Patents

Literature

171 results about "Pre extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

User authentication using biometric information

InactiveUS20070036400A1High precisionEfficiently retrieve the reference biometric informationCharacter and pattern recognitionData matchingUser verification

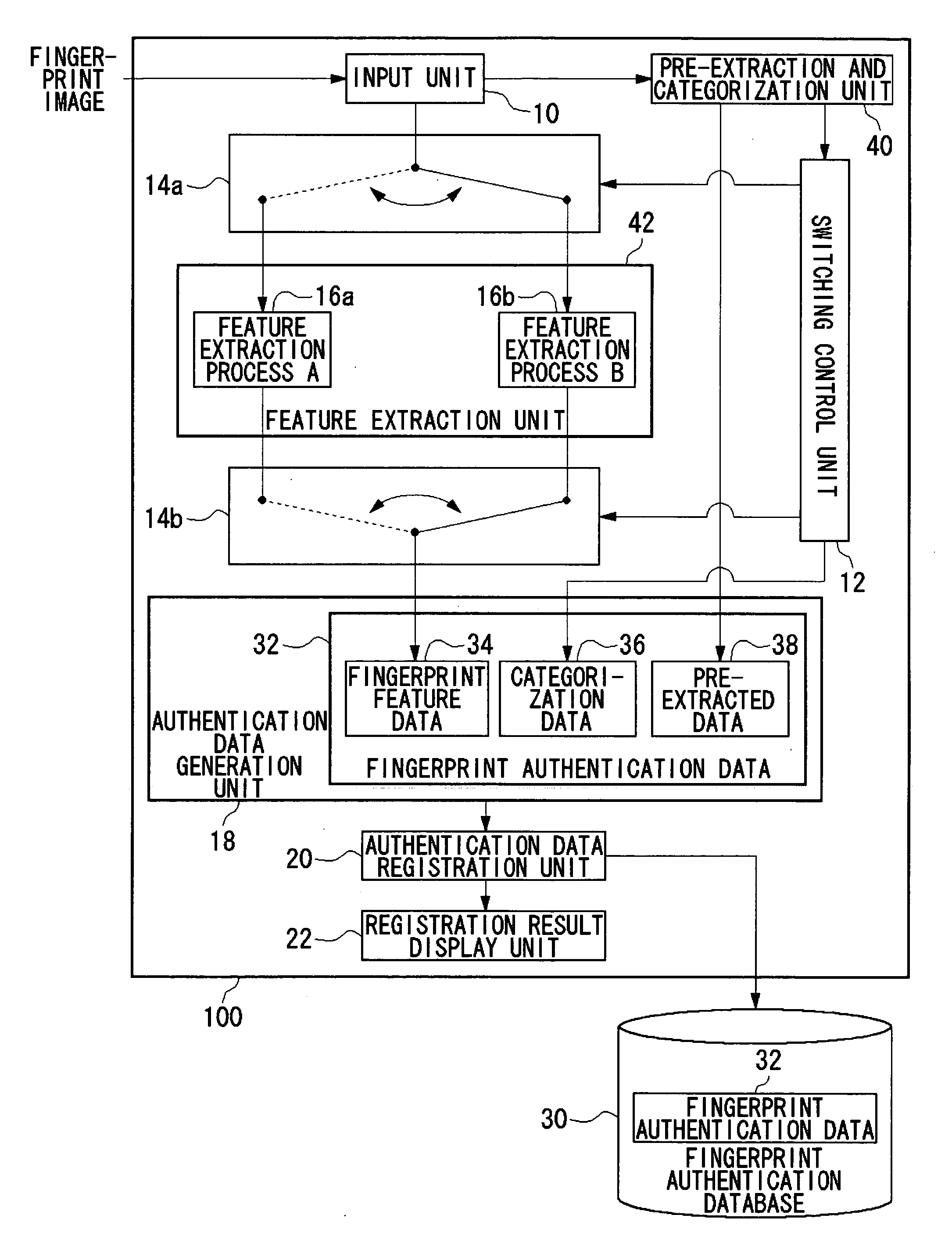

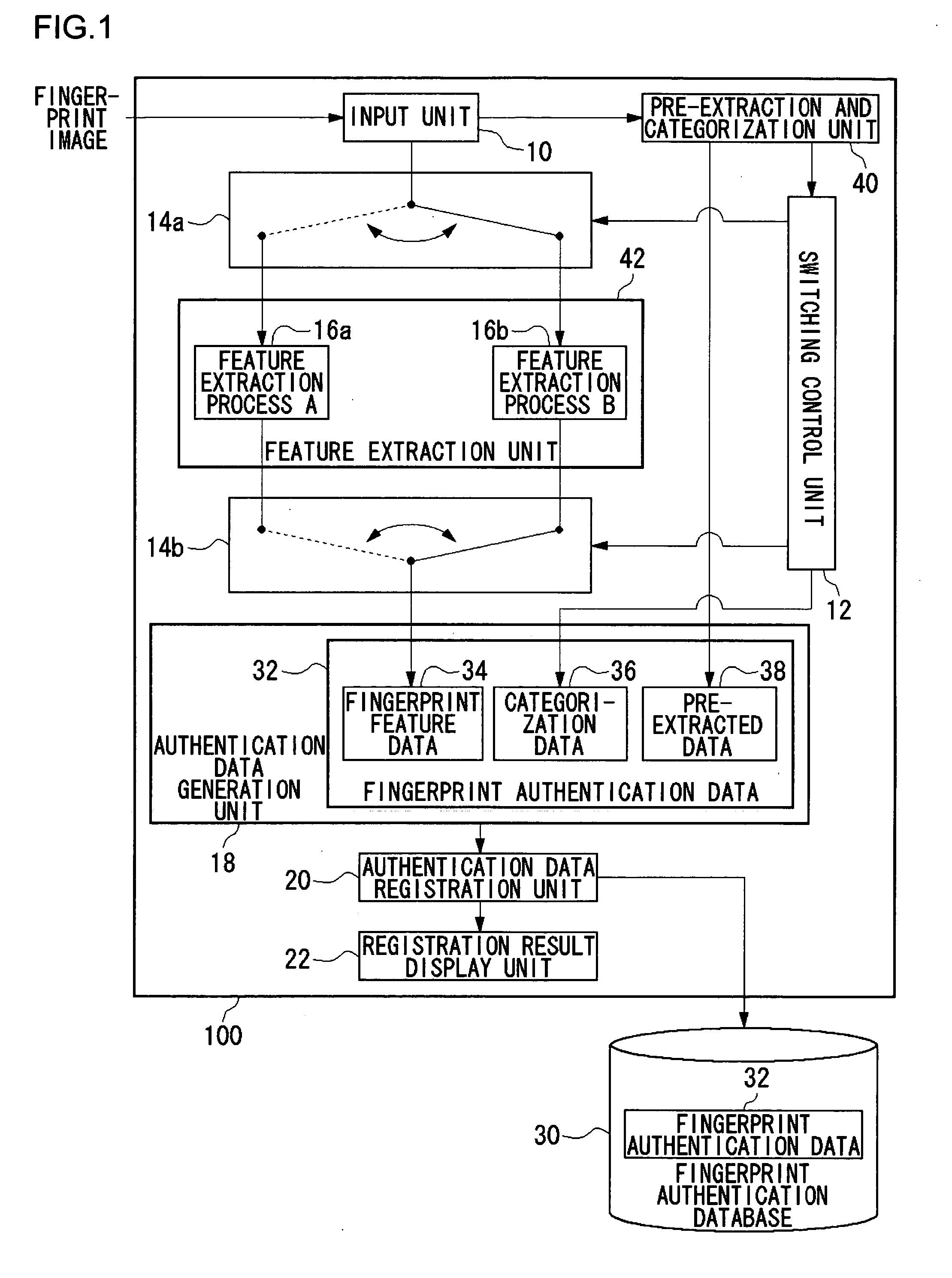

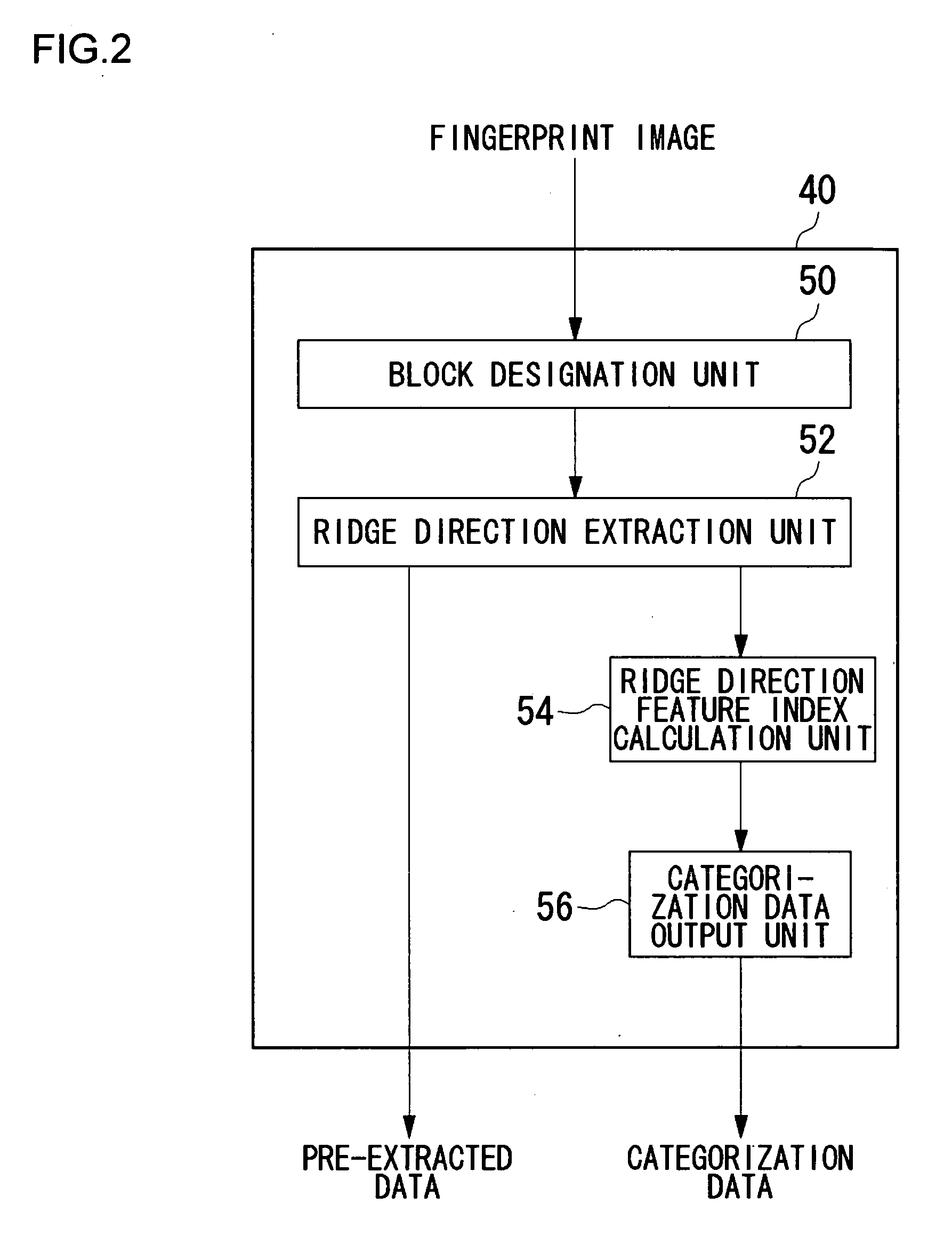

An input unit accepts a fingerprint image of a user. A pre-extraction and categorization unit generates pre-extracted data from the fingerprint image and uses the data to categorize the input fingerprint image into one of multiple groups. A feature extraction unit extracts fingerprint feature data from the fingerprint image by processing methods defined for the respective groups. A feature data matching processing unit matches the fingerprint feature data against fingerprint authentication data registered in a fingerprint authentication database by processing methods defined for the respective groups. An integrated authentication unit authenticates a user with the input fingerprint image based upon a result of matching.

Owner:SANYO ELECTRIC CO LTD

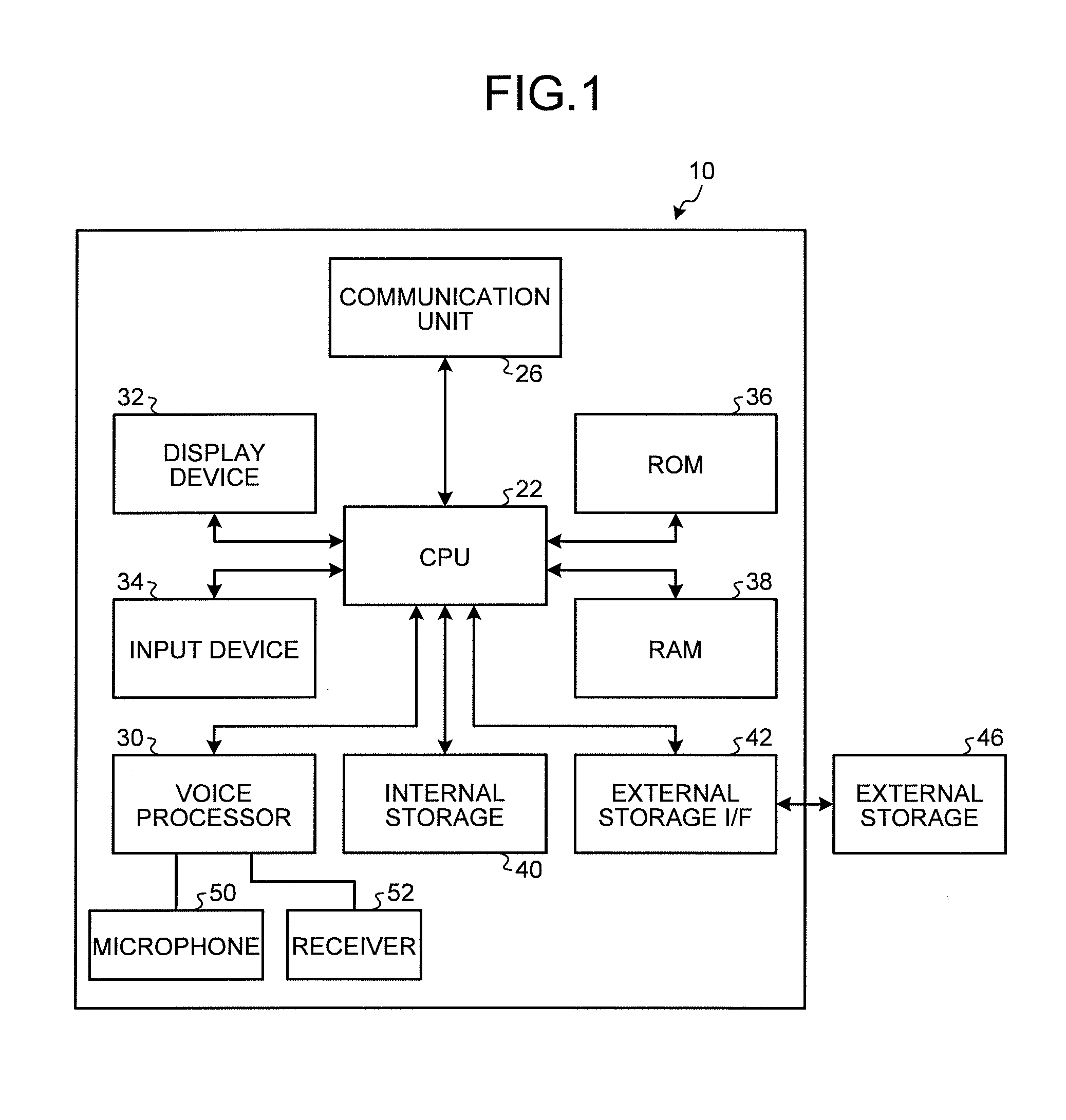

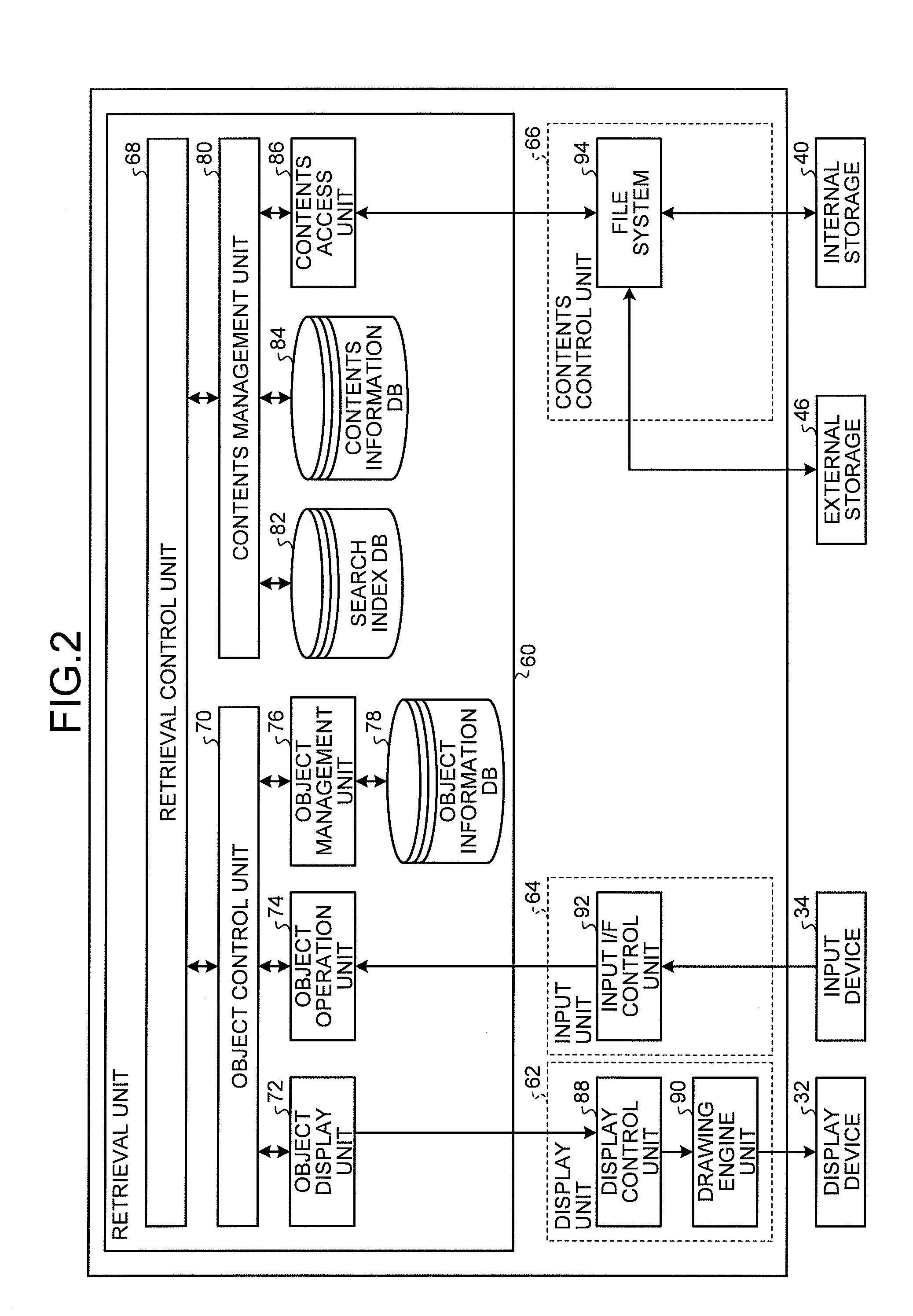

Communication device and electronic device

ActiveUS20120098780A1Easy to operateMetadata multimedia retrievalStill image data browsing/visualisationElectric equipmentCommunication device

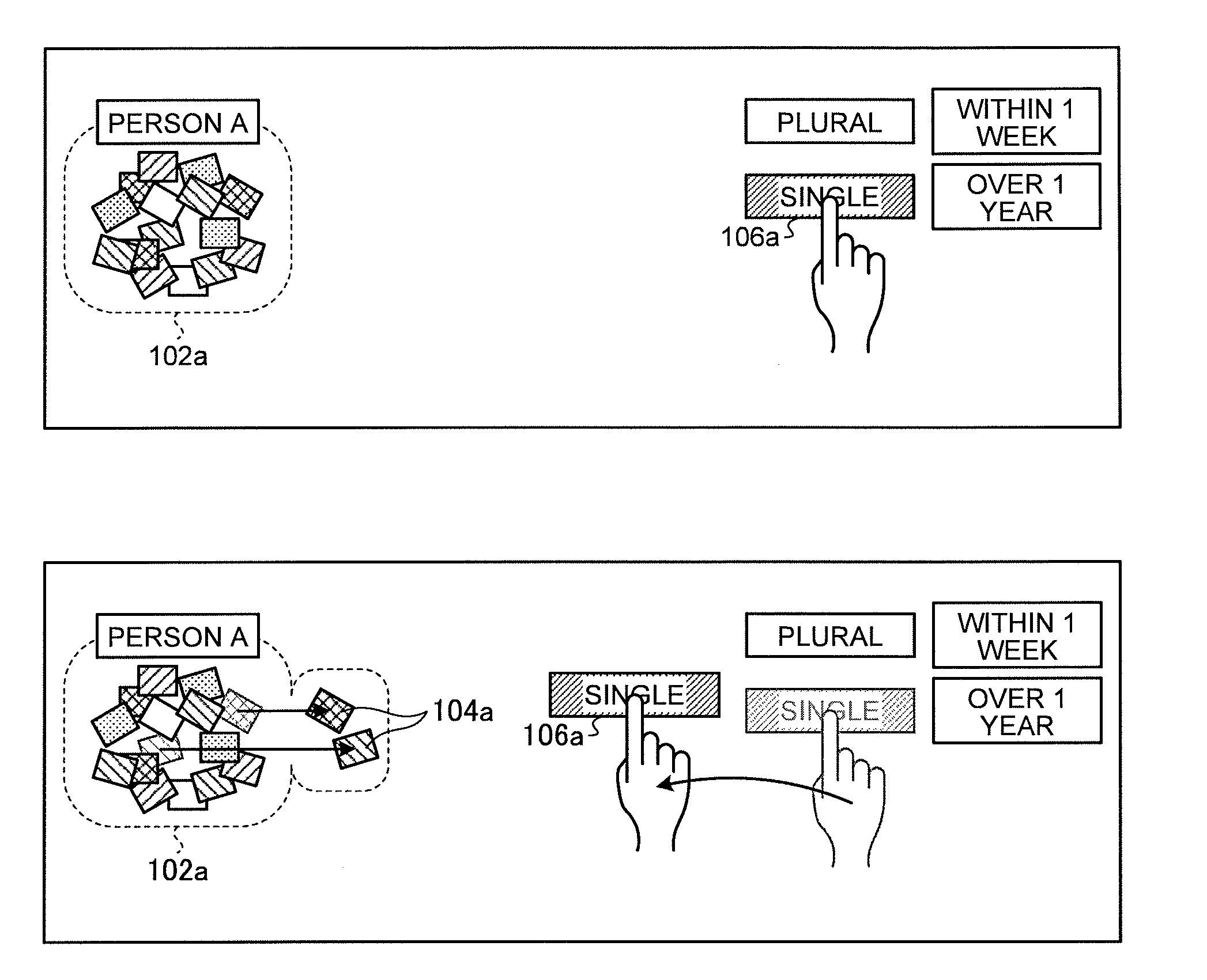

An electronic device or a communication device including a display unit for displaying an image, an input detector for detecting an input instruction input by touching an area where the image is displayed by the display unit, and a control unit for providing control based on the input instruction detected by the input detector and for providing control for an image to be displayed on the display unit. When the display unit displays a pre-extraction group object containing a plurality of item objects on its screen, and when the input detector detects an input of a predetermined instruction to refine the pre-extraction group object, the control unit extracts a group of item objects that match a refinement criterion in the input instruction, and displays the group as a post-extraction group object on the screen of the display unit.

Owner:KYOCERA CORP

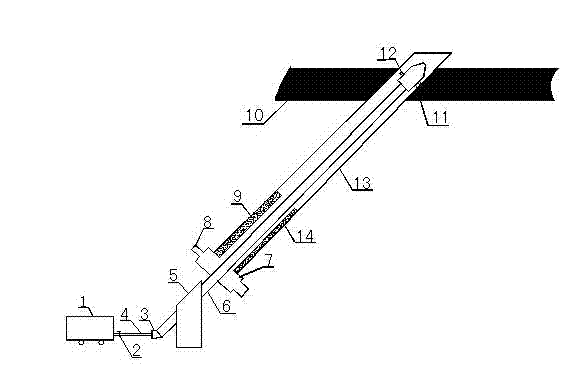

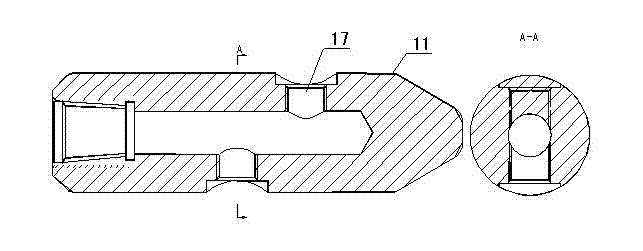

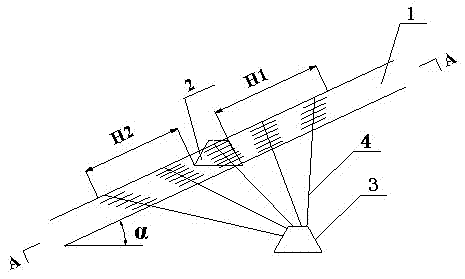

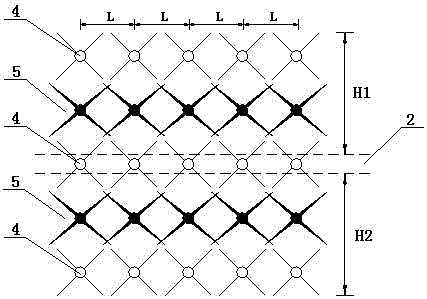

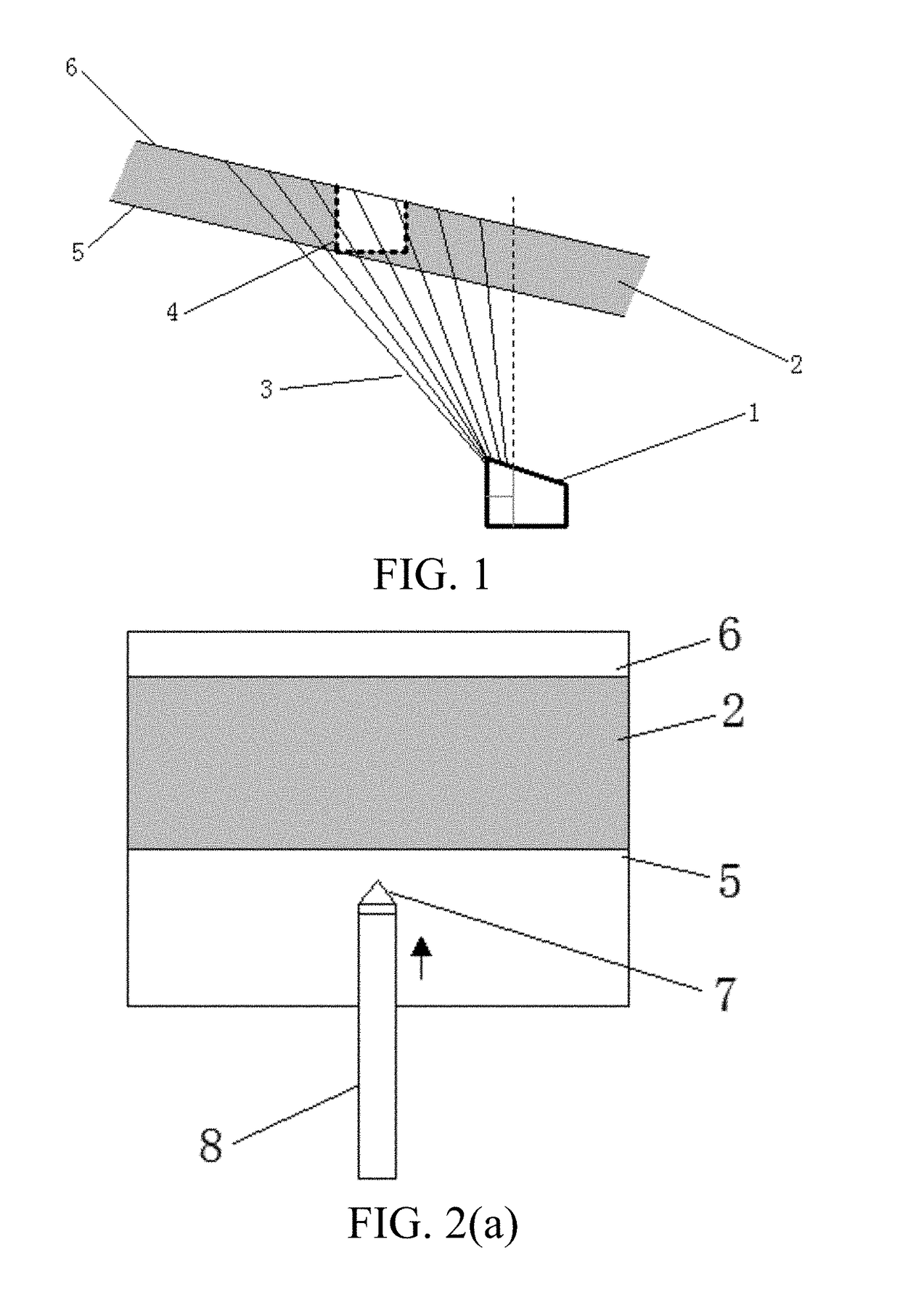

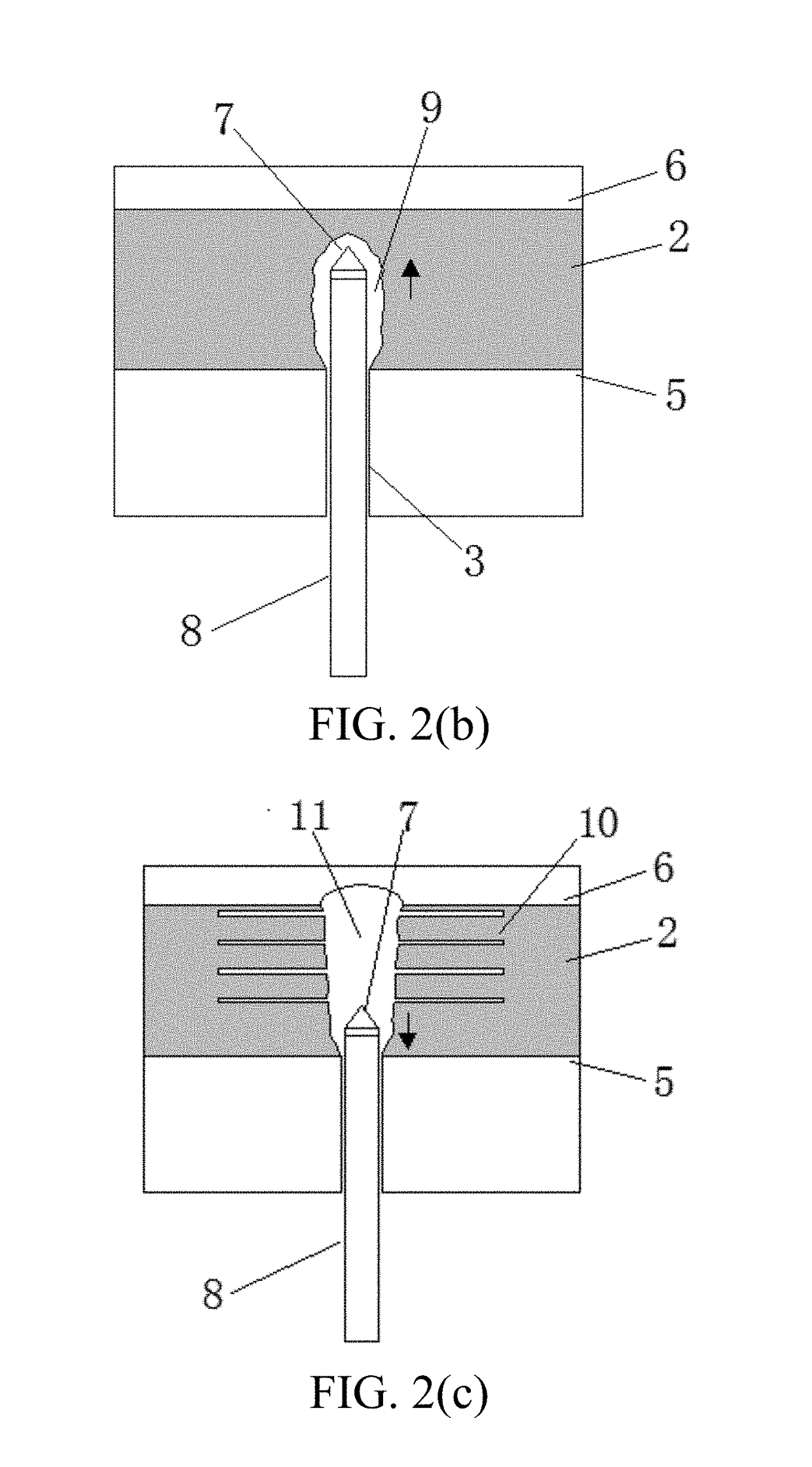

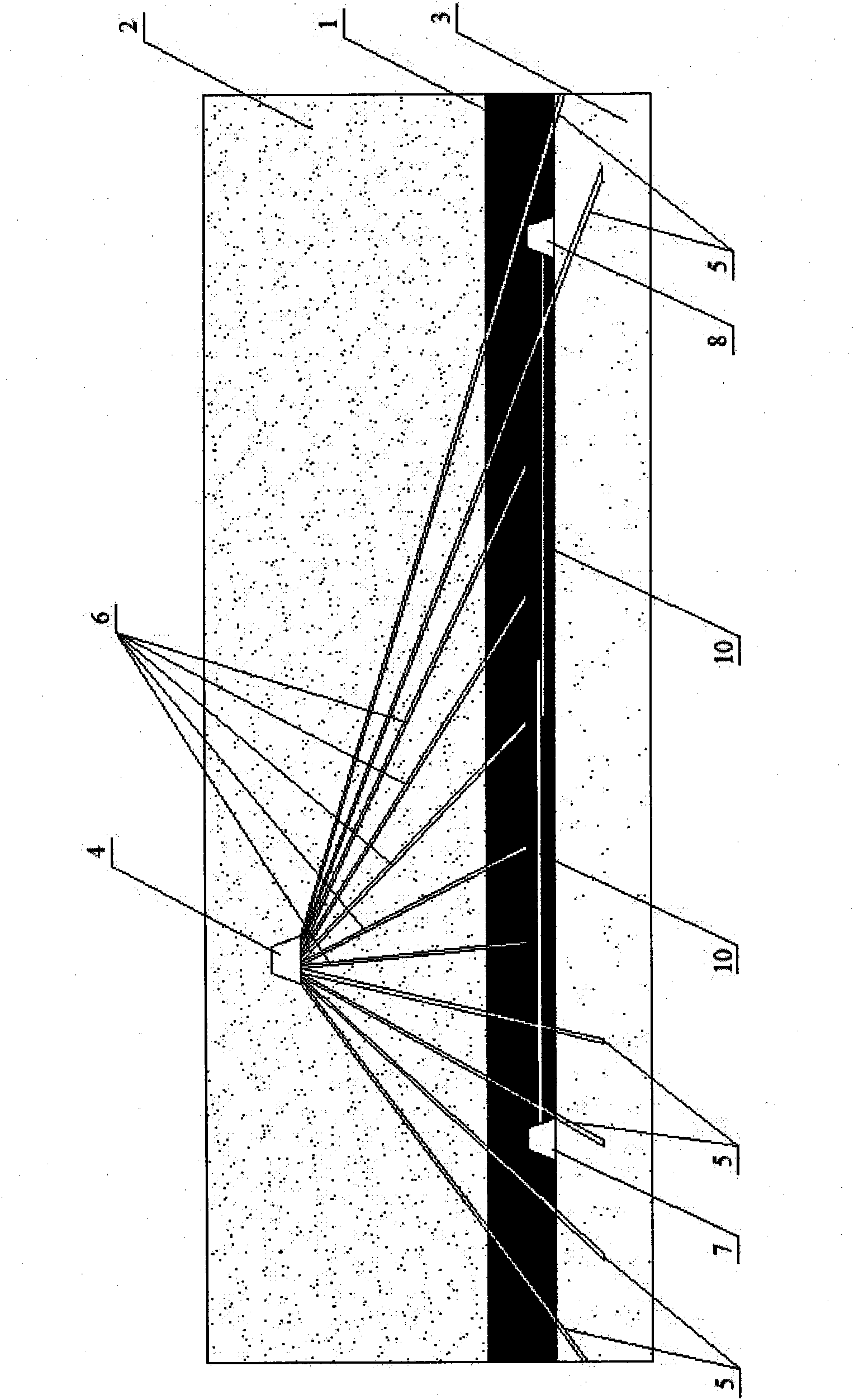

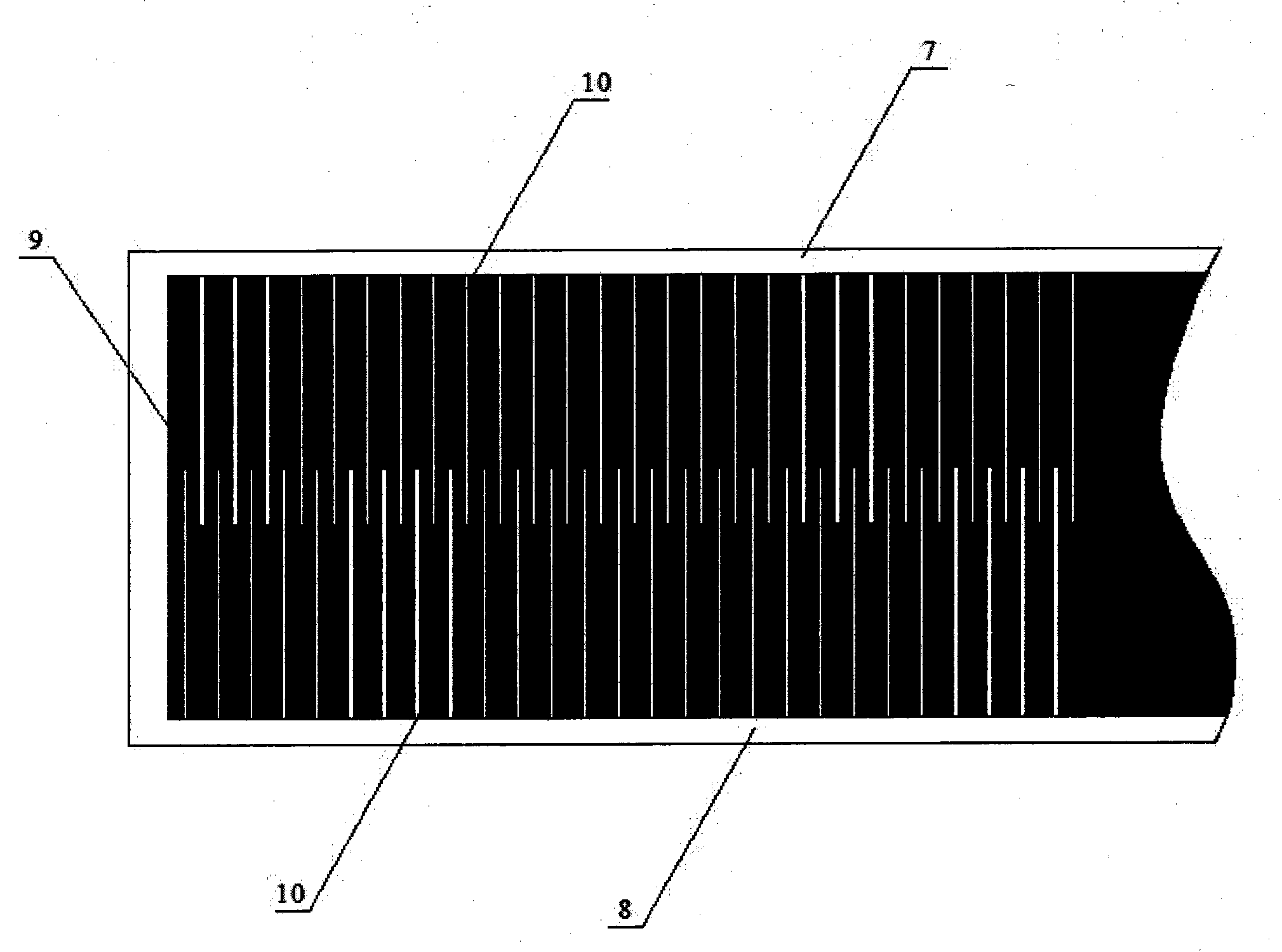

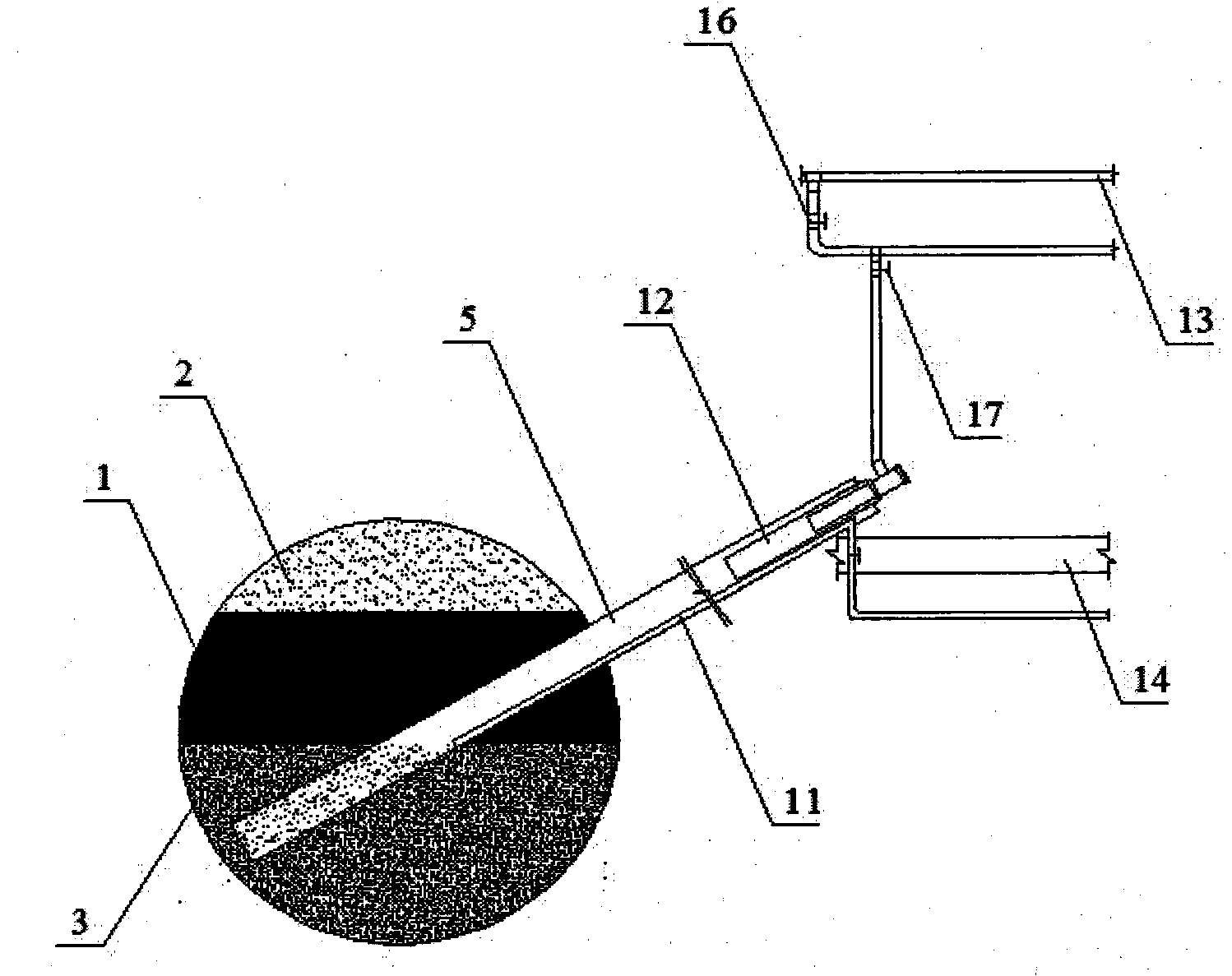

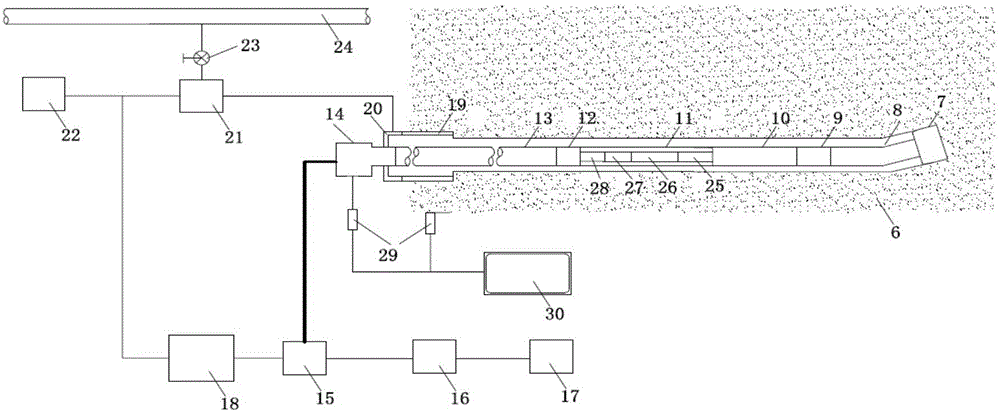

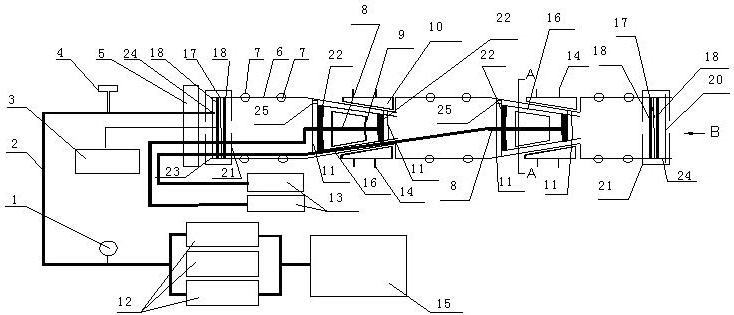

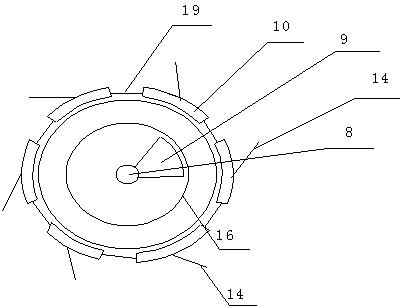

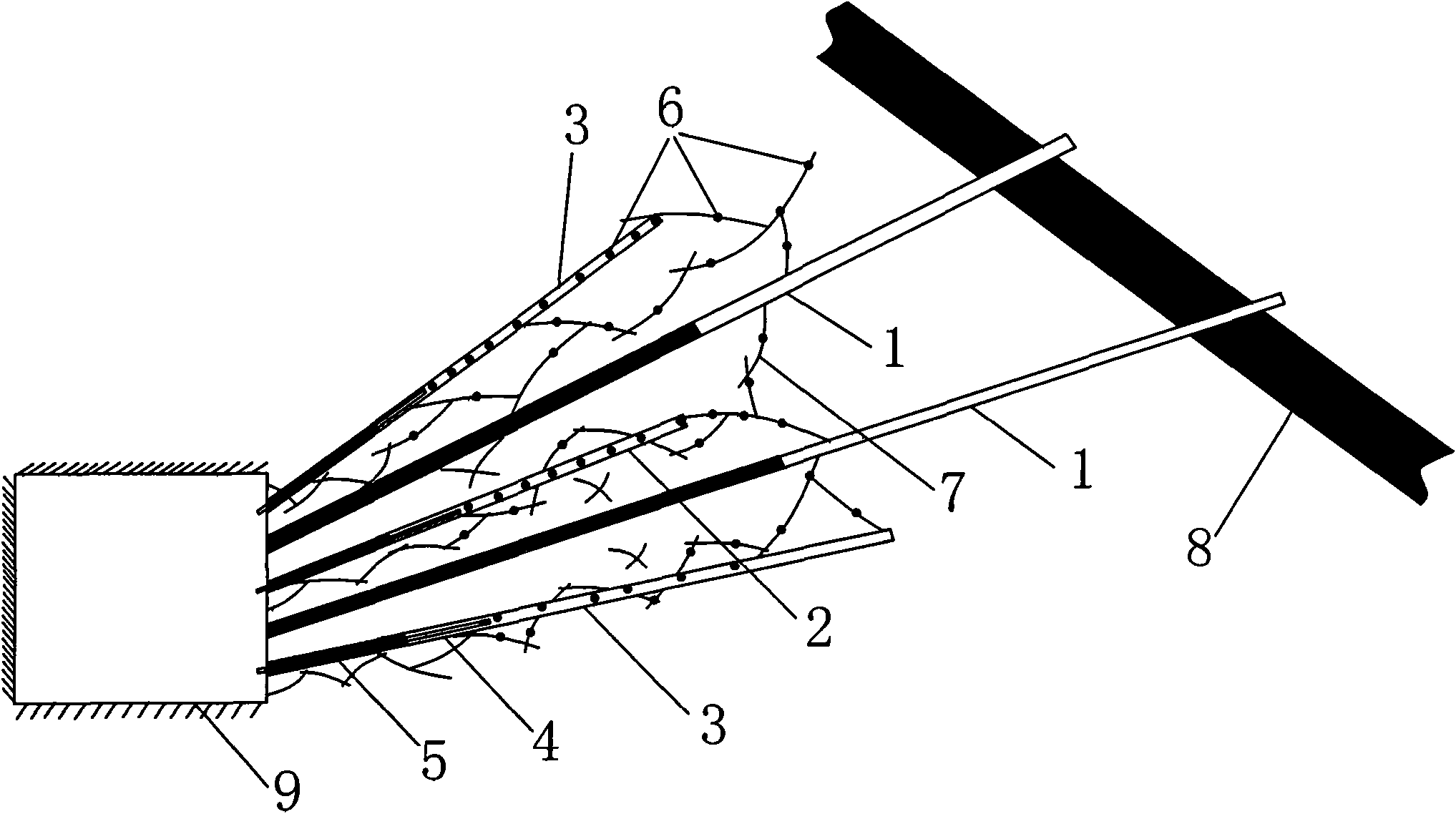

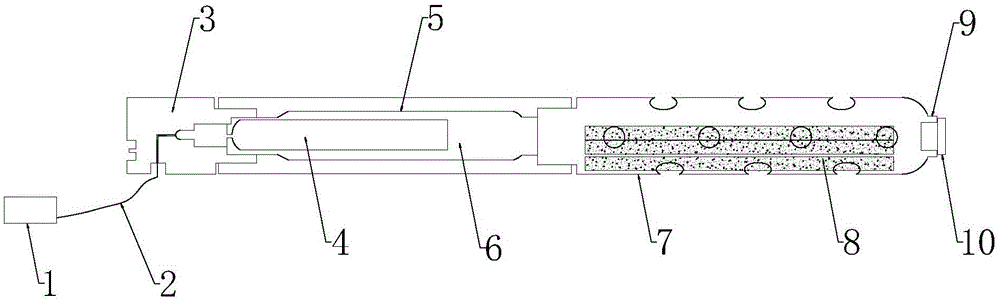

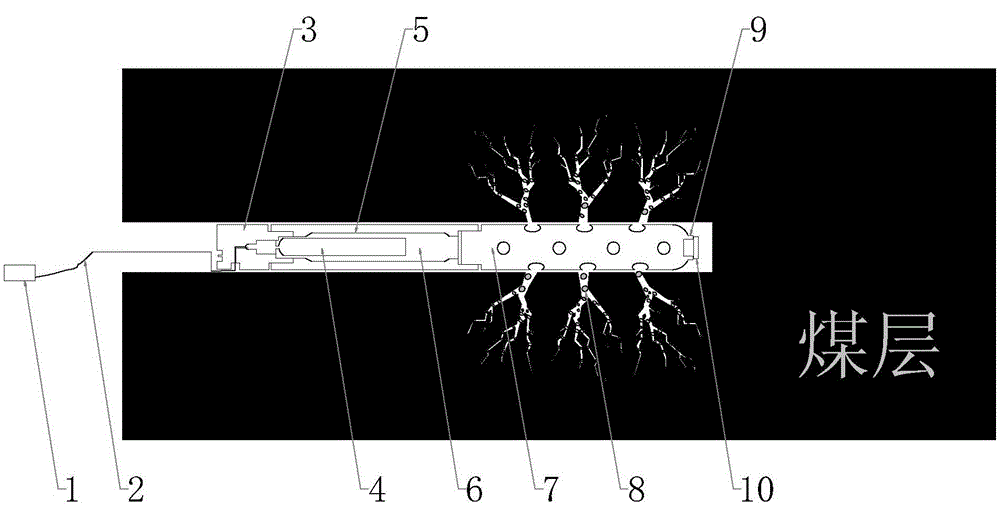

Coal seam reaming system using three-dimensional (3D) swirling water jet and reaming and fracturing method for permeability enhancement

InactiveCN102213077AEasy to crackLarge range of pressure reliefDrill bitsConstructionsHydraulic pumpHigh pressure water

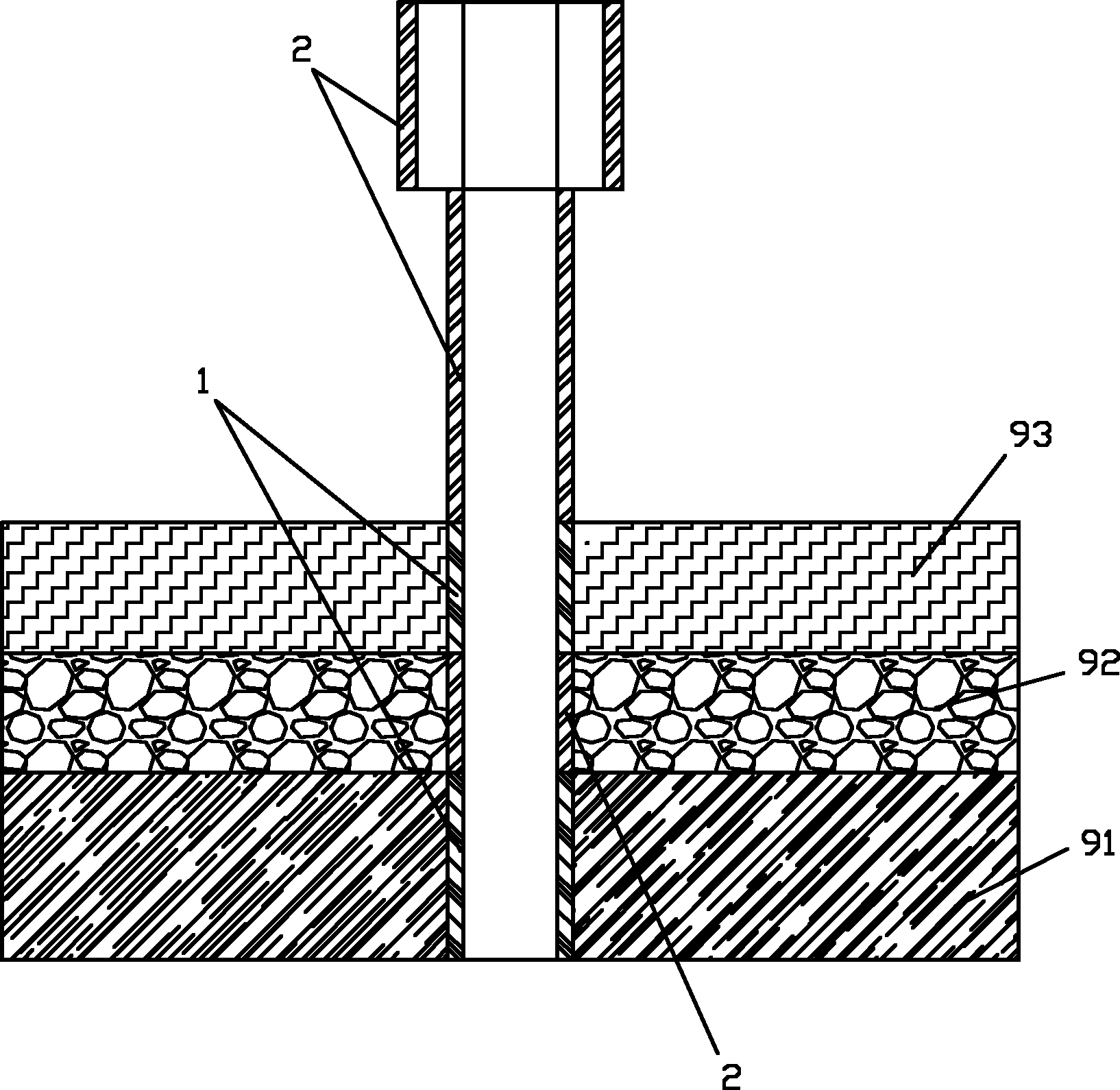

The invention relates to coalmine gas extraction and permeability enhancement equipment and technology, and discloses a coal seam reaming system using three-dimensional (3D) swirling water jet. The system is connected to a high-pressure rotary joint through a high-pressure hose provided with a stop valve by virtue of a high-pressure hydraulic pump station and is characterized by being connected to a high-pressure water jet drill stem through a drilling machine, wherein the front end of the high-pressure water jet drill stem is connected with a high-pressure water jet head with nozzle bases; and high-pressure swirling water jet nozzles are arranged on the nozzle bases. The invention further discloses a coal seam reaming and fracturing method for permeability enhancement using the 3D swirling water jet. In the coal seam reaming method using the 3D swirling water jet, coal is sheared so as to lower the hydraulic pressure loss, improve the cutting efficiency and increase the cracks and bore diameter of the coal; high-pressure water is injected so as to fracture the coal between a hydraulic reamed hole and control bored holes; and a coal seam is fully depressurized within a large range so as to shorten the pre-extraction time of the coal seam.

Owner:CCTEG SHENYANG RES INST +1

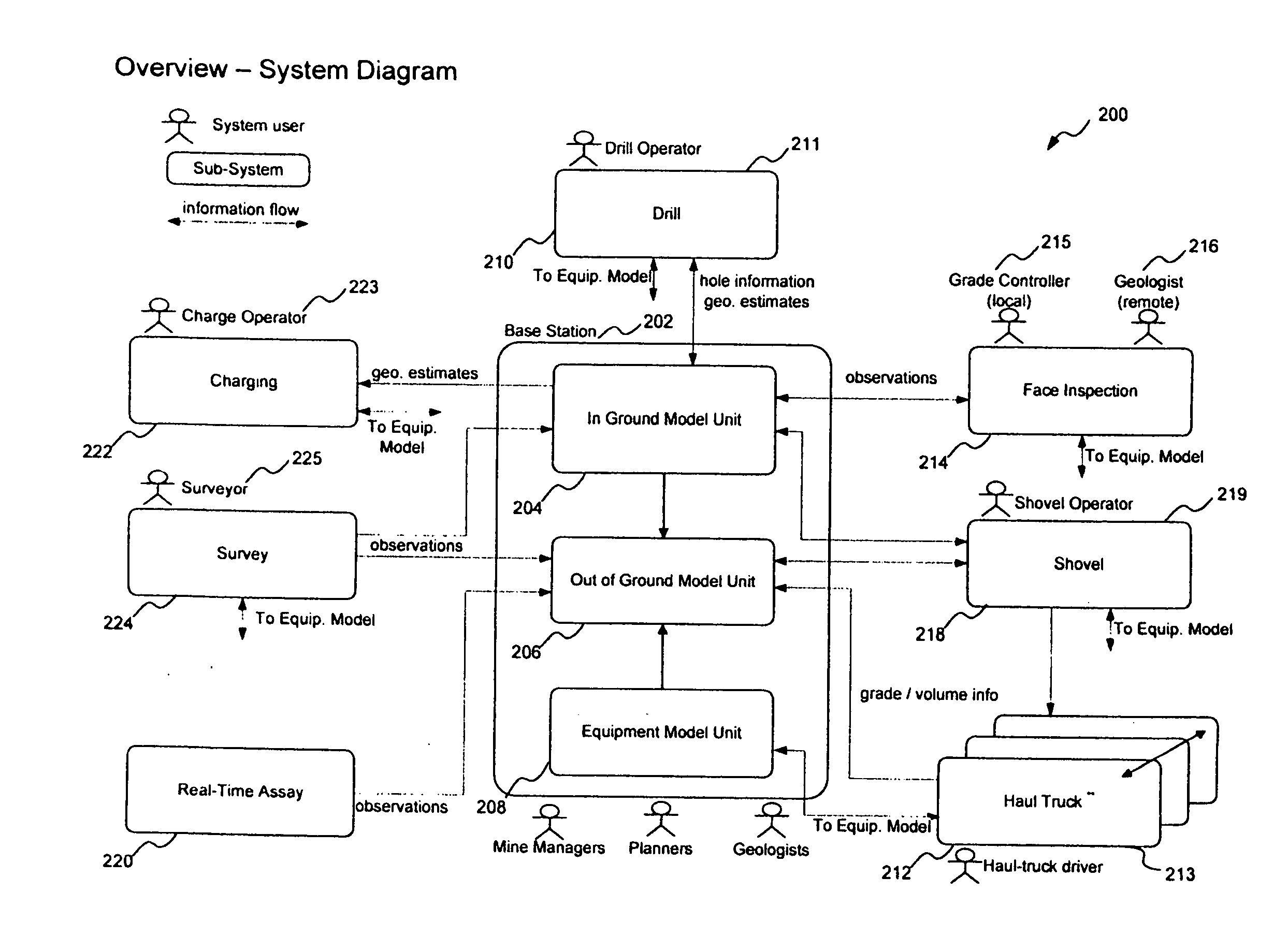

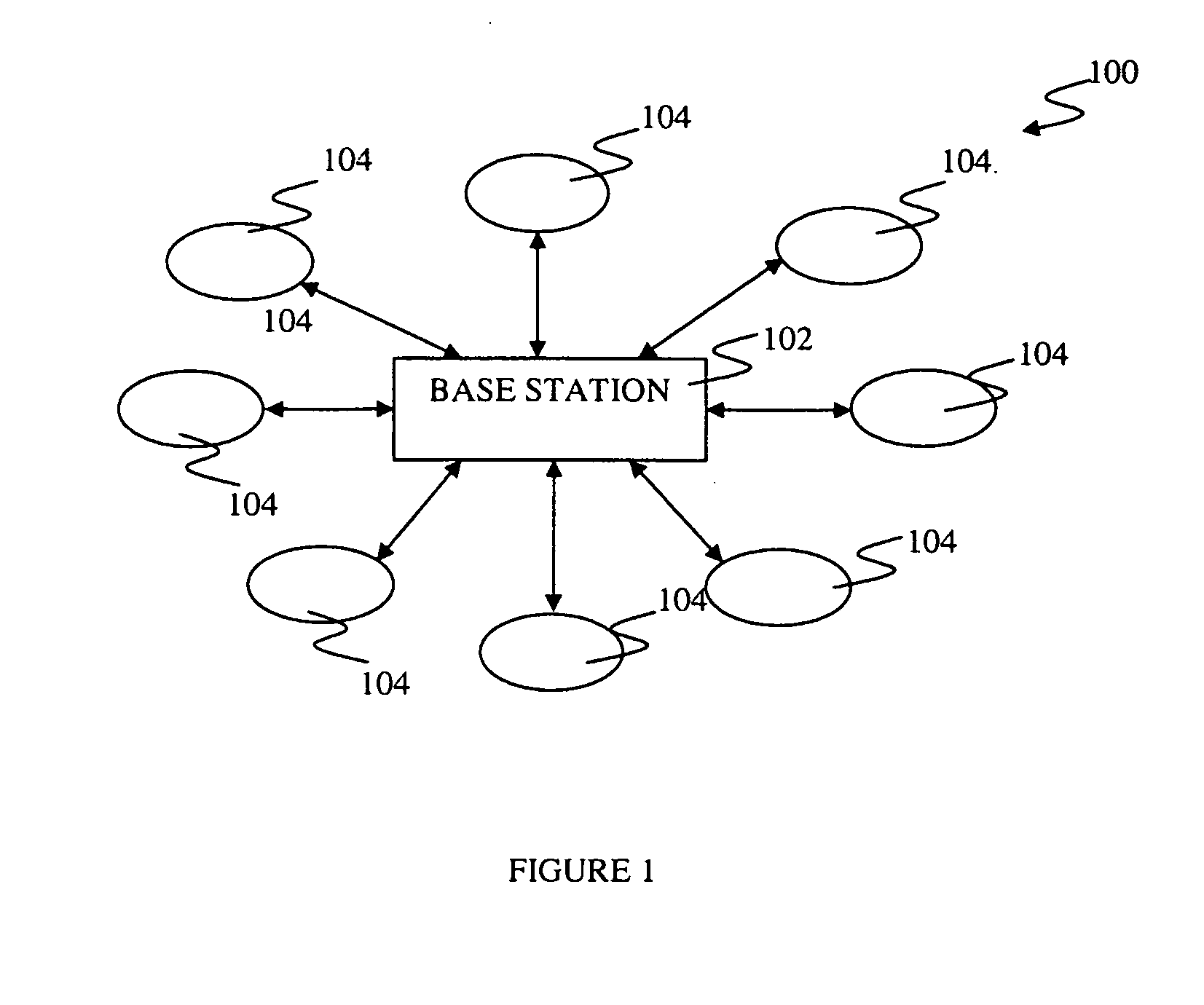

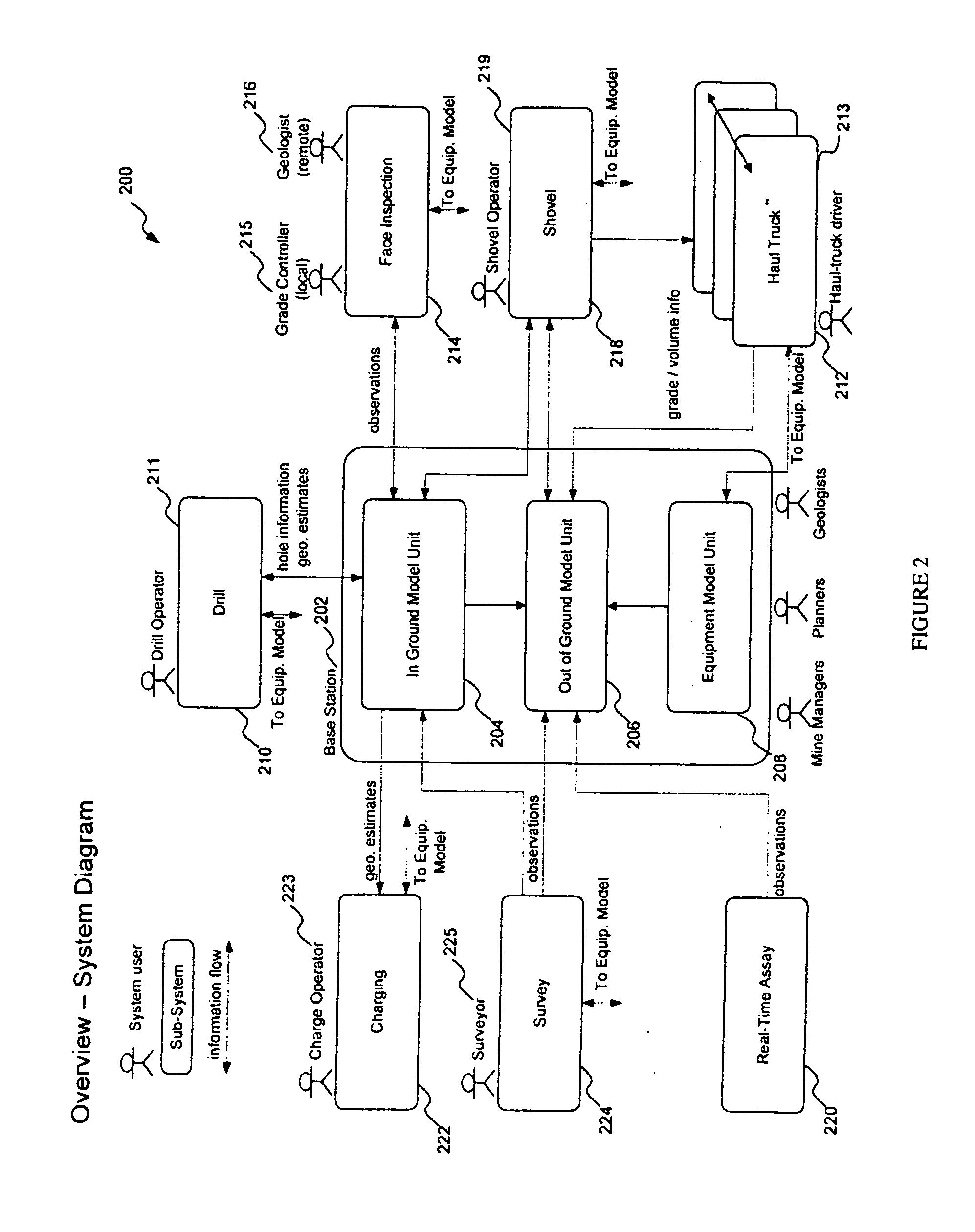

Method and system for exploiting information from heterogeneous sources

ActiveUS20090240481A1ResourcesSpecial data processing applicationsHeterogeneous sourceComputer science

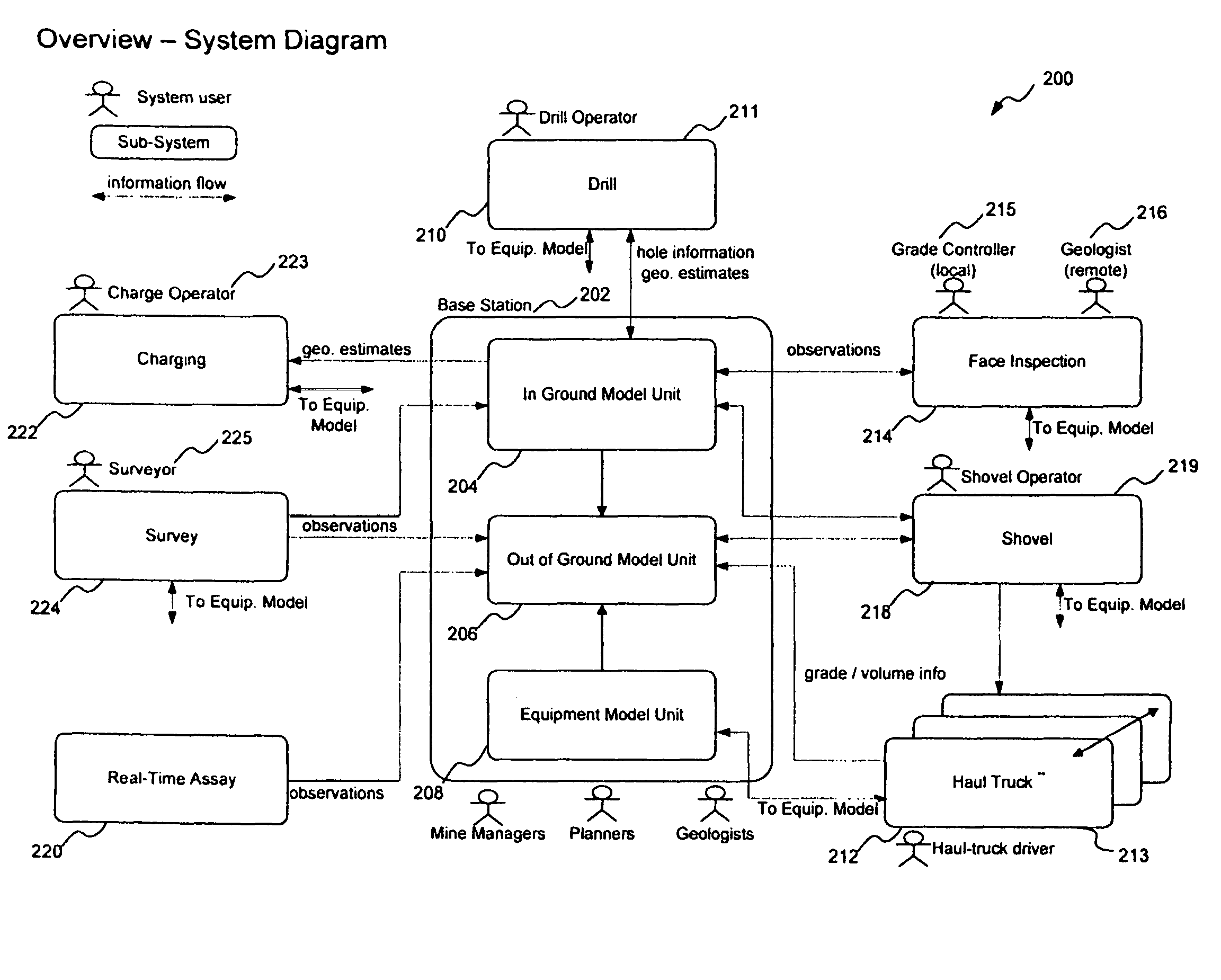

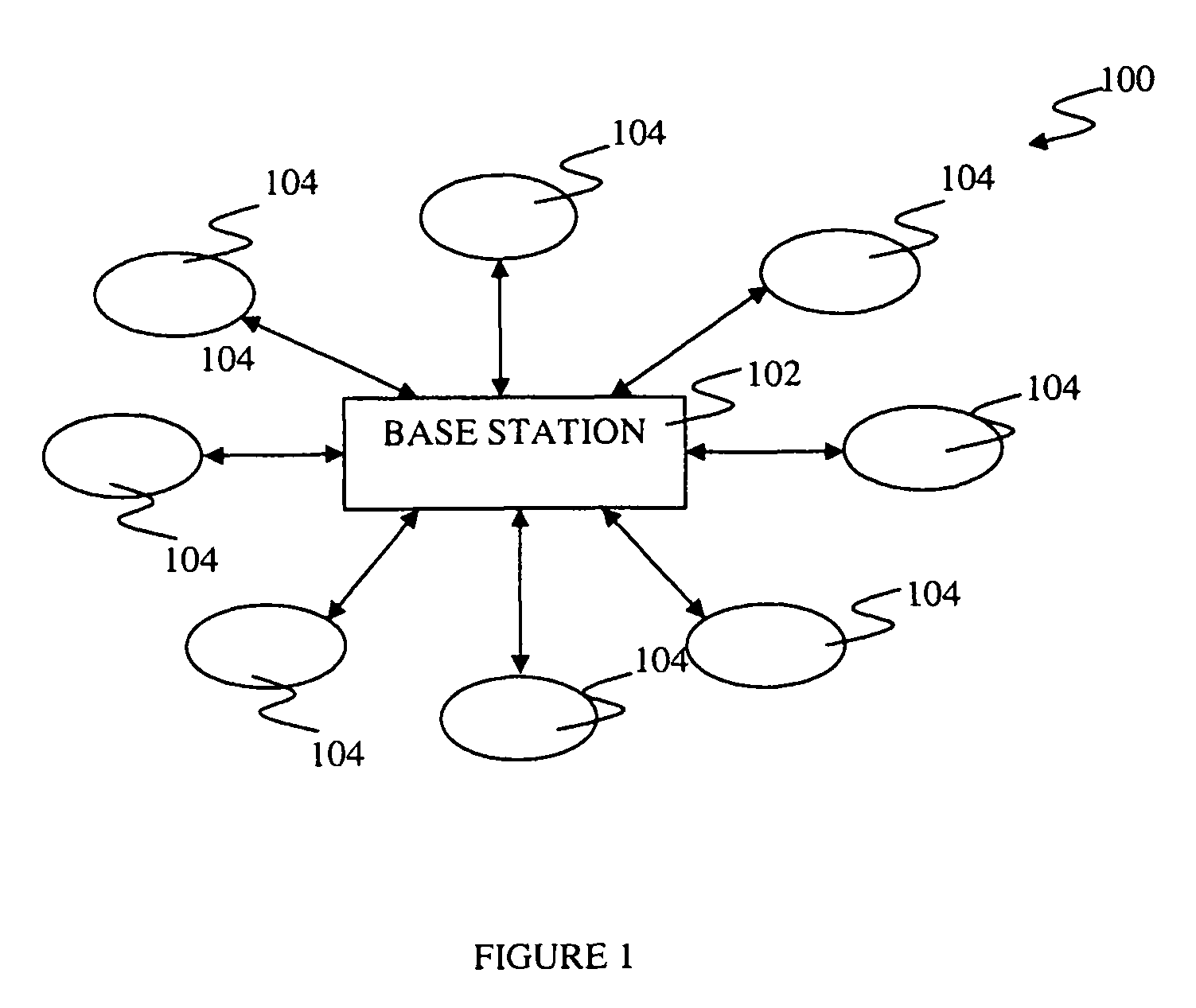

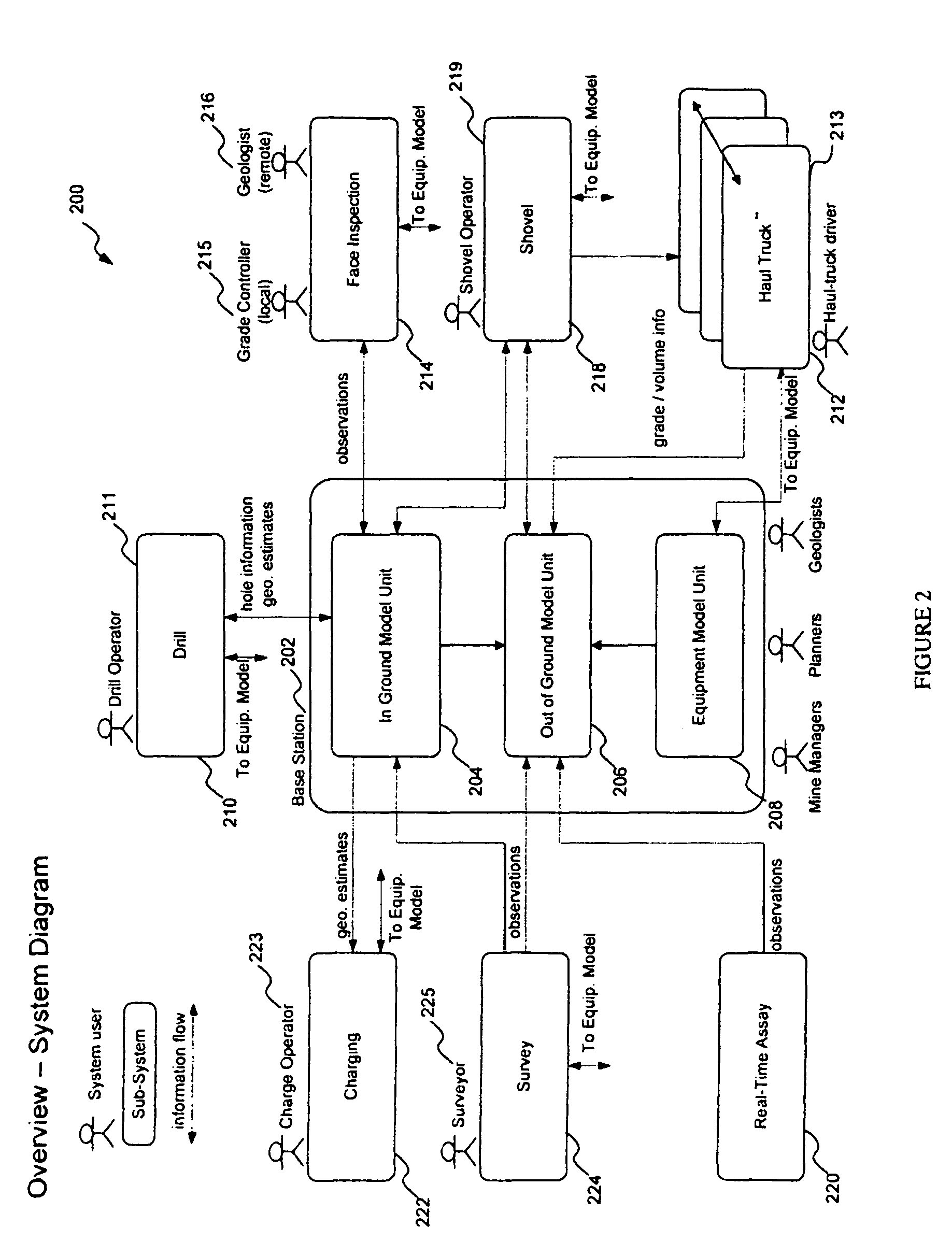

A system and method are described for generating a model of an environment in which a plurality of equipment units (104) are deployed for the extraction of at least one resource from the environment. The system comprises a pre-extraction or in-ground modelling unit (204) configured to receive data from a first plurality of heterogeneous sensors in the environment and to fuse the data into a pre-extraction model descriptive of the environment and the at least one resource. An equipment modelling unit (208) is configured to receive equipment data relating to the plurality of equipment units operating in the environment and to combine the equipment data into an equipment model. A post-extraction or out-of-ground modelling unit (206) is configured to receive data from a second plurality of sensors and to fuse the data into a post-extraction model descriptive of material extracted from the environment, wherein at least one of the equipment units operates to extract the at least one resource from the environment. Information from at least one of the pre-extraction model, the equipment model and the post-extraction model is communicable to the equipment units for use in controlling operation of the equipment units in the environment. The environment may be a mine.

Owner:TECH RESOURCES PTY LTD +1

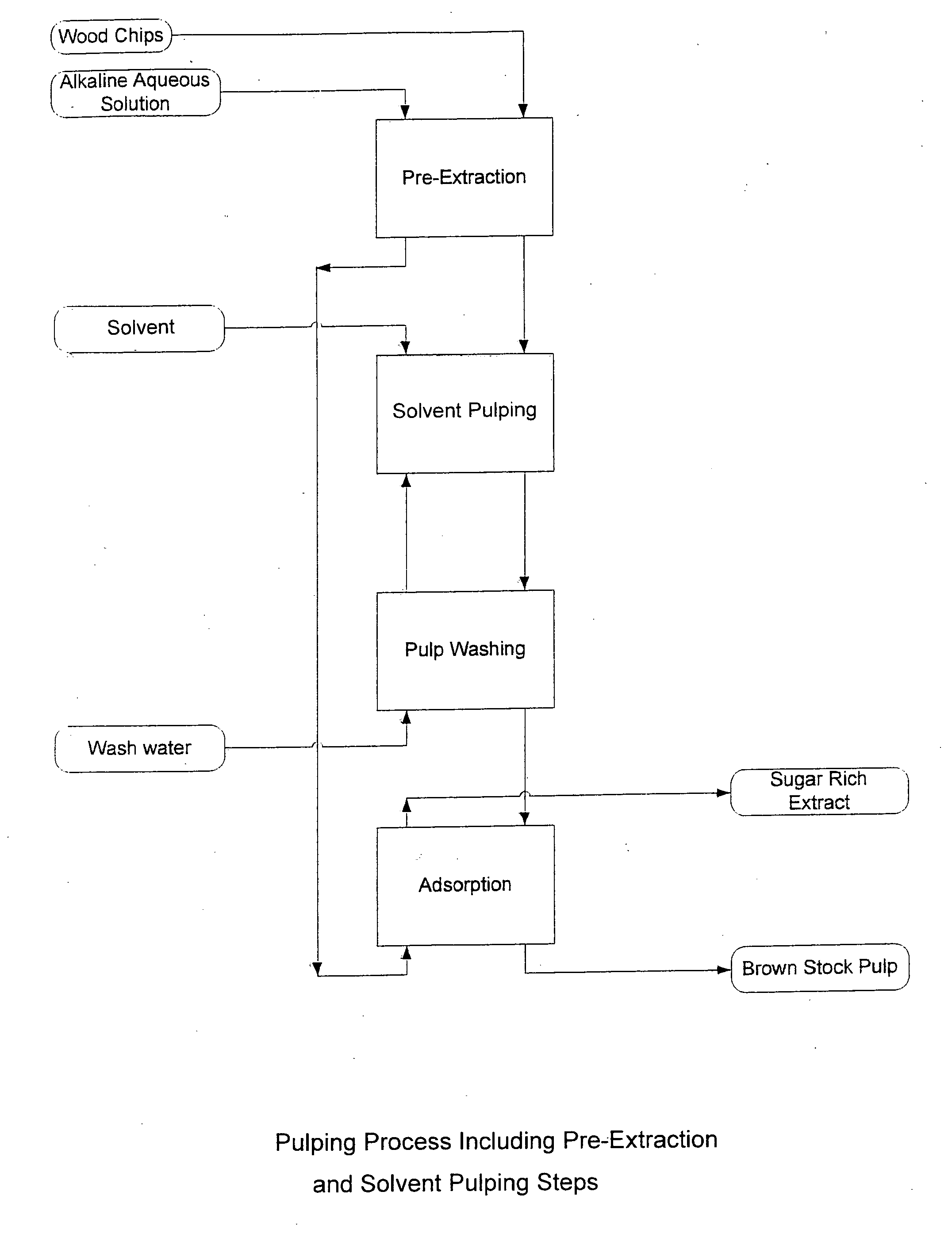

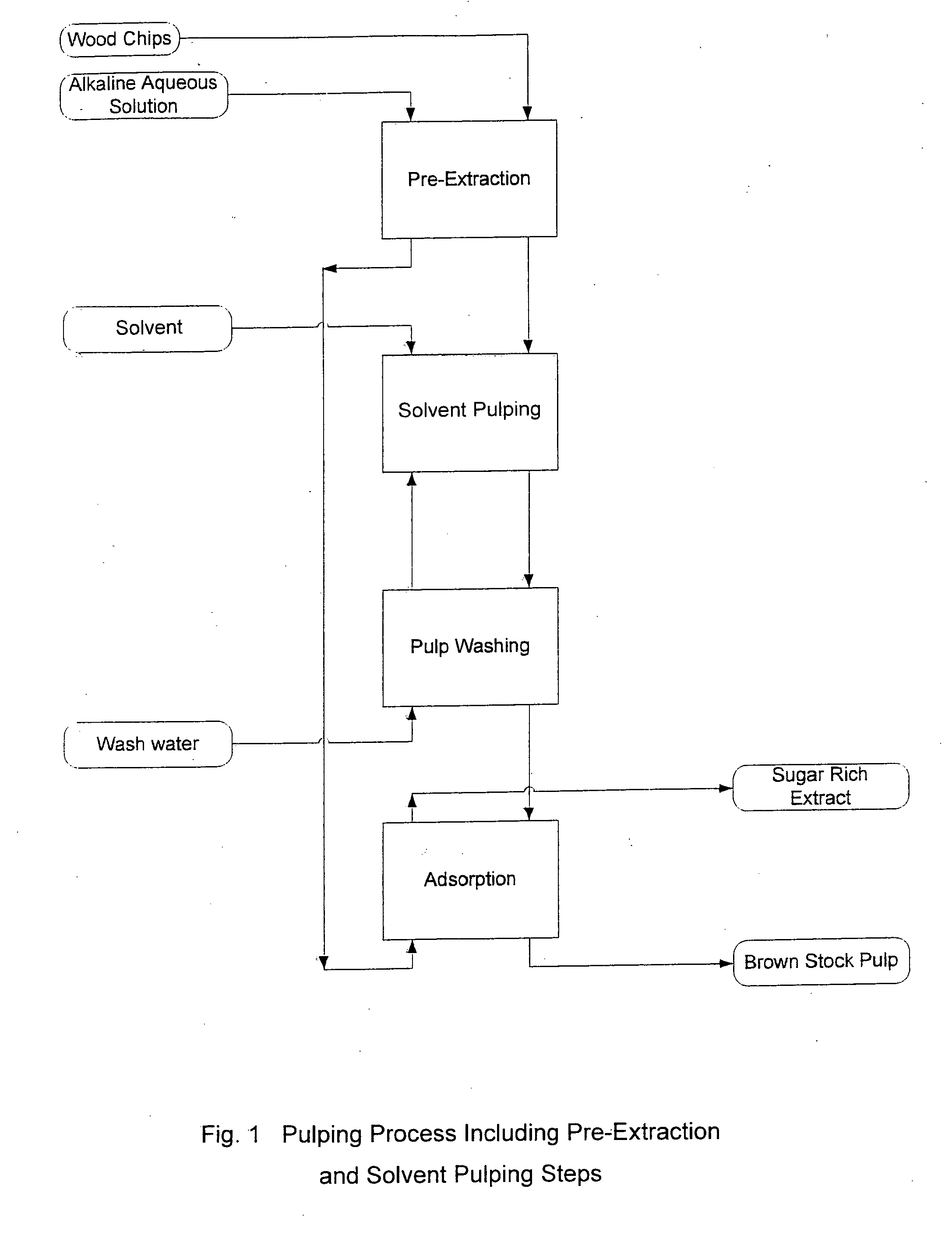

Pre-extraction and solvent pulping of lignocellulosic material

InactiveUS20080196847A1Pretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpBoiling pointSolvent

A process of treating a lignocellulosic material includes a pre-extraction step in which hemicellulose is extracted from the lignocellulosic material. Then, in a solvent pulping step, the lignocellulosic material is separated into pulp by contacting the lignocellulosic material with a cooking liquor comprising a solvent. In one embodiment, the solvent has a boiling point of at least about 150° C. In another embodiment, the cooking liquor comprises a mixture of solvent and water.

Owner:INT PAPER CO +1

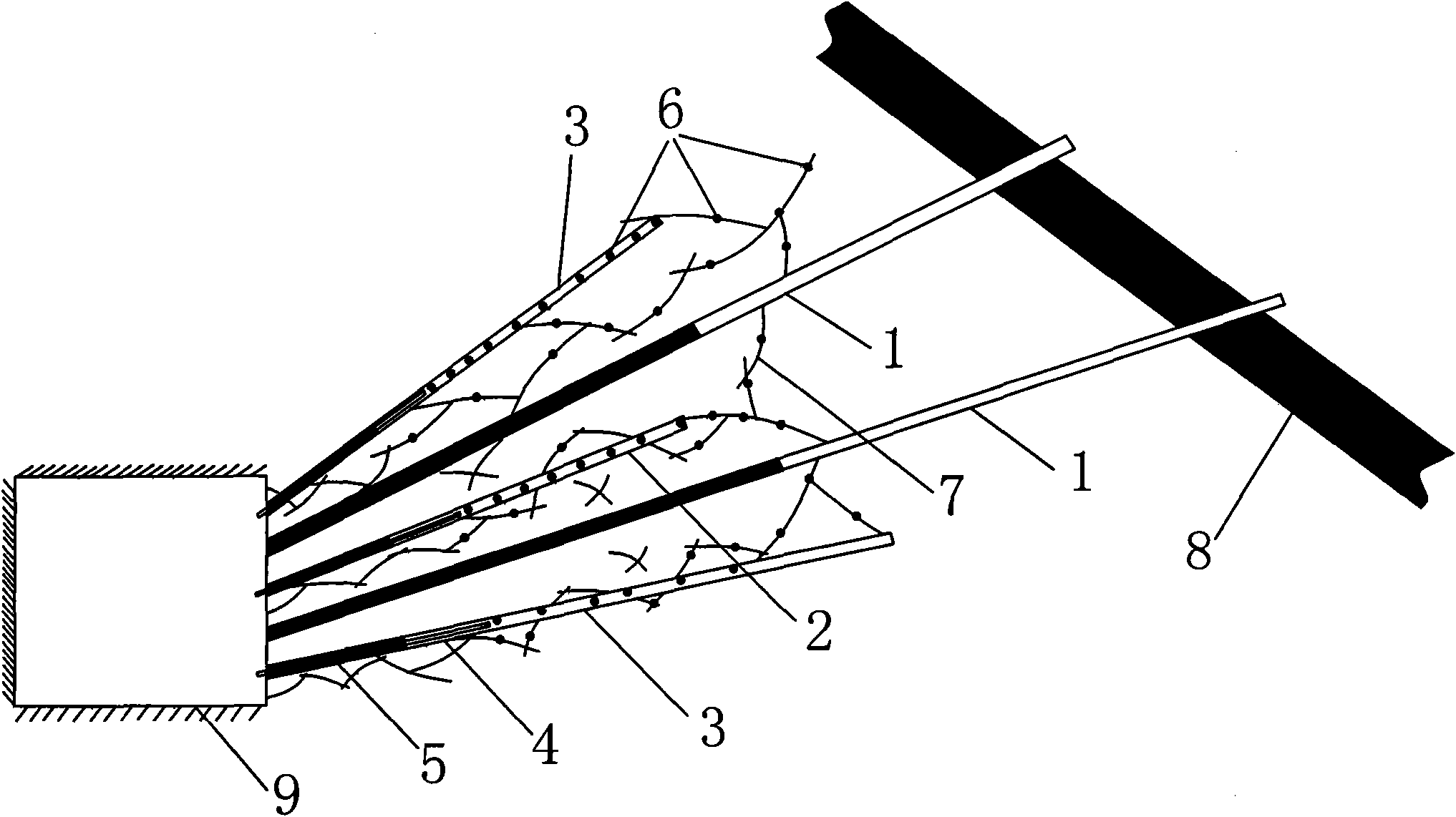

Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

InactiveCN102900460AIncrease the speed of excavationIncrease extraction concentrationGas removalStress distributionType fracture

The invention discloses a method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on a soft and high-outburst coal seam, and in particular is applied to quick tunneling in a coal seam which is high in outburst danger and a laneway is difficult to support in a coal mine. The method comprises the following steps of: forming a network type fractured net by high-pressure jet flow seam cutting, pressure relief and permeability enhancement technologies, and enhancing an effect of extracting strip-type coal seam gas on a coal laneway subjected to through-going drilling and pre-extraction; and forming a network type filling region by pressing and injecting filling materials, so that the strength and stress distribution of a coal body are improved, the coal laneway is easy to maintain in the tunneling process, a phenomenon that the gas rushes out of a tunneled laneway is avoided, gas accidents are eliminated in the tunneling process, and an aim of safely and quickly tunneling the laneway is fulfilled.

Owner:CHINA UNIV OF MINING & TECH

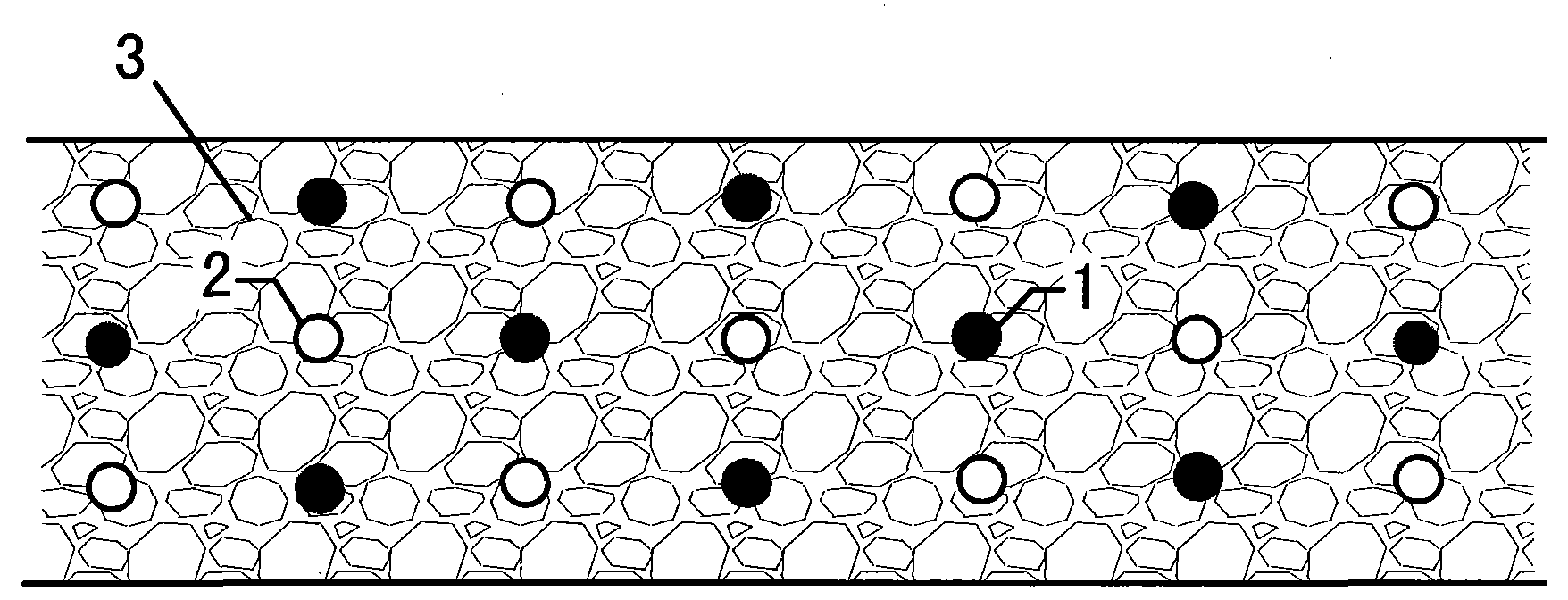

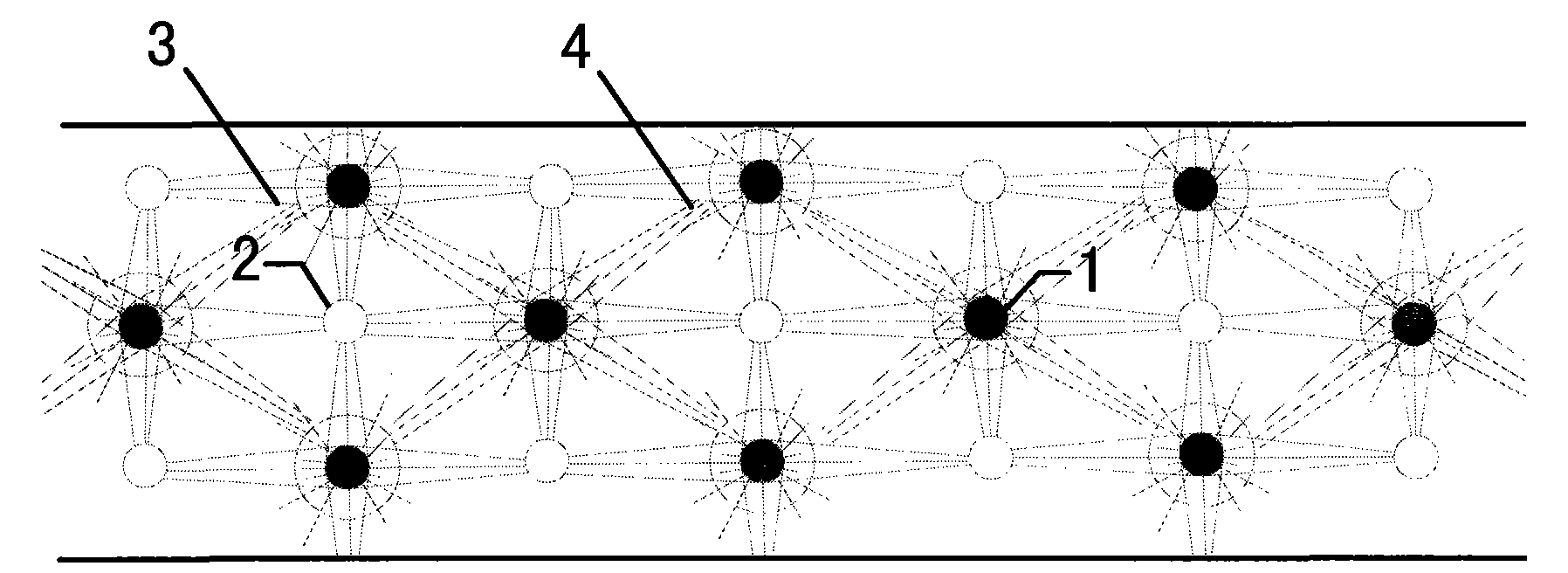

Drilling-explosion-pumping triadic gas extraction method

The invention relates to a drilling-explosion-pumping triadic gas extraction method, which is most suitable for regional gas extraction of a high gas and low permeability coal seam. The method comprises the following steps: alternately arranging hole positions of drainage holes and blast holes of an along bed or a cross seam on a coal seam in front of a coal mining or tunneling working surface; and performing construction work on the drainage holes one by one, and performing blasting operation, wherein through the edgetone effect of denotation gas in the blast holes, a columnar compression crushing circle and a crack body which passes through and blasts in the direction of a line of centers of the blast holes and the extraction holes are generated on the periphery of a blasting hole to transfer the ground stress, improve the gas permeability of a coal body, relieve the pressure in a coal body and facilitate for drainage of gas in the coal body. The gas permeability of the coal body can be improve by around 20 to 50 times, the gas extraction quantity of haplopore can be increased by 5 to 10 times averagely, the gas extraction concentration is more than or equal to 50 percent, and the gas extraction rate of a robbing working surface is more than or equal to 80 percent. After pressure releasing and permeability improving of drilling, explosion and pumping, the gas pre-extraction time can be shortened by half, and the number of drilling holes of gas extraction is decreased by 20 to 30 percent; and the method achieves safe, high-efficiency and uniform extraction of the gas in the high gas and low permeability outburst coal seam.

Owner:CHINA UNIV OF MINING & TECH

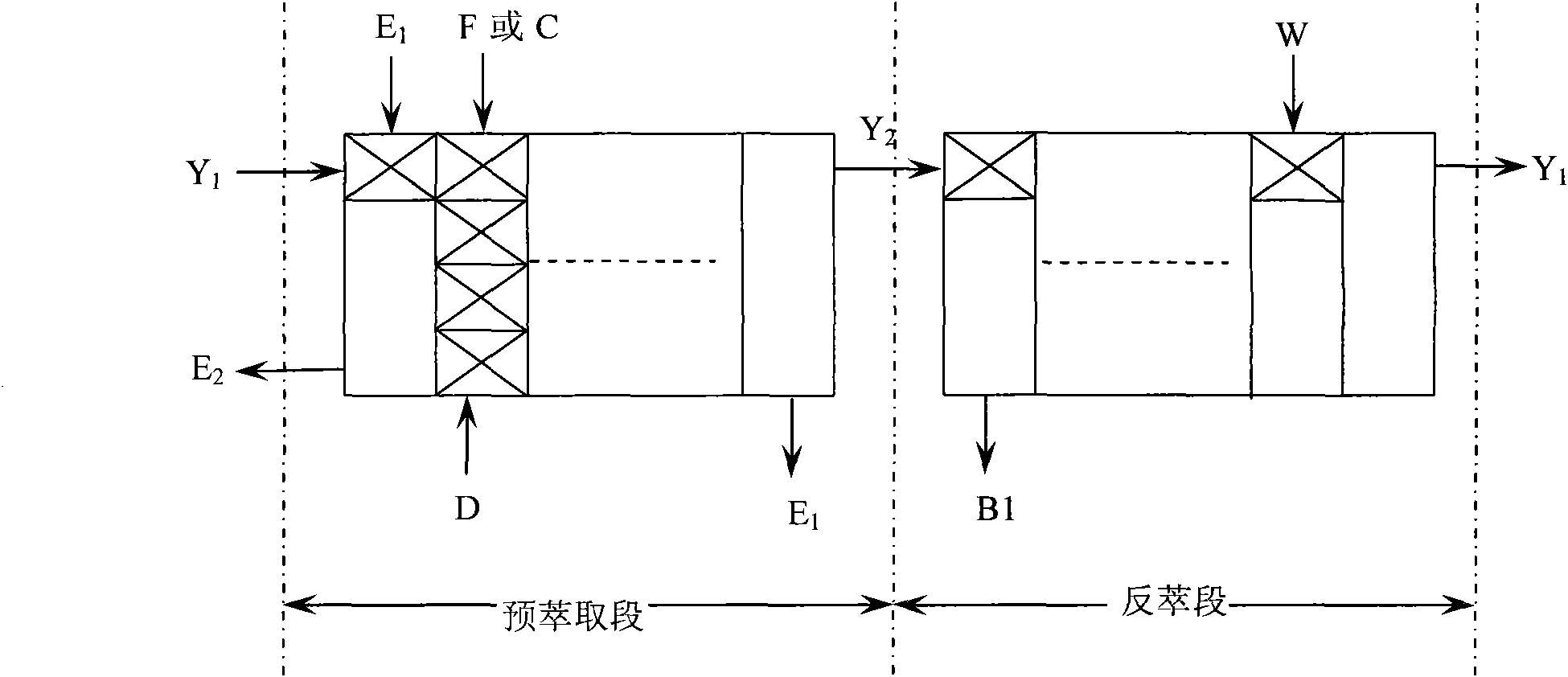

Process for separating rare-earth element by extraction

InactiveCN101781706ALow impurity contentEliminate pollutionProcess efficiency improvementRare-earth elementCalcium bicarbonate

The invention mixes and pre-extracts the mixed solution of acidic organic extractants such as P507, P204, C272, and naphthenic acid with magnesium bicarbonate and / or calcium bicarbonate solution and rare-earth solution. The rare-earth ions are extracted into the organic phase, then the loaded organic phase containing rare-earth ions are obtained through clarification, and can be used for the extract separation of the mixed rare-earth feed liquid. After a plurality of different levels of extraction, washing, stripping, single rare-earth compounds or rare-earth elements-containing enrichments can be obtained. The magnesium bicarbonate and / or calcium bicarbonate solution are prepared by roasting, digesting, carbonizing magnesite, limestone, calcite, dolomite and similar minerals, so that the content of impurities, such as silicon, iron, aluminum is lower. Ternary phase sediment is not produced in the pre-extraction and extraction separation process, so that the purity of the rare-earth products are not affected. The organic phase does not need ammonia saponification and does not produce ammonia-nitrogen wastewater. By adopting the invention, the production cost of rare-earth products is greatly lowered and the cost for three waste disposal is also greatly saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method and system for exploiting information from heterogeneous sources

A system and method are described for generating a model of an environment in which a plurality of equipment units are deployed for the extraction of at least one resource from the environment. The system comprises a pre-extraction modeling unit configured to receive data from a first plurality of heterogeneous sensors in the environment and to fuse the data into a pre-extraction model. An equipment modeling unit is configured to receive equipment data relating to the plurality of equipment units and to combine the equipment data into an equipment model. A post-extraction modeling unit is configured to receive data from a second plurality of sensors and to fuse the data into a post-extraction model. Information from the pre-extraction model, the equipment model and / or the post-extraction model is communicable to the equipment units for use in controlling operation of the equipment units in the environment.

Owner:TECH RESOURCES PTY LTD +1

Method for extracting coal bed gas by negative pressure on ground through gas-coal simultaneous extraction

InactiveCN102080519AReduce concentrationEnsure safe productionUnderground miningLiquid/gas jet drillingWell drillingNew energy

The invention provides a method for extracting coal bed gas by negative pressure on the ground through gas-coal simultaneous extraction aiming at a waterless coal bed in an ore field. The extraction of the coal bed gas sequentially comprising three stages, namely pre-extraction before coal mining, extraction during coal mining, and extraction after coal mining; and in the method, in the well drilling process, nonmetal sleeves are descended into an old top section and a coal bed section of a vertical well, steel sleeves are descended in other layers, the nonmetal sleeves arranged in the coal bed section avoid hidden danger of sparkles caused by collision of a coal cutter and metal sleeves in subsequent coal mining, and the nonmetal sleeves arranged in the old top section reserve channels for extraction in a worked out section after the rock and shaft below the old top section are collapsed. In the method for extracting the coal bed gas, one well has three purposes, namely gas is pre-extracted in the coal bed section before coal mining, air return and exhaust are performed in the coal mining process and gas in the worked out section is extracted by negative pressure after coal mining, and the utilization rate of a coal bed gas well is improved; and the gas-coal simultaneous extraction is realized, the safety production of a coal mine is ensured, and multi-win effects of efficiently extracting the coal bed gas, utilizing new energy, protecting environment and the like are achieved.

Owner:中矿瑞杰(北京)科技有限公司

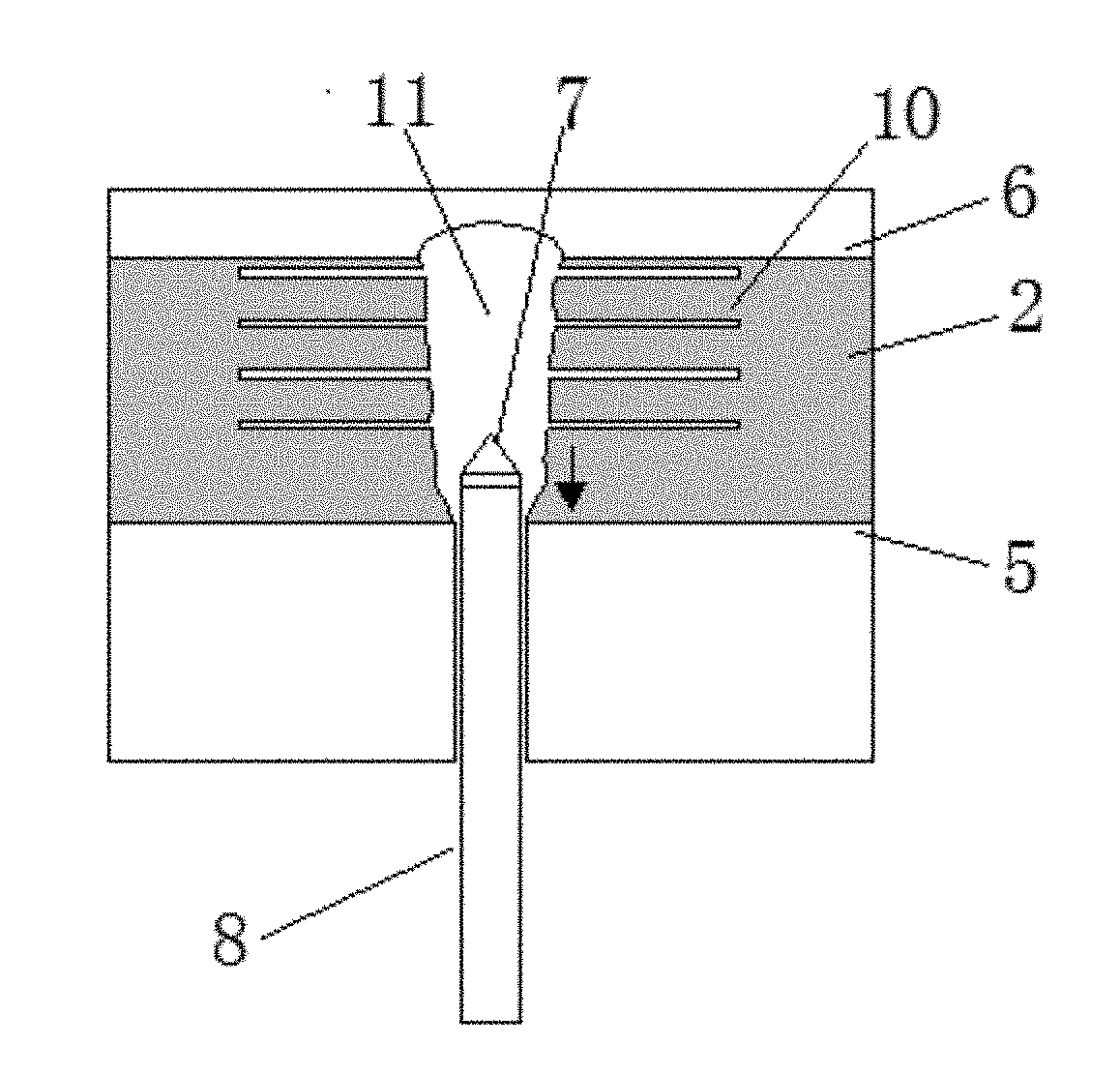

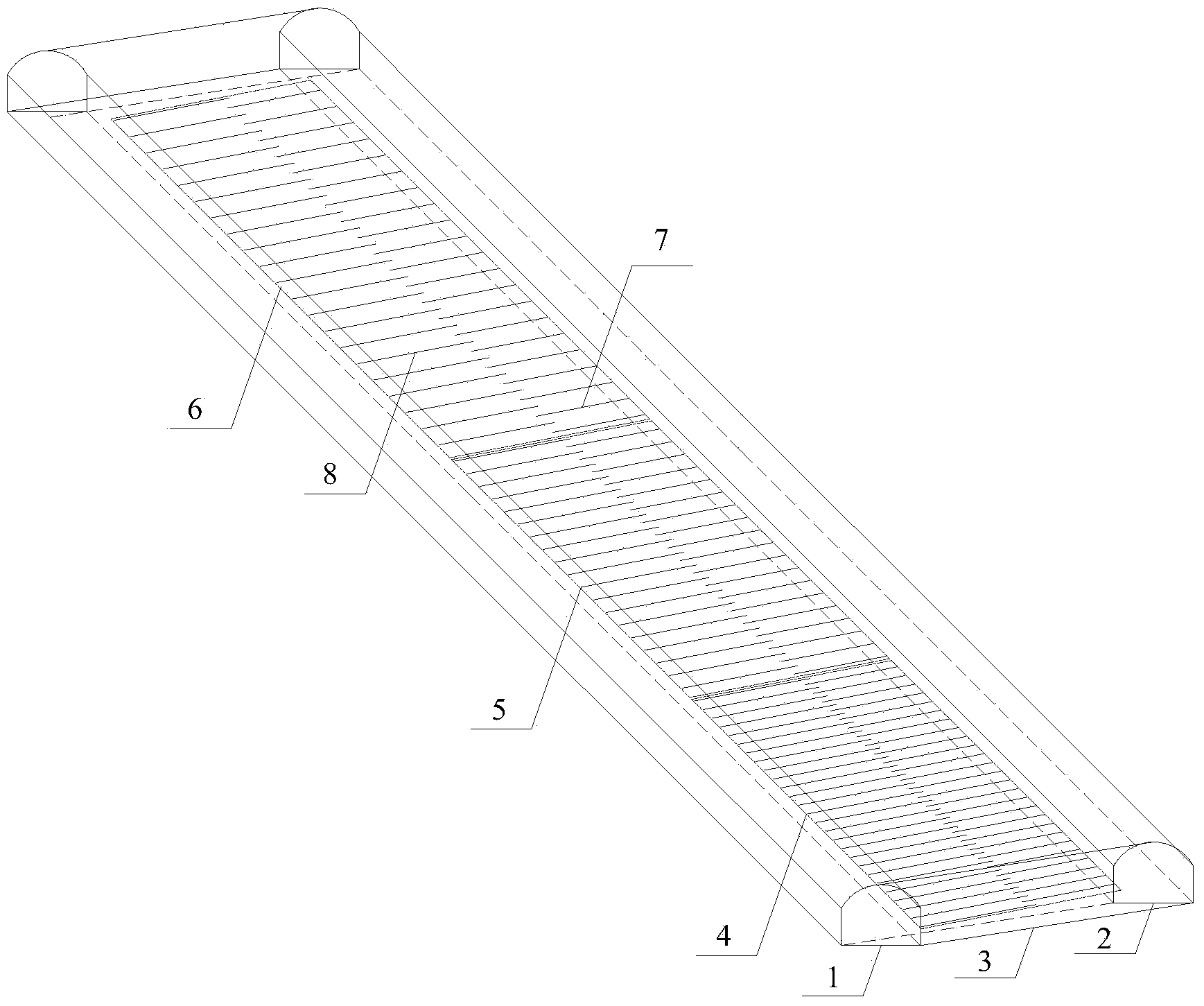

Method of performing combined drilling, flushing, and cutting operations on coal seam having high gas content and prone to bursts to relieve pressure and increase permeability

ActiveUS20170370156A1Simple processEfficient amplificationConstructionsLiquid/gas jet drillingWell drillingDesorption

The present invention relates to a “drilling-flushing-slotting” coupled pressure relief and permeability increasing method for a high gas outburst coal seam, which is more particularly suitable for the pressure relief and permeability increasing when gas of a roadway band of the high gas outburst coal seam is pre-extracted through crossing boreholes. On the basis of the crossing borehole pre-extraction measures for the coal seam gas, the hydraulic flushing and the hydraulic slotting are reasonably combined, and a “drilling-flushing-slotting” dedicated device is utilized to implement the coupled operation of “low pressure drilling-medium pressure flushing-high pressure slotting” in a borehole, so that the coal in the pre-extraction area is deformed and moved to form network cracks, passages are provided to the desorption flow of the gas, and the gas is easier to extract. The method can enlarge the single-hole pressure relief influence range, increase the gas permeability of the coal seam, improve the gas extraction efficiency, reduce the number of pre-extraction boreholes, shorten the pre-extraction time and have good applicability to the coal seams in different occurrence states. The present invention can reduce the number of the crossing boreholes by 32.5% and can reduce the length of each crossing borehole by 42.9%, is remarkable in coal roadway regional outburst eliminating effect, and obviously increases the tunneling speed.

Owner:CHINA UNIV OF MINING & TECH

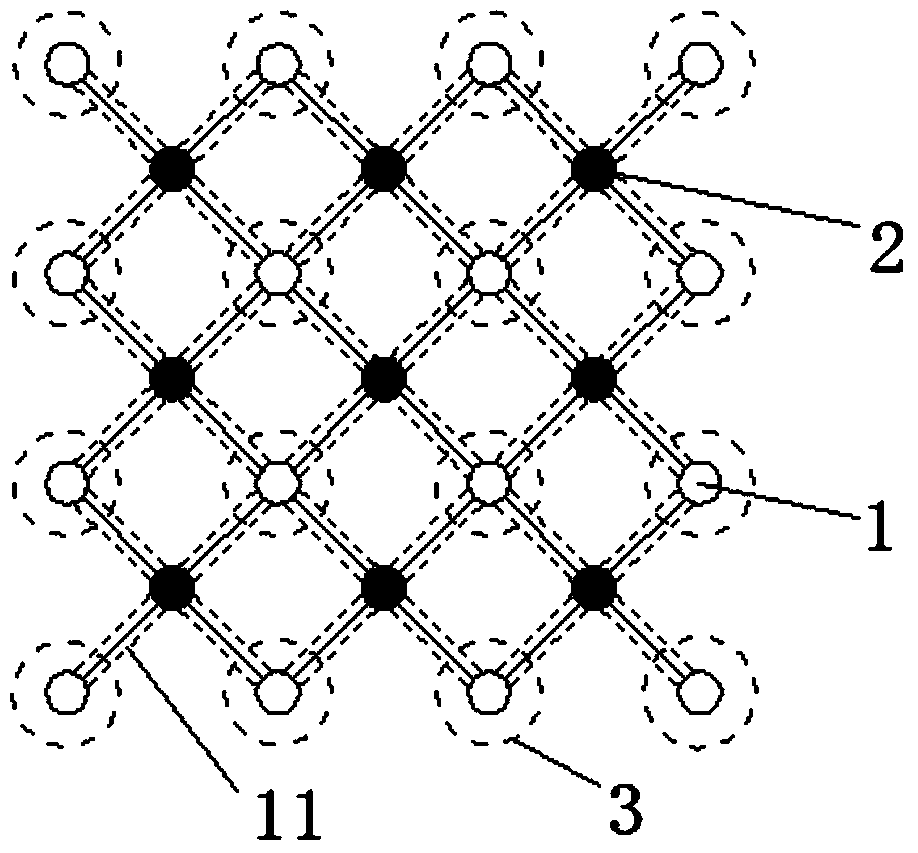

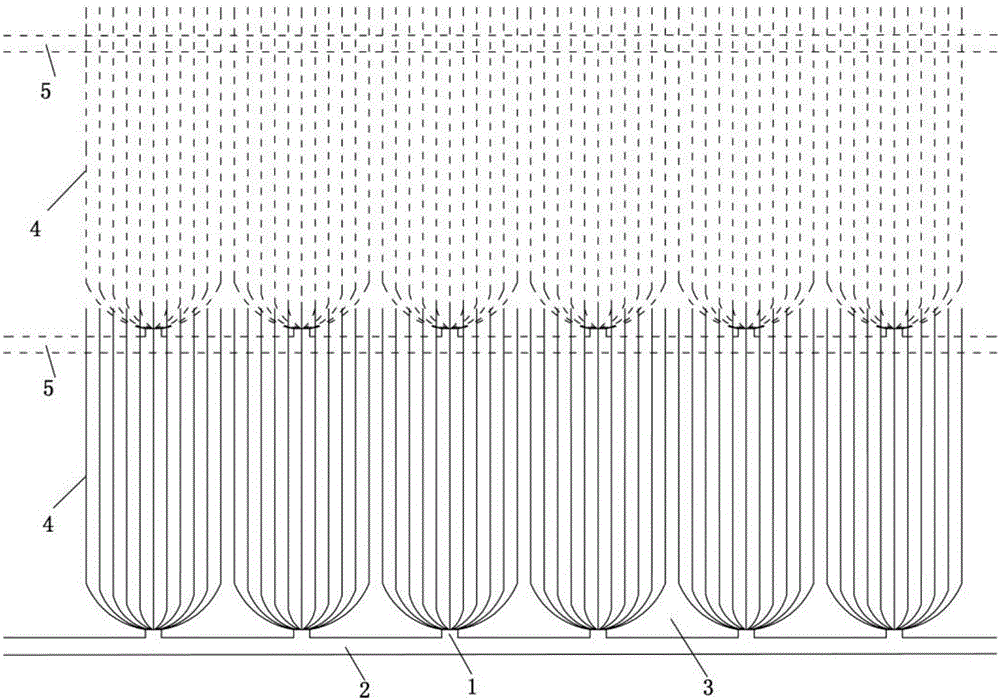

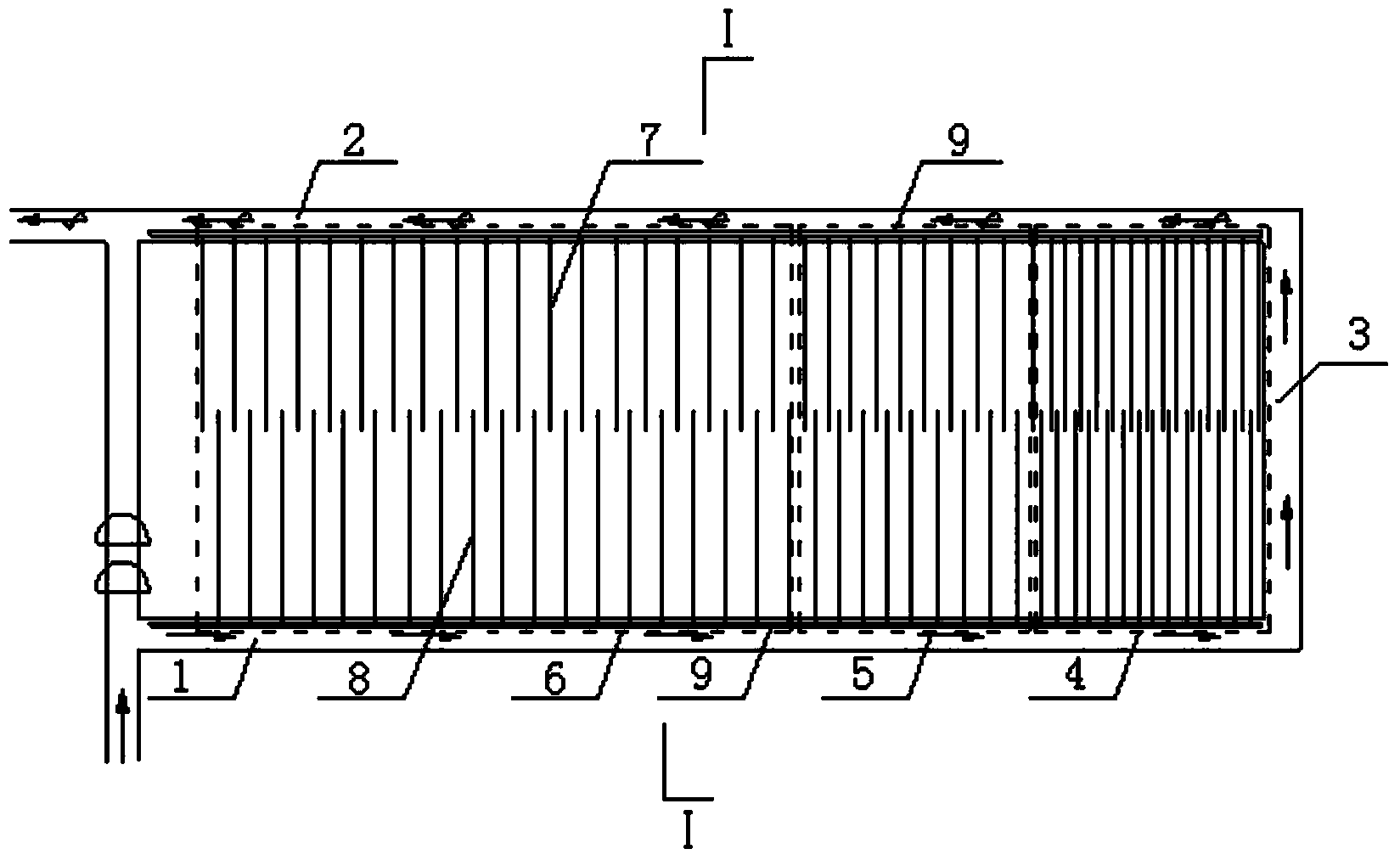

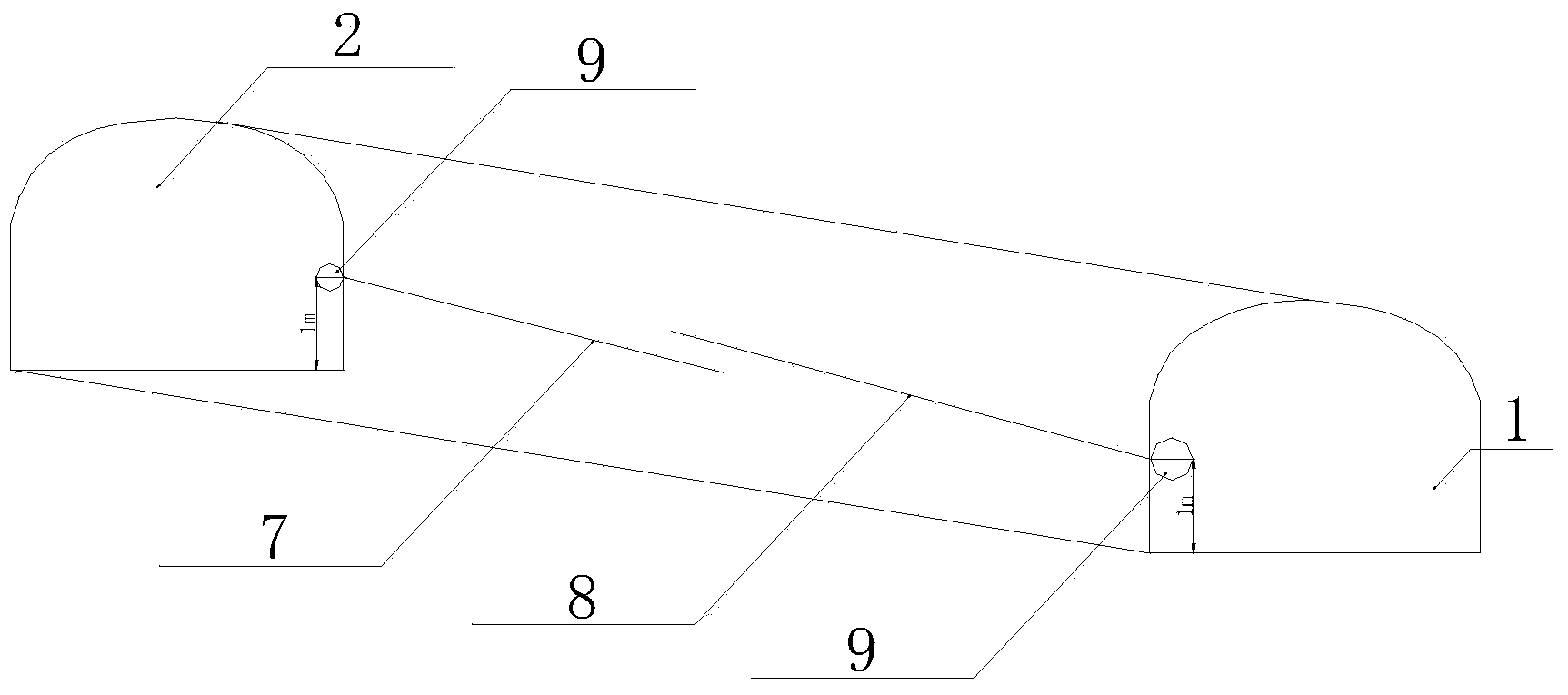

Slotting and fracturing cooperation networking permeability increasing method for low-permeability coal seam

ActiveCN104389631AImprove breathabilityIncreased air permeability coefficientFluid removalGas removalHigh pressure waterHigh pressure

The invention provides a slotting and fracturing cooperation networking permeability increasing method for a low-permeability coal seam, which is applicable to regional gas control for high-gas-content low-permeability coal seams. The permeability increasing method comprises the following steps that: firstly, hole positions of slotting drill holes and fracturing drill holes are arranged alternately at a floor suction roadway in a networking arrangement mode; each slotting drill hole is subjected to high-pressure water jet flow slotting to form an annular slotted hole; and then, each fracturing drill hole is subjected to segmented fracturing, and a fracture net is formed in the coal seam. The slotting drill holes and the fracturing drill holes are in cooperative arrangement; the slotted holes formed by slotting are used for controlling the expanding direction of fracturing cracks; the number of cracks in the coal seam can be effectively increased through segmented fracturing multiple times; and good conditions are created for the drill hole gas extraction and the gas flowing in the coal seam. After the fracturing cracks are communicated with the slotted holes, a crack network is formed in the coal seam; the permeability coefficient of a coal body around the drill holes can be improved by 150 to 400 times; the single-drill-hole gas extraction effective influence range can be expanded by 2 to 4 times; the drill hole gas extraction quantity can be increased by 3 to 6 times; and the gas pre-extraction time in the high-gas outburst coal seam can be effectively shortened.

Owner:CHINA UNIV OF MINING & TECH

Regional forced gas extraction method for single low-permeability outburst thick coal seam

ActiveCN104100292AEliminate the problem of blank bands in extractionImprove extraction efficiencyGas removalHigh pressure waterHigh pressure

The invention provides a regional forced gas extraction method for a single low-permeability outburst thick coal seam. The regional forced gas extraction method comprises the steps of (a) excavating a rock gangway in a rock fissure zone and drilling a lower-position seam through hole downwards, (b) drilling a high-position seam through hole downwards in the rock gangway, (c) starting a high-pressure water-injection pump station, performing hole expanding operation on the coal seam through sections of the drilled holes under the conditions of the water pressure of 10-20MPa, the flow rate of 8m<3> / h and the single-hole coal output greater than 5t, (d) sealing the drilled holes and carrying out drainage strip networking extraction operation after the hole expanding operation is finished, (e) after the extraction is up to the standard, carrying out tunneling operation of an air return way and a transportation roadway, and meanwhile, drilling a bedding pre-extraction hole in the working face and carrying out the hole sealing and networking extraction operations, and (f) continuously extracting the gas of the goaf in the rock gangway during the recovery of the working face. The regional forced gas extraction method is capable of converting a high-gas outburst coal seam into a low-gas outburst risk-free coal seam, comprehensively guaranteeing safe production of the working face, and meanwhile, obviously increasing the coal roadway tunneling speed.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Method for extracting protruded coal-bed downward bedding long-borehole step-by-step covering area gas

InactiveCN101029575AReduce gas contentEliminate outstanding hazardsGas removalSealing/packingEngineeringGas concentration

This is a gas extraction method for a single burst coal bed of stable coal occurrence, angle less than 10o, and firm index over 0.5. Drill a hole from top working face downward along the coal bed from shallow bed to deep, from low gas concentration zone to high for pre-extraction to lower down the gas concentration.

Owner:淮北矿业股份有限公司祁南煤矿 +1

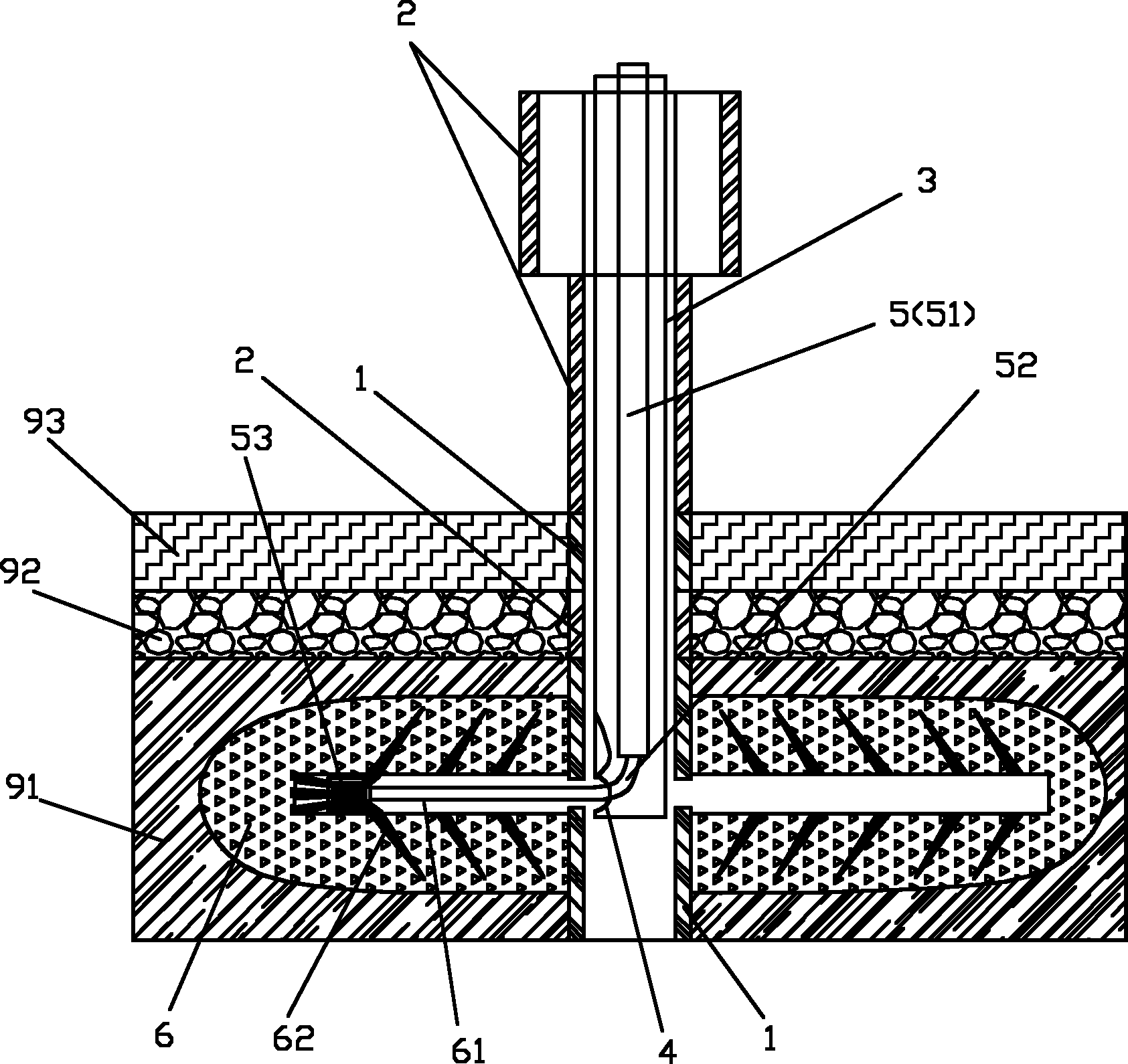

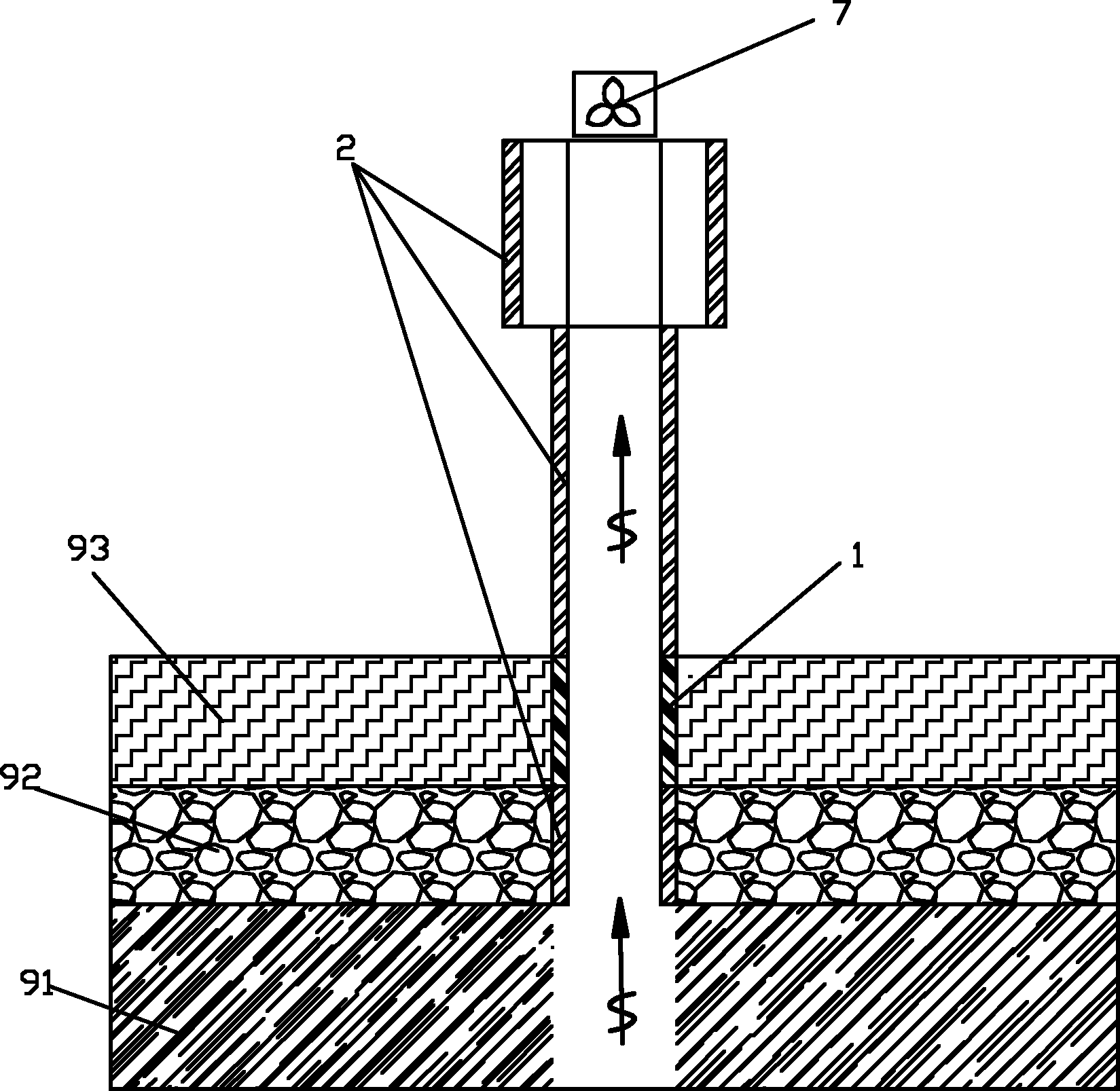

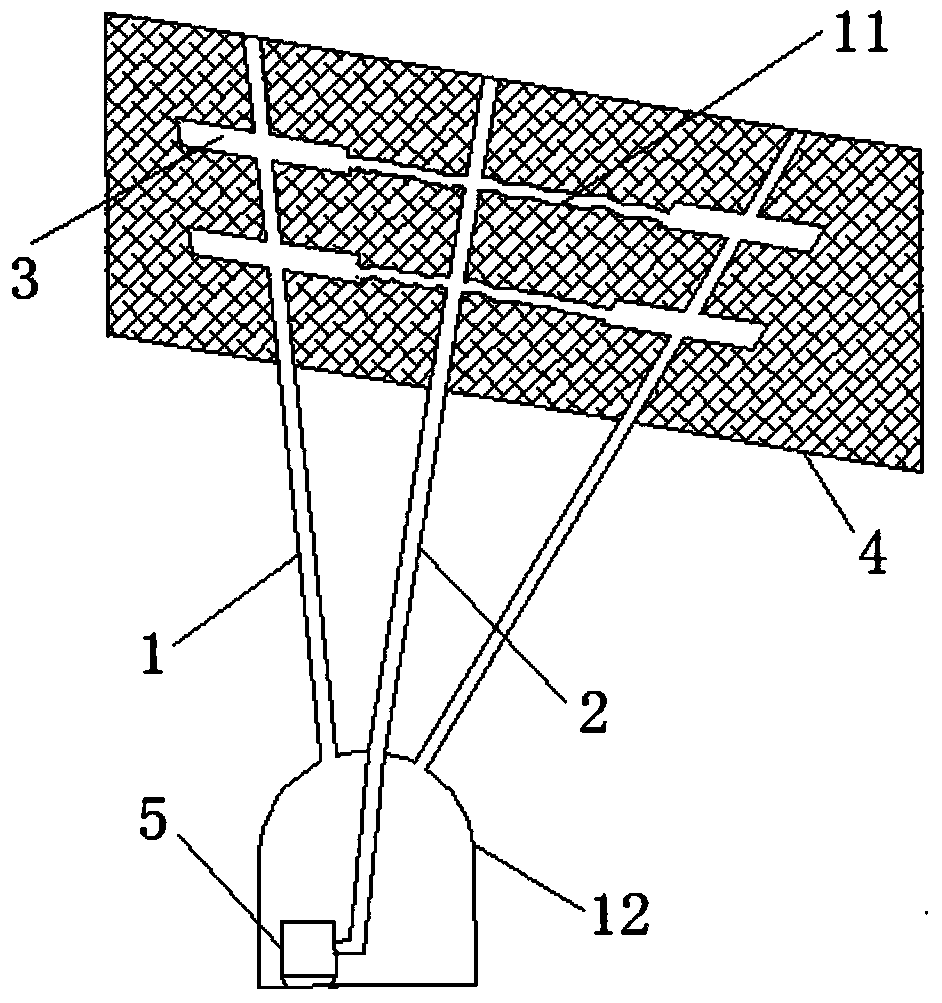

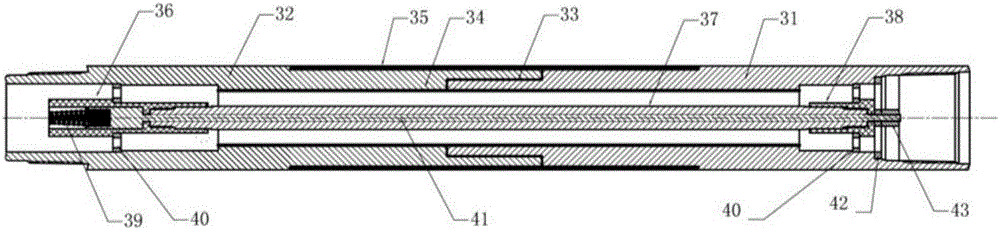

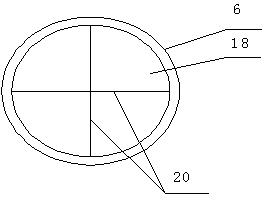

Underground progressive gas pre-extraction and directional hole drilling system and method for broken and soft coal seam

ActiveCN105971517AImprove hole depthHigh hole forming precisionSurveyDrilling rodsRock cuttingEngineering

The invention relates to an underground progressive gas pre-extraction and directional hole drilling system and method for a broken and soft coal seam. An orifice bubble filling system is utilized to provide a continuous bubble flow for a drill hole to drive hole bottom grooving air screw motor to perform rapid drilling, and scouring to the hole wall of the broken and soft coal seam is reduced. A triquetrum auger stem is used for strengthening residue discharge. An orifice bubble-eliminating extraction system is utilized to eliminate bubbles, remove rock cuttings and perform gas extraction, and construction safety is guaranteed. A dual-drive compound directional drilling technology is combined to regulate and control a drilling trajectory and ensure that the drill hole extends along the designed trajectory and penetrates through and covers an unmined working face and a roadway to be excavated. The hole forming depth, the hole forming precision, hole forming efficiency and hole forming rate of the broken and soft coal seam with the Platts hardness coefficient f greater than or equal to 0.5 but smaller than or equal to 0.8 are wholly improved, the formed hole is used for progressive gas pre-extraction in a broken and soft coal seam zone, and a standard-reaching period of the working face of the broken and soft coal seam and coal roadway driving gas extraction is shortened.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

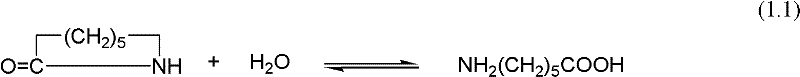

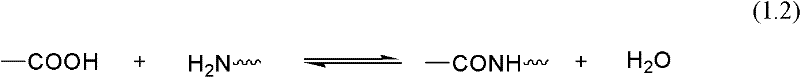

Continuous polymerization production process of high-viscosity polyamide 6

The invention relates to a continuous polymerization process of high-viscosity polyamide 6, comprising the following steps of: preparing caprolactam with de-ionized water; pre-heating the mixed caprolactam to a temperature in a range of 220+ / -30 DEG C by a pre-heater and conveying the mixed caprolactam into a pre-polymerizer by a feeding pump to carry out hydrolyzed ring opening and pre-polymerization on the caprolactam, wherein the pressure of the ring opening and the pre-polymerization is 2.50+ / -0.50 bar, the temperature is in a range of 270+ / -15 DEG C and the flow of the caprolactam is 2200+ / -500 kg / h; then, discharging materials into a post-polymerizer to carry out post-polymerization to obtain a polymer melt, wherein the pressure of the post-polymerization is 0.35+ / -0.25 bar and the temperature is 250+ / -30 DEG C; treating the polymer melt by a polymer filter, a casting strip head, an underwater granulator and a vibrating screen to obtain slices; adding the slices into a pre-extracting water pot to carry out pre-extraction with hot water at the temperature in a range of 115+ / -10 DEG C; then, conveying the treated slices into an extracting tower and extracting with the hot water at the temperature in a range of 100+ / -20 DEG C; conveying the extracted slices into a drying tower and carrying out counter-current drying by nitrogen gas; drying at the temperature in a range of 120+ / -30 DEG C and discharging the dried slices into a slice cooling bin; and conveying the cooled slices into a slice storage bin and a slice packaging bin by the nitrogen gas and packaging to obtain the high-viscosity polyamide 6 slices with the relative viscosity of 3.4-4.0.

Owner:湖南岳化化工股份有限公司

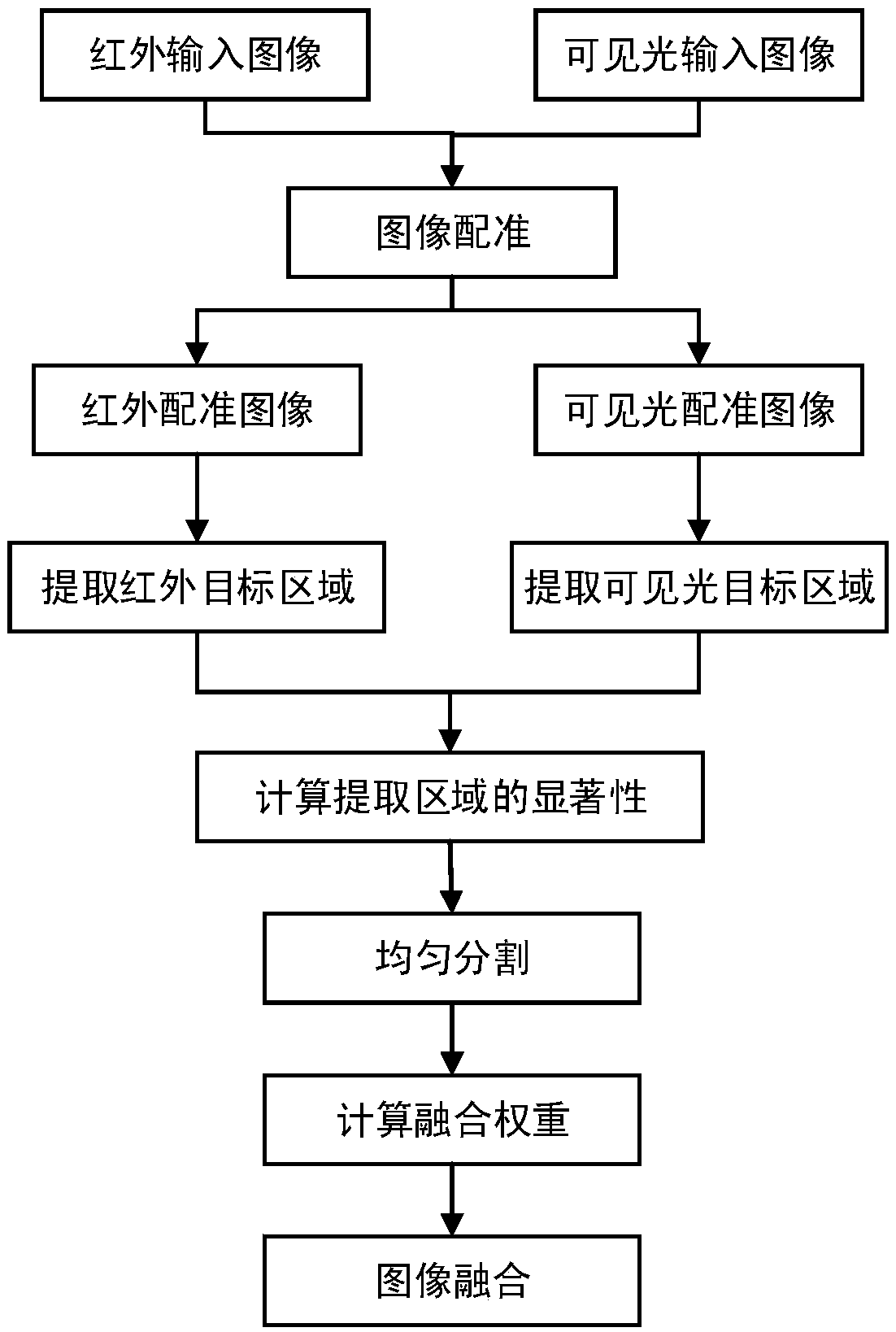

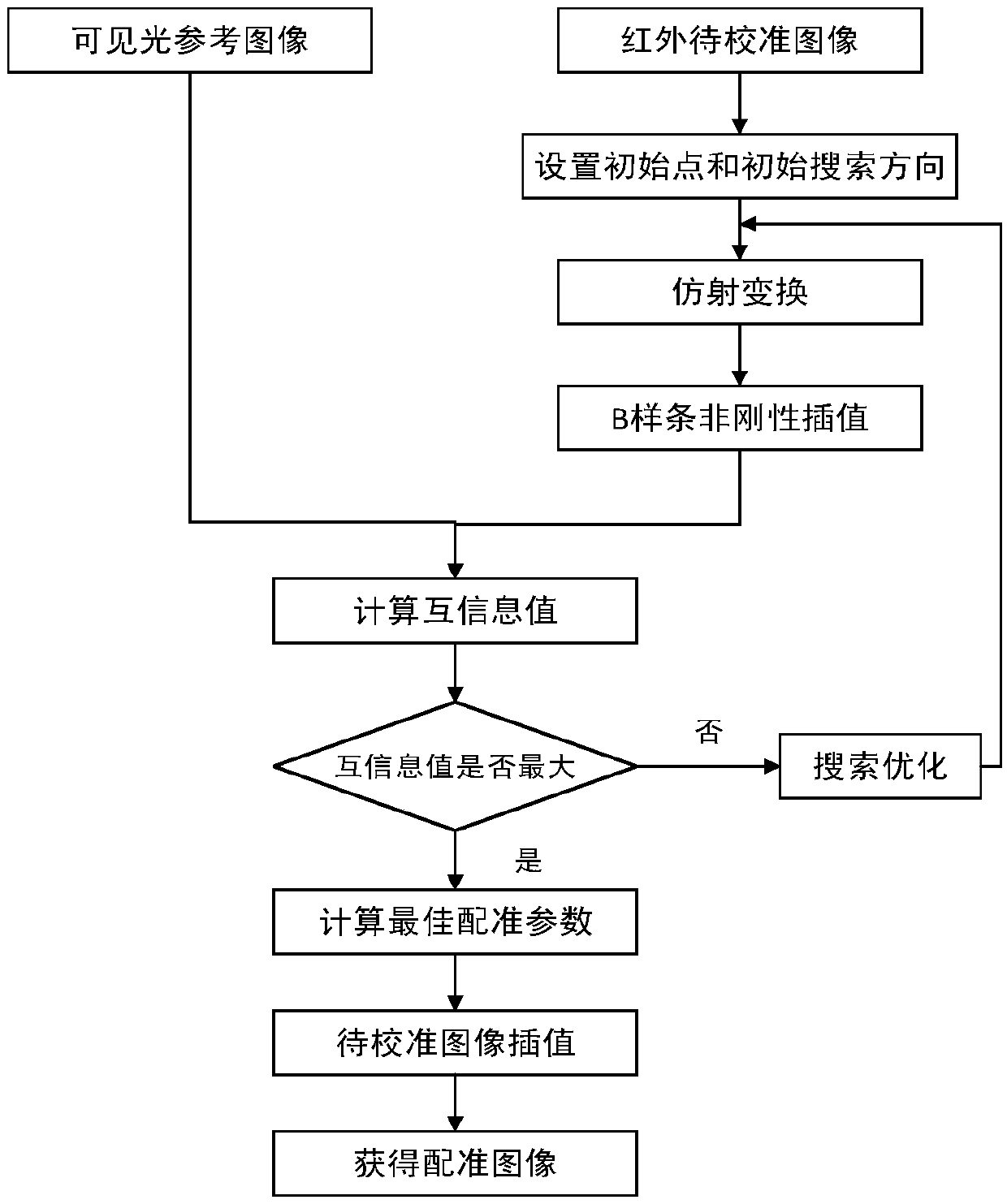

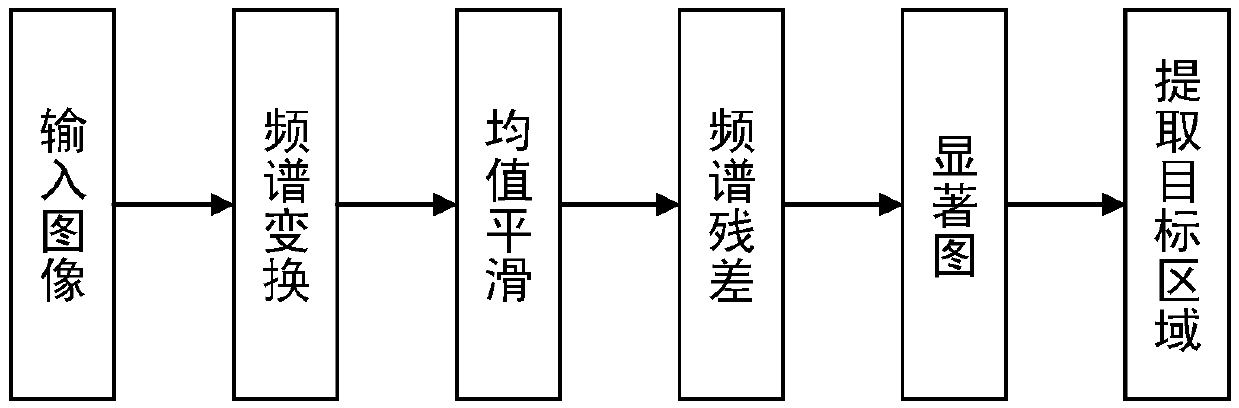

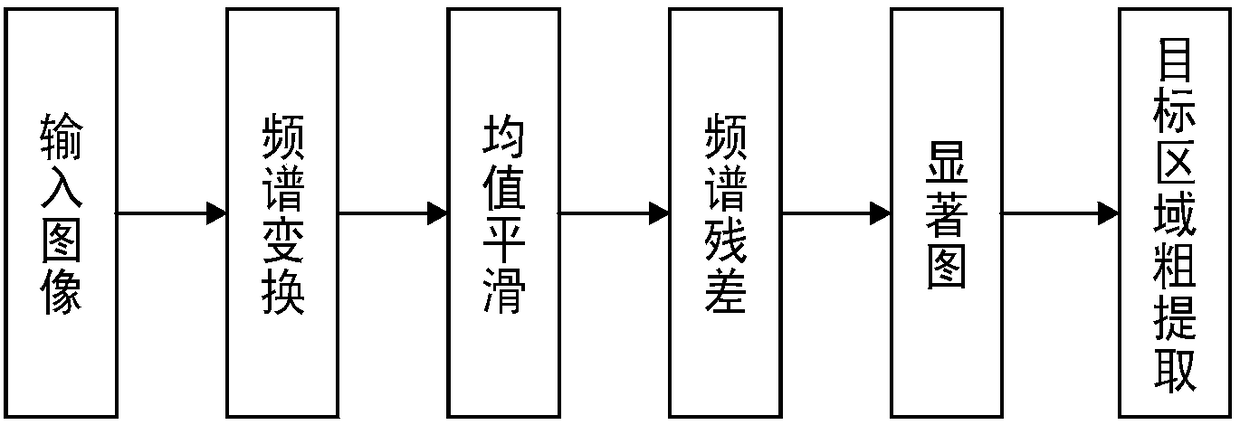

Unmanned aerial vehicle infrared and visible light image fusion method based on target pre-extraction

InactiveCN109584193ASolution perspectiveSolve the problem that different fields of view cannot be mergedImage enhancementImage analysisFrequency spectrumDecomposition

The invention belongs to the field of image processing and computer vision, and relates to an unmanned aerial vehicle infrared and visible light image fusion method based on target pre-extraction. Themethod comprises the following steps of Registering the infrared image and the visible light image of the unmanned aerial vehicle by adopting a registration algorithm based on image gradient mutual information; Carrying out target pre-extraction on the infrared image and the visible light image after registration by adopting a target pre-extraction algorithm based on frequency spectrum residue; And carrying out image fusion on pre-extracted areas of the infrared image and the visible light image after registration by adopting an area blocking fusion algorithm. According to the method, the problem that the infrared image and the visible light image cannot be fused due to different visual angles or visual fields is effectively solved, the whole image is prevented from participating in the fusion operation, and the algorithm calculation amount is reduced; On the premise that decomposition transformation is not carried out on the image, the target pre-extraction region is uniformly segmented, the mode of calculating the fusion weight of each segmented sub-region based on the significance of the pre-extraction region is more scientific, and the fusion result is more authentic.

Owner:AEROSPACE TIMES FEIHONG TECH CO LTD +1

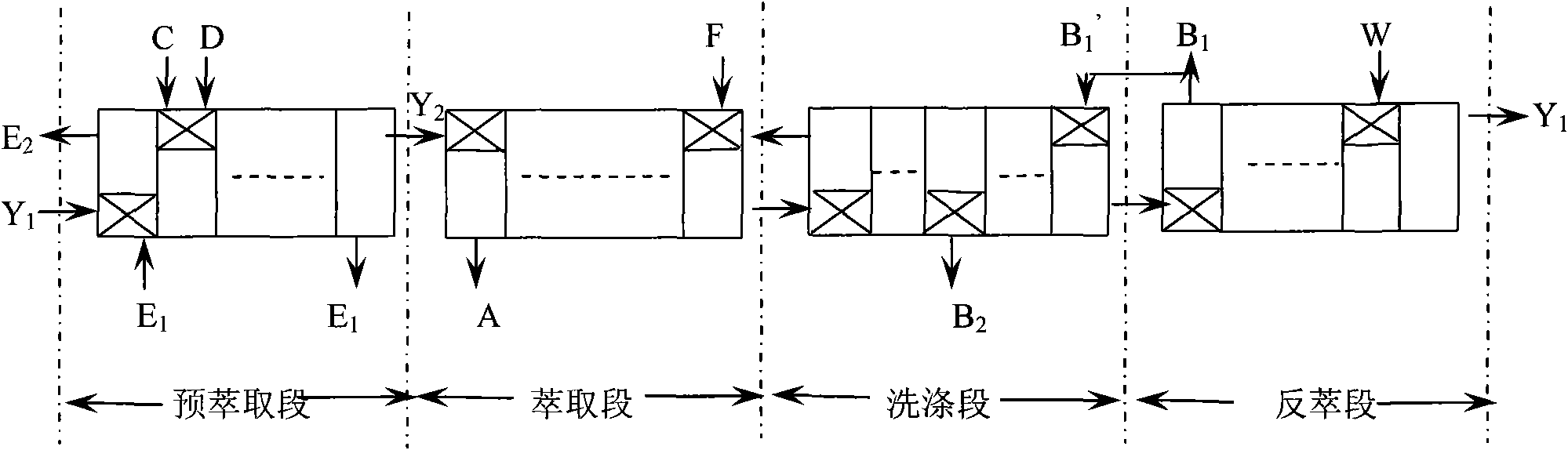

Preextraction method for organic extraction agent, product and uses thereof

ActiveCN101319276ALow in alkaline earth metalsReduce manufacturing costProcess efficiency improvementRare-earth elementAlkaline earth metal

The invention discloses a pre-extraction method for an organic extraction agent, a product and an application thereof in the extraction and separation of rare earths. The pre-extraction method comprises the following steps that: the organic extraction agent is directly mixed with a rare earth solution and alkaline-earth metal compound powder or water slurry containing magnesium and / or calcium forpre-extraction, rare earth metal ions in an aqueous phase are extracted into an organic phase, exchanged nascent hydrogen ions dissolve an alkaline-earth metal compound to maintain the acidity balance of an extraction system so as to produce a loaded organic extraction agent which contains the rare earth metal ions and is used for nonsaponifiable extraction and separation of rare earth elements. In the extraction method, the organic extraction agent does not need liquid ammonia and liquid alkali to saponify, no ammonia nitrogen waste water is produced during the extraction and separation process of the rare earths, the separation cost for the rare earths is greatly reduced, and a large amount of cost for three-waste treatment is saved. The method is suitable for the extraction and separation of the rare earths in all hydrochloric acid systems, sulphuric acid systems and nitric acid systems, has small investment, and takes effect quickly.

Owner:GRIREM ADVANCED MATERIALS CO LTD

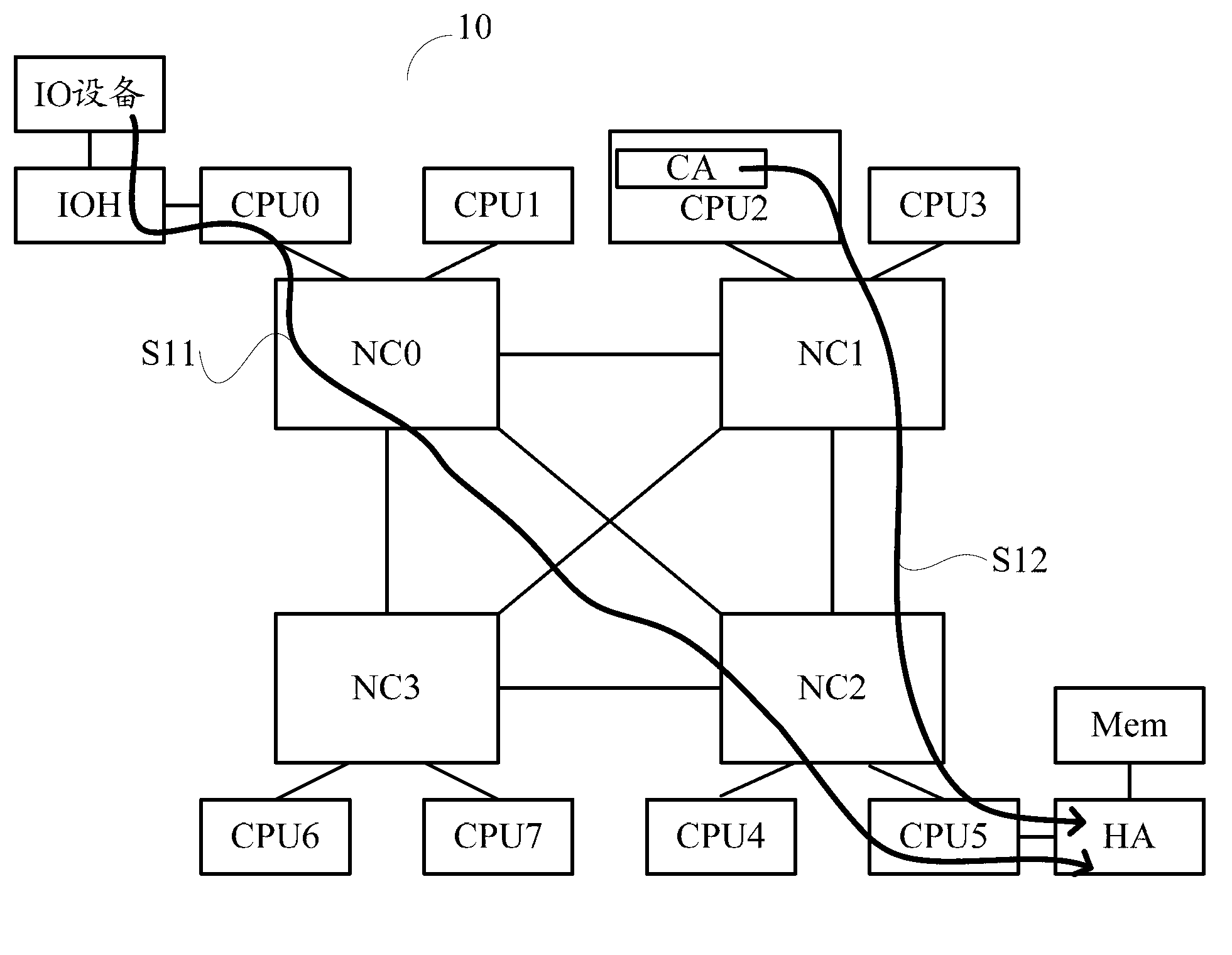

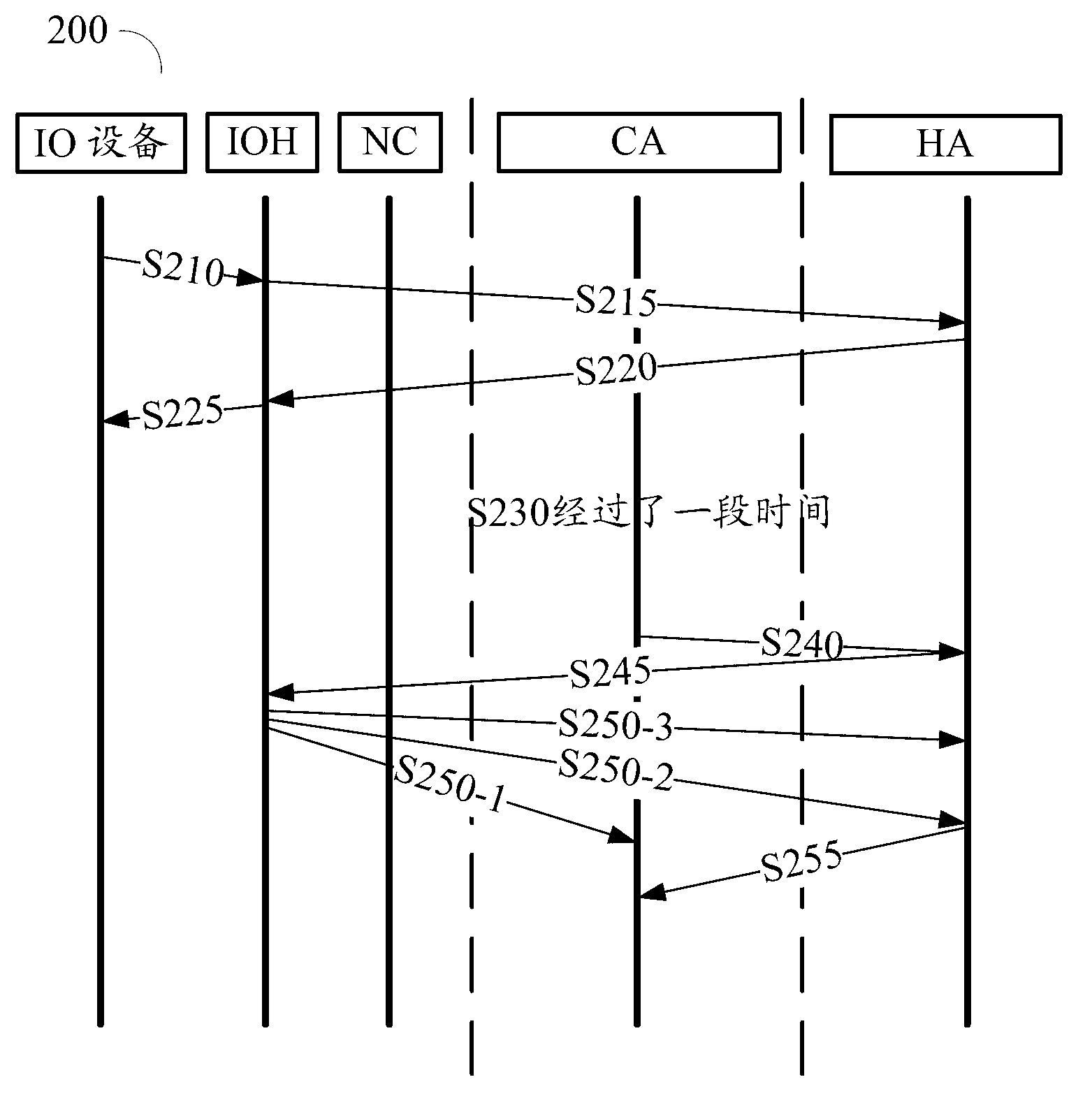

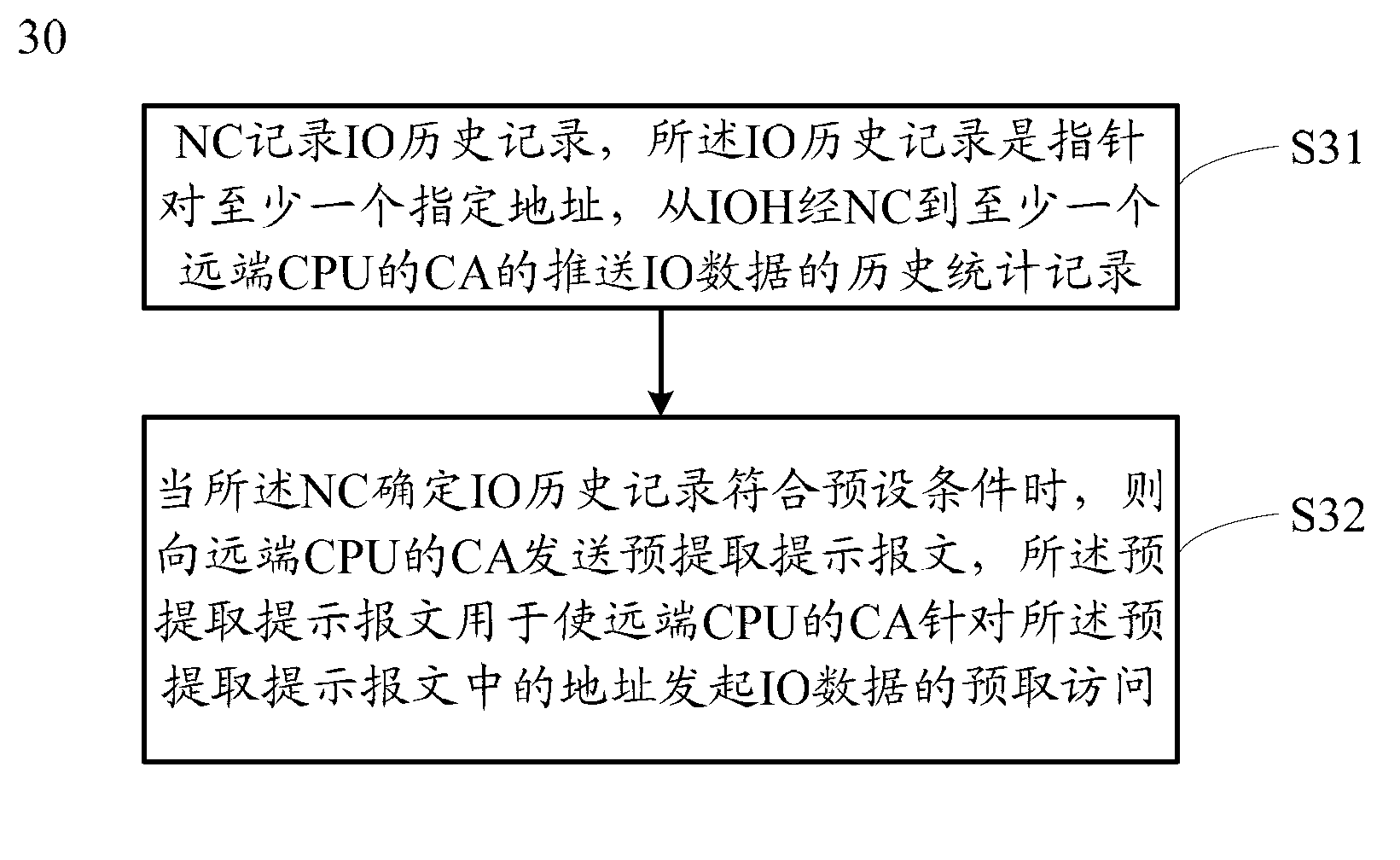

Access method and device for cache coherent-non uniform memory access system

ActiveCN103020004AReduce access latencyImprove performanceMultiple digital computer combinationsNon symmetricAccess method

The embodiment of the invention provides an access method and device for CC-NUMA (cache coherent-non uniform memory access) system. The method comprises the following steps that a node controller (NC) records an IO (input / output) history record, wherein the IO history record means the history statistic record of propelled IO data of a cache (CA) from an IOH (input / output hub) to at least one CPU (central processing unit) through the NC aiming to at least one designated address; when the NC determines that the IO history record meets the preset condition, the NC sends a pre-extraction prompting message to the CA of the remote CPU, and the pre-extraction prompting message is used for initiating pre-fetch access of the IO data by the CA of the remote CPU aiming at the address in the pre-extraction prompting message. By adopting such a technical scheme, through analyzing whether the history record meets the preset condition, the IO data prompting message aiming at the designated address is actively sent to the CA of the remote CPU, and moreover, the remote CPU initiates an IO data pre-fetch operation aiming at the designed address in advance, thus, the access delay of the remote IO data is shortened, and the performance of the system is improved.

Owner:XFUSION DIGITAL TECH CO LTD

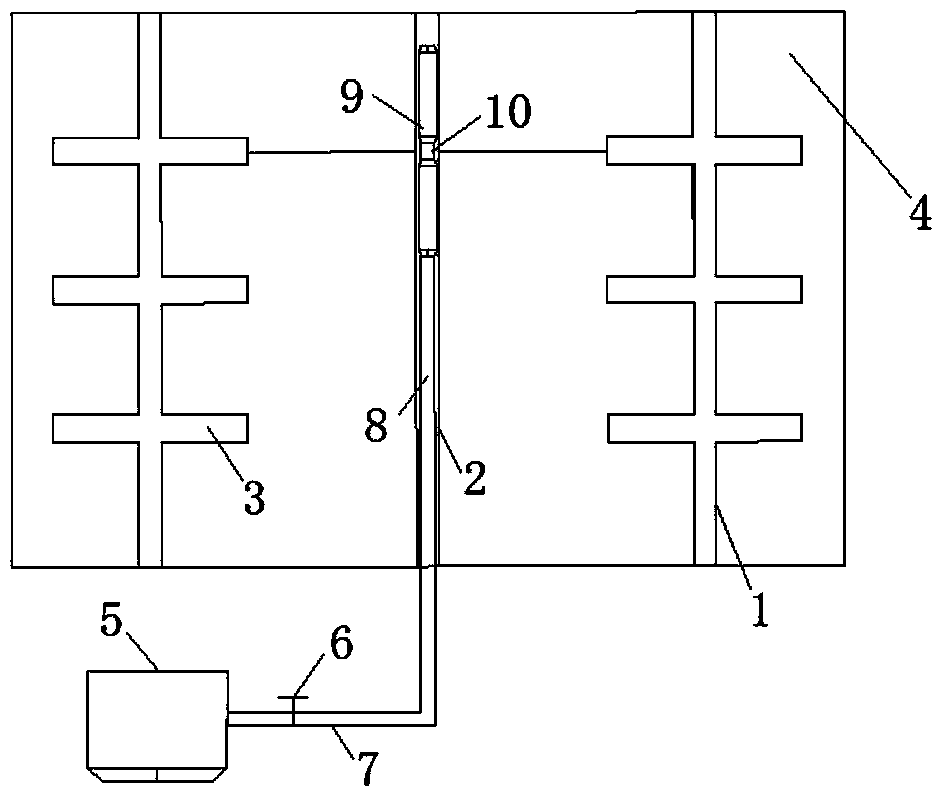

Gas extraction equipment and method for low coal penetration layer

InactiveCN102071920AImprove the extraction effectIncreased pumping distanceFluid removalGas removalSpray nozzleHigh pressure water

The invention discloses gas extraction equipment and a gas extraction method for a low coal penetration layer. The gas extraction equipment for the low coal penetration layer comprises a hollow drill rod, wherein the tail end of the drill rod is connected with a high-pressure water pump through a pipeline; the high-pressure pump is communicated with a water tank; nozzles are arranged at intervalson the rod body of the drill rod; and a vibrator is arranged in the drill rod. The gas extraction method for the low coal penetration layer comprises the following steps of: arranging the gas extraction equipment for the low coal penetration layer, inserting the drill rod into a drill hole, determining whether to start the vibrator or not according to the structure of a coal body, starting the vibrator for vibrating a coal layer if the coal body is a soft coal layer, feeding high-pressure water to the drill rod by using the high-pressure water pump and spraying the high-pressure water to the coal layer through the nozzles; and if the coal body is a hard coal layer, starting the high-pressure water pump for feeding water into the drill rod and spraying the water onto the coal layer throughthe nozzles of the drill rod or vibrating during water jetting. Specific to the problems of poor air permeability and the like of a coal reservoir in a gas pre-extraction process, in the gas extraction equipment and the gas extraction method for the low coal penetration layer, the stress of the coal reservoir is released effectively.

Owner:HENAN POLYTECHNIC UNIV

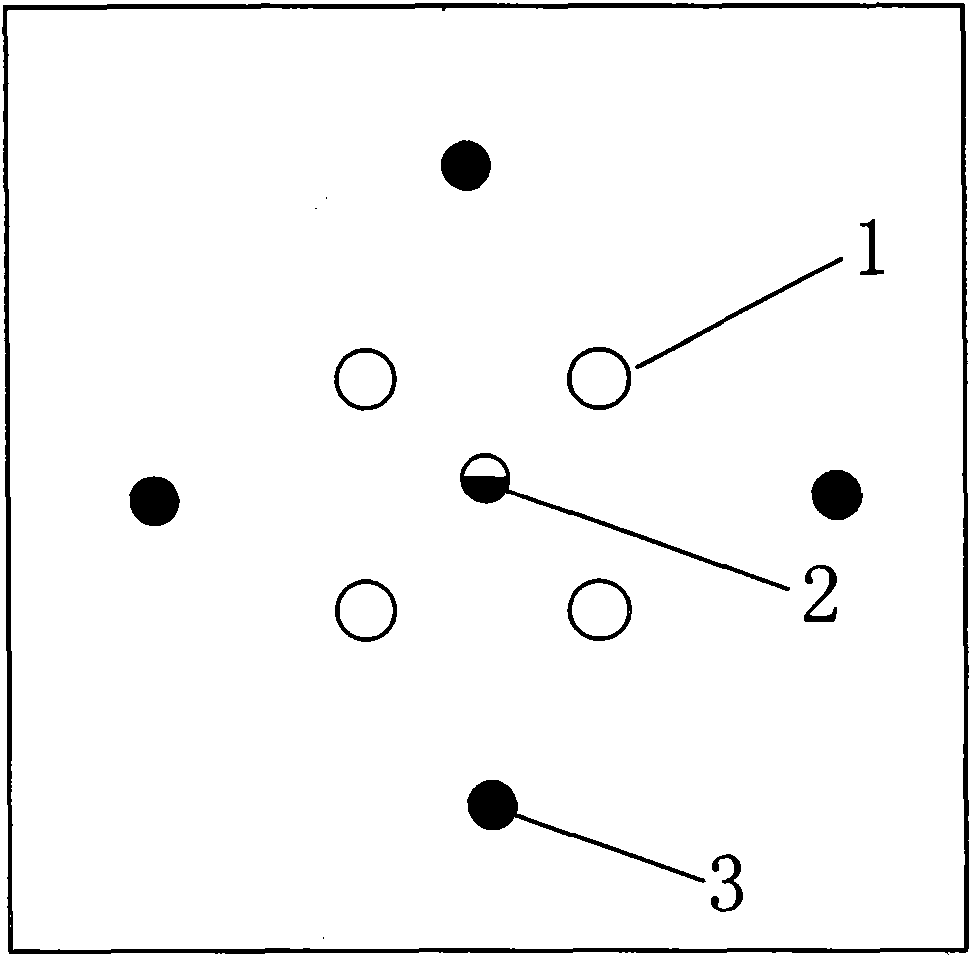

Method for improving crossing-hole gas extraction concentration

ActiveCN101956546AEfficient communicationEfficient use ofFluid removalGas removalPressure systemPositive pressure

The invention discloses a method for improving crossing-hole gas extraction concentration, which is particularly applied to crossing-hole later-stage pre-extraction coal bed gas in a hole cluster mode. When the gas extraction concentration is lower than 30 percent, a plurality of small peripheral holes are formed around the crossing-hole cluster, and at least one inner small hole is formed insidethe hole cluster; powder conveying pipes are arranged inside the small peripheral holes and the inner small hole and hole openings are sealed by a polyurethane sealant; and fine powder is respectively blown into the small peripheral holes and the inner small hole through the powder conveying pipes due to an underground air pressure system, and the fine powder enters fracture air leakage channels around crossing holes and blocks channels through which airflows enters the crossing holes in a tunnel under the coaction of positive pressure of the underground air pressure system and negative pressure of extracting the gas. The method for improving the crossing-hole gas extraction concentration has the advantages of capacity of greatly improving the crossing-hole gas extraction concentration, prolonging the drilling hole effective extraction period, along with simple, convenient and rapid operation.

Owner:CHINA UNIV OF MINING & TECH

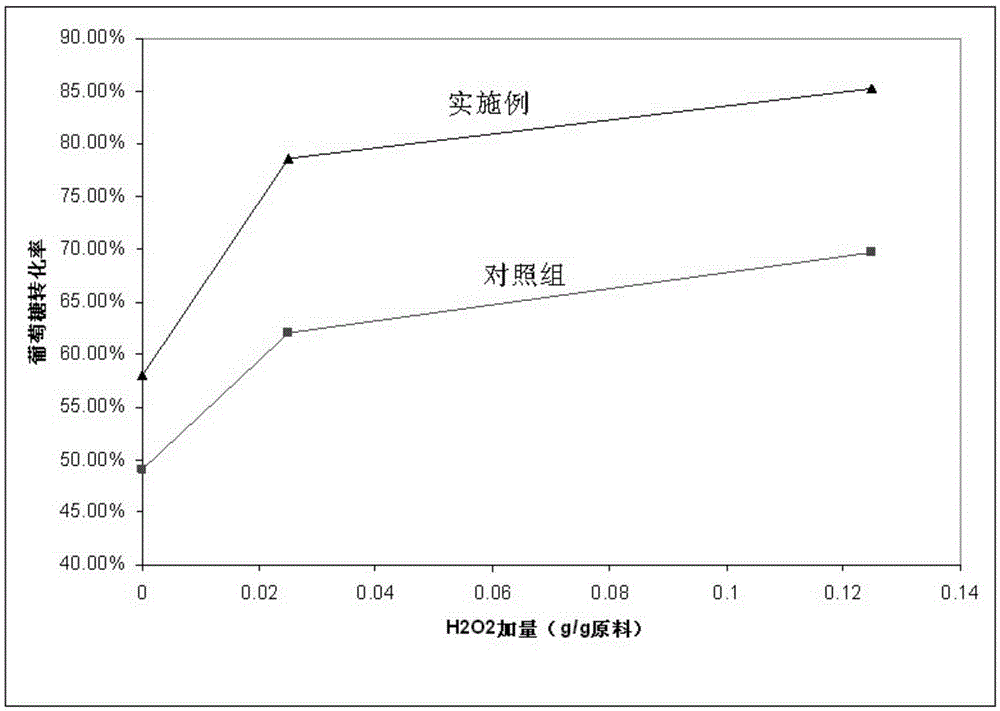

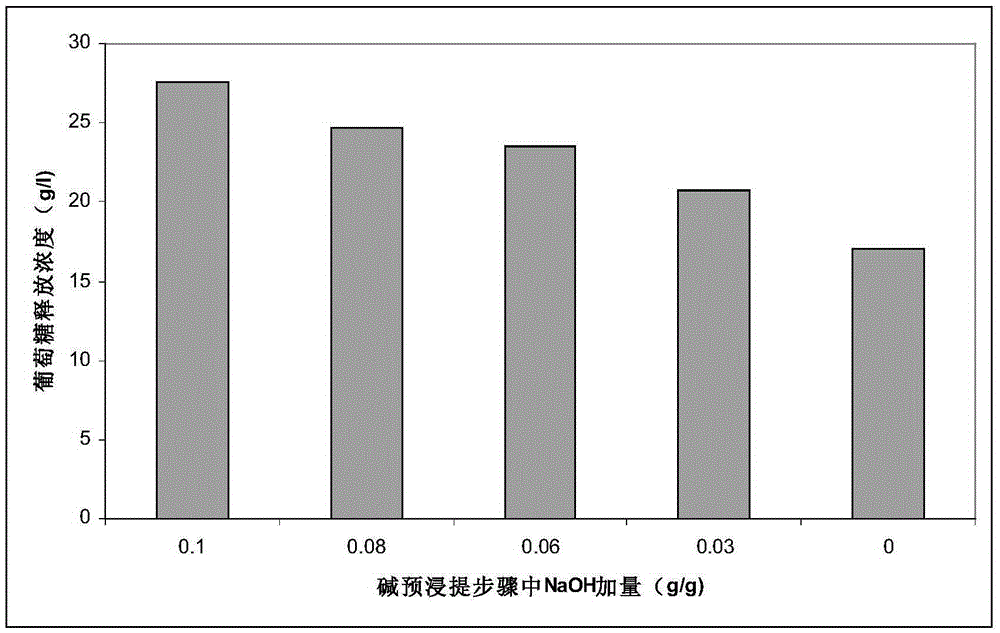

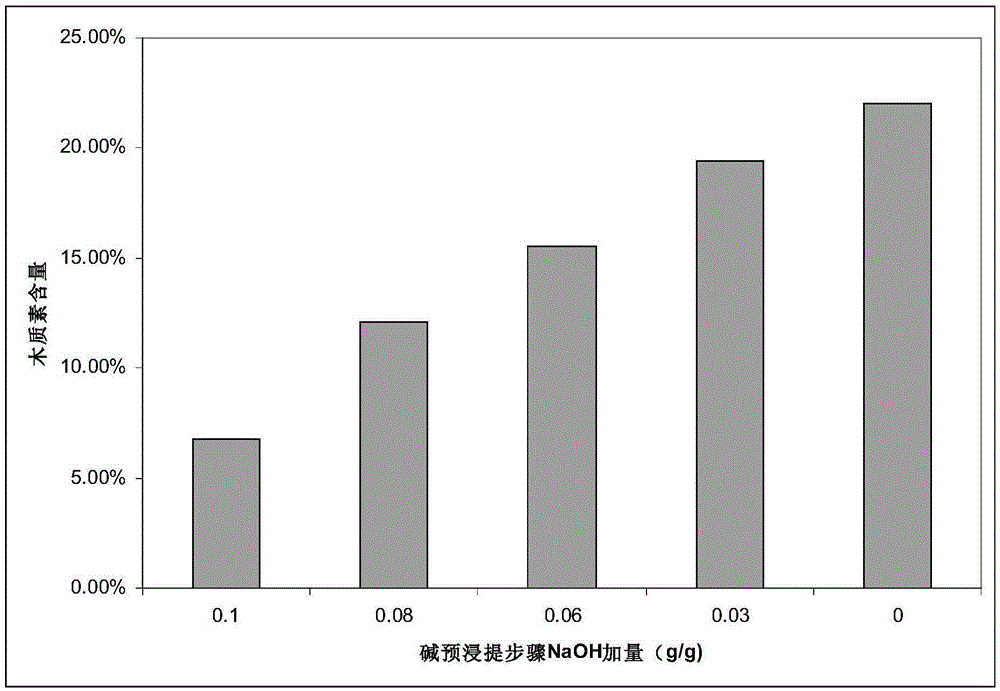

Method for improving conversion efficiency of lignocellulose through combined treatment and method for efficiently preparing ethyl alcohol

InactiveCN105385724AImprove the conversion rate of enzymatic hydrolysisImprove sugar conversion rateBiofuelsMicroorganism based processesCelluloseCombined treatment

The invention relates to a method for improving the conversion efficiency of lignocellulose through combined treatment and a method for efficiently preparing ethyl alcohol. The method for improving the conversion efficiency of the lignocellulose through combined treatment includes the steps that a lignocellulose raw material is pre-extracted through alkaline, then alkaline H2O2 treatment is conducted, and afterwards, enzyme hydrolysis is carried out. According to the treatment method, alkaline pre-extraction is carried out first, and then alkaline H2O2 treatment is conducted, so that the enzymolysis conversin rate of the lignocellulose is greatly increased, and the glucose conversion rate of the cellulose can be urged to be further increased. The pretreatment process is simple and easy to implement, and wastewater which is difficult to deal with can be avoided. The using amount of H2O2 in traditional alkaline hydrogen peroxide pretreatment is reduced, and meanwhile the H2O2 can be made to act on remaining lignin more effectively.

Owner:QILU UNIV OF TECH

Method for highly efficiently extracting protein from walnut dreg

InactiveCN102936610ALow costHigh extraction ratePeptide preparation methodsFermentationChromatography columnElectrolyte

The invention provides a method for highly efficiently extracting protein from walnut dreg. The method comprises the steps that: a, walnut dreg is crushed into walnut dreg powder; b, according to a ratio that n-hexane:succinic diisooctyl sodium sulfonate=1mL:0.04-0.10g, n-hexane is dissolved in succinic diisooctyl sodium sulfonate, such that a mixed solution is obtained; the mixed solution is mixed with an electrolyte buffering solution, such that a reverse micelle solution is obtained; c, the walnut dreg powder in the step a and the reverse micelle solution obtained in the step b are mixed according to a ratio that reverse micelle solution:walnut dreg powder=1mL:0.02-0.10g; the mixture is subjected to stirring or microwave and enzyme method assisted extraction; centrifugation is carried out, and a supernatant is a protein pre-extraction liquid; d, the protein pre-extraction liquid obtained in the step c and the electrolyte buffering solution is mixed according to a volume ratio that protein pre-extraction liquid:electrolyte buffering solution=1:0.5-1:2; the mixture is subjected to stirring or microwave-assisted extraction; centrifugation is carried out, and lower-layer clear liquid is protein post-extraction liquid; and e, the protein post-extraction liquid obtained in the step d is subjected to chromatography column desalting, such that a product is obtained.

Owner:新疆林科院经济林研究所 +1

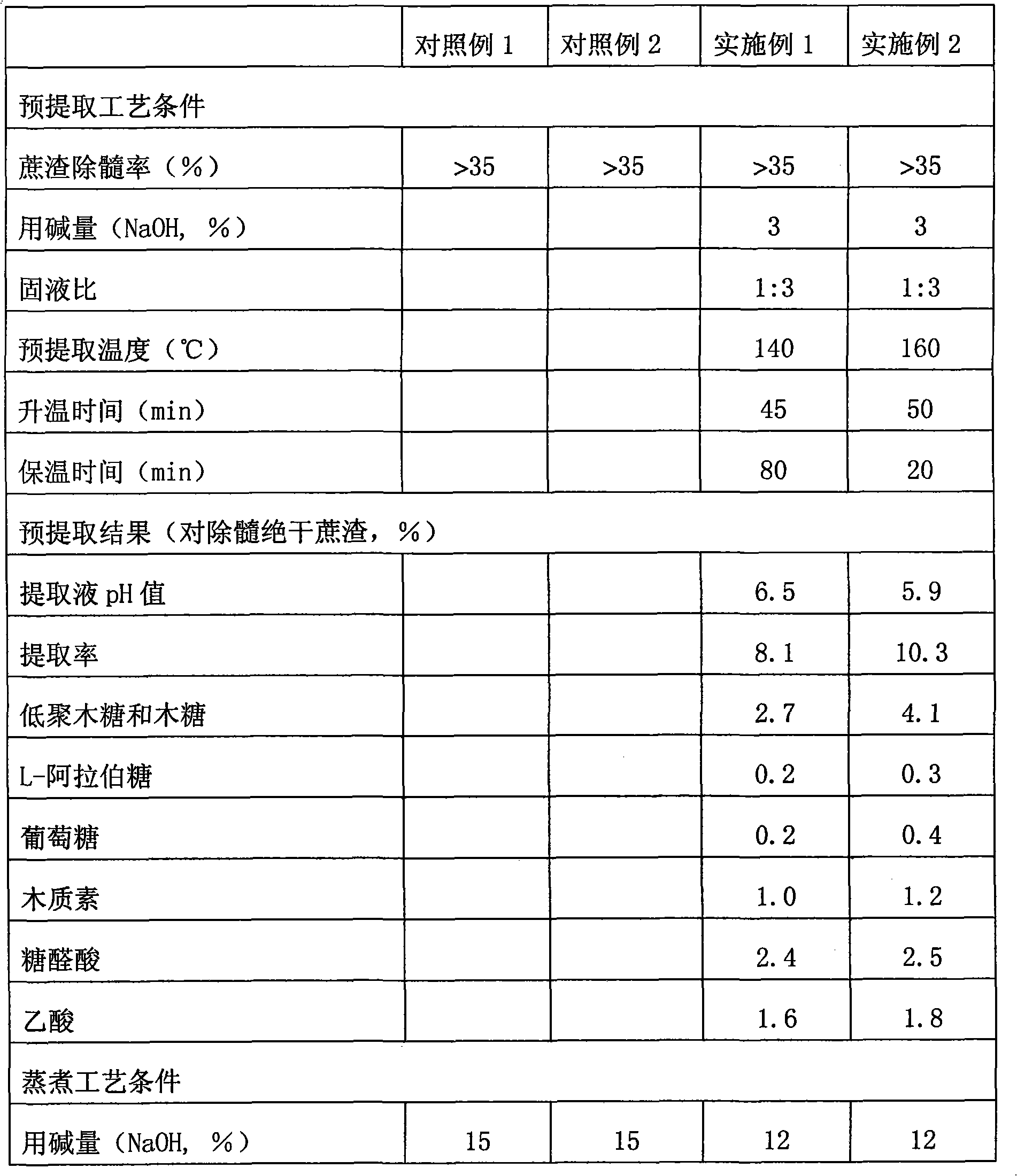

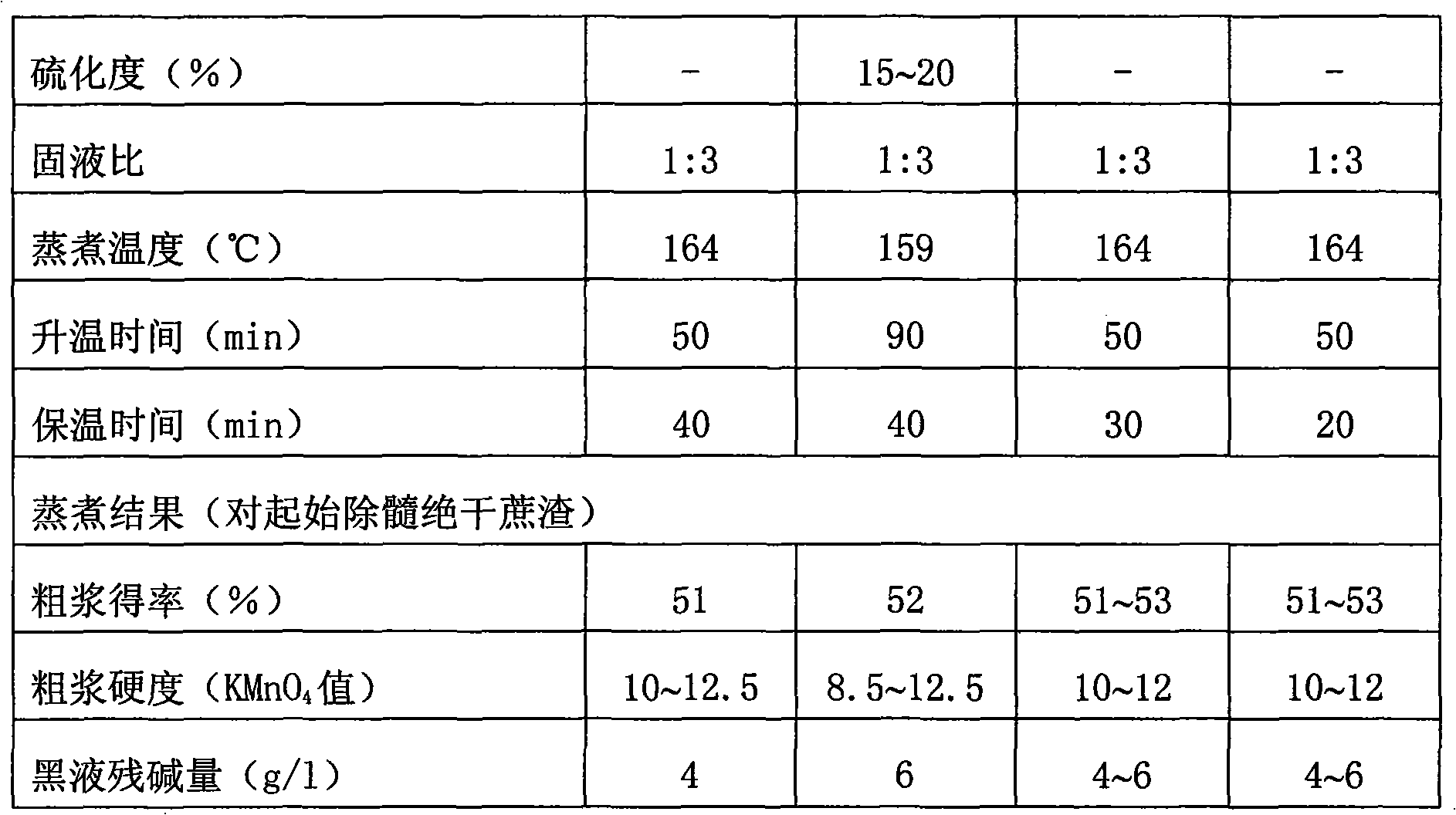

Bagasse alkaline pulping method by pre-extracting hemicellulose and product thereof

InactiveCN101565907ALess investmentReduce manufacturing costSugar derivativesPretreatment with acid reacting compoundsSteam pressureSolvent

The invention relates to a bagasse alkaline pulping method by pre-extracting hemicellulose and a product thereof; the method includes the following steps of: preparing bagasse: depithing and washing the bagasse; pre-extraction, in which the extracted solvent is sodium hydroxide solution and the technical condition comprises an alkaline content of 1-8percent, a solid-to-liquid ratio of 1:2.5-8.0, extraction temperature of 80-180 DEG C, heating-up time of 10-120 minutes, holding time of 0-120 minutes, a pH value of 4.5-6.9 at a reaction end point, and the pressure of saturated steam pressure at corresponding temperature; liquid solid separation and washing: collecting filtrate to produce extract; and preparing the pulp by residue alkaline process. In the invention, bagasse extract capable of extracting xyio-oligosacchandes, and the like and bagasse rough pulp for preparing whitened chemical pulp can be obtained; with a pre-extraction procedure added before stewing, the unscreened yield and hardness of bagasse are equivalent to that of pure pulping without pre-extraction by controlling the pre-extraction and stewing technical condition; bagasse biological refining on a pulping basis is realized; and the cost for pulping and pre-extracting hemicellulose is reduced, thereby saving resources.

Owner:上海士林纤维材料有限公司

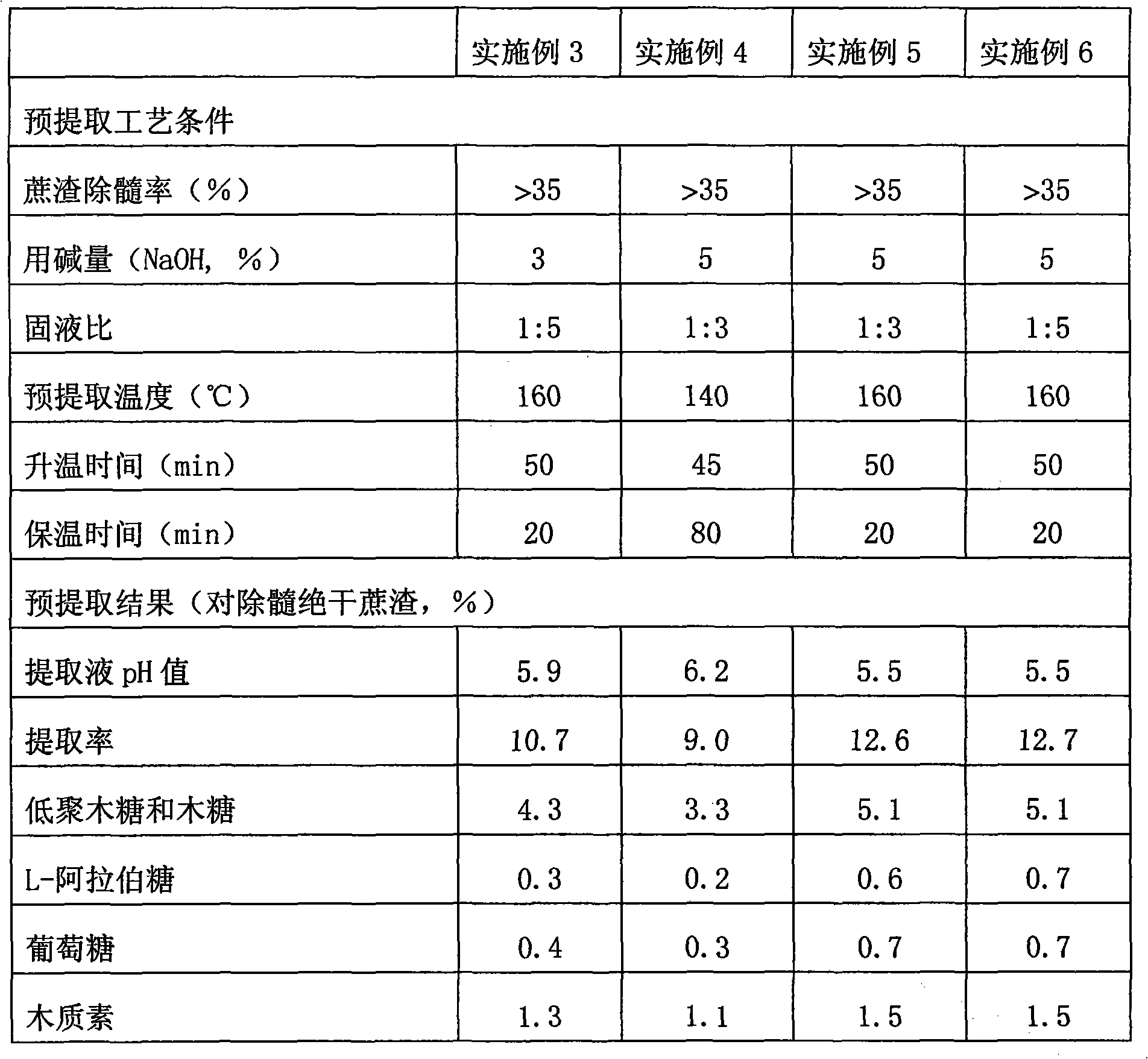

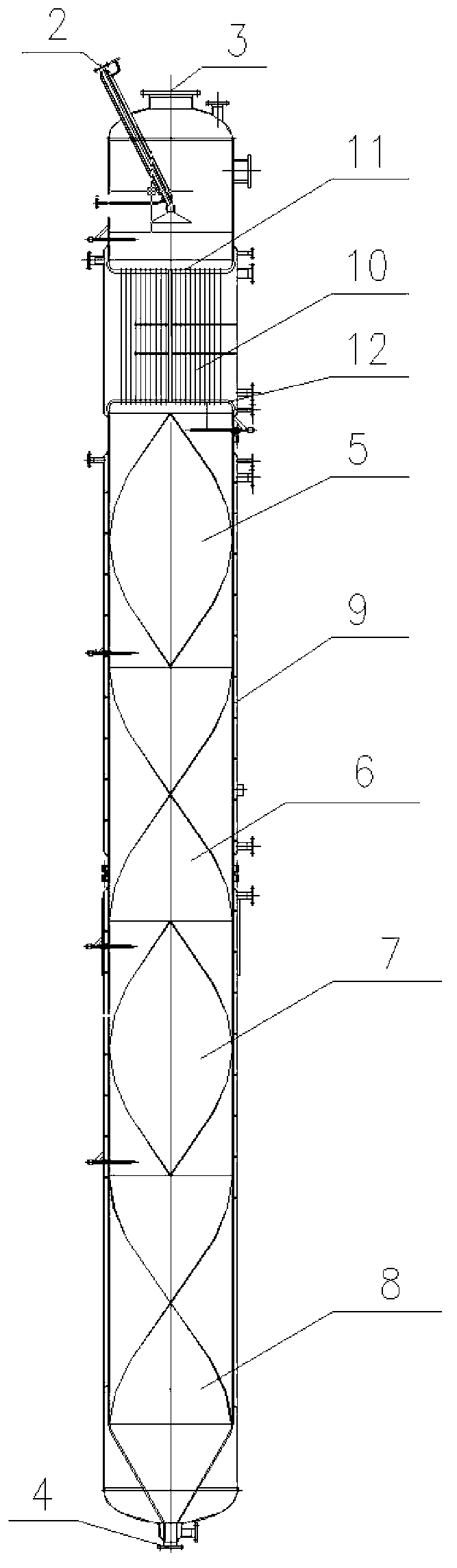

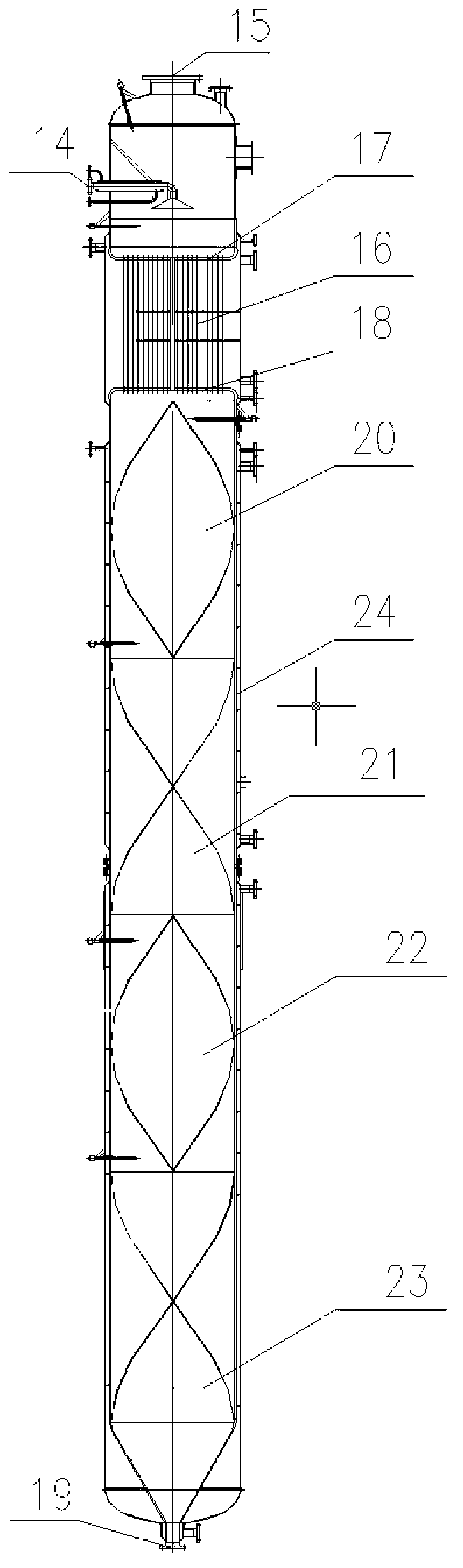

Polyamide polymerization production process and equipment for same

The invention relates to a polyamide polymerization production process and equipment for the same. The polyamide polymerization production process comprises the following steps of: carrying out prepolymerization on melted caprolactam, titanium dioxide, benzoic acid, and the like at a high temperature, and then carrying out front polymerization and post polymerization; pelleting; pre-extracting; extracting; pre-drying; and drying to obtain a product. The production equipment comprises a hexanolactam melting system, a preparation system, a feed system, a high-temperature prepolymerization device, a front polymerization tower, a rear polymerization tower, a pelleting system, a pre-extraction tower, an extraction tower, a pre-drying tower, a drying tower, and the like. According to the invention, static state flow guide spiral mixer assemblies are additionally arranged in the extraction tower and the lower sections of each row of tubes of the high-temperature prepolymerization device, the front polymerization tower and the post polymerization tower; the polyamide hydrolyzing ring opening and dewatering are more uniform and sufficient and faster; the front polyaddition reaction is sufficient and stable; the rear polycondensation stage is more uniform and stable in molecular distribution; the extraction tower more sufficiently and stably extracts a caprolactam monomer; the pre-drying tower can be used for removing the surface moisture of a slice; the drying tower dries combined water; a recovery system can be used for recovering an oligomer and extracts the caprolactam monomer contained in water.

Owner:武汉森大科技研究发展中心

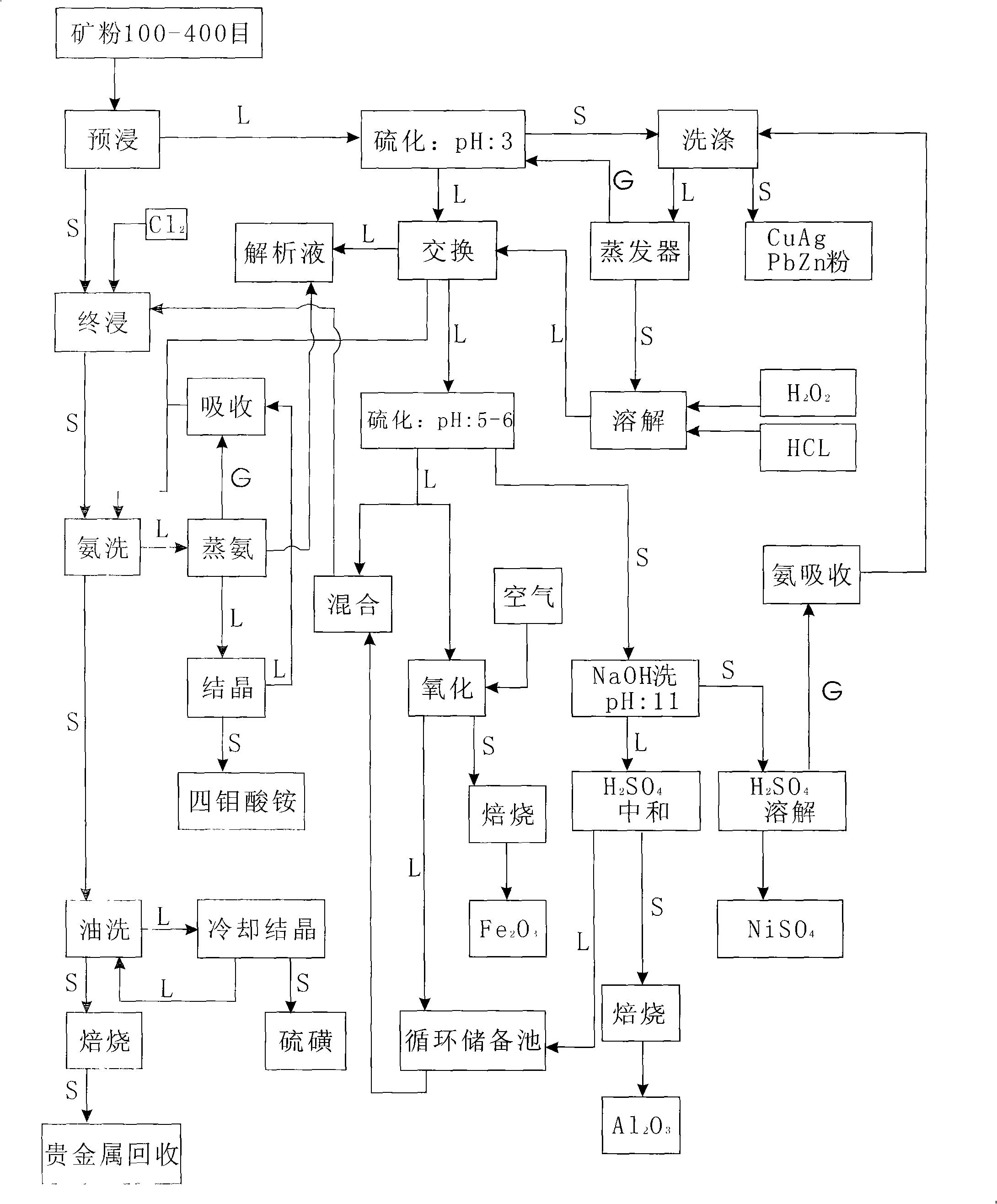

Synthesizing method for molybdenum-nickel ore

The invention discloses a method for comprehensively processing a molybdenum-nickel ore which needs to solve the technical problem of achieving the high extraction rate of molybdenum, nickel, zinc, copper and lead as well as comprehensively utilizing the valuable component of a carbon molybdenum-nickel ore. The invention includes the following steps: grinding a raw ore material to 100 to 400 meshes; pre-extraction, terminal-extraction, the processing of the slag of terminal-extraction and the separation of a pre-extraction liquid. Compared with the prior art, the invention has a high comprehensive recycling rate; the molybdenum-nickel achieves 99 percent; the other nonferrous metals achieve 96 percents. Besides, the method of the invention avoids the valuable component from being lost during the next separation process; the pre-extraction liquid is closed and circulated during the technique; the waste water drain is removed; the demand of the technique to a device is low; the used chemical materials are cheap; the technical condition is gentle; the cost is low; the hidden safety danger brought by the traditional high temperature and high pressure operation is removed; the production process is easy to realize mechanization.

Owner:SHENZHEN YUHONG TECH

Liquid carbon dioxide bomb, propping agent blasting anti-reflection method and device

InactiveCN106703773AImprove permeabilityImprove breathabilityFluid removalCoal mine methaneEngineering

The invention relates to a liquid carbon dioxide bomb and a propping agent blasting anti-reflection method and a device. The device comprises a liquid storage tube provided with a priming device and liquid carbon dioxide. A releasing tube with propping agent inside is arranged in the front part of the liquid storage tube. A plurality of spray-holes are disposed on the tube wall of the releasing tube. The propping agent is wrapped in a thin strip-shape with plastic film and put into the releasing tube. High-pressure gases produced by vaporized liquid CO2 after liquid CO2 bomb detonates in coal seam form a large number of fractures in drill holes. The high-pressure gas destroys the plastic film wrapping the propping agent during an explosion process. The propping agent with the high-pressure gases enters into coal seam fractures and fractures formed by propping, prolongs existing time of the fractures. The fractures have big presplit radius in coal seam, which can effectively reduce drilling hole amounts in a current extraction and exploitation system in underground coal mines, improve extraction efficiency, reduce pre-extraction time of gas and extraction cost of gas in coal mine, improve a production efficiency of coal, and enhance security of coal production.

Owner:CHINA UNIV OF MINING & TECH

Method for bedding drilling and working surface gas pre-extraction

InactiveCN104018874AShorten production timeImprove the extraction effectGas removalSealing/packingProcess engineeringEngineering

The invention discloses a method for bedding drilling and working surface gas pre-extraction. According to the extraction time difference and the difference in distances to the cut openings, downward bedding drilled holes with different hole distances are parallelly constructed along the tendency of a coal seam respectively in working surface air returning following grooves, upward bedding drilled holes with different hole distances are parallelly constructed along the tendency of the coal seam in working surface conveying following grooves, gas extraction pipelines are respectively arranged on the sides of the conveying following grooves and the air returning following grooves close to a working surface coal wall, the downward bedding drilled holes and the upward bedding drilled holes of the conveying following grooves and the air returning following grooves enter a mine gas extraction system through the gas extraction pipelines, and after grouting and hole sealing, the extraction system is in combination to perform gas extraction. According to the technical scheme, by adjusting a drilling arrangement mode, the bedding drilled holes with different hole bottom distances are constructed according to the extraction time difference and the difference in distances to the cut openings, the drilling engineering quantity is reduced, production time of the working surface is shortened to the largest extent, the gas extraction effect is improved, and coal and gas simultaneous extraction is achieved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST +1

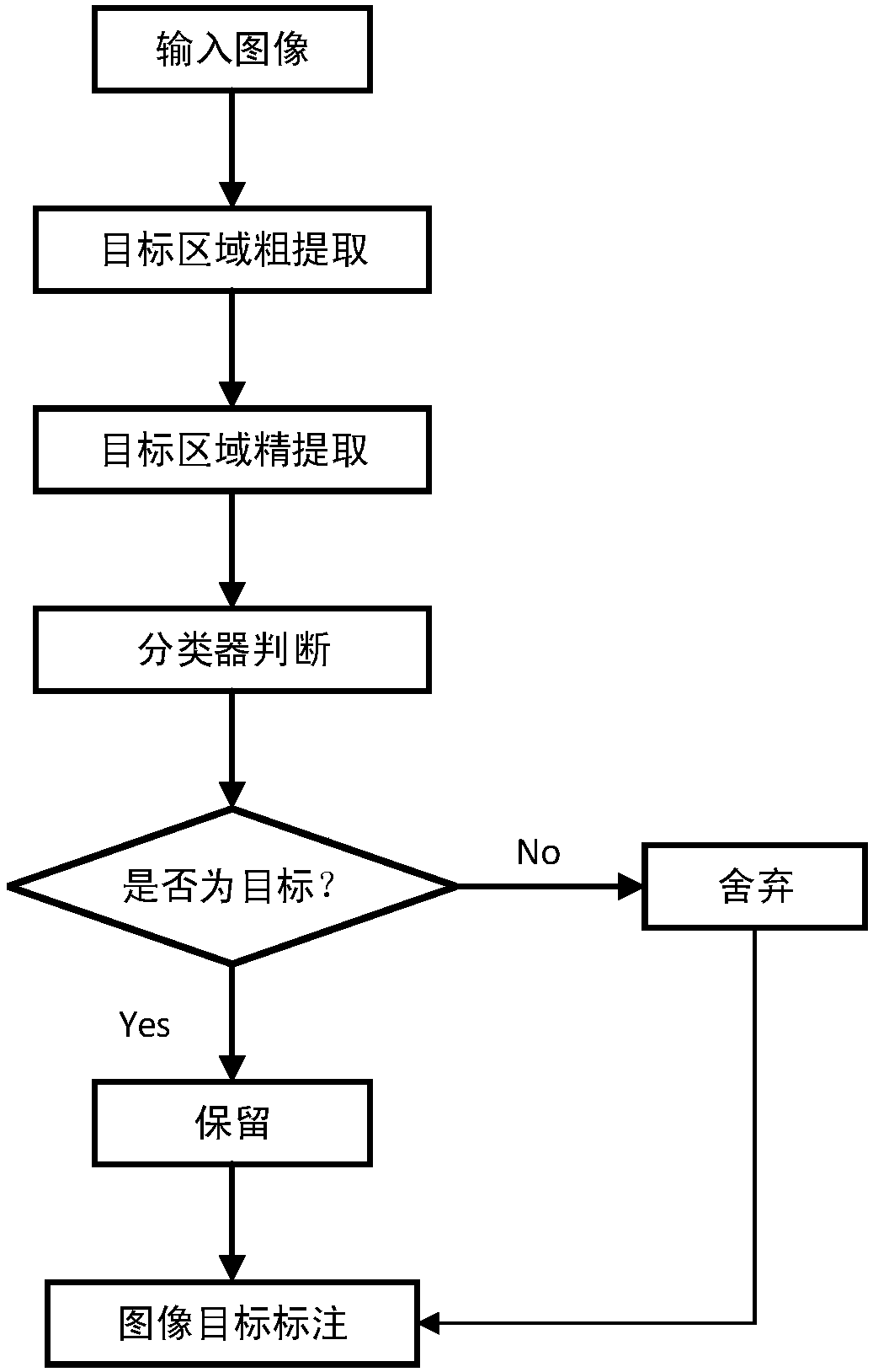

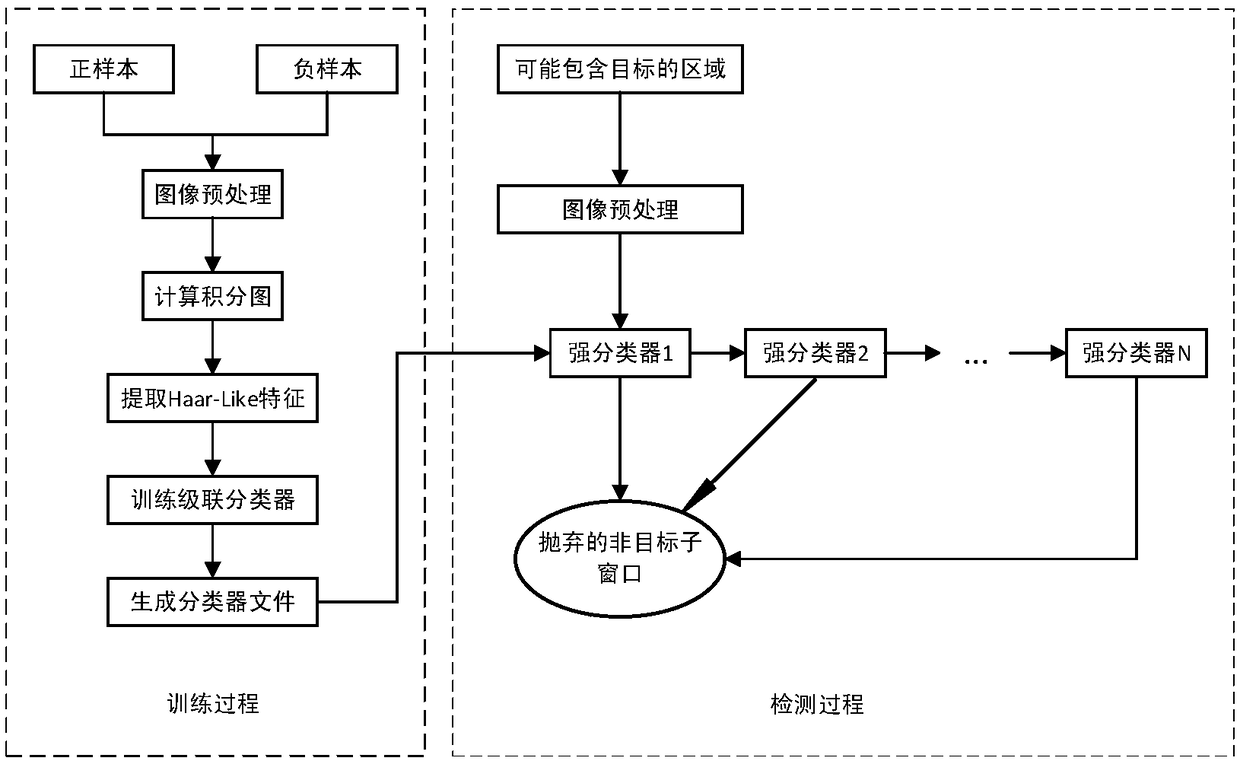

UAV (unmanned aerial vehicle) reconnaissance video image object automatic detection method

ActiveCN108446584AAvoid missing detectionAvoid false detectionScene recognitionImaging processingSlide window

The invention relates to the field of image processing, and specifically relates to a UAV (unmanned aerial vehicle) reconnaissance video image object automatic detection method. The method comprises the steps: employing a target coarse extraction algorithm and a fine extraction algorithm for pre-extraction of a target region, carrying out the judgment of the pre-extracted region through a classifier, eliminating a non-target pre-extracted region, maintaining and marking the target region, and achieving the automatic detection of a target in the video image. According to the invention, a pre-extraction algorithm is introduced for the pre-extraction of the target in the video image, thereby avoiding a condition that a detection algorithm causes the detection leakage or wrong detection because the size of a sliding window and the step length cannot achieve the stepless changes or the features of the target are not apparent, and improving the detection accuracy. Meanwhile, the invention introduces the pre-extraction algorithm for the pre-extraction of the target in the video image, thereby achieving the sharing of the weight of a classifier detection algorithm in the whole automatic detection process of a reconnaissance target, reducing the requirements for the number of samples required by the training of the classifier and the order of magnitudes of diversity, and improving the operation efficiency.

Owner:中国航天电子技术研究院

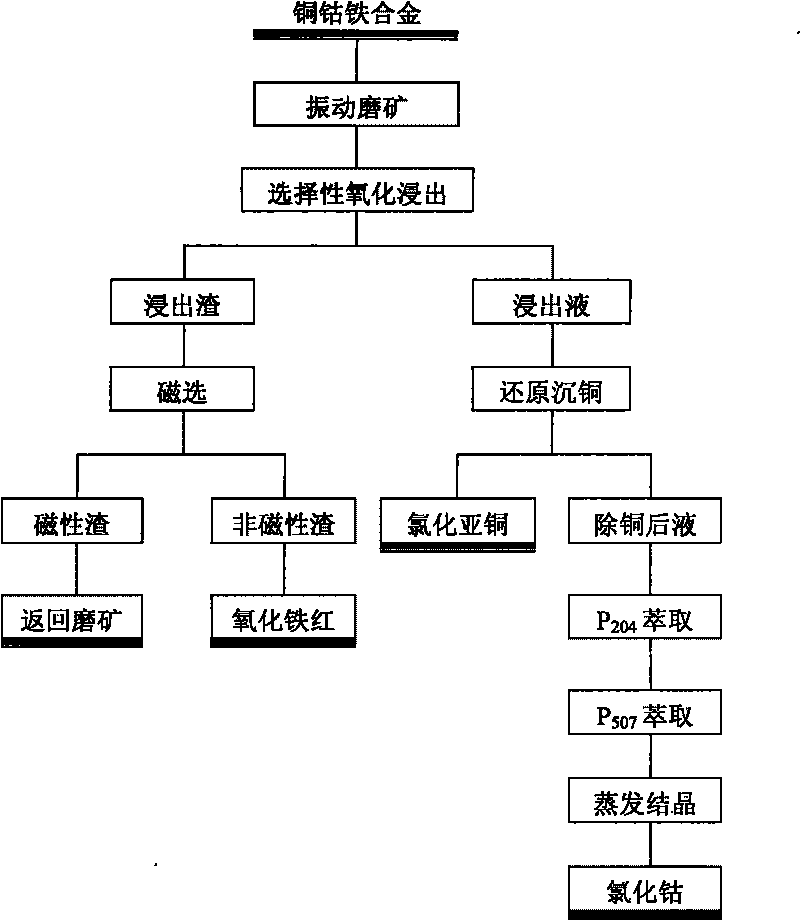

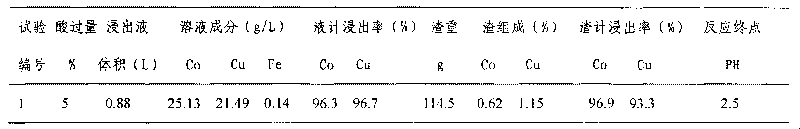

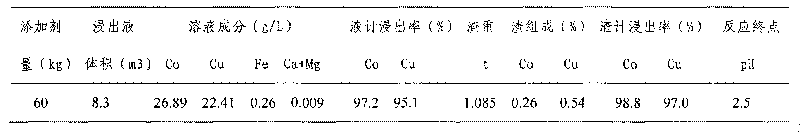

Production process for comprehensively recovering valuable metal of copper, cobalt and iron alloy

InactiveCN101717862AReduce energy consumptionWide range of reaction initial temperatureProcess efficiency improvementAlloyHydrometallurgy

The invention relates to a production process for comprehensively recovering valuable metal of copper, cobalt and iron alloy, belonging to the technical field of hydrometallurgy and comprising the steps of: preparing fine alloy powder with the mesh of -100 by vibrating, grinding, screening and grading the copper, cobalt and iron alloy; adding water to the fine alloy powder to stir; then adding a required theoretical quantity of fluorine ions F-; adding inorganic acid to react for 1.5 hours; slowly adding oxidant solution; stirring for 1.5 hours at the continuous temperature of larger than 85 DEG C after adding the oxidant solution; separating solid from the solution; adding a reducer whose use quantity is 1.05 times of the theoretical quantity to the obtained filtrate; stirring at normal temperature; reacting for 2 hours; obtaining cuprous chloride and pre-extraction solution after filtering; and finally carrying out P204 extraction and P507 extraction on the pre-extraction solution; and evaporating and crystallizing to obtain cobalt chloride. The production process has the advantages of environmental-friendly performance, simple operation, high efficiency, energy saving and suitability for industrial production.

Owner:HUNAN KAITONG METAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com