Drilling device for road construction and using method thereof

A technology for drilling device and road construction, applied in drilling equipment and methods, support device, earthwork drilling and other directions, can solve the problems of complex shock absorption mechanism, increase drilling cost, drill bit shaking, etc., and reduce the workload of workers , Reduce the cost of punching and improve the effect of punching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

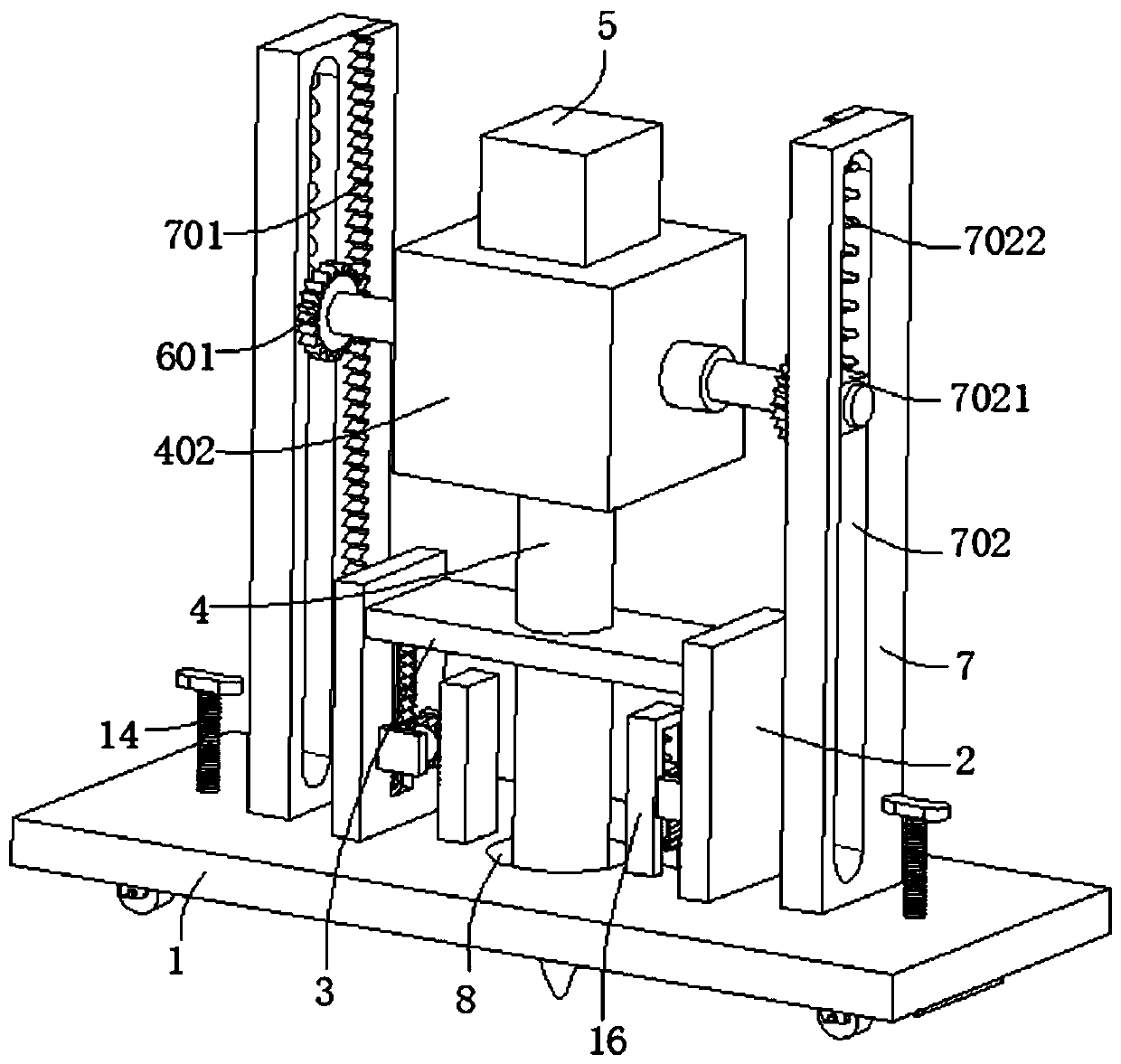

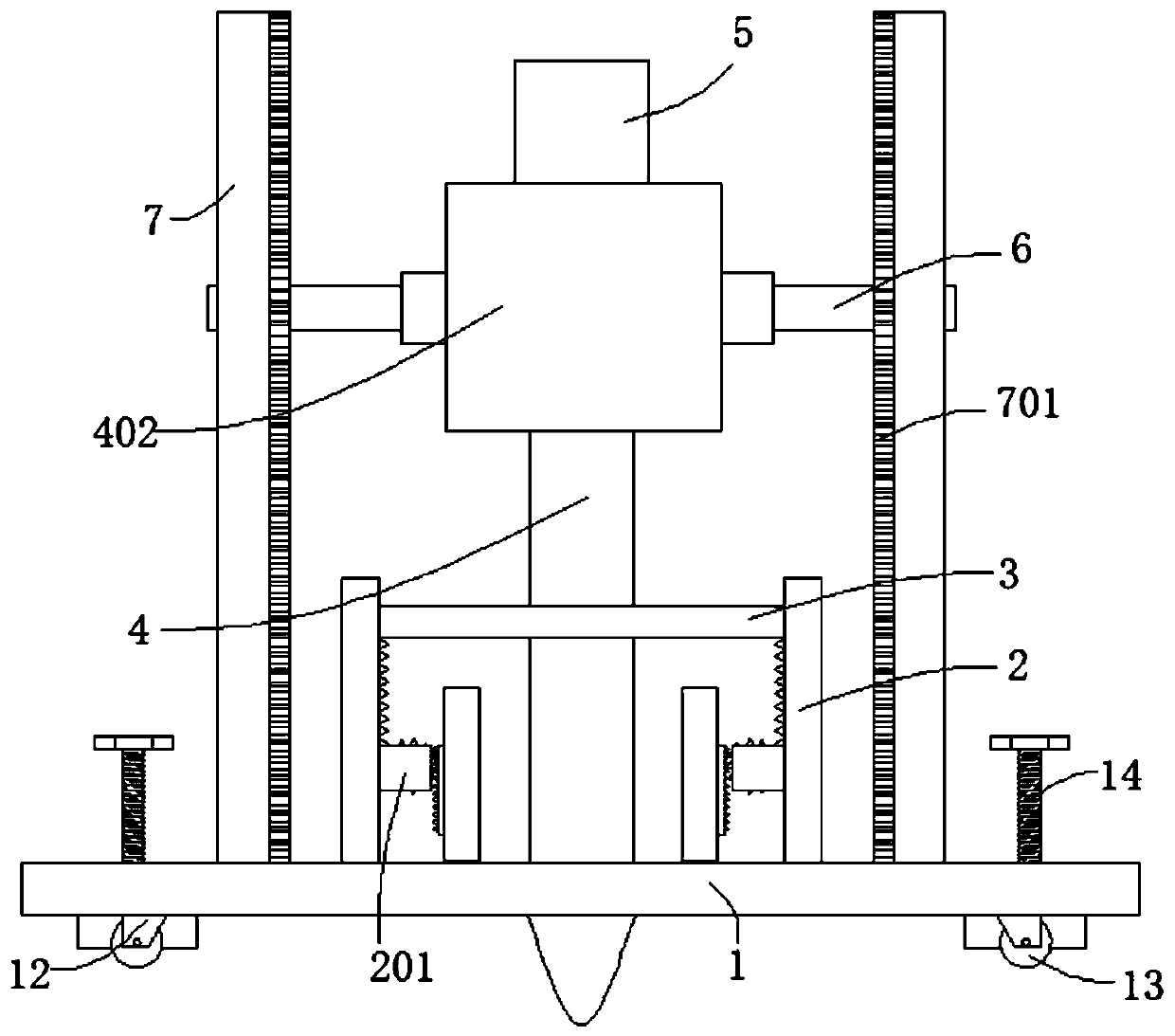

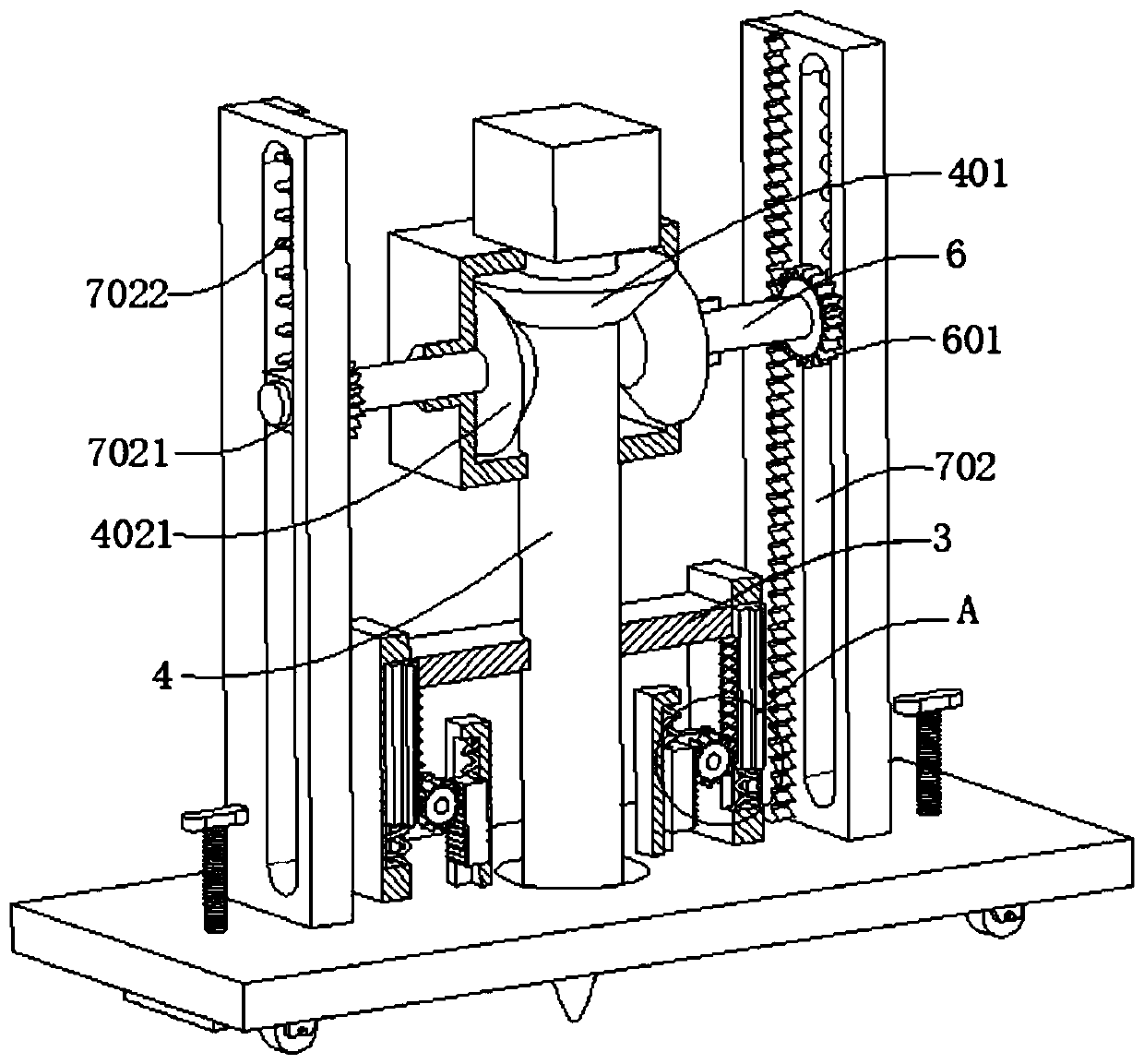

[0036] refer to figure 1 , figure 2 , image 3 and Figure 6, a drilling device for road construction, comprising a base 1, a first vertical plate 2 is connected to both sides of the top of the base 1, a shock absorbing plate 3 is connected between the two first vertical plates 2, and inside the shock absorbing plate 3 Slidingly connected with a rotating shaft 4, the outer wall of the rotating shaft 4 is rotatably connected with a casing 402 through a bearing, the outer wall of the rotating shaft 4 is connected with a first bevel gear 401, and the inner wall of the casing 402 is rotatably connected with a second bevel gear 401 that meshes with the first bevel gear 401. The bevel gear 4021 is connected with the motor 5 on the top of the box 402, the output end of the motor 5 is connected with the rotating shaft 4, and the end of the rotating shaft 4 away from the motor 5 is detachably connected with a drill bit 403, and the outer wall of the second bevel gear 4021 is connect...

Embodiment 2

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 , a drilling device for road construction, which is basically the same as Embodiment 1, furthermore, the outer wall of the first vertical plate 2 is dug with a second groove 9, and the inner wall of the second groove 9 is slidably connected with a second rack plate 901, the second rack plate 901 is fixedly connected to the outer wall of the shock absorbing plate 3, and a second elastic element 902 is connected between the bottom wall of the second rack plate 901 and the inner wall of the second groove 9, and the second groove 9 The inner walls of both sides are dug with chute 903, the inner wall of chute 903 is slidably connected with slider 9011, the slider 9011 is fixedly connected with the outer wall of the second rack plate 901, and the outer wall of the first vertical plate 2 is connected with two side plates 201, A fixed rod 202 is rotatably connected between the two side plates 201, and the ou...

Embodiment 3

[0042] refer to Figure 1-7 , a drilling device for road construction, basically the same as embodiment 1, furthermore, the bottom of the base 1 is connected with a fixed block 12, the fixed block 12 is connected with a roller 13 for rotation, and the inner thread of the base 1 is connected with a threaded rod 14. The top of the threaded rod 14 is connected with a handle 141, and the end of the threaded rod 14 away from the handle 141 is connected with a connecting plate 142, and the connecting plate 142 is connected with a rotating shaft 1421 for rotation, and the outer wall of the rotating shaft 1421 is connected with a rubber block 15, and the rubber block 15 The bottom wall is provided with anti-slip lines; move the device to the area where holes need to be punched through the roller 13, and after reaching the designated position, turn the handle 141 to make the handle 141 drive the threaded rod 14 to rotate, so that the threaded rod 14 moves down relative to the base 1, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com