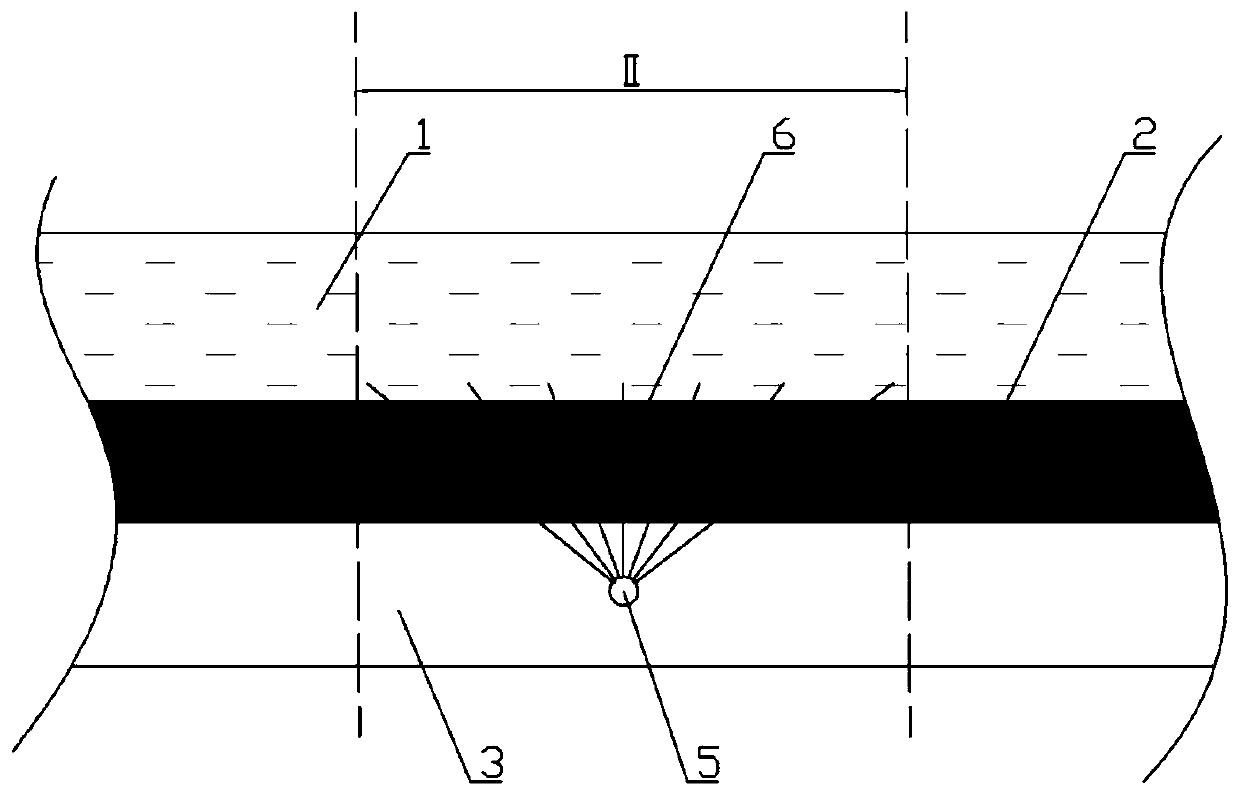

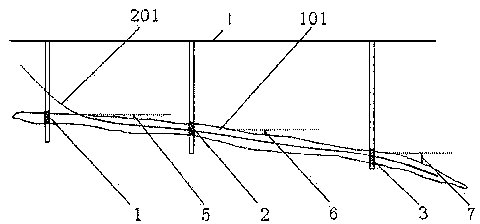

Sectioned multi-cluster synchronous volume fracturing technology for double horizontal wells

ActiveCN102606124AThe average air penetration rate is smallGood oilinessFluid removalMulti clusterHorizontal wells

The invention belongs to the field of oil and gas field exploration, discloses novel technology for volume fracturing of a compact oil reservoir, and particularly relates to a sectioned multi-cluster synchronous volume fracturing technology for double horizontal wells. The technology is characterized by including the steps of synchronous fracturing selection, synchronous fracturing well selection, multi-section and multi-cluster perforation position determination, synchronous fracturing construction and synchronous fracturing effect evaluation. In the technology, cracks are impelled to turn by means of interference among the cracks, thereby realizing complicated netted cracks and effectively modifying the compact oil reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

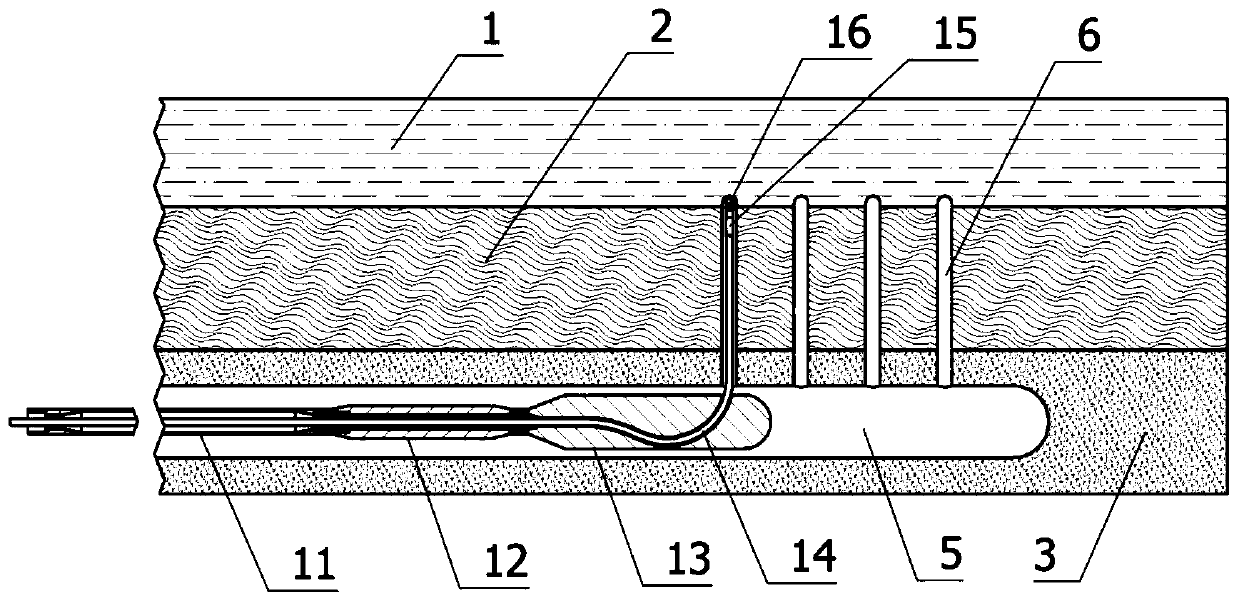

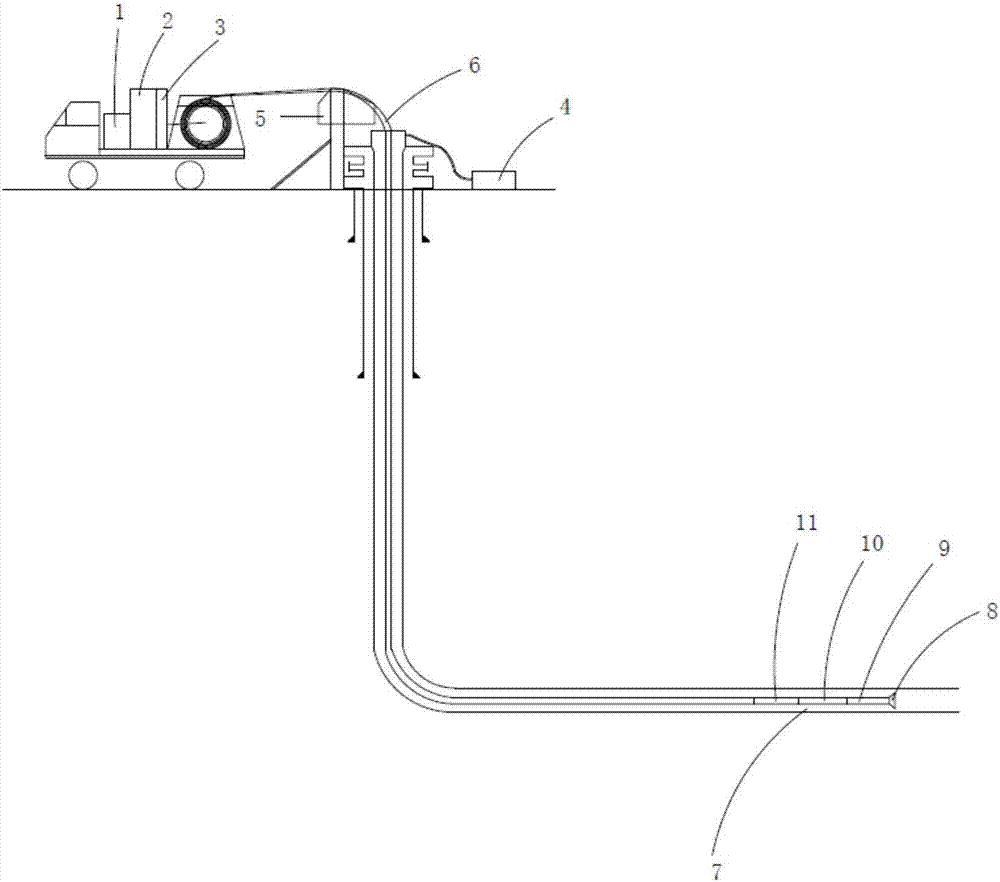

Method for gas extraction through bedding directional long drill hole traversing working face in broken and soft coal seam

InactiveCN107740677AIncreased drilling depthImprove coal seam encounter rateFluid removalDirectional drillingDrill holeSoft Coals

The invention relates to a method for gas extraction through a bedding directional long drill hole traversing working face in a broken and soft coal seam. According to the method, through an air screwmotor directional drilling technology, the bedding gas extraction long drill hole is constructed in a tunneled roadway on one side of the working face of the coal seam, and the drill holes penetratesthrough a to-be-tunneled roadway on the other side of the working face to the position, within the control range of 15-20 m, of the outer side of the roadway; and after the drill hole is completed, adrill tool is lifted up, an open-close type guiding drill bit and a drill rod with a large through hole are put down, then a hole protection screen pipe is put down through the center of the drill rod, then the drill rod is lifted up, the screen pipe stays in the hole, and then a gas extraction pipeline is connected for gas pre-extraction. An air screw motor directional drilling method is adoptedin the gas treatment technology so that the drilling depth of bedding extraction of the broken and soft coal seam and the coal seam drilling-encounter rate can be greatly increased, invalid footagesare reduced in quantity, meanwhile the drill hole coverage range is ensured, the purpose of gas pre-extraction outburst elimination of the stope face and the to-be-tunneled roadway is achieved, and safe tunneling of the coal seam roadway and safe extraction of coal extraction work face are ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP +1

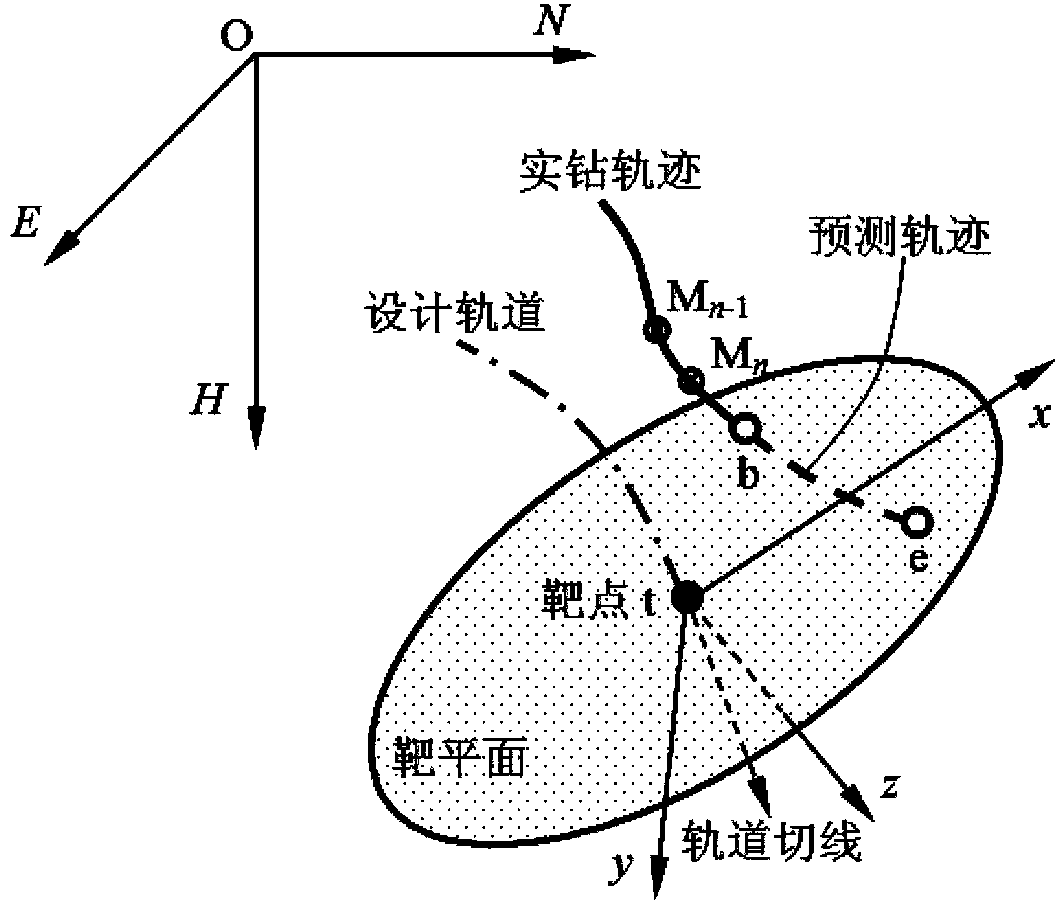

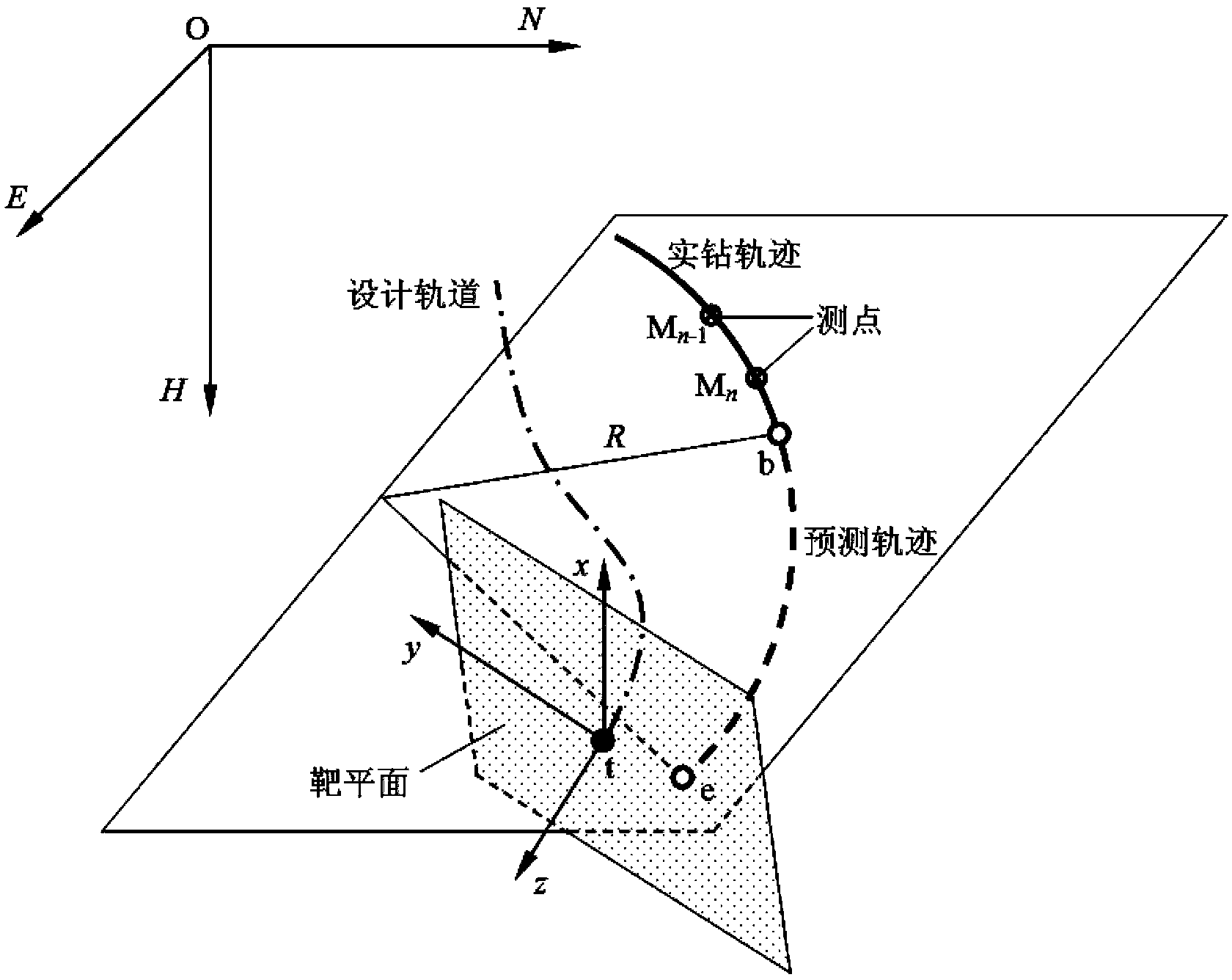

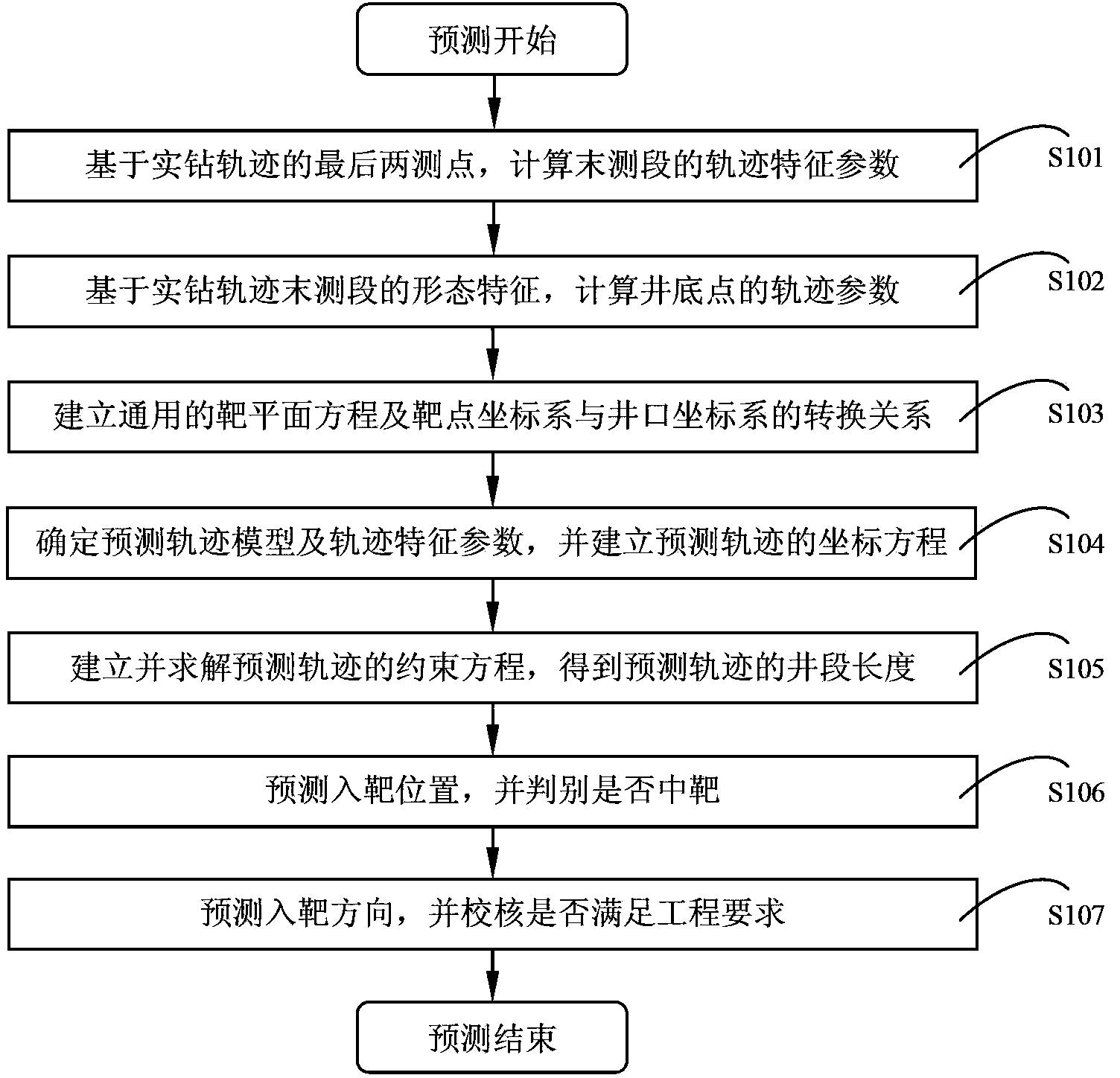

Universal method for forecasting in-target situation of guide drilling

ActiveCN103883312AIncrease the encounter rateIncrease success rateSurveyDirectional wellHorizontal wells

The invention discloses a universal method for forecasting in-target situation of guide drilling. The universal method includes: on the basis of survey data of last two survey points of a real drilling trajectory, calculating trajectory characteristic parameters of unsurveyed sections; calculating trajectory parameters of a well bottom point on the basis of the trajectory characteristic parameters of the unsurveyed sections of the real drilling trajectory; establishing coordinate transformation relations between a general target plane equation as well as a target coordinate system and a wellhead coordinate system; according to a landing-controlled anticipating guide drilling technology, determining a borehole trajectory model and the trajectory characteristic parameters of a forecasting trajectory and establishing a coordinate equation of the forecasting trajectory; establishing and calculating a constraint equation of the forecasting trajectory to acquire well section length of the forecasting trajectory; calculating the in-target location and judging whether a target is in place or not and forecasting the in-target direction. By the universal method, the target-in location and the target-in direction can be forecast, and the universal method is applicable to different well types like directional wells and horizontal wells even to special formed target sections and various drilling modes like sliding guide drilling, rotating guide drilling and composite guide drilling.

Owner:CHINA PETROLEUM & CHEM CORP +1

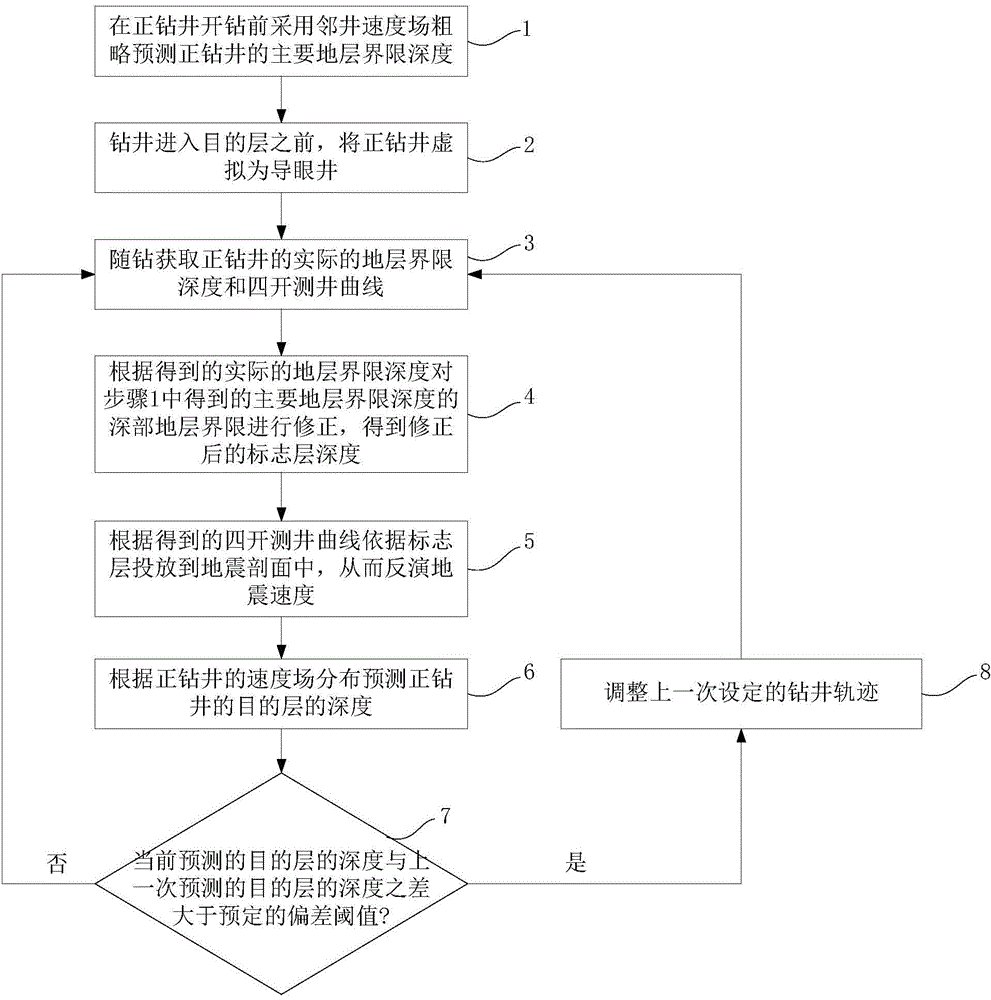

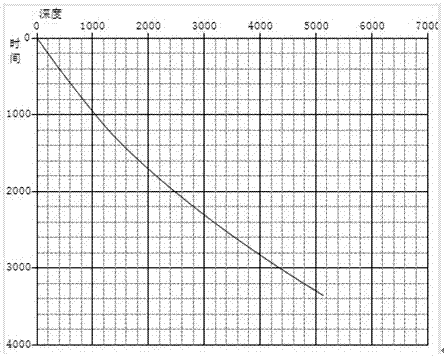

Deep horizontal well drilling track regulating method

ActiveCN104975808ARemarkable resultsGood economic and social benefitsSurveyDirectional drillingSection planeEnvironmental geology

The invention discloses a deep horizontal well drilling track regulating method, which comprises the following steps of: before the drilling of a drilling well, using an adjacent well speed field for predicting the main formation limit depth of the drilling well; before the drilling to a target layer, virtualizing the drilling well into a pilot well; obtaining the actual formation limit depth of the drilling well and a quarto well logging curve while drilling; correcting the deep formation limit at the main formation depth obtained before the drilling according to the obtained actual formation limit depth, and obtaining a corrected marking layer depth; performing the putting into a seismic profile according to the obtained quarto well logging curve in accordance with the marking layer so as to reverse the speed field of the drilling well; predicting the depth of the target layer of the drilling well according to the speed field of the drilling well; and regulating the drilling track set in the last time if the difference of the current predicted depth of the target layer and the depth of the target layer predicted in the last time is greater than the preset deviation threshold. The method has the advantages that the Yuanba horizontal well track optimization and regulation are effectively guided, and the effective reservoir drilling ratio is improved.

Owner:CHINA PETROCHEMICAL CORP +4

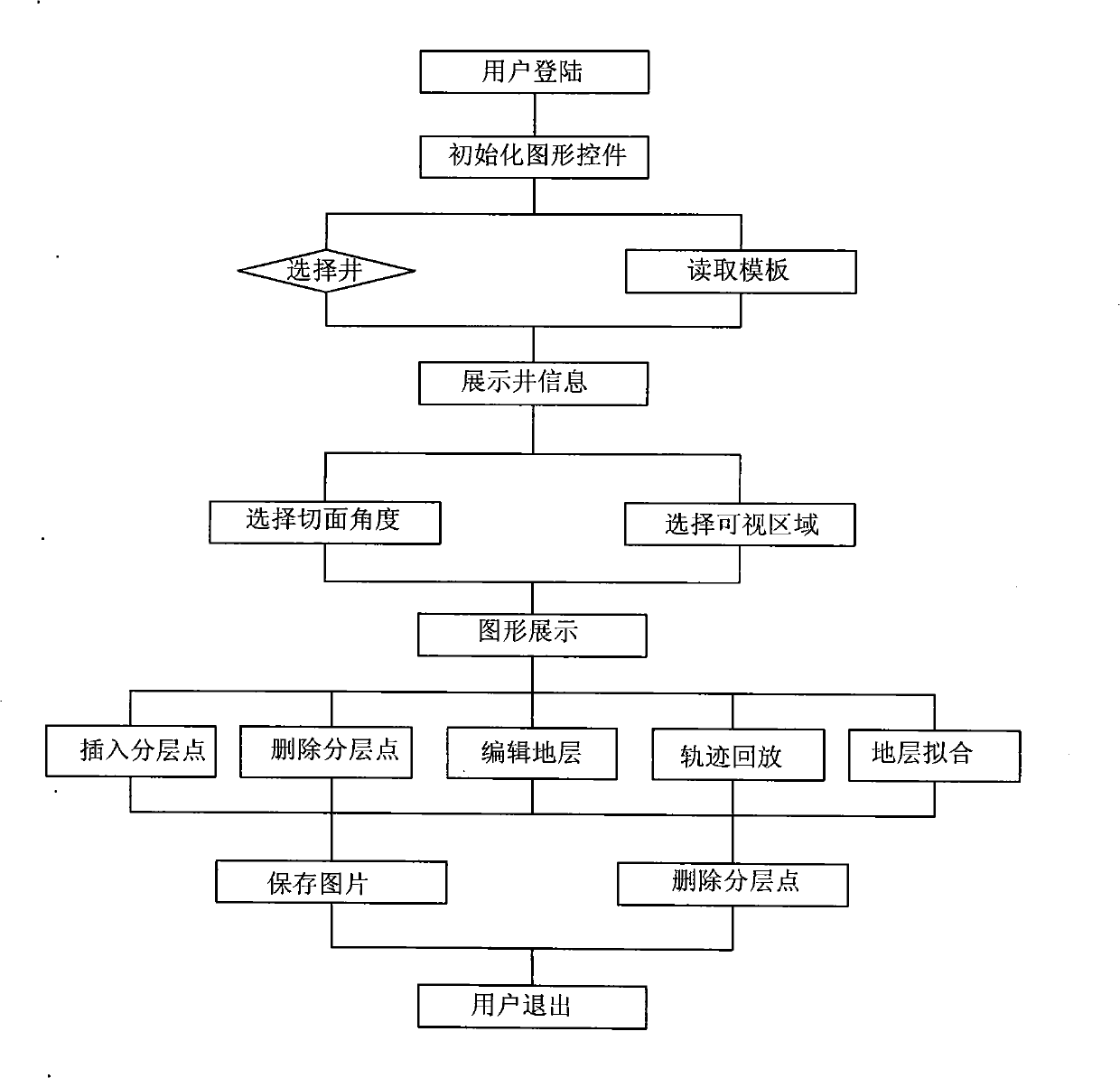

Remote real-time tracking method for well path

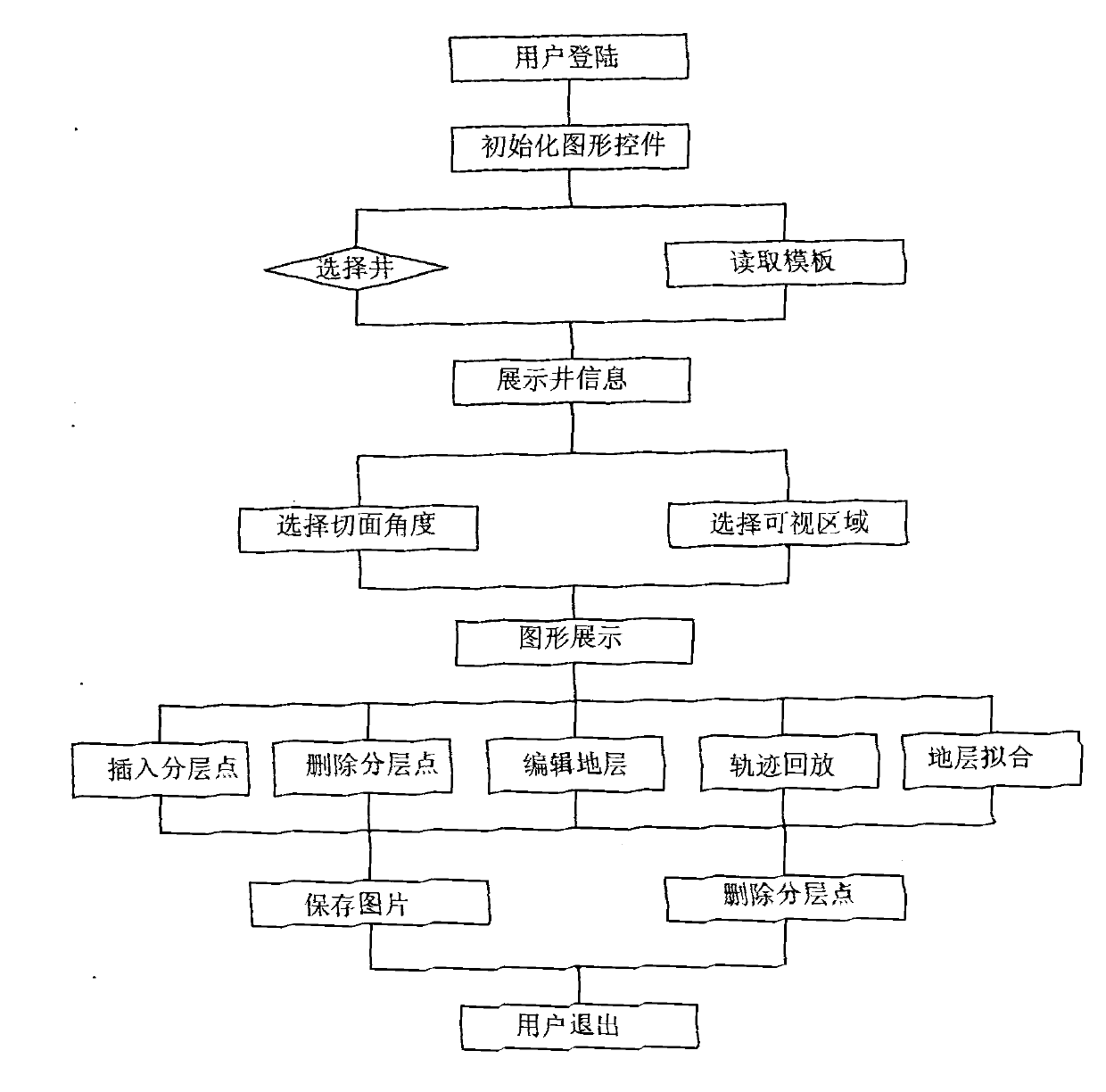

InactiveCN101949286AAchieve playbackDynamic display of downhole changesSurveyMathematical modelPetroleum

The invention discloses a remote real-time tracking method for a well path, which relates to the technical field of real-time tracking of a wellbore path of a petroleum drilling well. The method of the invention comprises the following steps: remotely transmitting the wellbore path (LWD / MWD) measured in real time on the field, real-time measured data when drilling, well top coordinate data, well deflection data, stratum data, lithological profile data and stratigraphic dip data to a base server, reading the data from a database of the base server, generating a real-time well deflection path tracking chart according to an established mathematical model, and issuing synchronously through Web. The invention excludes the influence of adverse factors of complex geologic structure, obscure stratigraphic dip, thin objective target reservoir and the like, can accurately shoot the target point according to design, and obviously improves the exploratory development effect of a horizontal well.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

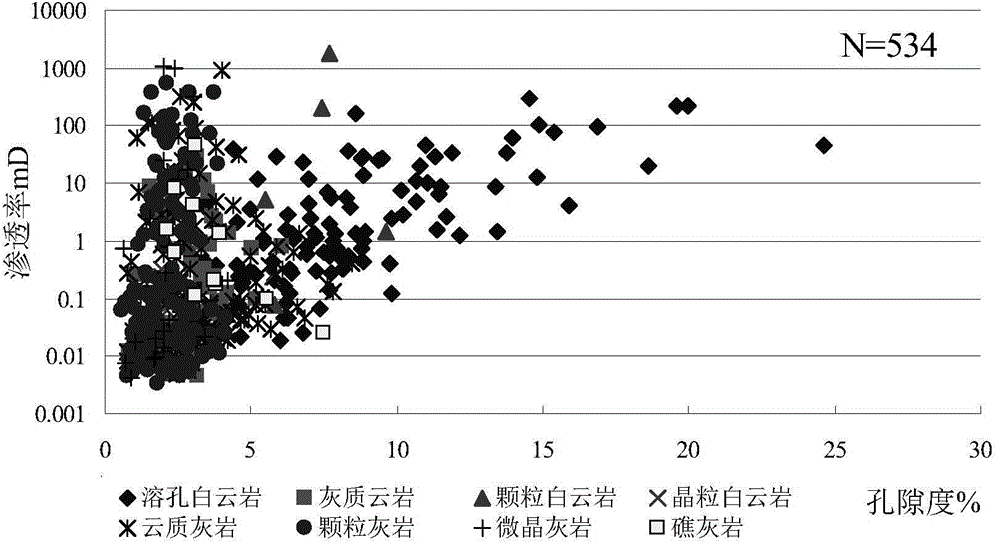

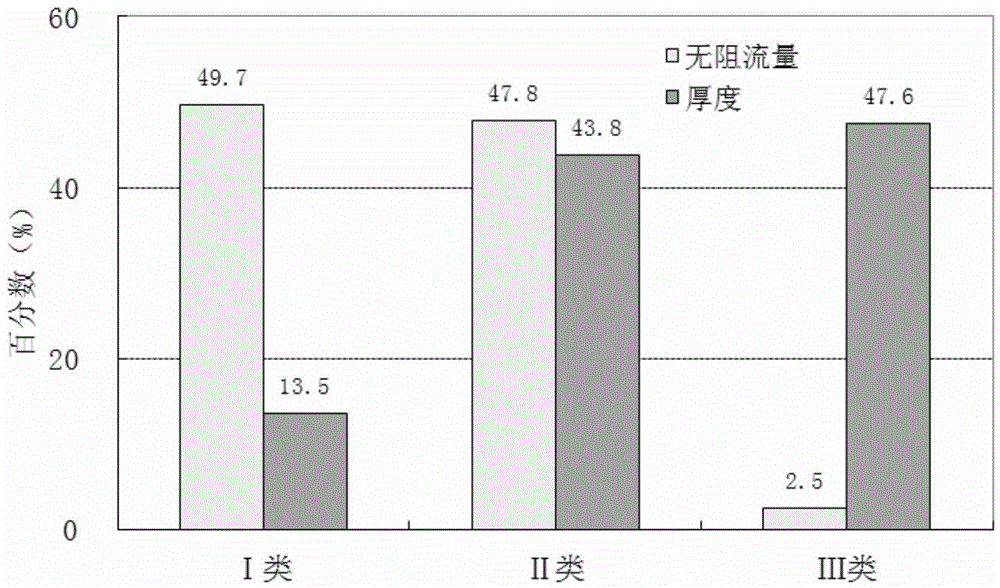

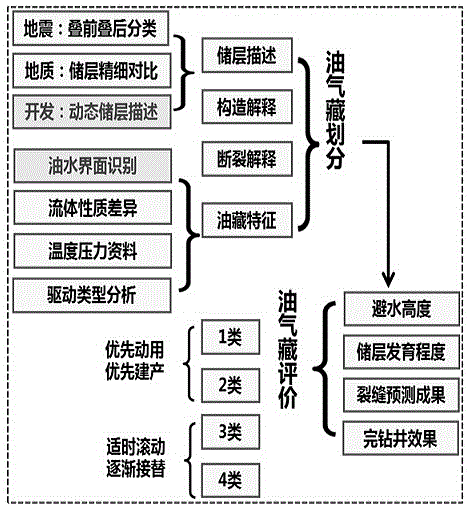

Method for judging carbonatite hole crack growth characteristics

The invention discloses a method for judging carbonatite hole crack growth characteristics. The method comprises the following steps: a) processing three-dimensional seismic data and performing breakage explanation and position tracking; b) utilizing seismic data to forecast effective reservoir thickness and effective reservoir porosity; c) analyzing reservoir lithology, reservoir space type, filled degree of hole crack reservoir and change rule of the filled degree of hole crack reservoir along longitudinal direction and horizontal direction; d) while confirming boundary, researching connectivity of reservoir along the longitudinal direction and horizontal direction, inter-well connectivity and oil-gas-water boundary; e) establishing regional oil and gas reservoir profile and unit oil and gas reservoir profile according to fault line, tectonic line, fluid line, pinch-out line and phase-change line, depicting, dividing a developing unit and drawing a developing unit and oil bearing area graph. According to the method provided by the invention, the drilling rate of the reservoir is increased, the leading comprehensive success rate of exploration and development drilling in China is achieved and single-well high yield and stable yield are achieved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

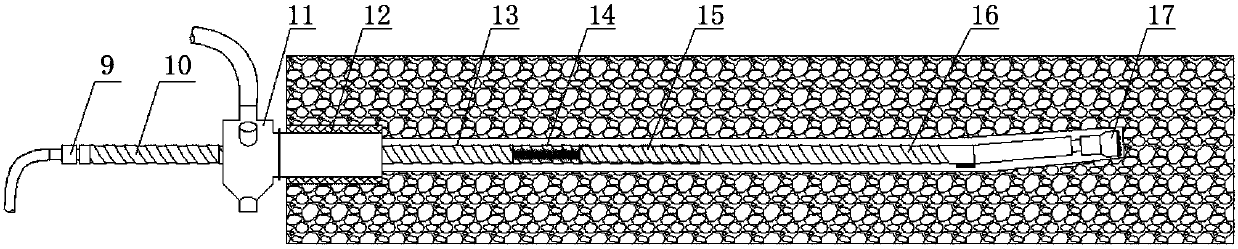

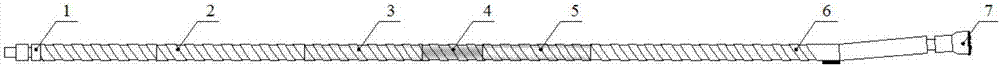

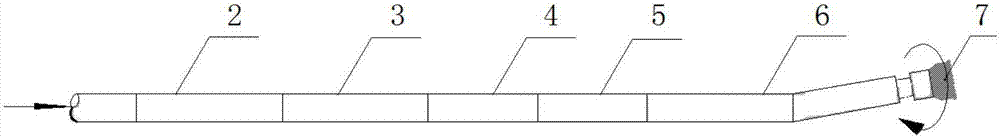

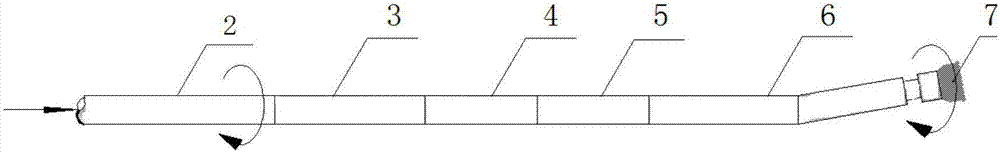

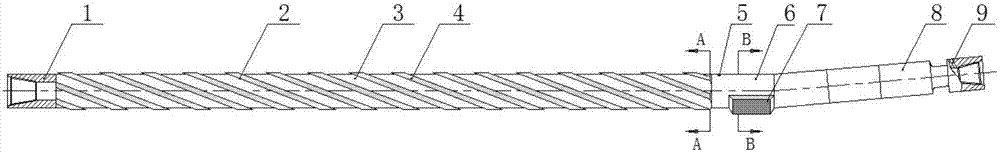

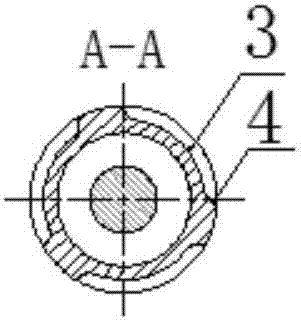

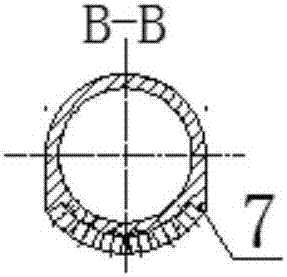

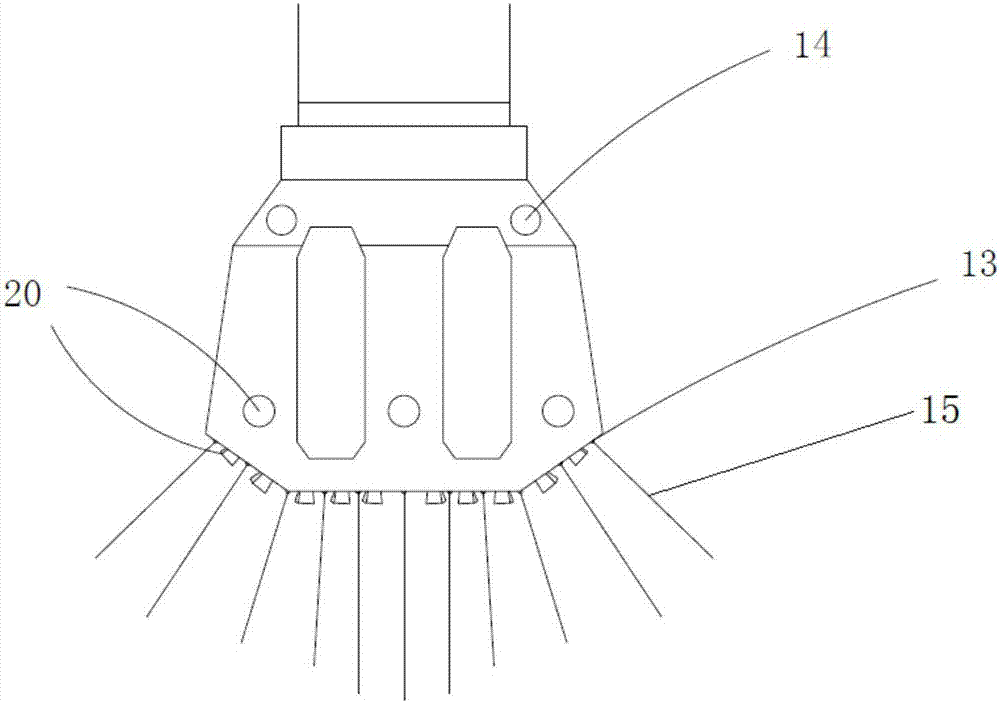

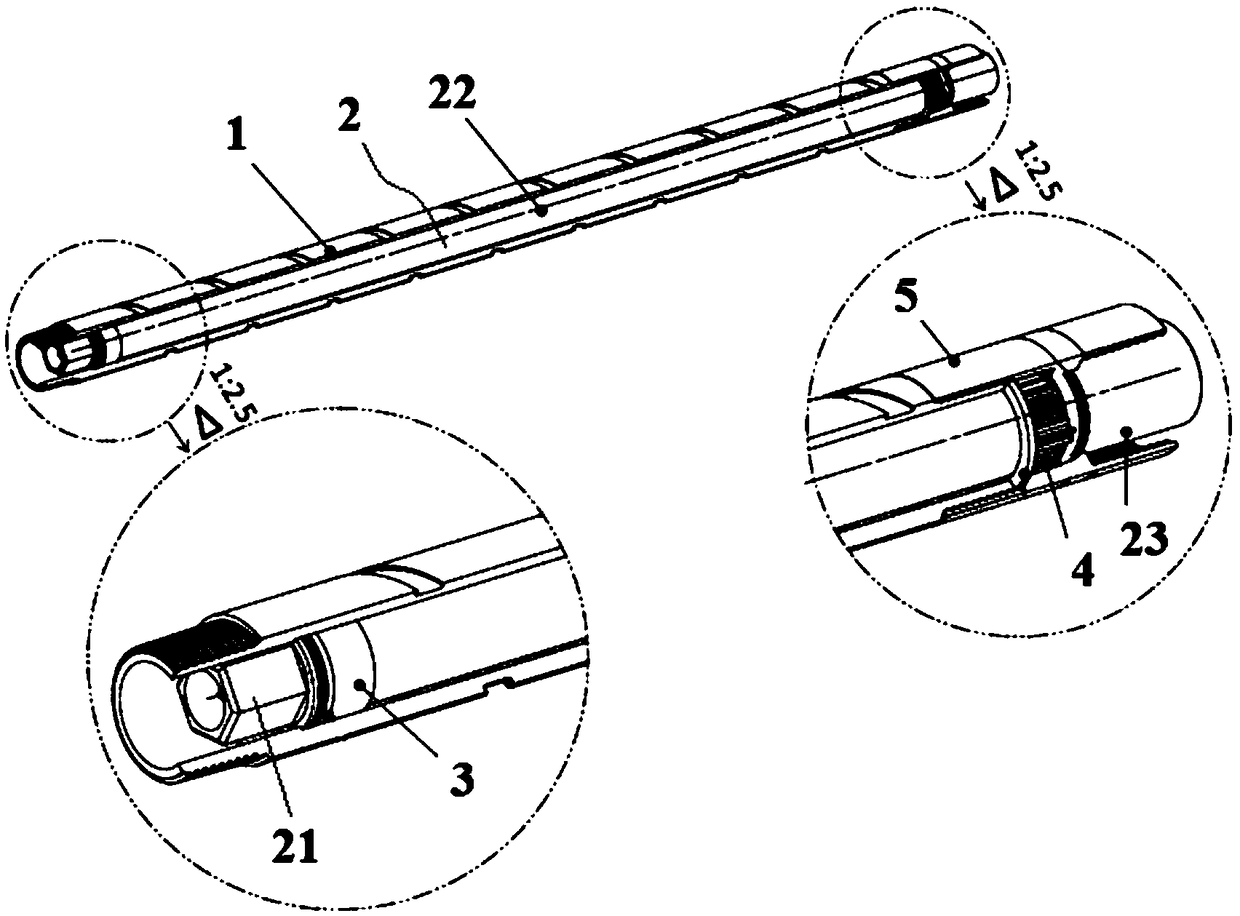

Drilling tool assembly used for directional hole-forming underground coal mine and provided with air screw motor and construction method

InactiveCN106869791AIncrease the encounter rateIncreased drilling depthDrilling rodsConstructionsMotor driveNon magnetic

Disclosed is a drilling tool assembly used for directional hole-forming underground a coal mine and provided with an air screw motor and construction method. The drilling tool assembly comprises a directional drill bit, the air screw motor, a lower non-magnetic drill rod, a wireless electromagnetic wave measurement while drilling short section, an upper non-magnetic drill rod, a middle drill rod and a blower which are connected in sequence. The drilling tool assembly can carry out composite drilling and sliding directional drilling for construction: when composite drilling is conducted, the air screw motor drives the directional drill bit to crush rocks in rotatably, meanwhile, the middle drill rod rotates to drive the air screw motor to rotate, boring mud at the bottom of a hole is discharged from the bottom of the hole by compressed air along an annular gap, and the middle drill rod can be used for auxiliary slagging; and when sliding directional drilling is conducted, the middle drill rod does not rotate, the directional drill bit is driven by the air screw motor driven by the compressed air to rotate to crush rocks, and the track of the hole is controlled by changing the elbow orientation of the air screw motor. Thus, according to the drilling tool assembly used for directional hole-forming underground the coal mine and provided with the air screw motor and construction method, the drilling depth of a soft coal seam and the coal seam drilling-encounter rate can be improved greatly, and the drilling gas extraction effect is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

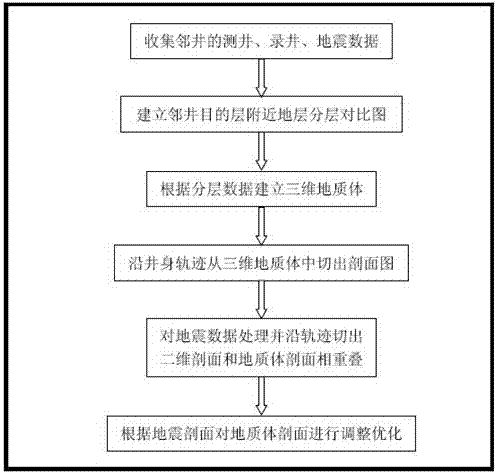

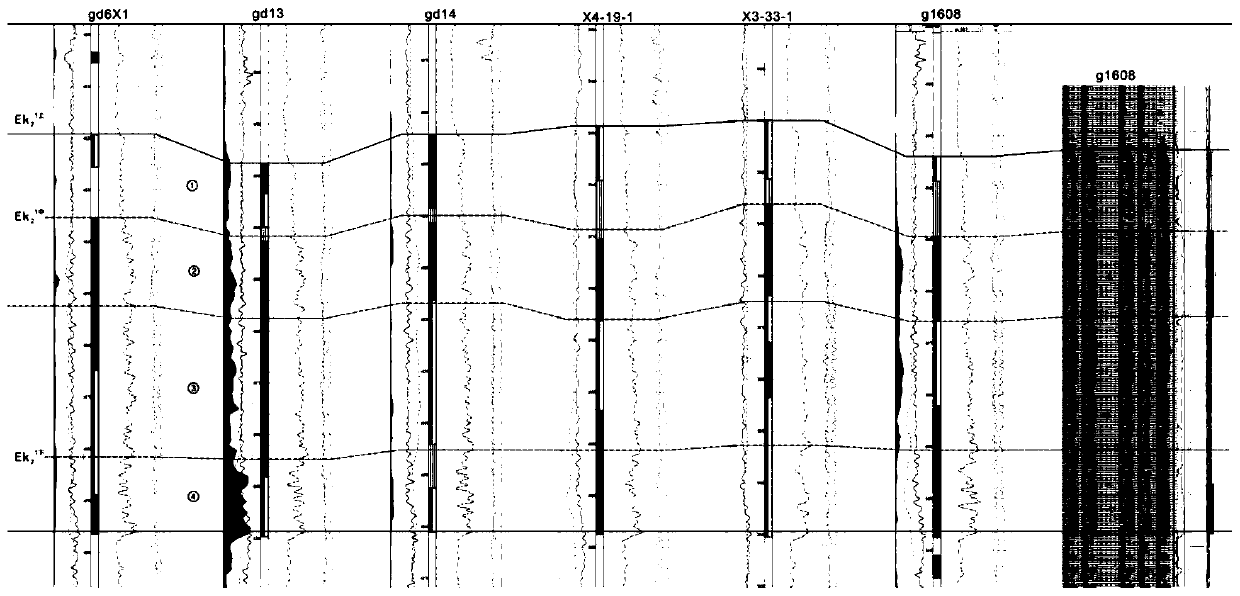

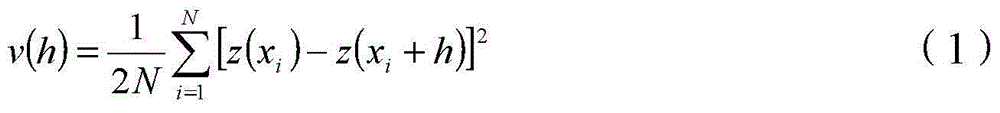

Well-to-seismic integration based horizontal well geosteering modeling method

ActiveCN108008469AImprove target rateRaise dynamic awarenessGeomodellingSeismic signal processingGeomorphologyAfter treatment

The invention provides a well-to-seismic integration based horizontal well geosteering modeling method. The method includes a step 1 of collecting adjoining well data and three-dimensional seismic data in a small range of a working zone; a step 2 of performing stratum comparison according to the collected working zone adjoining well data and dividing into small layers; a step 3 of establishing a working zone three-dimensional digital geologic body by utilizing a common Kriging interpolation method according to the adjoining well layering data; a step 4 of cutting a two-dimensional profile mapfrom the three-dimensional geologic body along a well body track; a step 5 of cutting a two-dimensional profile along the well body track after treatment of three-dimensional seismic data by utilizinga time-depth relation in the working zone and performing overlapping display on the two-dimensional profile and the stratum model cut from the three-dimensional geologic body; a step 6 of adjusting the stratum body according to a form of an event of the seismic section so as to enable the stratum model form to fit the form of the seismic event. By adopting the method provided by the invention, the construction description precision and the reservoir predication accuracy are improved and a sound technique guarantee is provided for horizontal well geosteering.

Owner:CHINA PETROLEUM & CHEM CORP +4

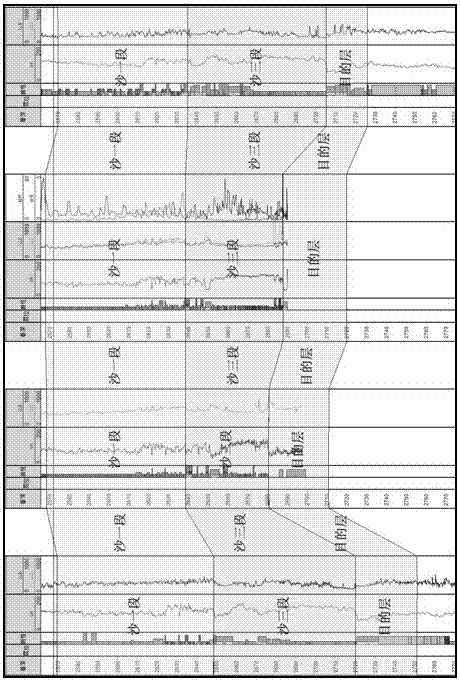

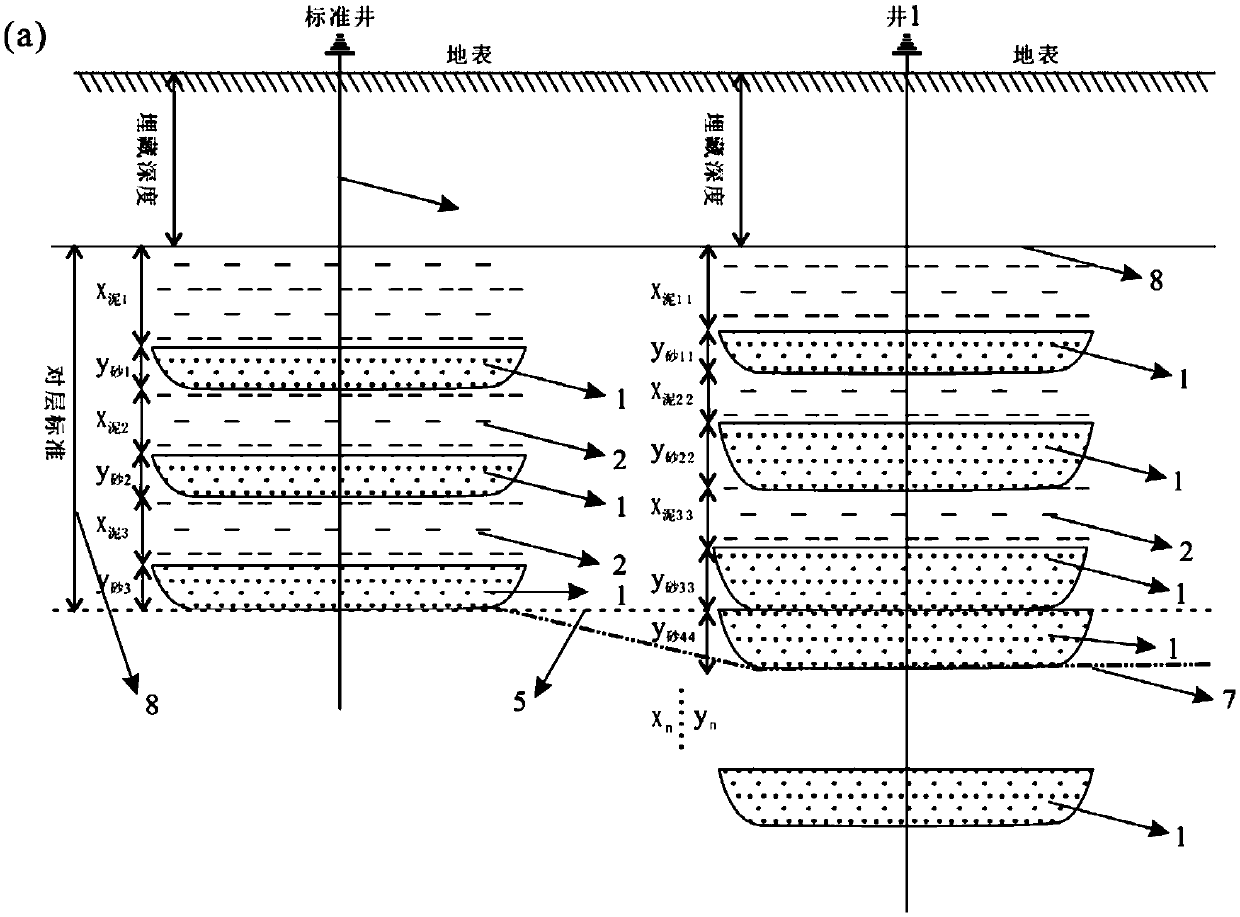

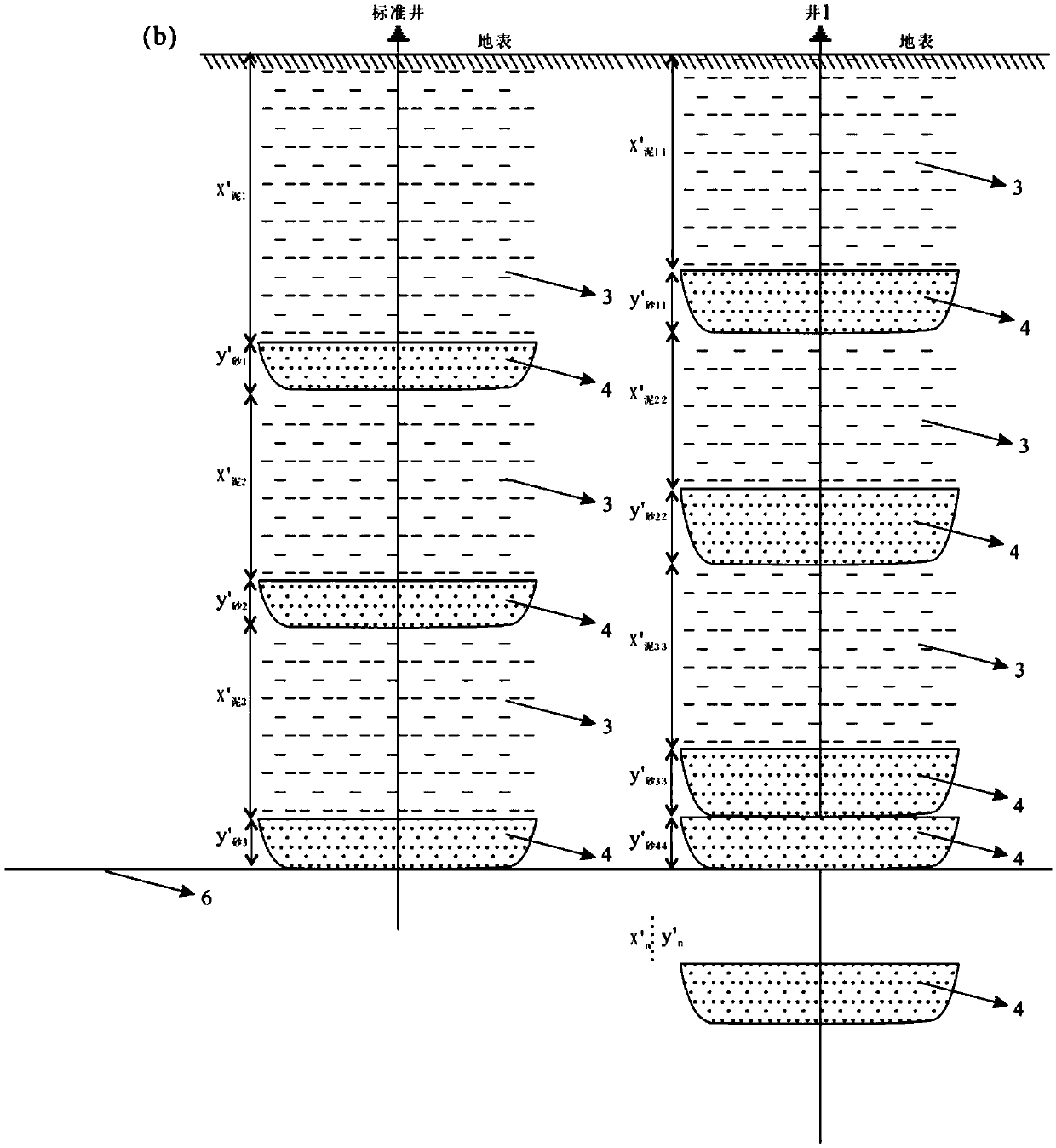

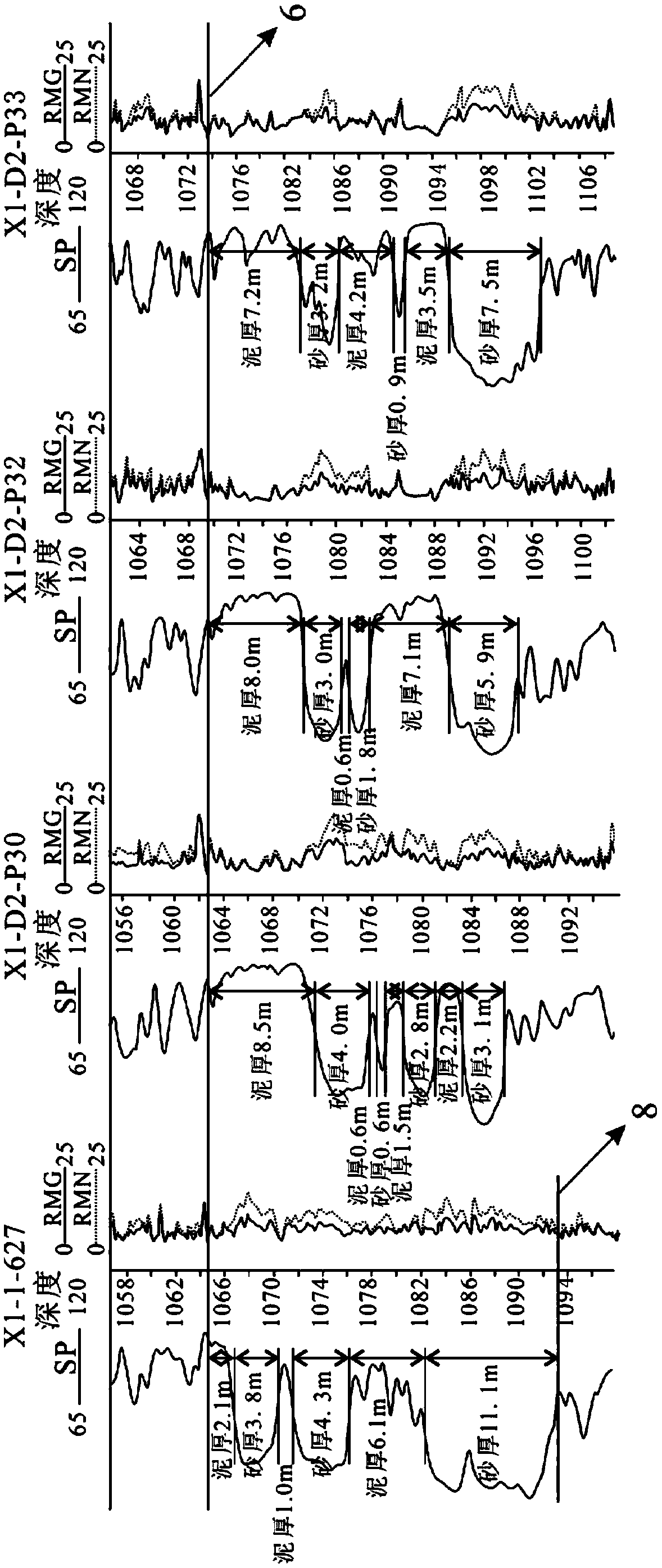

Compaction-correction-based isochronous stratigraphic interface tracking and contrasting method

ActiveCN105370269AThe recognition effect is accurateAccurate comparisonBorehole/well accessoriesWell placementComputer science

The invention provides a compaction-correction-based isochronous stratigraphic interface tracking and contrasting method. The compaction-correction-based isochronous stratigraphic interface tracking and contrasting method comprises the following steps: step one, selecting a well with a clear mark layer and a clear research layer section as a standard well, taking the well as reference well for building a connecting-well section, and then flatly drawing the tops of the mark layers of the standard well and the well to be researched to build an isochronous standard reference surface; step two, estimating the ancient restoration thickness of destination bedded sandstone and mudstone; and step three, determining the isochronous stratigraphic interface of the well position to be layered according to the isochronous standard reference surface determined in the step one and the ancient restoration thickness of destination bedded sandstone and the mudstone estimated in the step two. Through the compaction-correction-based isochronous stratigraphic interface tracking and contrasting method, the practical restoration thickness of the sandstone and the mudstone can be judged through the differential compaction effect of the sandstone and the mudstone, so that the influence of the sandstone and the mudstone on the differential compaction effect can be eliminated; the accurate identification and contrast of the isochronous interface can be finally achieved.

Owner:北京福瑞宝能源科技有限公司

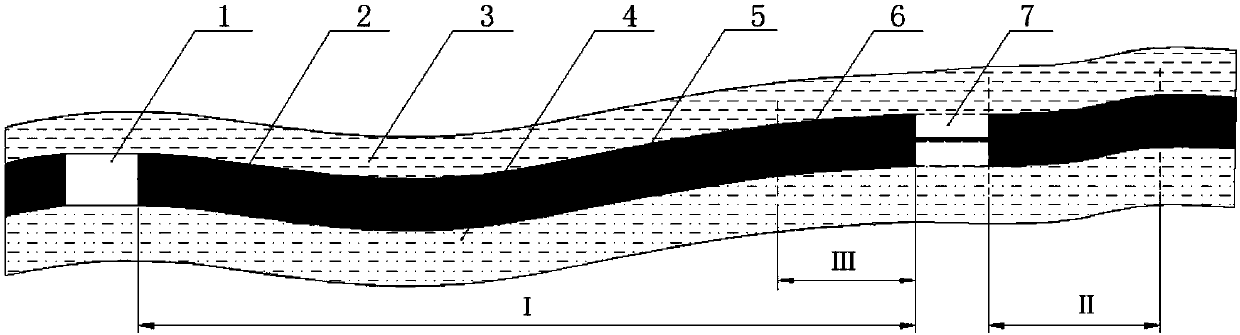

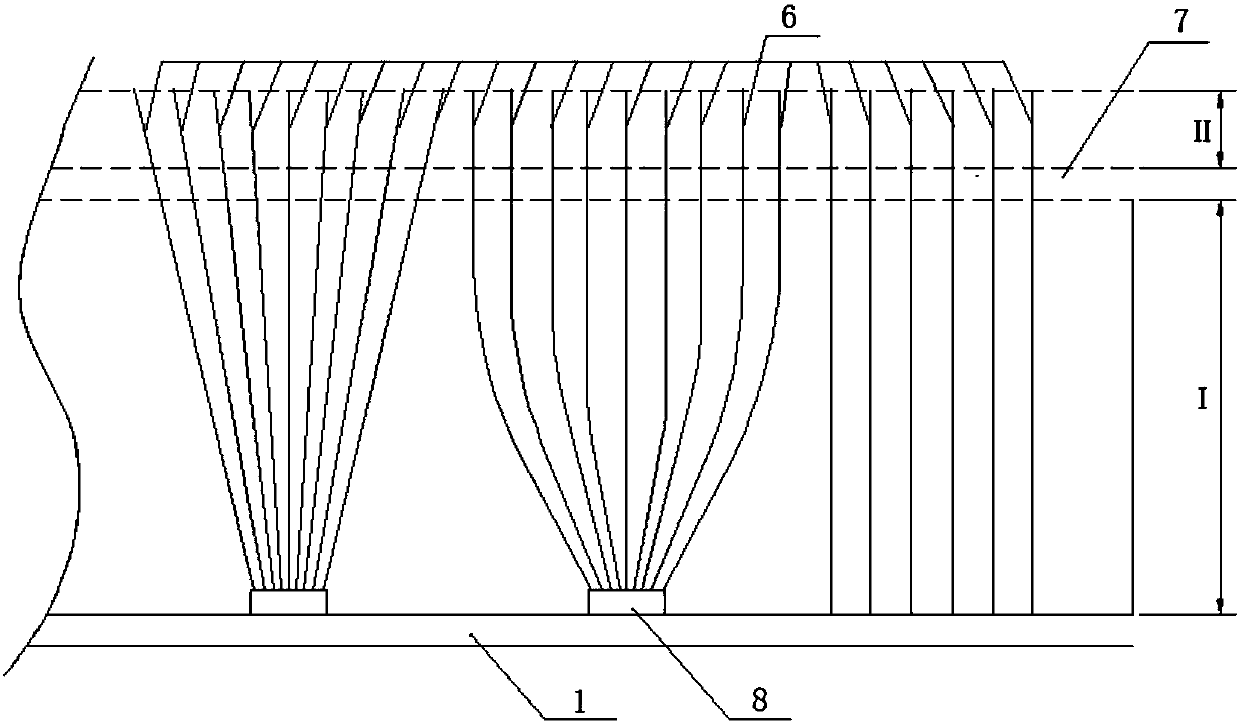

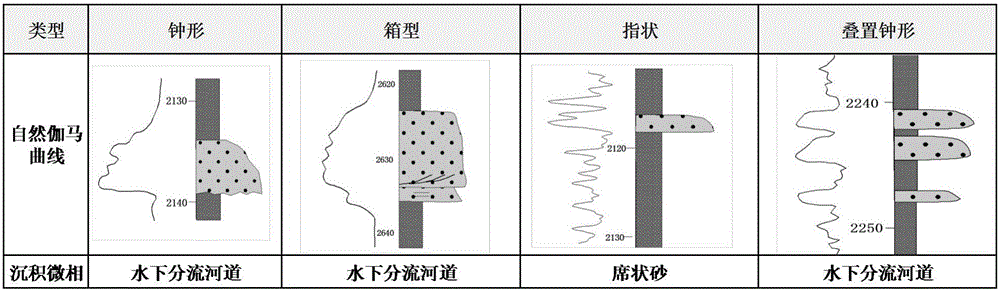

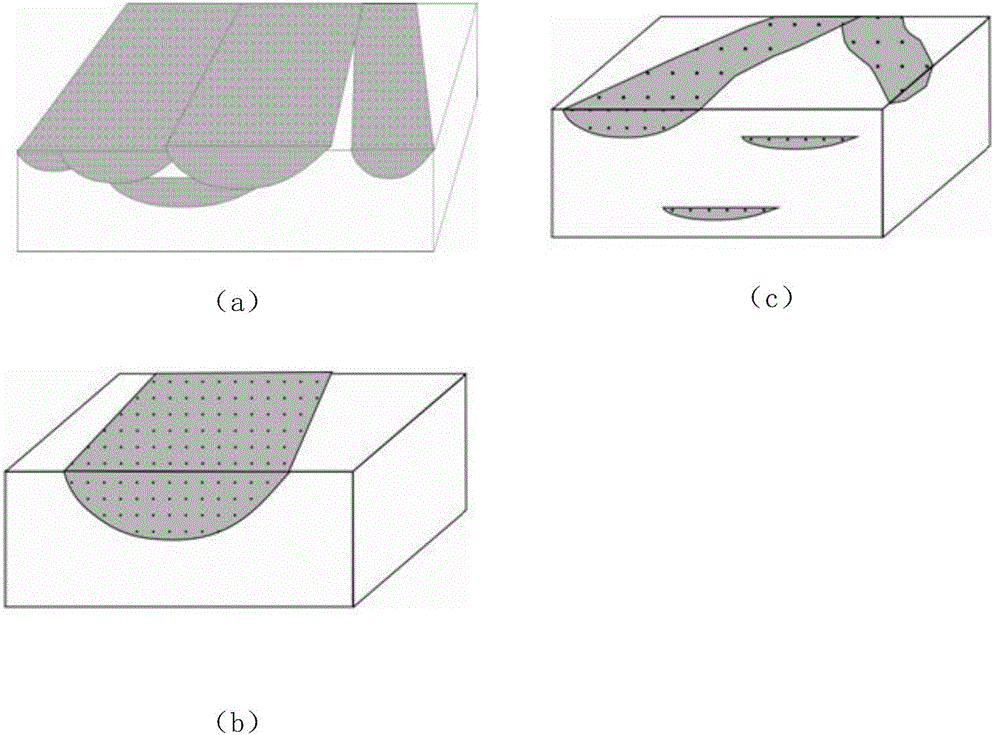

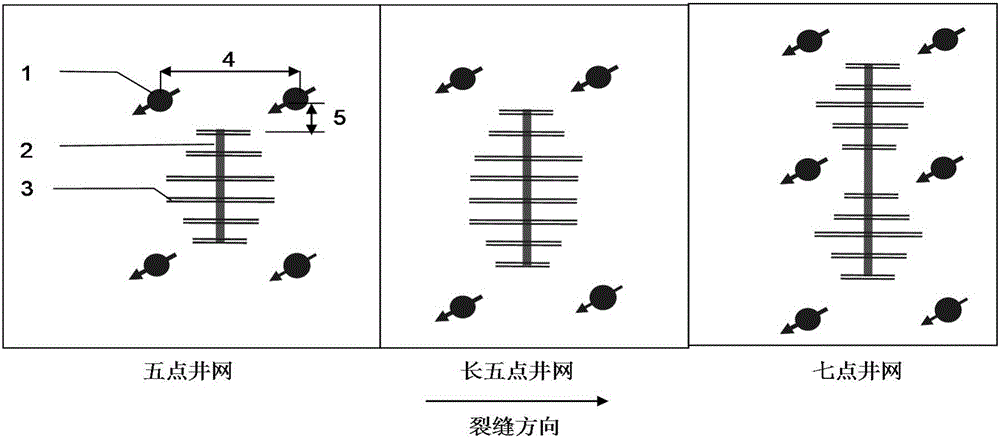

Horizontal well spacing method based on sand body structure

ActiveCN106014372AIncrease the encounter rateRealize integrationFluid removalSoil scienceWell logging

The invention provides a horizontal well spacing method based on a sand body structure. The method comprises the following steps of selecting a natural gamma ray curve of a layer section to be studied of a target region; classifying the sand body structure according to the curve form and the sand layer thickness; drawing a sand layer thickness isograms according to the sand body structure features, the sand body combination mode and the sand body thickness of a single well; determining a sand body well spacing range according to the oil layer thickness and the plane distribution features of the sand body; selecting different well networks according to the sand body structure; deploying a short-five-point well network for the single-layer stable type sand body; and deploying a long-five-point well network and a seven-point well network for the multilayer superimposed sand body. The horizontal well spacing method has the advantages that the horizontal well spacing can be performed on the basis of the sand body structure and sand body distribution rule study; the sand body structure is expressed by using the smooth degree of the natural gamma ray curves of well logging curve data; and the horizontal well five-point and seven-point water injection development well networks are deployed by combining the riverway sand body width.

Owner:PETROCHINA CO LTD

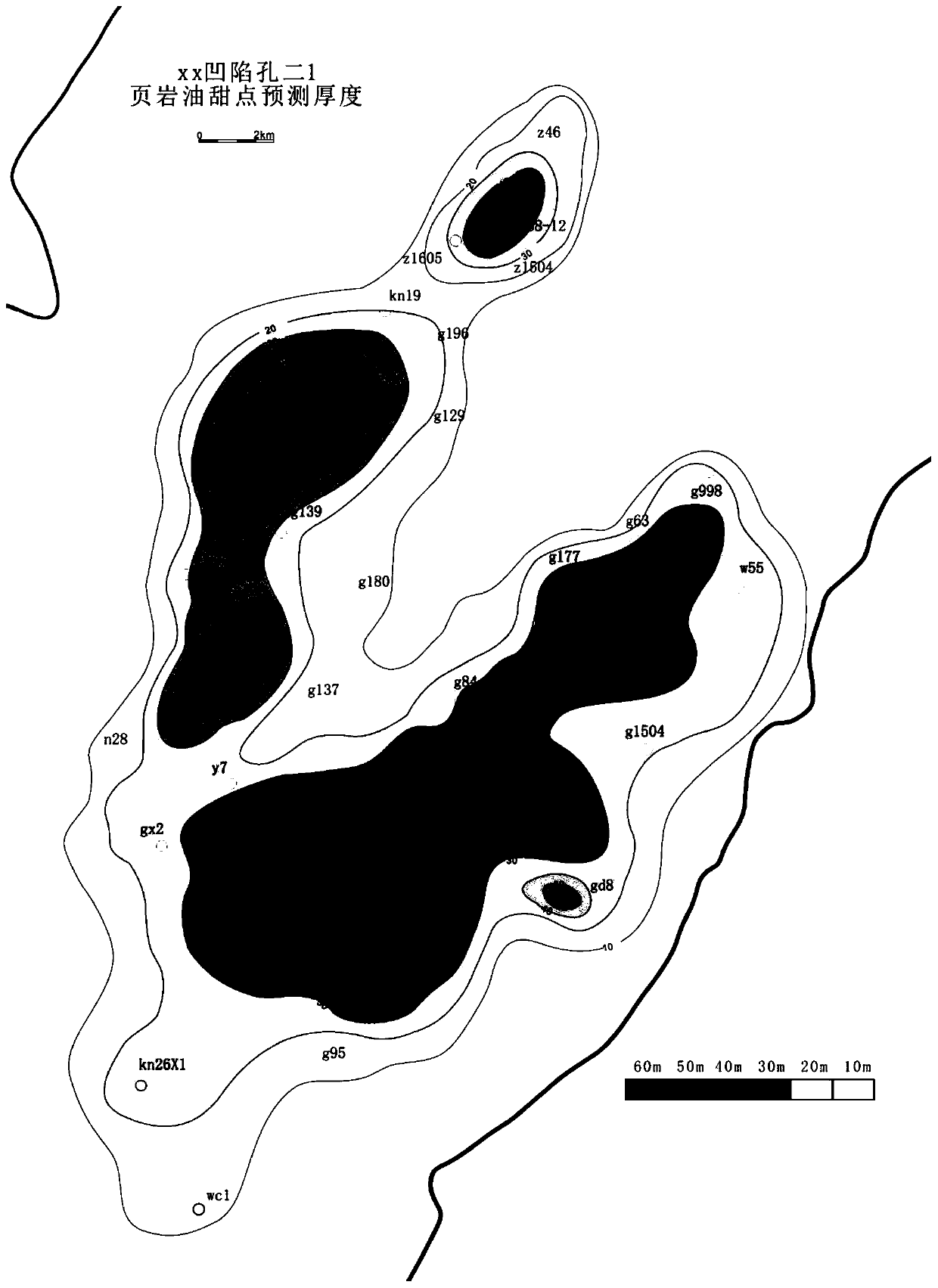

Shale oil horizontal well track design and on-site tracking adjustment research method

InactiveCN109960897AGuaranteed maximum effectivenessImprove interpretation accuracySurveyFluid removalWell drillingStudy methods

The invention discloses a shale oil horizontal well track design and on-site tracking adjustment research method. The method comprises shale oil sweet spot identification and evaluation, horizontal well optimization and track design and shale oil horizontal well on-site tracking adjustment. A 'four-optimal-two-precision' method formed by the shale oil horizontal well track design and on-site tracking adjustment research method lays a foundation for realizing integration of high and stable yield of shale oil in a blocked lake basin and production and storage increase. A set of technical methodis provided for carrying out horizontal well position optimization design research and drilling well dynamic tracking analysis in a shale oil development area, and the method has great reference and popularization significance.

Owner:PETROCHINA CO LTD

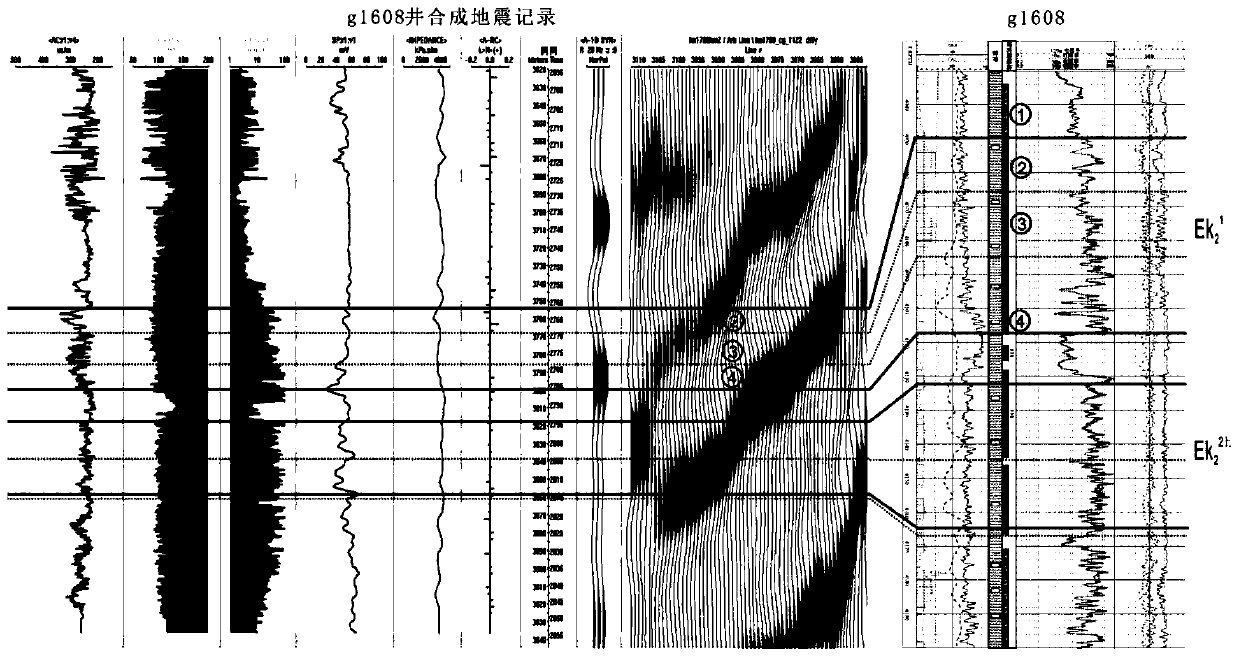

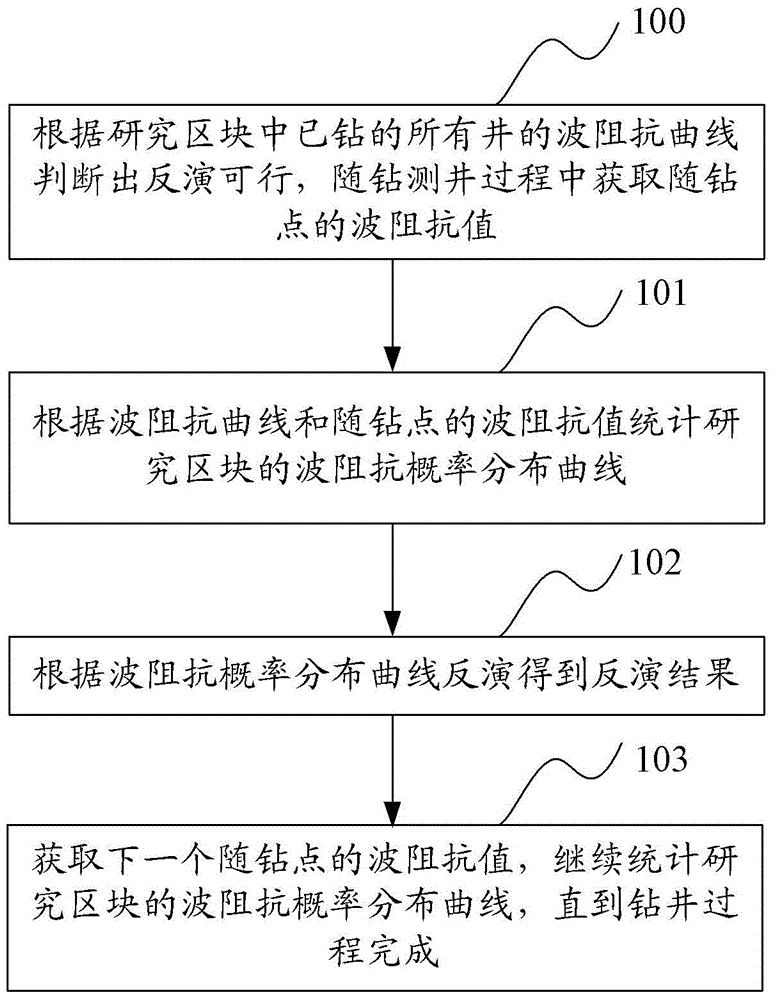

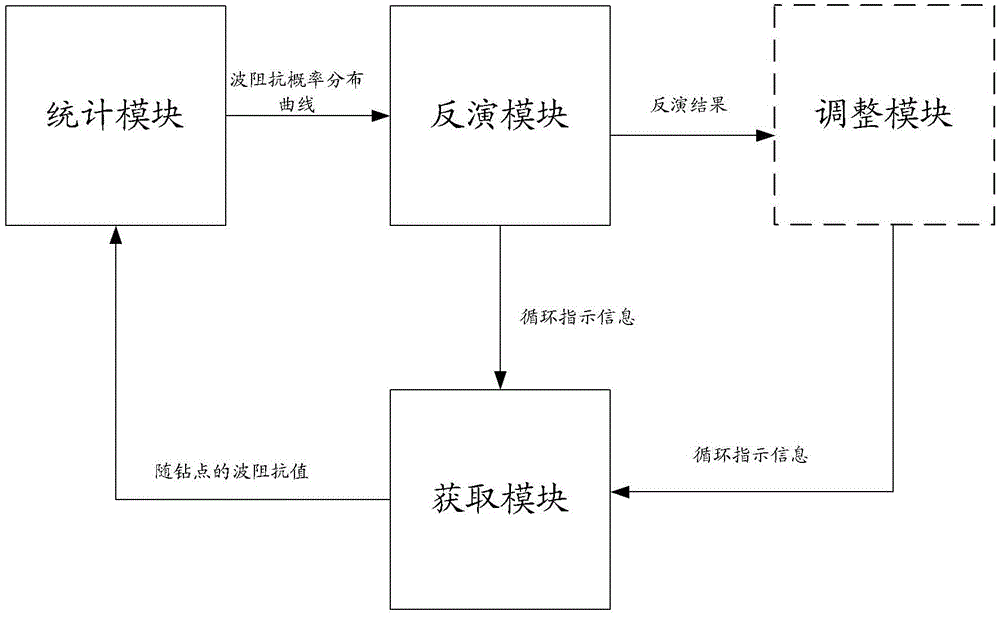

Seismic inversion method and device

ActiveCN104090303AImprove inversion accuracyIncrease the encounter rateSeismic signal processingSeismology for water-loggingWell loggingHorizontal wells

The invention discloses a seismic inversion method and device. The method comprises the steps that according to wave impedance curves of all drilled wells in a research block, it is judged that inversion is feasible, and a wave impedance value of a while-drilling point is obtained in the process of logging while drilling; according to the wave impedance curves and the wave impedance value of the while-drilling point, statistics is performed on wave impedance probability distribution curves of the research block; inversion is performed according to the wave impedance probability distribution curves to obtain an inversion result; a wave impedance value of a next while-drilling point is obtained, and statistics is continued to be performed on the wave impedance probability distribution curves of the research block until the drilling process is completed. According to the seismic inversion method and device, inversion accuracy can be improved. Furthermore, a hole drift angle is adjusted according to the inversion result, and the drill encounter rate of a reservoir of a horizontal well is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Water jet dense comb-shaped hole drilling type to-be-tunneled roadway coal seam gas outburst elimination backing pump treatment method

The invention discloses a water jet dense comb-shaped hole drilling type to-be-tunneled roadway coal seam gas outburst elimination backing pump treatment method which comprises the following steps: I,constructing orientated long drilling holes; II, constructing water jet dense comb-shaped holes; III, sealing holes, and extracting and exploring gases. By adopting the method, very small radius water jet dense comb-shaped branched holes are constructed in a bottom plate of a to-be-tunneled roadway in an underground coal mine, hole drilling depths of single branch holes are reduced, the number ofbranch holes is greatly increased, the coal layer permeation improvement and gas extracting and discharge effects of the orientated long drilling holes are improved, the purpose of to-be-tunneled roadway coal seam gas backing pump outburst elimination can be achieved, and safe tunneling of a coal seam roadway is ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

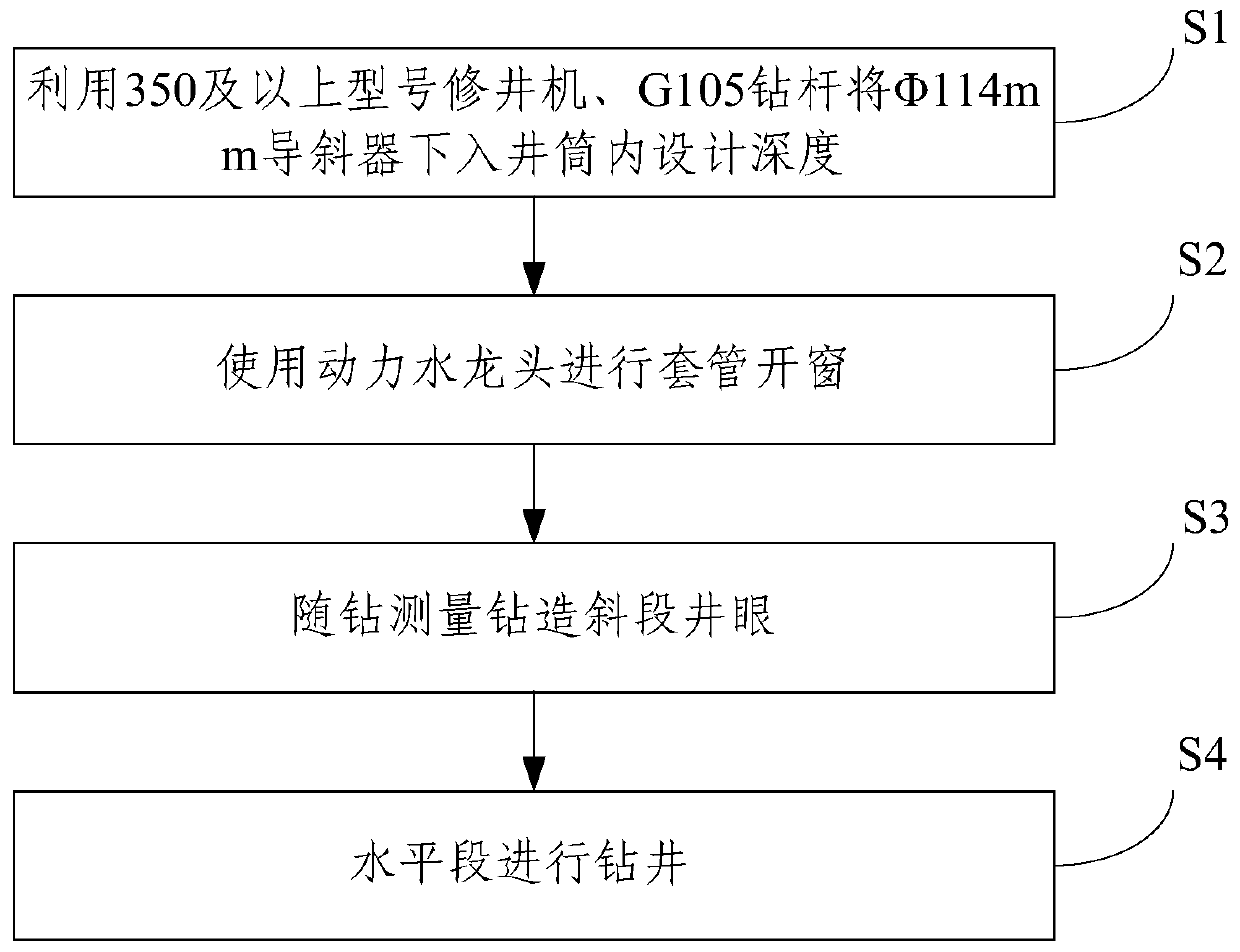

Measurement while drilling and precise control ultrashort radius horizontal drilling method

The invention relates to the field of oil field drilling, in particular to a measurement while drilling and precise control ultrashort radius horizontal drilling method. The method concretely comprises the following steps of Step 1, feeding a phi 114mm wedge deflection tool to the design depth in a shaft by a workover rig with the model being 350 or greater and a G105 drill pipe; Step 2, performing casing window cutting by using a power swivel; Step 3, drilling and forming inclined section well hole through measurement while drilling; and Step 4, performing drilling in a horizontal section. The measurement while drilling and precise control ultrashort radius horizontal drilling method provided by the invention has the advantages that by using the method, the measurement while drilling canbe performed in real time in a drilling process; the drilling well deviation and the position can be regulated according to measuring data; the horizontal section of an oil reservoir is precisely controlled; and the horizontal section drilling distance and the oil reservoir drilling catching rate are greatly improved.

Owner:大庆辰平钻井技术服务有限公司

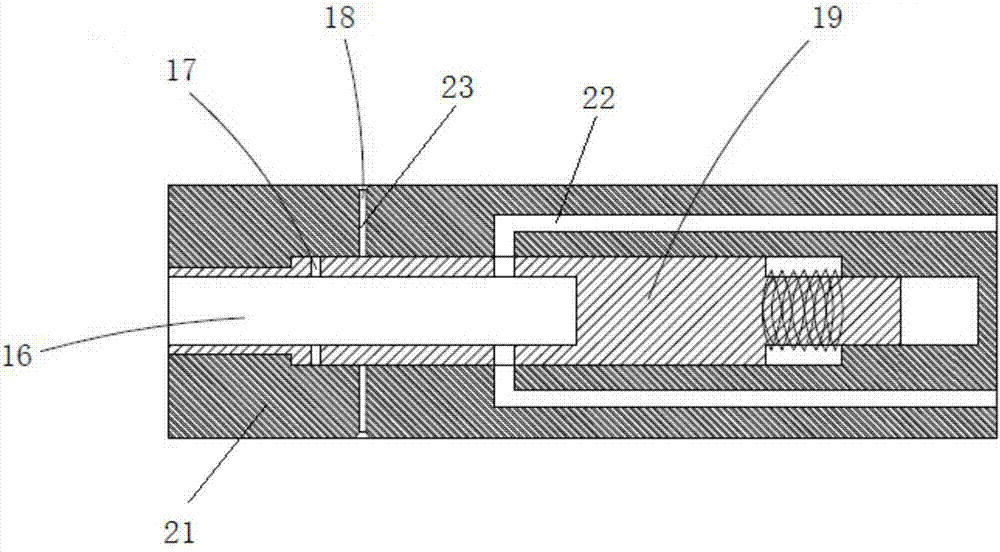

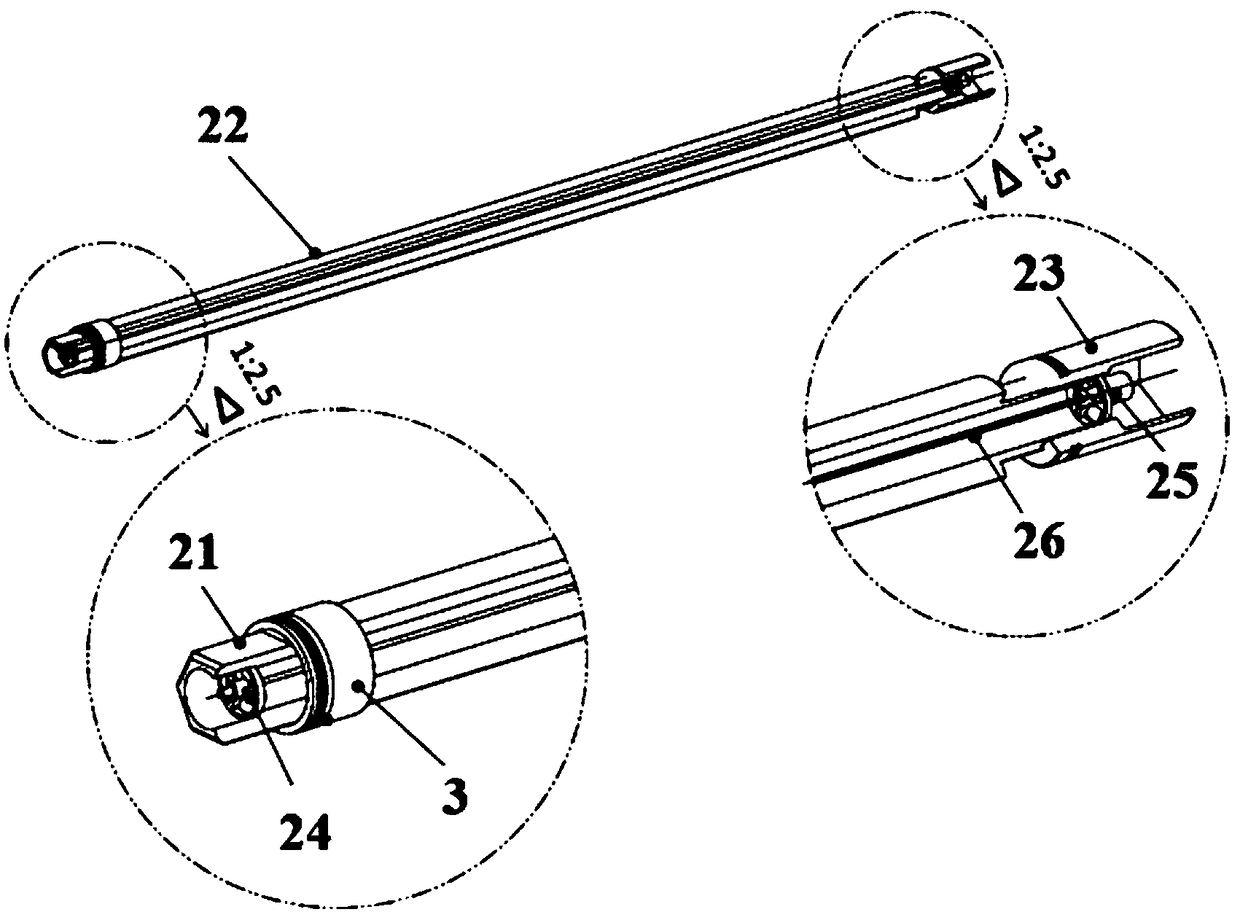

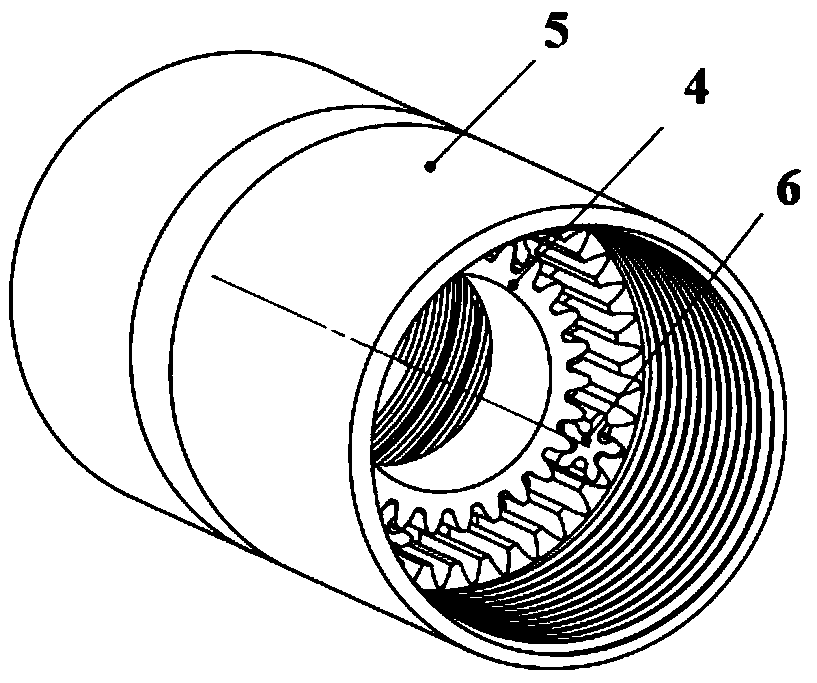

Multistage cuttings discharge air-screw motor for underground coal mine drilling

ActiveCN107217982AImprove slagging abilityEnables directional drillingConstructionsDirectional drillingTransmitted powerDrive shaft

A multistage cuttings discharge air-screw motor for underground coal mine drilling comprises a connector, a motor assembly, a universal shaft assembly, and a transmission shaft assembly; the motor assembly inputs compressed air for rotation driving, the universal shaft assembly and the transmission shaft assembly transmit power, a single-bend outer pipe of the universal shaft assembly can provide directional drilling, and the motor assembly is provided with a continuous right-handed spiral groove; when rotating, the screw motor stirs depositing cuttings, assisting air in discharging the cuttings out of a borehole; multistage cuttings discharge is achieved by adding two sets of reverse bypass holes, and it is ensured that the motor can still normally rotate to discharge powder when a bit blocks at the bottom of the borehole or cuttings accumulate at the bottom; by providing a one-way valve, high-pressure gas is avoided carrying the cuttings reversely into the motor, causing damage to the motor. The multistage cuttings discharge air-screw motor is used with an underground while-drilling measuring system in the construction of long boreholes along an underground coal mine broken-soft coalbed, cuttings discharge effect can be improved, intra-borehole resistance is decreased, construction safety is ensured, and construction depth of boreholes along underground coal mine broken-soft coalbeds and coalbed drilling catching ratio are increased.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Oil-gas drilling production increasing combined operation device and method

ActiveCN107288540AImprove work efficiencyFast and efficient drillingDrill bitsLiquid/gas jet drillingEnvironment effectJet flow

The invention discloses an oil-gas drilling production increasing combined operation device and method. The device comprises a high-pressure pump, high-pressure coiled tubing and a downhole drilling tool combination, wherein the downhole drilling tool combination comprises a drill bit and a downhole cutting nipple; the drill bit is connected with the high-pressure coiled tubing, and a rock breaking nozzle and a thrust nozzle are formed in the front end and the rear end of the drill bit correspondingly; the downhole cutting nipple comprises a shell and a valve body; the valve body is provided with an axial hydraulic channel and a radial hydraulic channel; a jet flow channel is formed in the shell and provided with a radial jet flow nozzle; a drilling water channel is further formed in the shell; and the axial hydraulic channel communicates with the rock breaking nozzle of the drill bit. When the valve body moves in the shell to enable the axial hydraulic channel to communicate with the drilling water channel, the radial hydraulic channel does not communicate with the jet flow channel; and when the radial hydraulic channel communicates with the jet flow channel, the axial hydraulic channel do not communicate with the drilling water channel. Compared with an existing oil-gas exploitation technology, the oil-gas drilling production increasing combined operation device and the method have the advantages that (1) operation efficiency is high; (2) the production increasing effect is good; (3) reservoir adaptability is wide; and (4) the environmental influence is less.

Owner:CHINA PETROLEUM & CHEM CORP +1

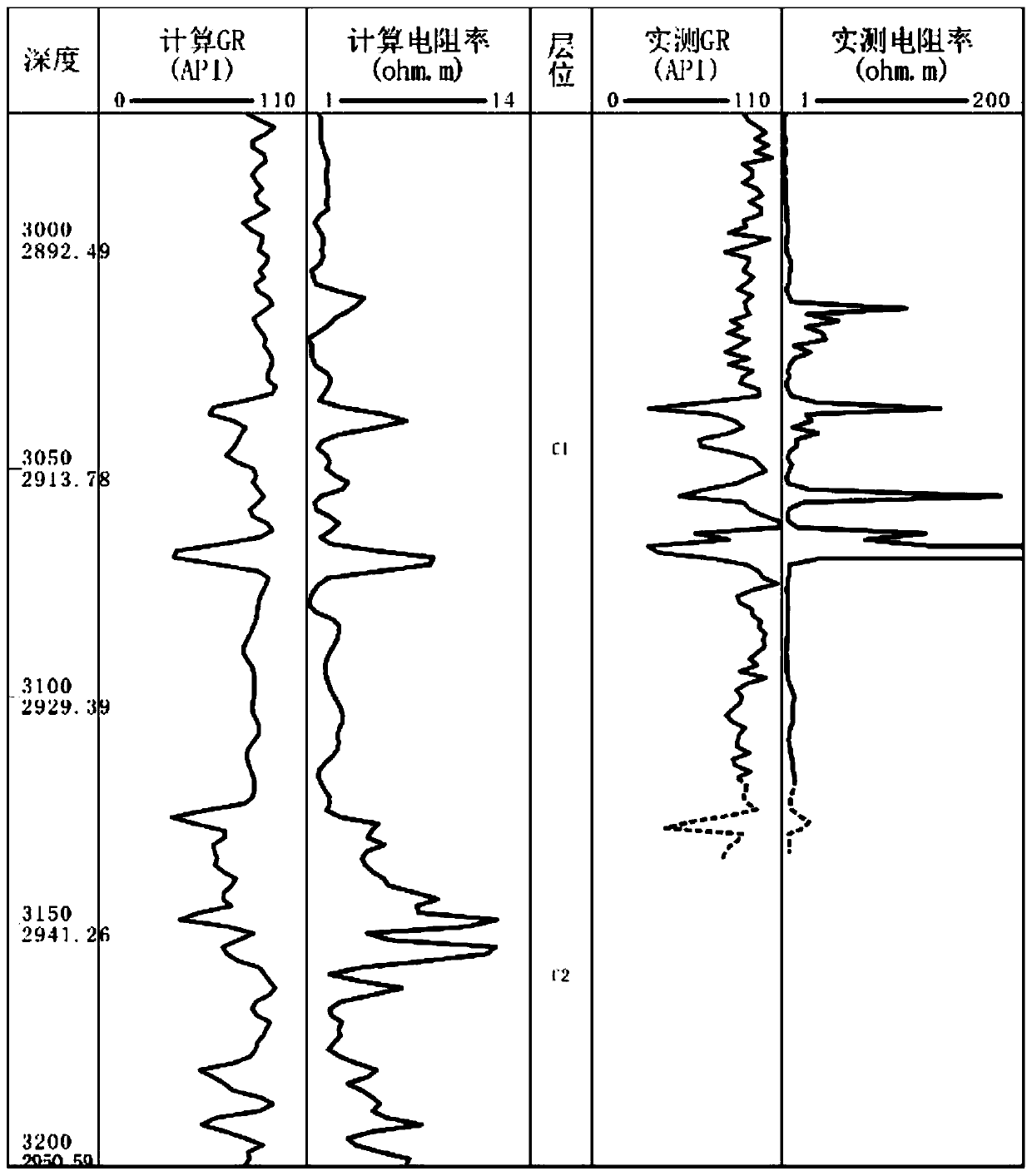

Horizontal well target layer dynamic modeling method while drilling

InactiveCN103510854AIncrease the encounter rateImprove forecast accuracyDirectional drillingGeotechnical engineeringDrill bit

The invention belongs to the field of horizontal well logging guiding technologies, and discloses a horizontal well target layer dynamic modeling method while drilling. The method is mainly characterized in that before landing, the dip angle, in a profile, of a target layer is firstly calculated; then the drilling thickness of the target layer is calculated according to the depth of the top surface of the target layer to be drilled; with the lithology, the electrical property, gas logging and other longitudinal change characteristics, in an adjacent well, of the target layer as reference, the longitudinal position, in the layer, of a drill bit is judged while drilling, an upper boundary line and a lower boundary line of the target layer are reverse calculated with the position of the drill bit, target layer dynamic modeling while drilling is achieved, and track design in a next step is carried out according to a latest deduction model. Through calibration, correction and deduction carried out on the form of the target layer by information while drilling, the horizontal well target layer dynamic modeling method while drilling achieves dynamic fine depiction of the target layer, improves prediction accuracy, guides fining adjustment and control over a track, guides the drill bit to effectively penetrate through the target layer, and finally improves the drilling catching rate.

Owner:CNPC BOHAI DRILLING ENG

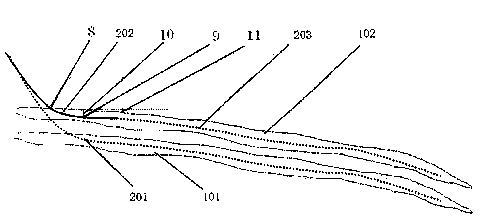

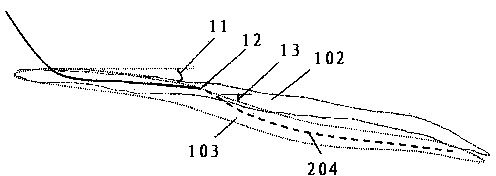

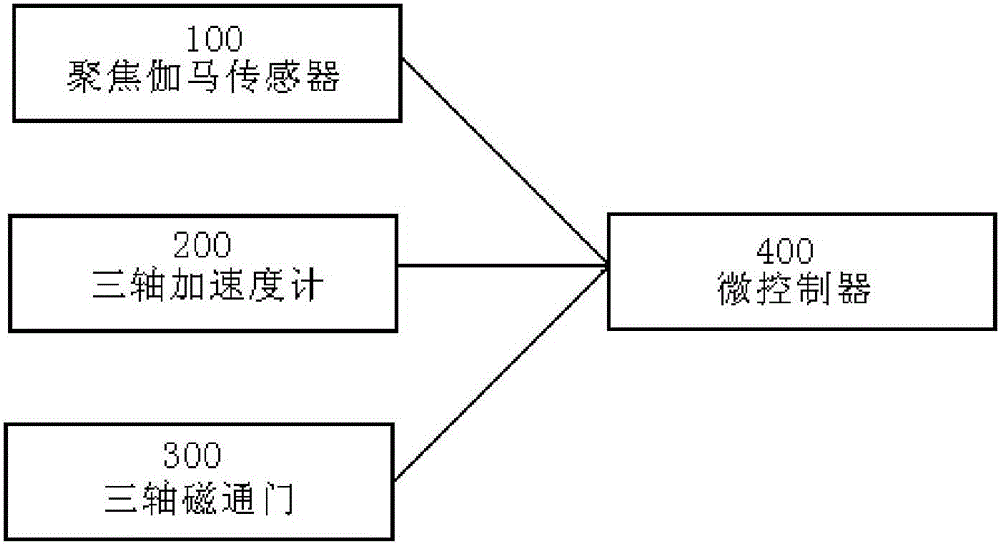

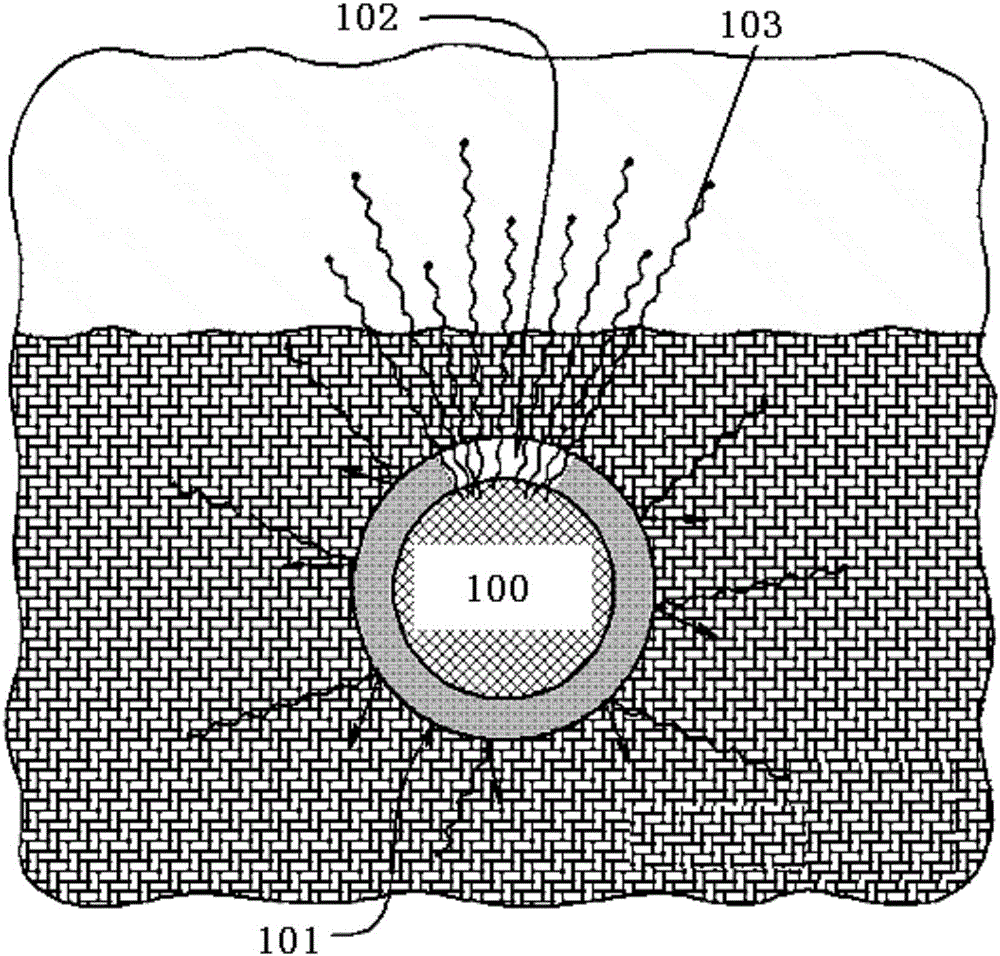

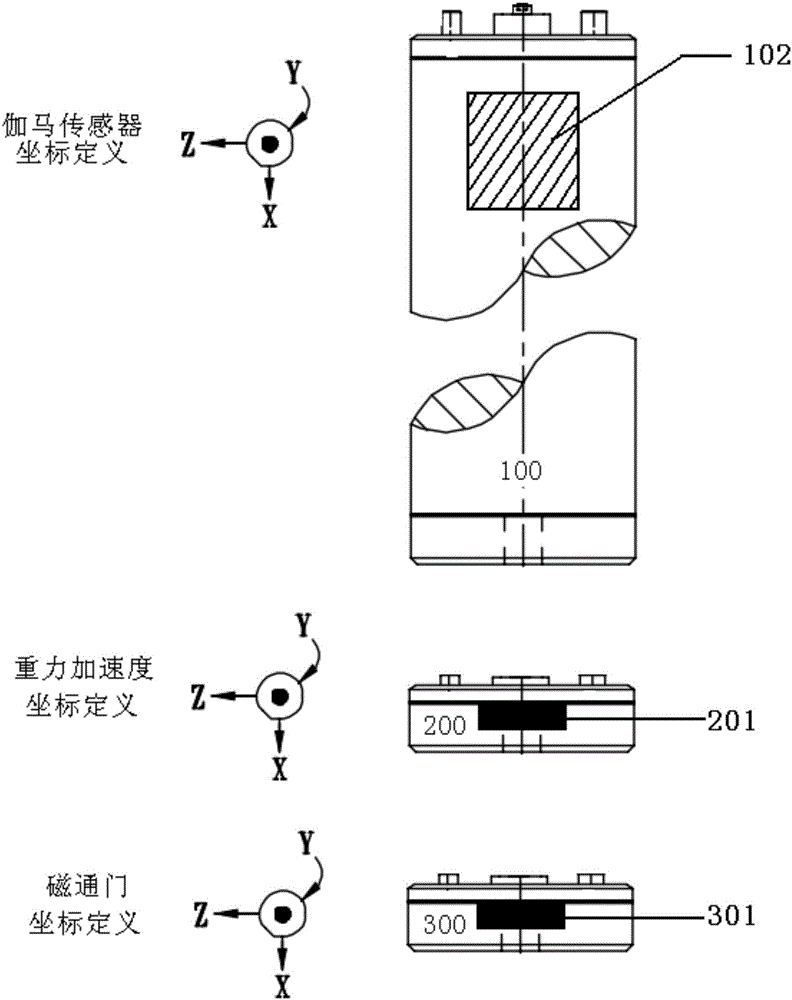

Gamma azimuth measuring device and collecting method

ActiveCN106285632AGamma measurement implementationIncrease the encounter rateSurveyNuclear energy generationMicrocontrollerTriaxial accelerometer

The invention discloses a gamma azimuth measuring device. The gamma azimuth measuring device comprises a focusing gamma sensor, a triaxial accelerometer, a triaxial fluxgate and a microcontroller, wherein the focusing gamma sensor is used for collecting gamma count values; the triaxial accelerometer and the triaxial fluxgate are used for determining the posture of the focusing gamma sensor in a stratum and the normal direction of a probe correspondingly, and the triaxial directions of the triaxial accelerometer and the triaxial fluxgate are the same; and the input end of the microcontroller is connected in a communication mode and receives the information of the posture of the focusing gamma sensor in the stratum and the normal direction of the probe collected by the triaxial accelerometer and the triaxial fluxgate correspondingly and the gamma count values collected by the focusing gamma sensor, so that the gamma count values of all directions are obtained. According to the gamma azimuth measuring device and the collecting method, gamma rays in all the directions can be continuous measured, the nature of the stratum and the change conditions of the stratum can be judged and identified, gamma data can be collected and resolved to one direction, azimuth measuring of the gamma data can be achieved, and drilling encountering efficiency can be largely improved no matter what posture that the gamma sensor is in and rotates at different rotating speeds.

Owner:上海神开石油测控技术有限公司 +3

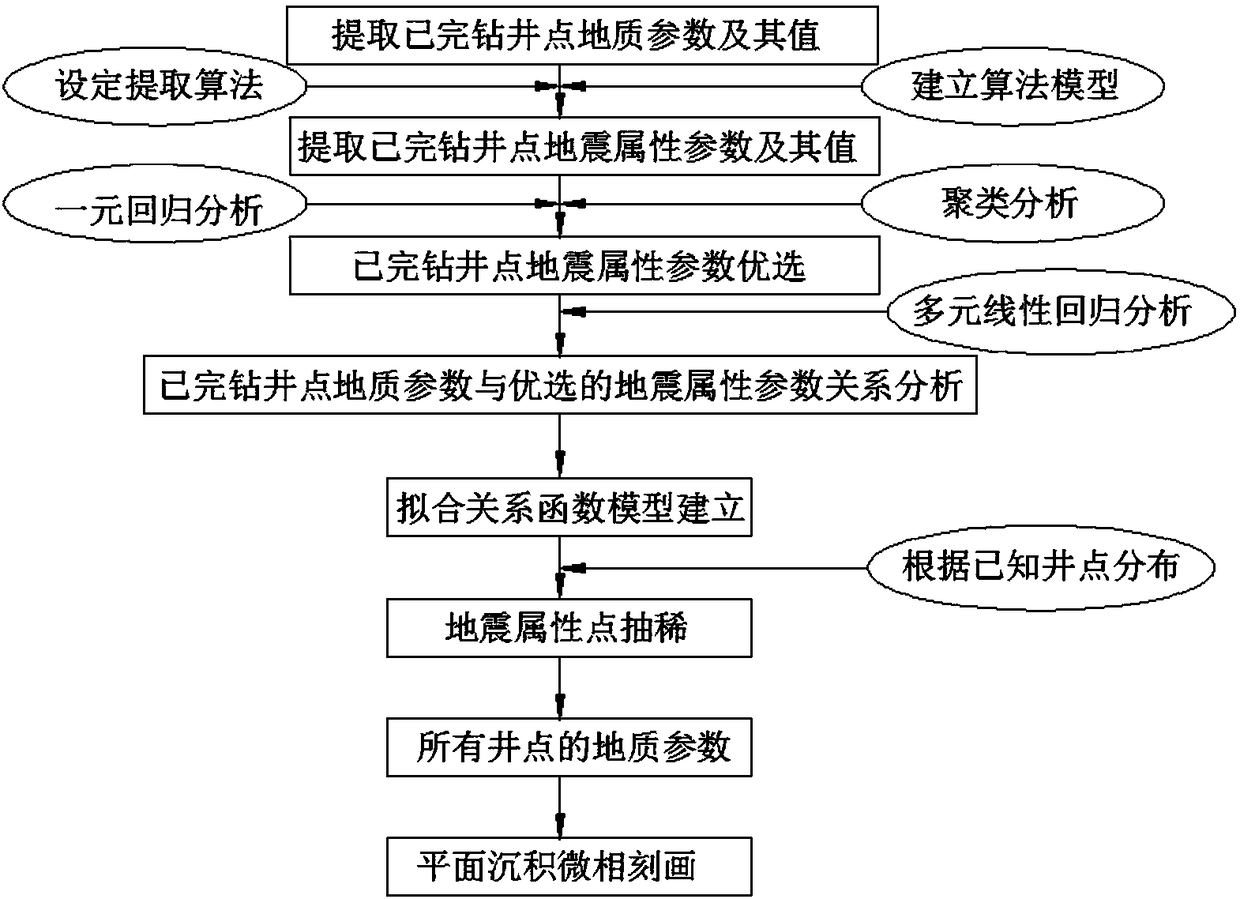

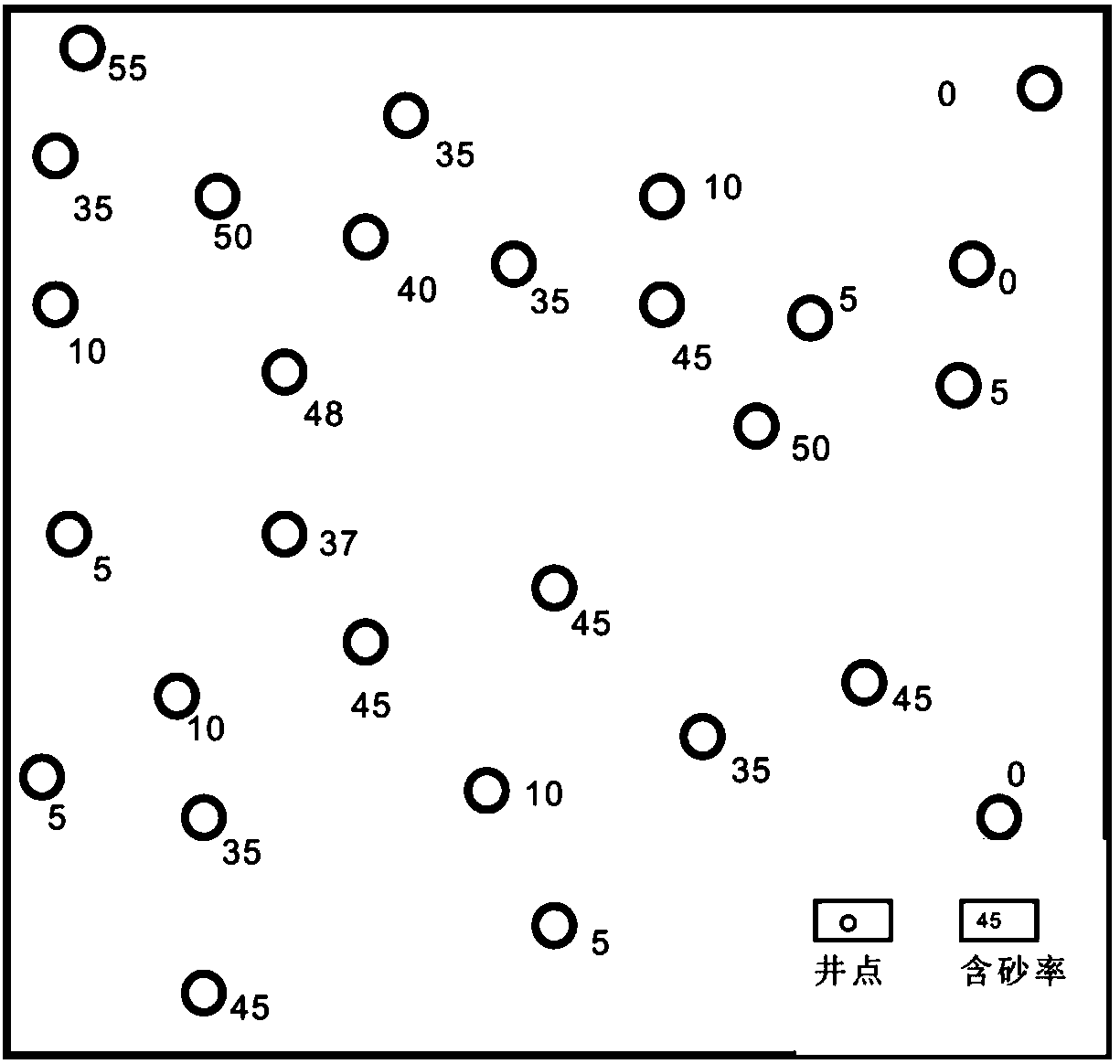

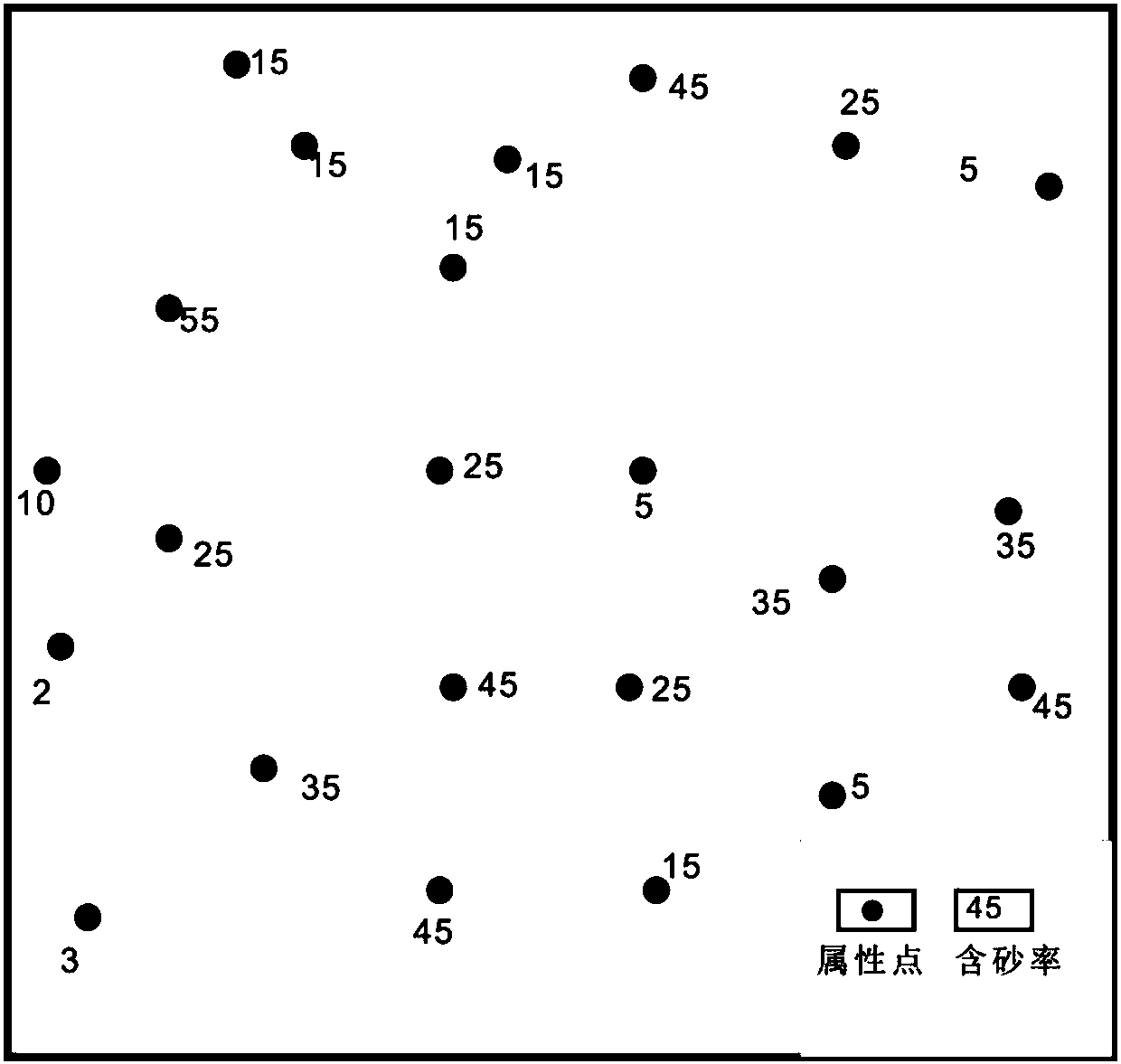

Sedimentary microfacies depicting method

InactiveCN108663714AHigh precisionImprove explorationSeismic signal processingSeismology for water-loggingRegression analysisWell logging

The invention provides a sedimentary microfacies depicting method which combines well logging information, geological data and planar seismic data of single points of completed well drilling points inthe longitudinal direction to realize well seismic combined fine depicting of deposition microfacies. The microfacies depicting precision is improved through one-way regression analysis, clustering analysis of preferable seismic attribute parameters. A multi-element linear regression method is combined with the seismic attribute parameters so as to obtain a fitting relation function model. The geological parameters of the well points are fully utilized through a thinning step, and the geological parameters converted by the seismic attribute parameters of the virtual well points between the completed well drilling points are effectively utilized, so that the finally-depicted sedimentary microfacies precision is higher. In addition, only partial seismic attribute points are extracted, so that the workload is greatly reduced in actual operation, and the labor cost is reduced. The reservoir distribution among wells can be predicted on the basis of the sedimentary microfacies depicted by the method. A geological basis is provided for well deployment, and the exploration and development success rate of the oil and gas field is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

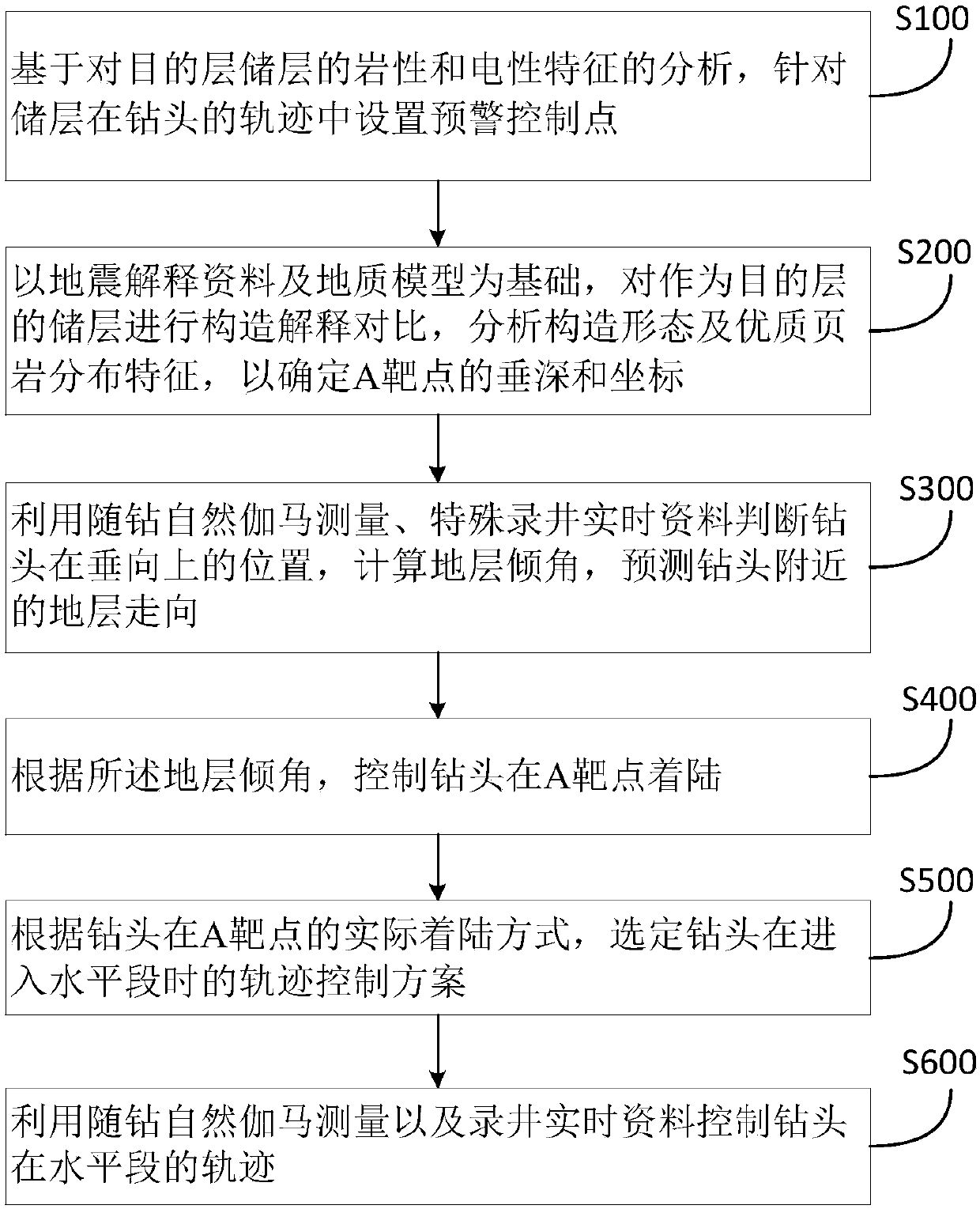

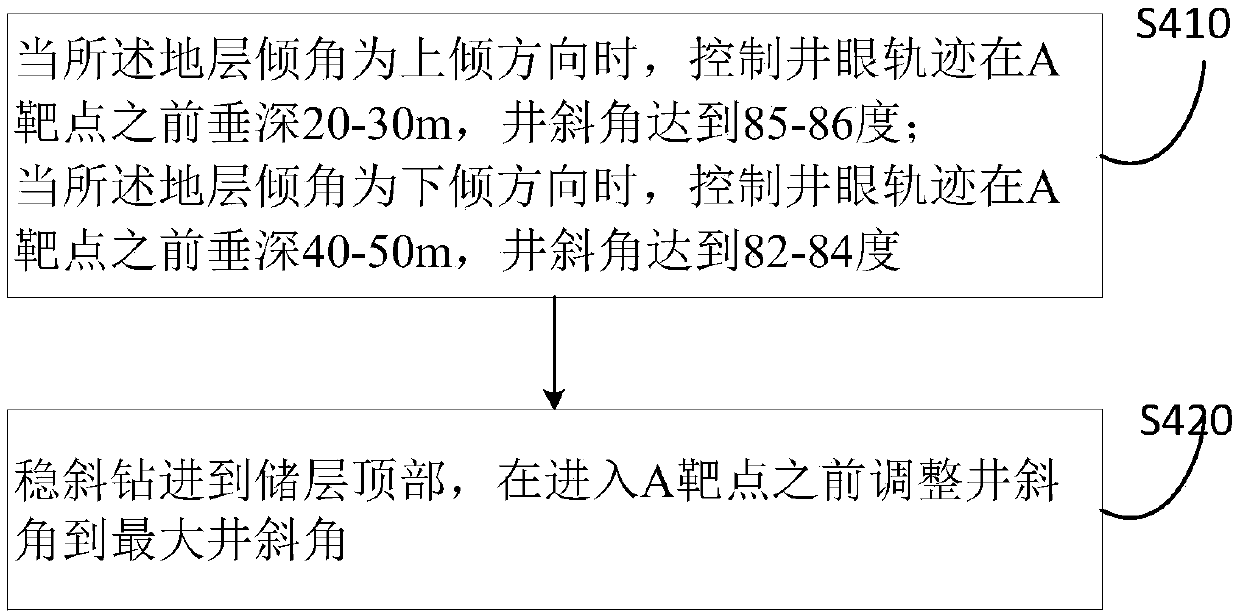

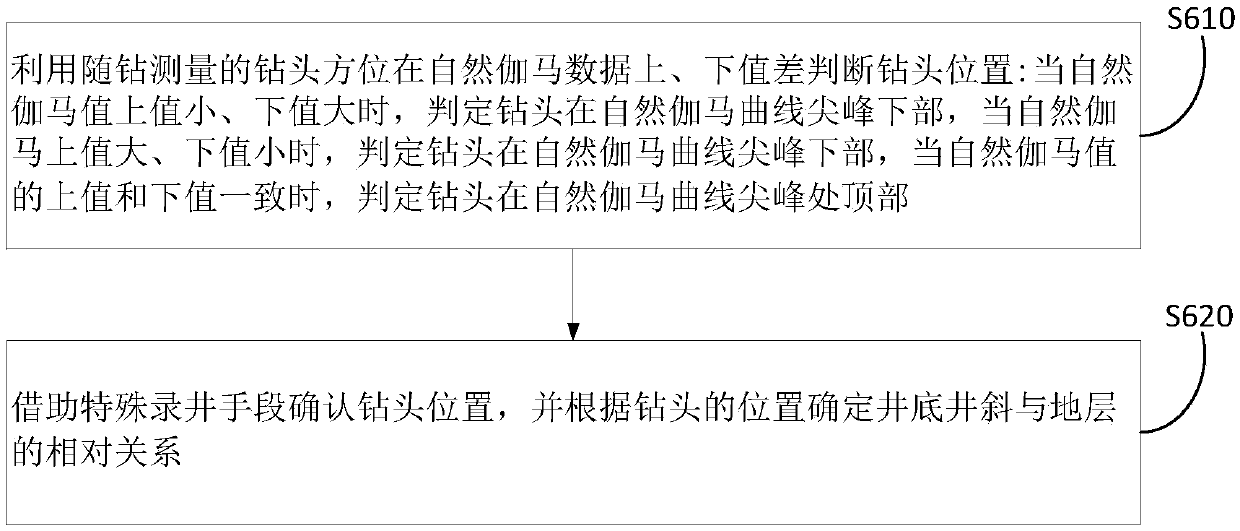

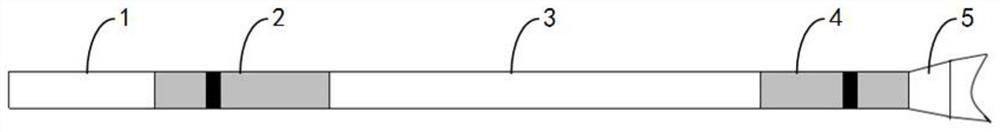

Drilling method and system

ActiveCN108019150AIncrease the encounter ratePrecise control of drill trajectoryDirectional drillingLithologyReal-time data

The invention relates to the field of petroleum and natural gas exploration and provides a drilling method and system. The drilling method comprises the steps that based on the analysis of the lithologic characters and the electric characteristics of a reservoir of a target stratum, forewarning control points are arranged in the track of a drill bit aiming at the reservoir; on the basis of seismicinterpretation data and a geological model, structure interpretation comparison is conducted on the target stratum, and the structure form and the excellent shale distribution characteristics are analyzed so as to determine the vertical depth and coordinates of an A target point; the position of the drill bit in the vertical direction is judged through while-drilling natural gamma measurement andspecial logging real-time data, the stratum dip angle is calculated, and the strike of a stratum near the drill bit is predicted; according to the stratum dip angle, the drill bit is controlled to land at the A target point; according to the actual landing mode of the drill bit at the A target point, the track control scheme of the drill bit at the time of entering the horizontal section is selected; and through the while-drilling natural gamma measurement and logging real-time data and according to the gamma values of the forewarning control points, the track of the drill bit on the horizontal section is controlled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Trona deep and thin layer multi-connected horizontal well borehole track control method

ActiveCN107060642AEfficient developmentGood control areaSurveyDirectional drillingButt jointThin layer

The invention discloses a trona deep and thin layer multi-connected horizontal well borehole track control method. The trona deep and thin layer multi-connected horizontal well borehole track control method is characterized by comprising the following steps of (1) optimal design of double-connected horizontal well track sections; (2) application of an error correction technology; and (3) application of an LWD and RMRS fused measurement and borehole track accurate control technology. The design problem of the deep-layer double-connected horizontal well track sections is solved; a conventional LWD measurement instrument is adopted, an RMRS measurement technology is introduced, acting as a go-between is achieved through precise control over borehole tracks, two vertical well boreholes with the diameters being 118 mm and 105 mm are connected at one stroke at the positions with the vertical depth being 2981 m and 3013 m and the slant depth being 3239.5 m and 3512.6 m, and point-to-point butt joint is successfully achieved.

Owner:HENAN ZHONGYUAN CHEM

Near-bit geosteering system

ActiveCN111911134AGuaranteed drillingEarly detectionSurveyDrilling rodsTelecommunicationsWell drilling

The invention relates to a near-bit geosteering system. The system involves a measurement-while-drilling subsystem, a receiving nipple, a screw drill, a near-bit measurement transmitting nipple and adrill bit which are connected in sequence; the near-bit measurement transmitting nipple comprises a transmitting nipple main body, a transmitting end sensor set and a transmitting end main control board, wherein the transmitting end sensor set is arranged in the transmitting nipple main body and measures first drilling data including near-bit vibration data, azimuth gamma data and well deviation data, and the transmitting end main control board is arranged in the transmitting nipple body, is connected with the transmitting end sensor set and is used for transmitting the first drilling data; and the receiving nipple comprises a receiving nipple main body and a receiving end main control board, wherein the receiving end main control board is arranged in the receiving nipple main body, is inwireless communication connection with the transmitting end main control board and is used for sending the first drilling data to the measurement-while-drilling subsystem. The system can solve the problems that the landing point judgment is possibly inaccurate, a drill bit cannot enter a reservoir and the drilling rate is extremely low due to the fact that a sensor is far away from the drill bit in the prior art.

Owner:KINGDREAM PLC CO +1

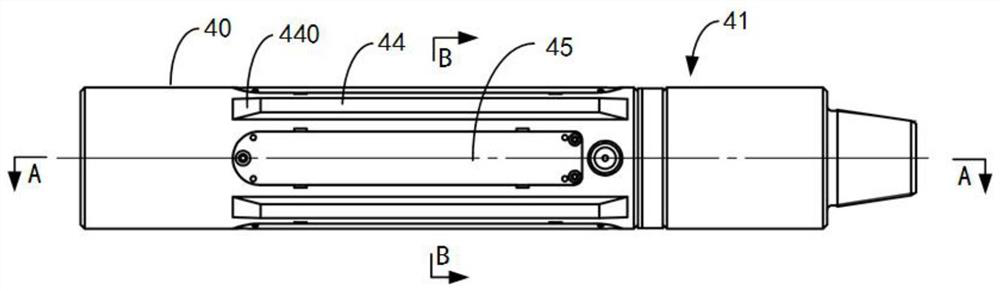

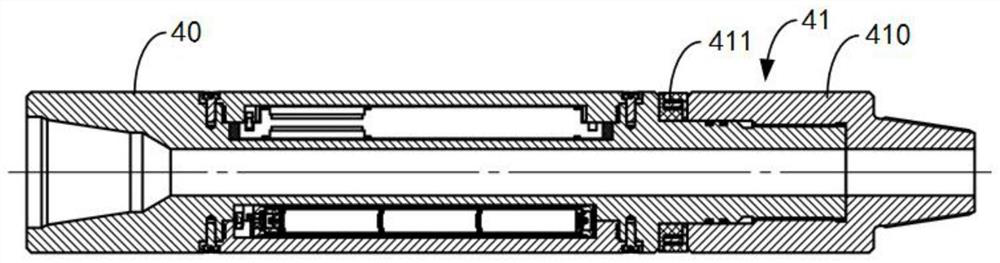

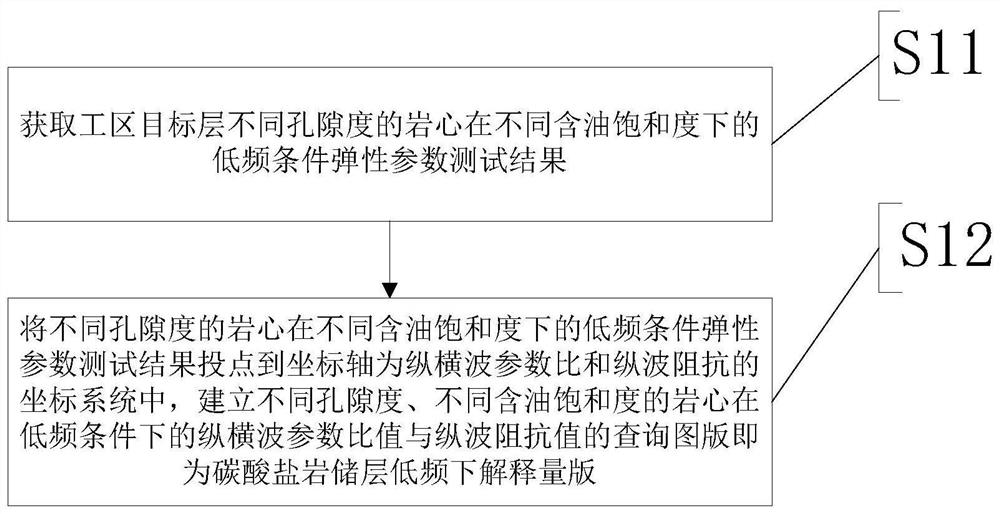

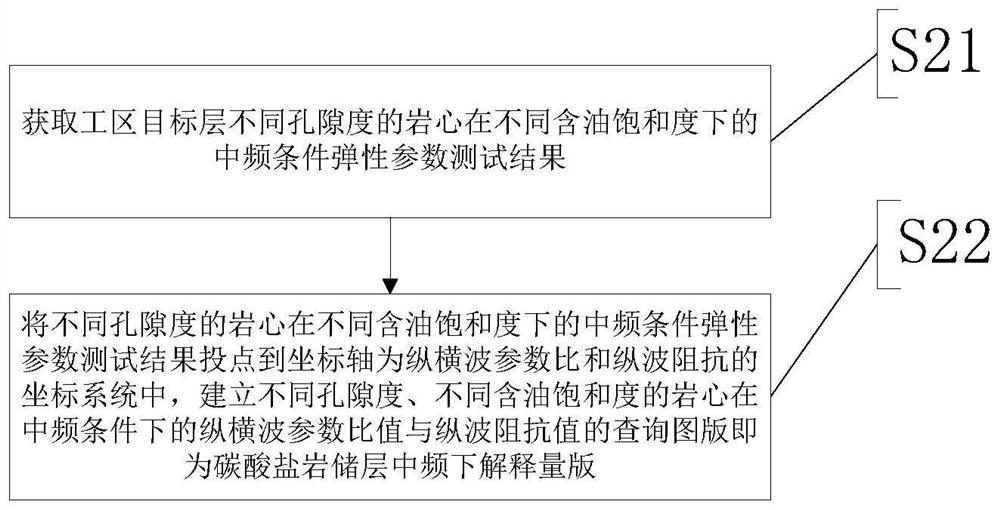

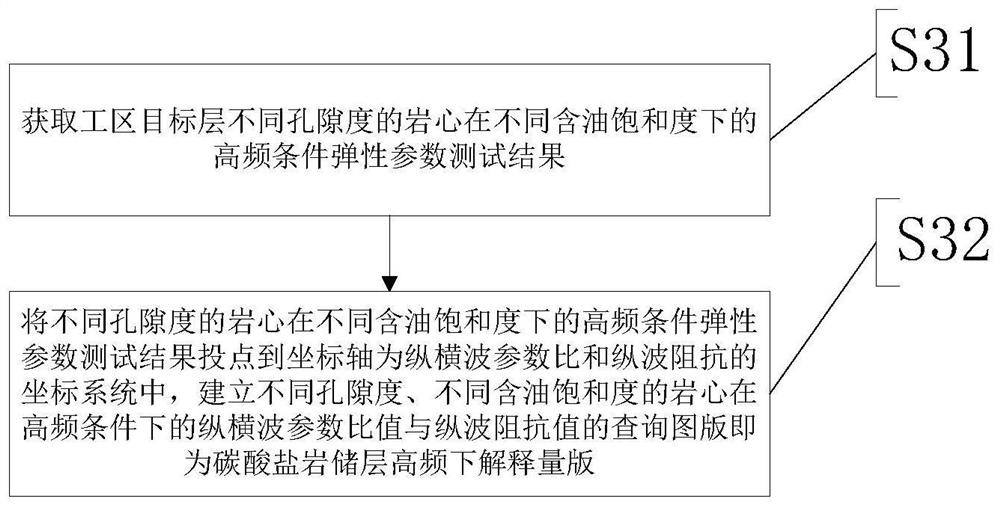

Carbonate reservoir interpretation method and interpretation template establishment method

PendingCN112147689APromote perfectionOvercome Conditional IssuesSeismic signal processingSeismology for water-loggingGeophysicsPetroleum engineering

The invention provides a carbonate reservoir interpretation method and an interpretation template establishment method. The interpretation template establishment method comprises the steps that a interpretation template of a carbonate reservoir under low frequency and / or medium frequency and / or high frequency is established; low-frequency and / or medium-frequency and / or high-frequency condition elastic parameter test results of cores with different porosities in a target layer of a work area under different oil saturation degrees are acquired; the low frequency is consistent with earthquake dominant frequency, the medium frequency is consistent with logging frequency, and the high frequency is consistent with stratum ultrasonic testing frequency; the low-frequency and / or medium-frequency and / or high-frequency condition elastic parameter test results of the cores with different porosities under different oil saturation degrees are projected into a coordinate system of which the coordinate axes represent longitudinal and transverse wave parameter ratio and longitudinal wave impedance; and a query chart of longitudinal and transverse wave parameter ratio values and longitudinal wave impedance values of the cores with different porosities and different oil saturation degrees under low-frequency and / or medium-frequency and / or high-frequency conditions is established, where the querychart is the interpretation template of the carbonate reservoir under the low-frequency and / or medium-frequency and / or high-frequency conditions.

Owner:PETROCHINA CO LTD

Method for offsetting circumferential frictional resistance of double-layer drill stem and double-layer drill stem

ActiveCN109025842AOffset circumferential frictionAvoiding reverse shackle problemsDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention discloses a method for offsetting the circumferential friction resistance of a double-layer drill stem and the double-layer drill stem. In the method, a TC bearing and an outer gear shaft sleeve are coaxially arranged between an outer pipe and an inner pipe assembly of the double-layer drill stem, when the outer pipe rotates, the TC bearing and the outer gear shaft sleeve generate opposite circumferential frictional resistance to the inner pipe assembly, and thus the circumferential friction resistance of the double-layer drill stem is offset. By means of the method, the circumferential frictional resistance generated by the inner pipe assembly in the rotating state of the outer pipe can be offset, and the phenomenon of circumferential torsion of the hole bottom section of the inner pipe assembly is avoided; the stability of the tool face angle of a hole bottom drill is improved, the drilling trajectory control difficulty is lowered, and the control precision is improved;the problem that when forced rotation is adopted for handling the accident that a drill gets stuck in a hole, the drill releases load suddenly due to the torsion state, then an outer pipe rebounds and rotates rapidly, and consequently an inner pipe assembly is reversely detached is avoided; the problem of low strength of small-diameter through cable joints is solved, a sufficient air supply passage at a small-diameter inner pipe joint is ensured, and the wind force loss is controlled within an allowable range.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

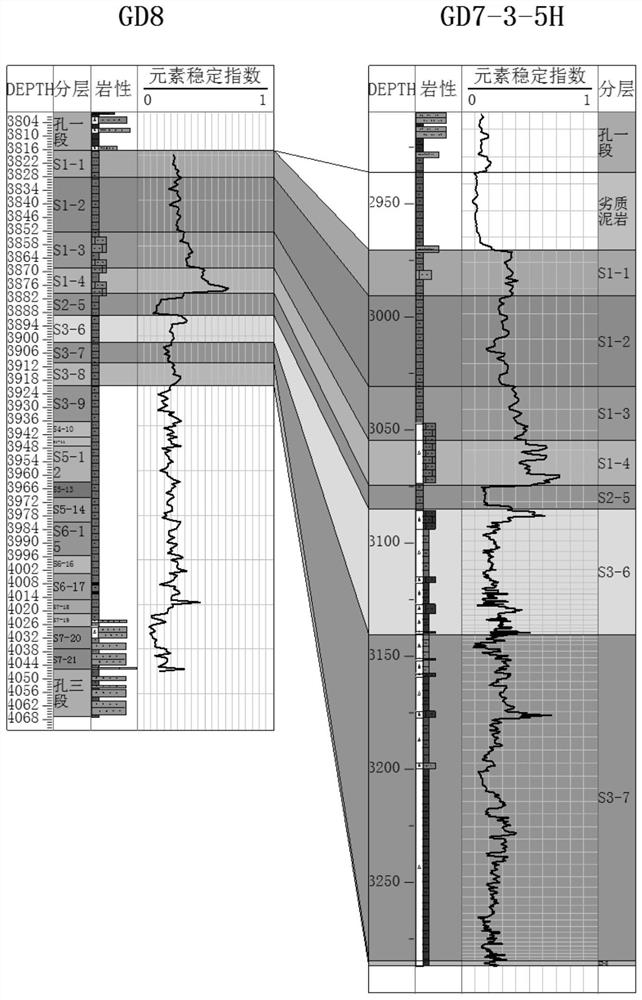

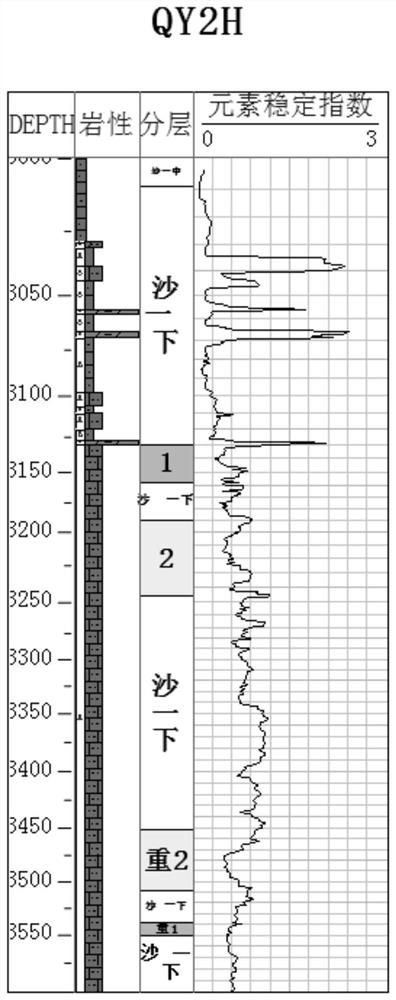

Method for identifying and comparing stratums by using element comparison relationship

InactiveCN111980687ADescribe wellIncrease the encounter rateSurveyDesign optimisation/simulationMining engineeringWell drilling

The invention discloses a method for identifying and comparing stratums by using an element comparison relationship. The method comprises the following steps of collecting element logging data of a well adjacent to a drilled well, and calculating the relative content of each element logging; establishing an element stability index curve of the adjacent well; obtaining element logging data in welldrilling through element logging work in well drilling, calculating an element stability index in well drilling, summarizing and concluding morphological characteristics of the element stability indexin well drilling and summarizing quantitative characteristics; comparing the element stability index morphological characteristics and quantitative characteristics of the drilling well and the adjacent well, and identifying the drilling position of the drilling well; and judging the drilling condition of a target stratum of the drilled well, and forming stratum position description of the drilledstratum. According to the method, data fitting is carried out by using data in an element logging technology to form a method for stratum identification and comparison by using the element comparisonrelationship, and the method is mainly used for on-site exploration and development of oil and gas fields.

Owner:CNPC BOHAI DRILLING ENG +1

Soluble weighting salt low-damage drilling fluid and preparation method thereof

InactiveCN103045190BRheology is easy to adjustHigh densityDrilling compositionInorganic saltsAlkalinity

The invention discloses a soluble weighting salt low-damage drilling fluid and a preparation method thereof. The soluble weighting salt low-damage drilling fluid comprises the following components in percentage by mass: 10-20% of organic salt, 3-5% of inorganic salt, 0.1-0.3% of viscosifier, 0.5-1.0% of fluid loss agent, 0.5-5.0% of temporary shielding agent, 0.1-0.3% of alkalinity control agent, 0.03-0.1% of preservative, 0.5-0.8% of deoxidant, 0.1-0.2% of corrosion inhibitor and the balance of water. The soluble weighting salt low-damage drilling fluid disclosed by the invention has stable performance and high liquid phase density, is easy to regulate, realizes good rheological property, can effectively protect the storage layer, maintain stability of the well wall and improve the drilling encounter ratio of the storage layer, and is particularly suitable for a horizontal-section storage layer of mudstone.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Coal-bed gas well short frontal distance from target point horizontal well integration process method

ActiveCN111706302AImprove accuracyIncrease the encounter rateFluid removalDirectional drillingGeosteeringHorizontal wells

The invention relates to the technical field of short frontal distance from target point horizontal well drilling processes, in particular to a coal-bed gas well short frontal distance from target point horizontal well integration process method. According to the coal-bed gas well short frontal distance from target point horizontal well integration process method, window sidetracking can be carried out in a minimum casing pipe of five and a half inches (the outer diameter is 139.7 mm and the inner diameter is 124 mm), new well hole drilling can be carried out, and the adaptability is wide; theangle building hole rate ranges from 0.4-1 degrees / m, and the effective footage is saved; the drilling construction is combined with geosteering, and the coal seam landing accuracy and the drilling ratio are improved; clean water is used for horizontal section well drilling construction, and the reservoir pollution is avoided; the length of a horizontal section is larger than 200 m, and a coal seam control area is enlarged; a well completion pipe string adopts a hanger, a steel casing pipe and a ball activated sliding sleeve, the well completion well cementation is carried out, an annulus below the hanger is sealed, the support is provided for follow-up transformation while a well wall is supported; and the reservoir transformation is combined with a fracturing technology, an oil and gaschannel is enlarged, and the single well yield is increased.

Owner:陕西瑞鹰国际油气工程技术服务有限公司 +1

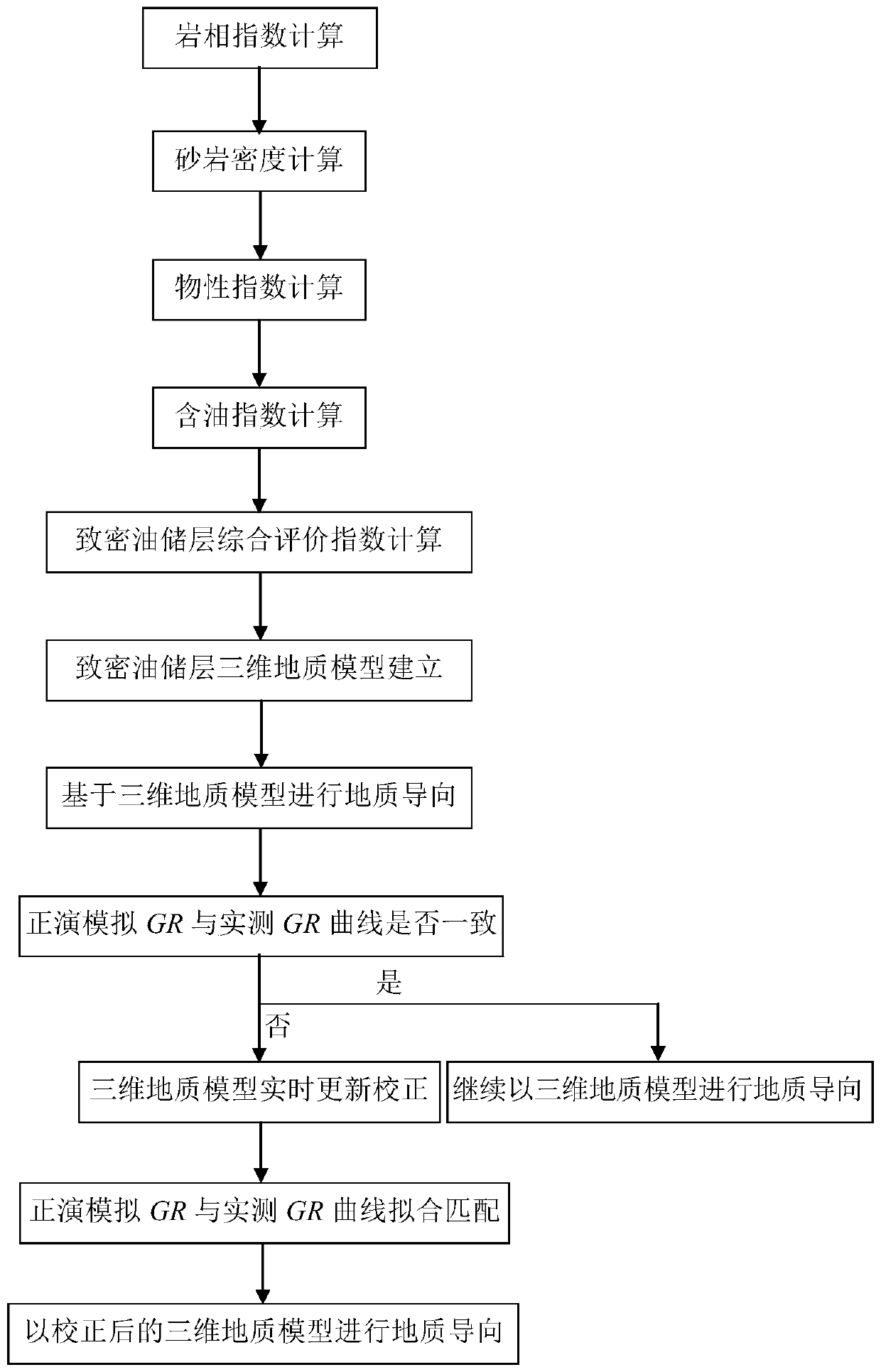

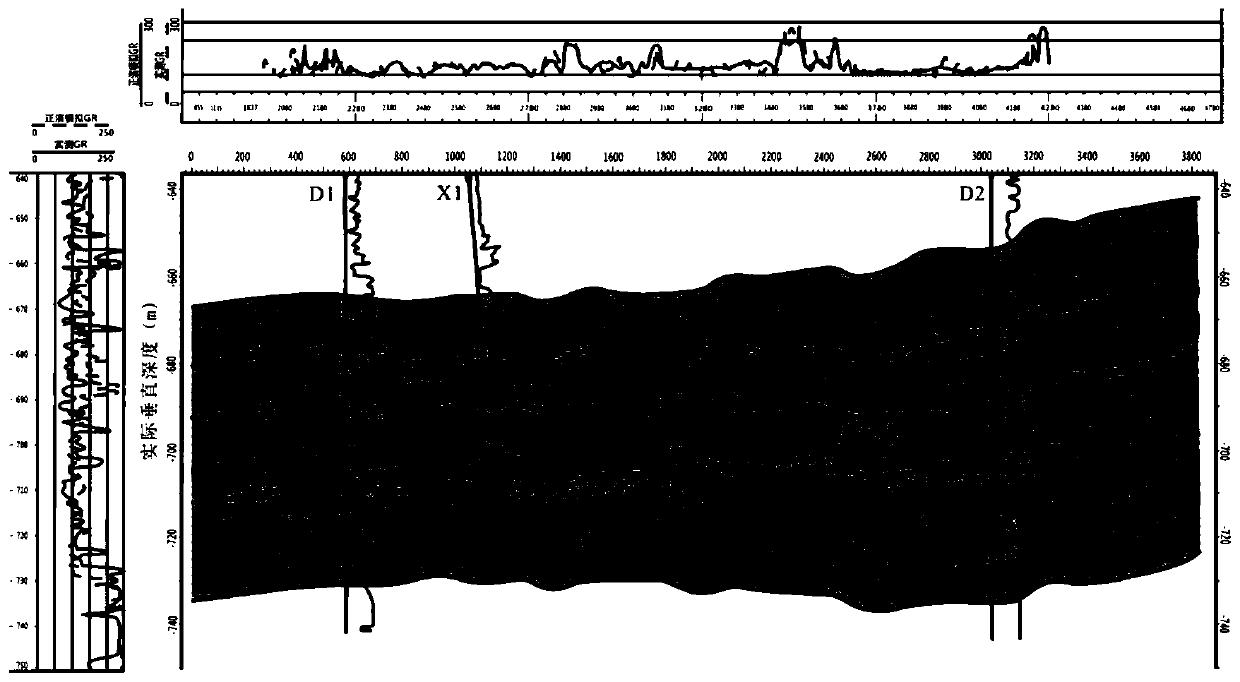

Method for increasing drilling rate of horizontal well tight oil reservoir

ActiveCN110532507AIncrease the encounter rateLow applicabilityDirectional drillingResourcesOil contentTight oil

A method for increasing the drilling rate of a tight oil reservoir of a horizontal well comprises the steps that 1, lithofacies indexes are calculated; 2, calculating the sandstone density of the tight oil reservoir; 3, calculating the physical property index of the tight oil reservoir; 4, calculating the oil content index of the tight oil reservoir; step 5, creating a tight oil reservoir comprehensive evaluation index calculation model; step 6, establishing a three-dimensional geological model of the tight oil reservoir; step 7, geoderivation is carried out based on the tight oil reservoir three-dimensional geologic model; 8, updating and correcting the three-dimensional geologic model of the tight oil reservoir in real time, and guiding the drilling direction according to the updated andcorrected three-dimensional geologic model to improve the drilling rate of the tight oil reservoir of the horizontal well; the geological model provided by the invention is closer to real geologicalcharacteristics, and the drilling rate of the tight oil reservoir is further improved.

Owner:XI'AN PETROLEUM UNIVERSITY

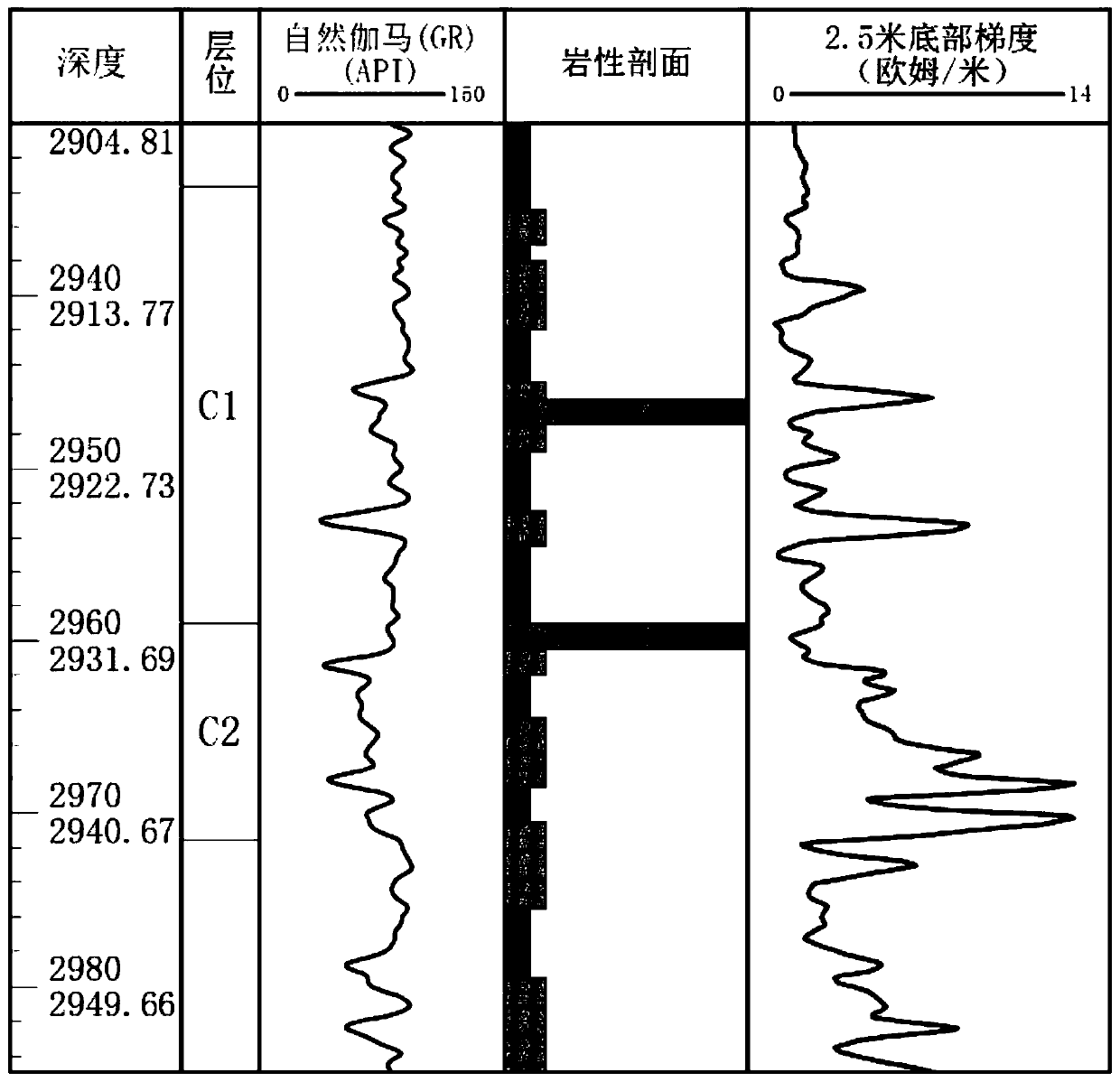

Track while drilling control method of shali shale oil horizontal well

ActiveCN110107282APrecise time-depth relationshipOptimize trajectory while drillingSurveySection planeSeismic velocity

The invention discloses a track while drilling control method of a shali shale oil horizontal well. The track control while drilling method includes the following steps that (1) an optimal synthetic seismic trace is determined, and according to the seismic velocity of the sweet spot section the horizontal well, a seismic sweet spot time window is generated; (2) a standard logging response curve atthe sweet spot section is established by using the corresponding form of a well log of a known well, and a prediction logging curve is generated according to a designed track of the shale oil horizontal well; and (3) in the process of while drilling, according to a real-time logging curve, and in reference to a logging absolute value and the variation amplitude of a marker bed section, a track while drilling is adjusted in time. The track while drilling control method has the beneficial effects that (1) in the case of human intervention, a more accurate time-depth relationship is established;(2) on the basis of time-depth relationship establishment, the seismic profile position of the top and bottom of a sweet spot is calculated, the sweet spot time window is determined, and during drilling, the track while drilling is optimized by projecting the position of a drill bit in real time; and (3) a formation standard logging curve of the area is established by using the known well and theformation dip angle, the track is adjusted in time, and the reservoir drilling rate is increased.

Owner:PETROCHINA CO LTD

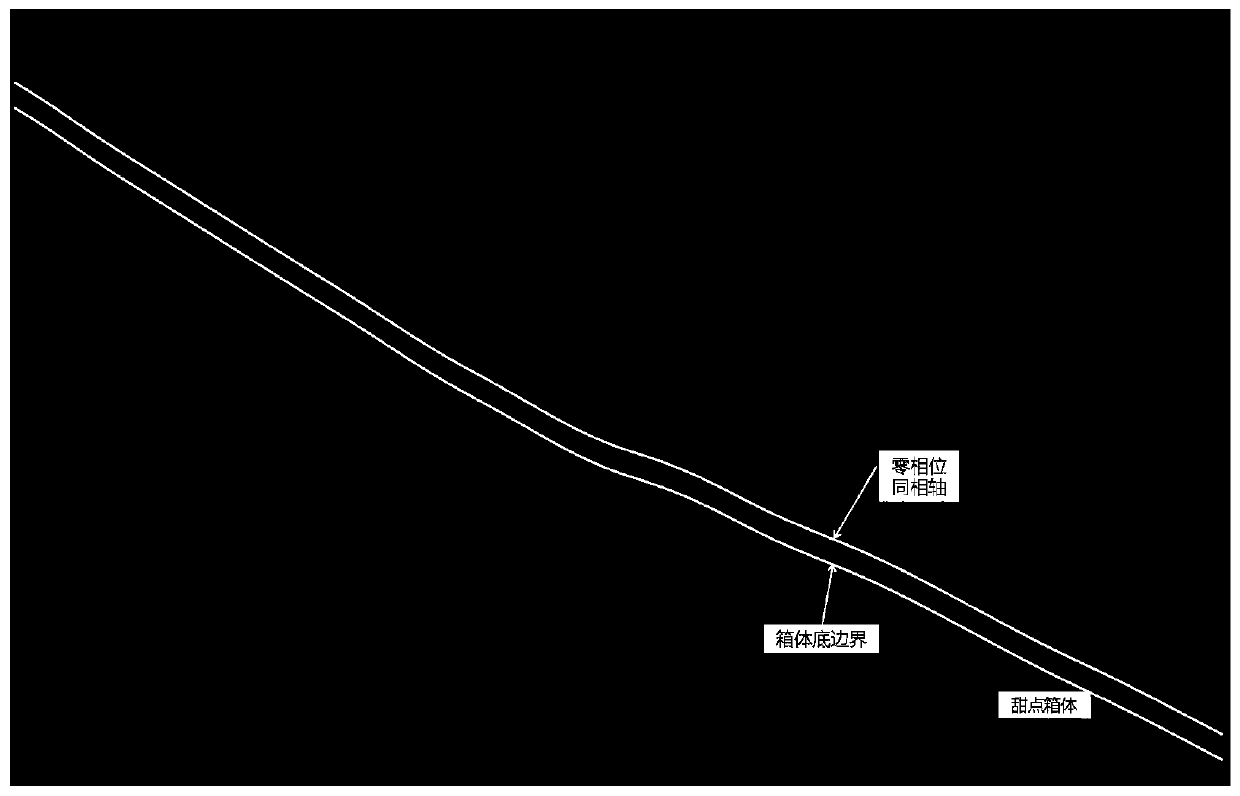

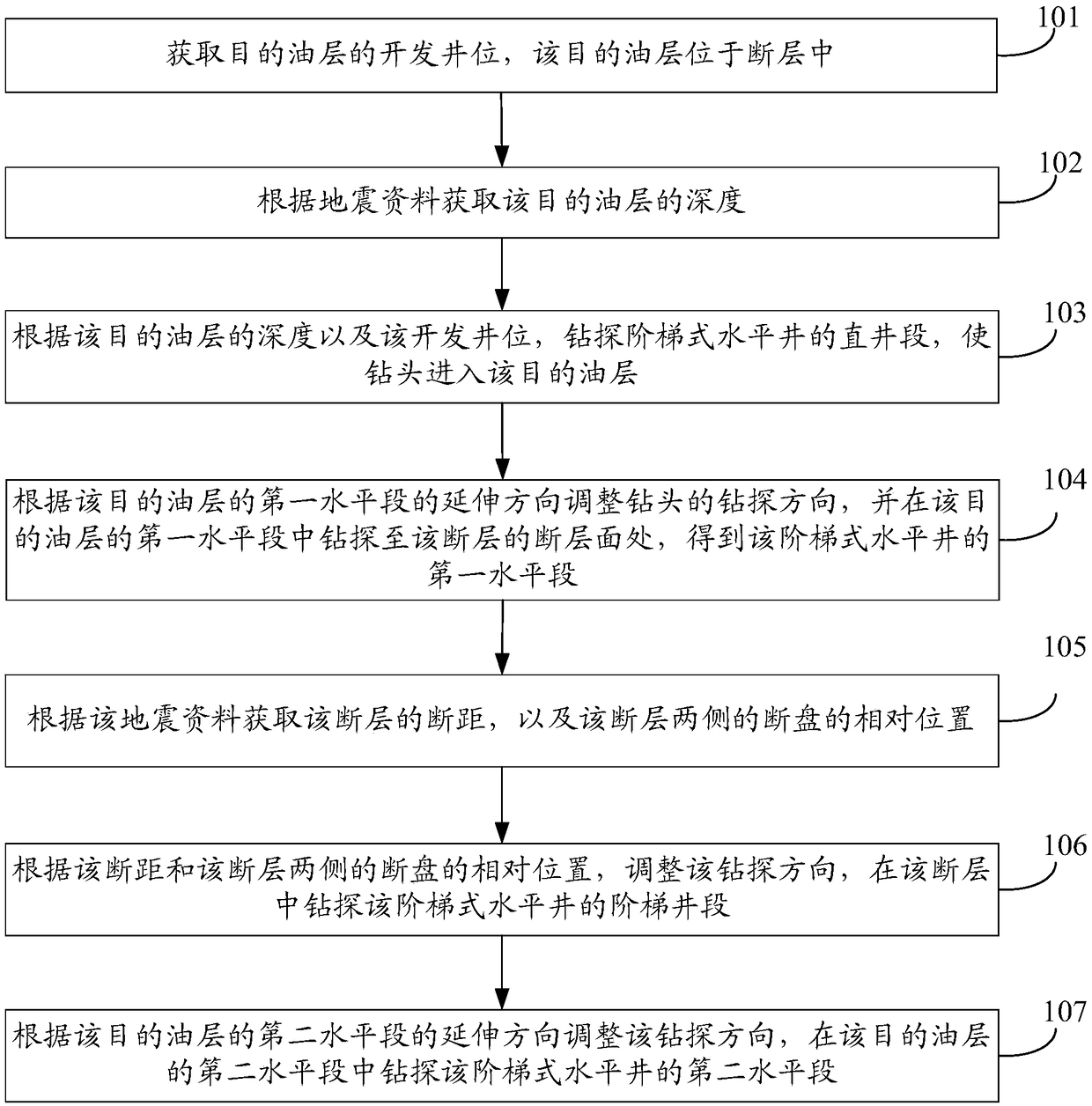

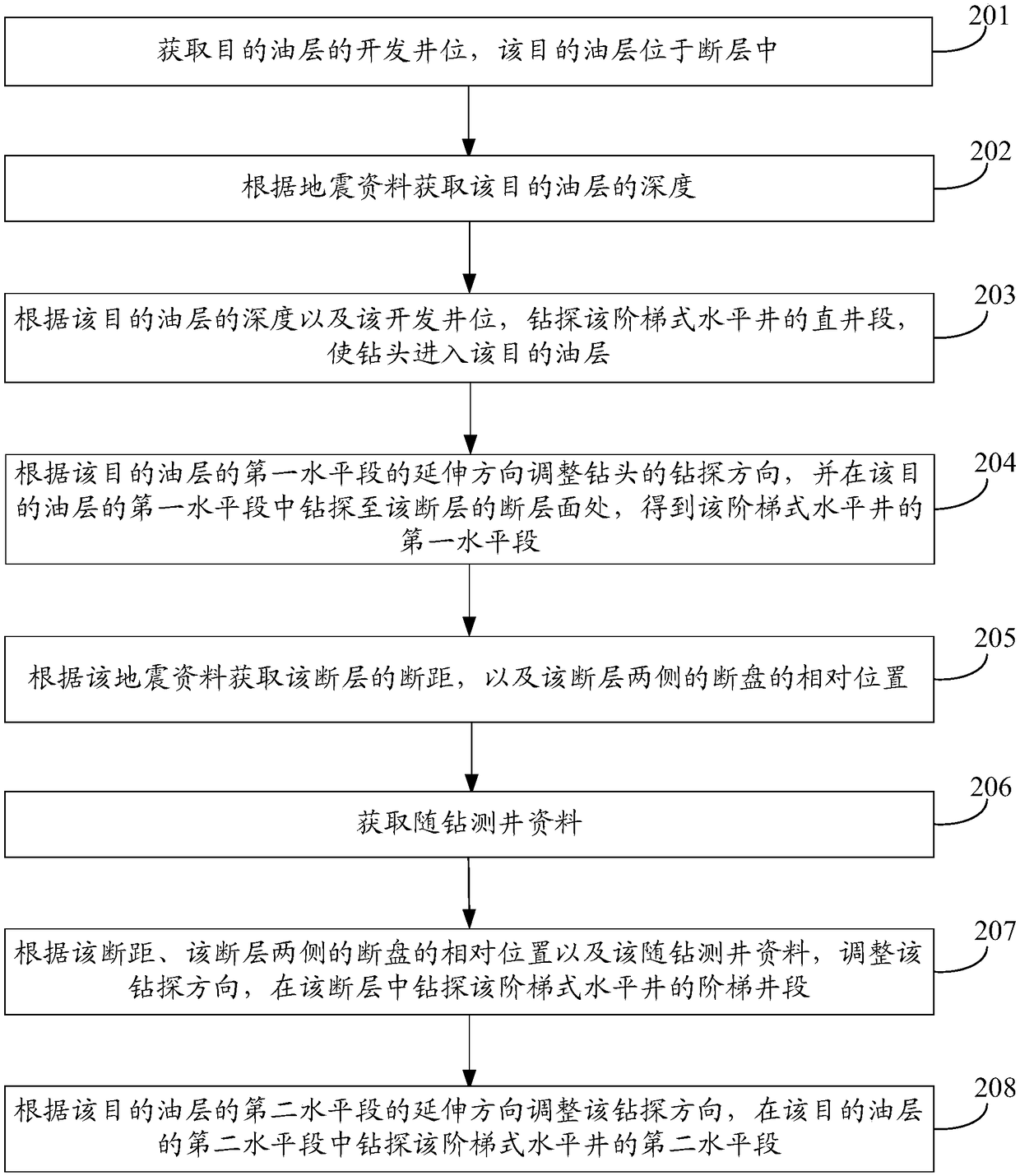

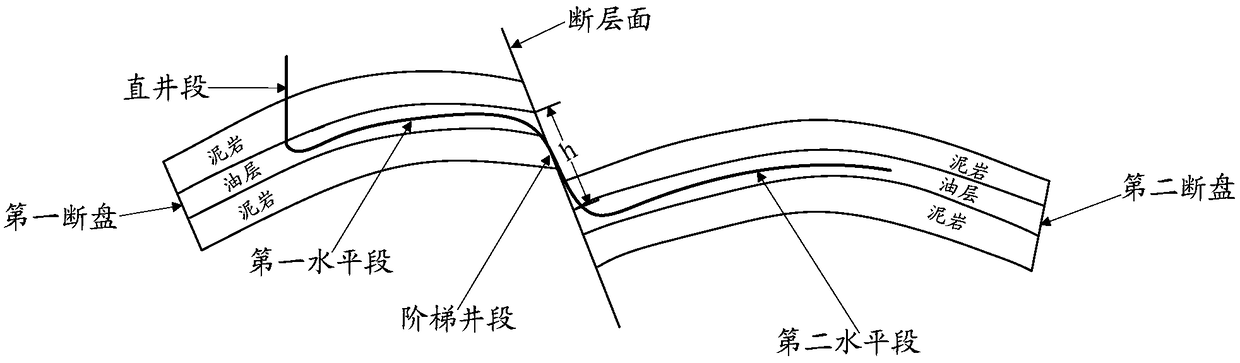

Method and device for controlling wellbore trajectory of stepped horizontal well

ActiveCN109184560AHigh control precisionIncrease the encounter rateDirectional drillingAutomatic control for drillingWellboreDrill bit

The invention discloses a method and a device for controlling the wellbore trajectory of a stepped horizontal well, which belong to the field of oilfield exploitation. The method includes the following steps: acquiring the depth of a target oil reservoir, the change of the dip angle of the target reservoir, the fault distance of a fault and the relative positions of fault plates according to the seismic data; and by starting from the development well location of the target oil reservoir, continuously adjusting the drilling direction of the drill bit to complete the drilling of a straight section, a first horizontal section, a stepped section and a second horizontal section of the stepped horizontal well. The depth of the target oil reservoir, the fault distance of the fault and the relative positions of the fault plates on the two sides of the fault can be acquired in advance according to the seismic data. Therefore, the drilling distance and direction can be adjusted directly in the process of drilling according to the data acquired in advance, the drill bit can enter the target oil reservoir accurately and enter the second horizontal section of the target oil reservoir from the first horizontal section of the target oil reservoir, and the control accuracy of the wellbore trajectory of the stepped horizontal well is improved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com