Method for gas extraction through bedding directional long drill hole traversing working face in broken and soft coal seam

A technology of gas drainage and long boreholes, which is applied in the fields of long borehole gas drainage and directional long borehole gas drainage in broken soft coal seams, to achieve low entry resistance, increase utilization rate, and increase borehole depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

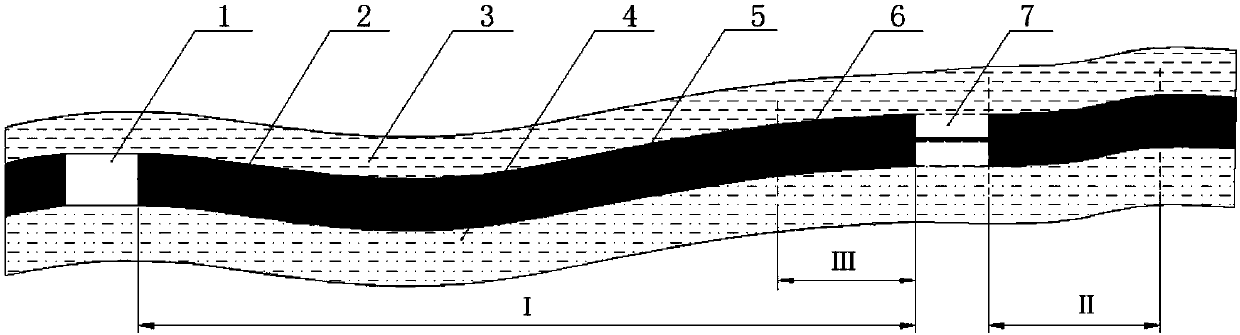

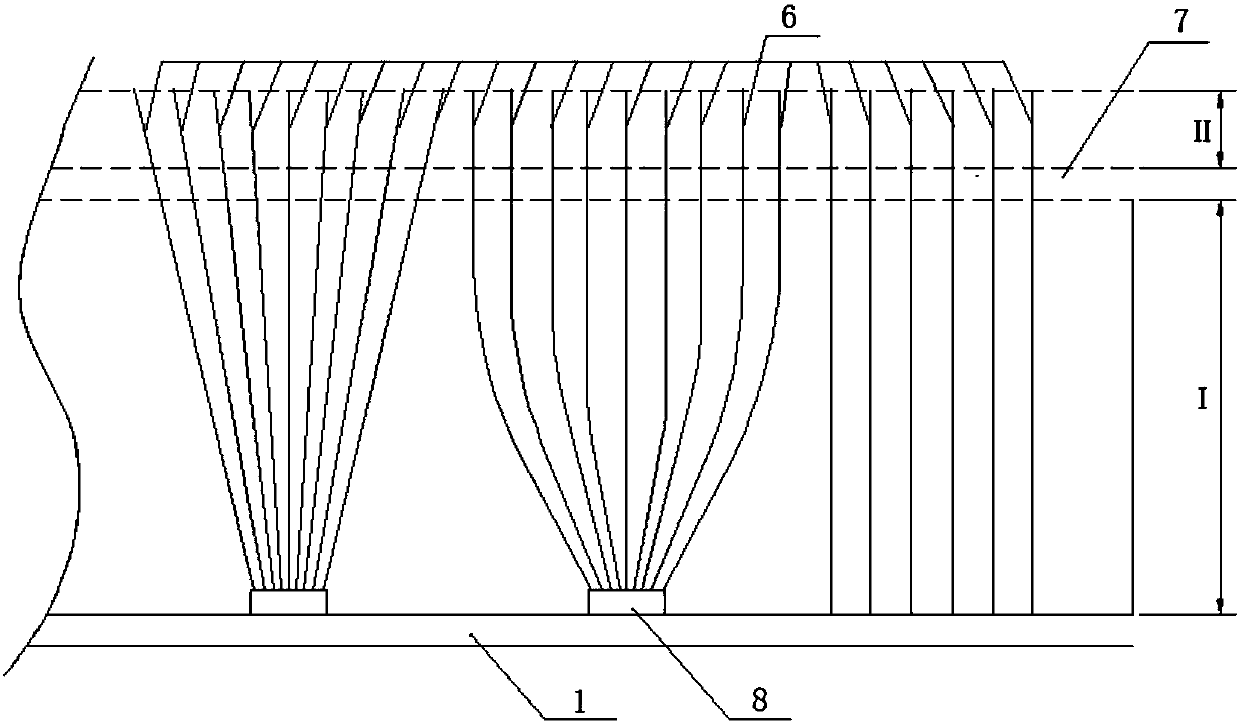

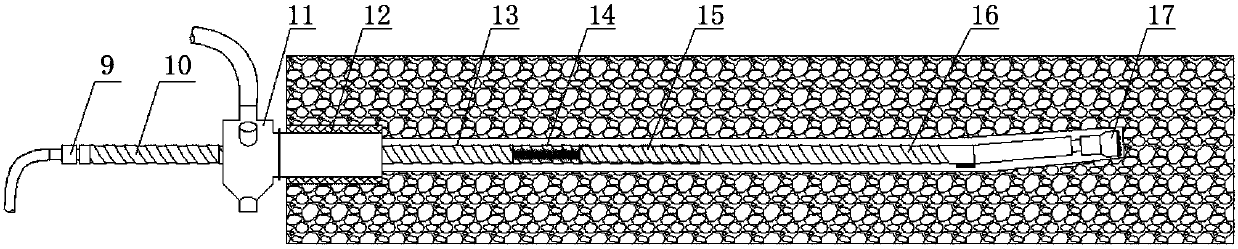

[0040] Step 1: Design of directional long boreholes for bedding gas drainage in broken and soft coal seams

[0041] The drilling design is carried out according to the requirements of gas drainage, and the drilling depth requirement is: from the excavated roadway (1) through the coal mining face (I) to the roadway to be excavated (7), while ensuring the length of the roadway (7) Not less than the required control range (Ⅱ) of roadway excavation, generally 15m or 20m, which meets the requirements of coal mine safety regulations and outburst prevention regulations. In terms of borehole layout, combined with actual conditions and needs, the designed boreholes (6) can be arranged in parallel, fan-shaped, or several combinations; the distance between boreholes (6) is determined by the gas drainage radius R (the distance between boreholes ≤2R).

[0042] Borehole inclination: The inclination of the drill hole (6) at different depths is determined according to the undulation of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com