Process for separating rare-earth element by extraction

A rare earth element and extraction technology, applied in the field of rare earth solvent extraction and separation, can solve the problems of slow and incomplete solid-liquid reaction, affecting product quality, etc., and achieve the effects of eliminating pollution, reducing production costs, and saving three wastes treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

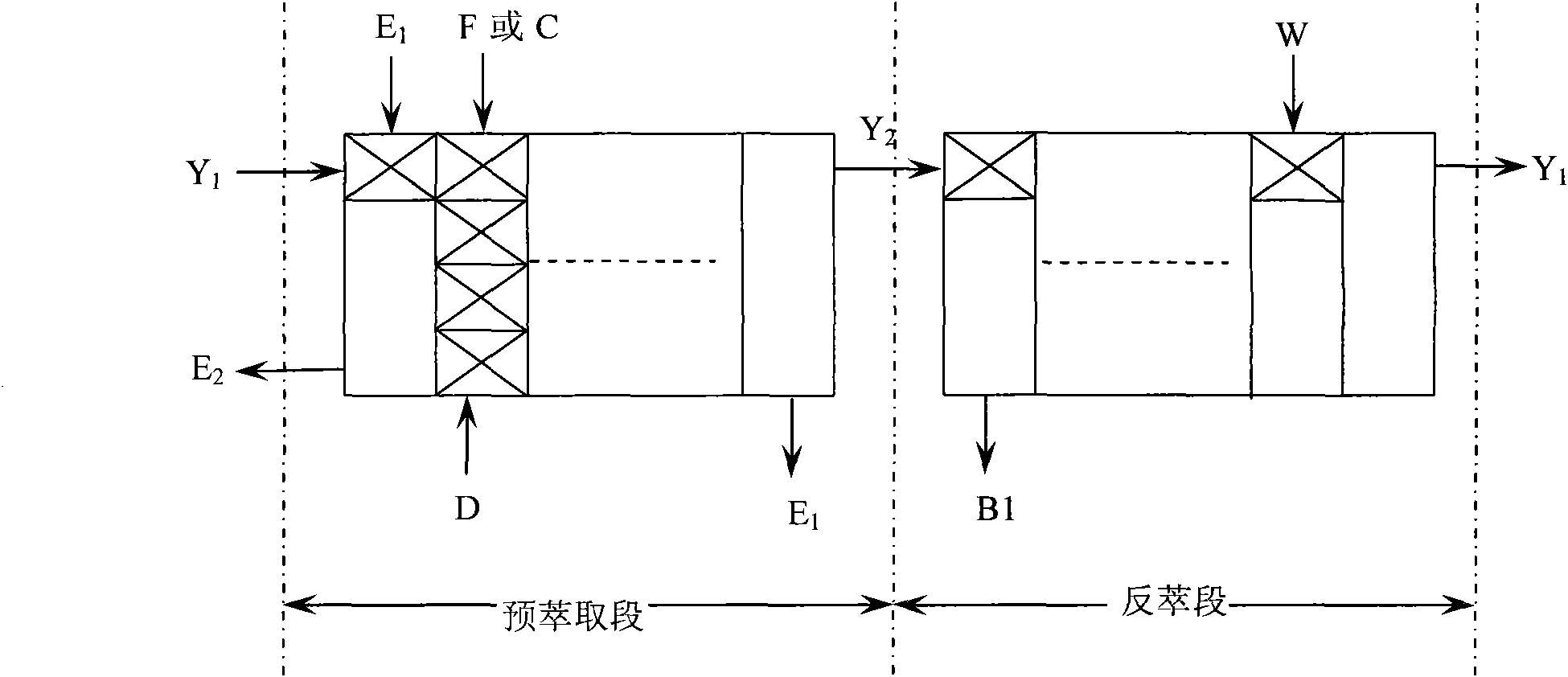

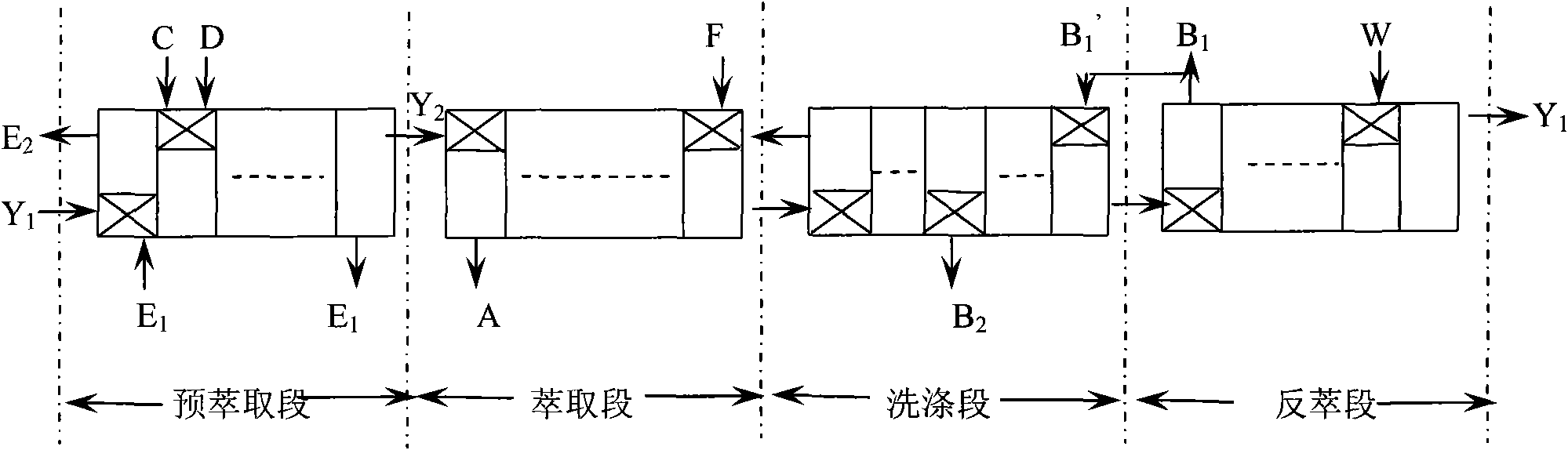

Method used

Image

Examples

Embodiment 1

[0045] The light-burned magnesia obtained by roasting magnesite at 850-900°C for 2 hours, add 3-5 times of water to digest at 80°C for 30 minutes, then adjust the slurry with water, the liquid-solid weight ratio is 80:1, and pass through Add carbon dioxide gas (concentration: 30%), react at 20°C for 40 minutes, and obtain a pure aqueous solution of magnesium bicarbonate (Mg0: 1.2%) through clarification and filtration.

[0046] Add magnesium bicarbonate aqueous solution at a flow rate of 3.73L / min, lanthanum cerium chloride solution (0.928mol / L) at a flow rate of 0.8L / min, and 1.5mol / L P507 organic phase at a flow rate of 4L / min into the 6-stage pre-extraction Co-flow extraction is carried out in the tank, the mixing time is 25 minutes, and the clarification is 20 minutes to obtain a loaded organic phase containing refractory rare earth ions lanthanum and cerium. The content is less than 0.001mol / L.

[0047] The loaded organic phase is directly used for LaCe / Pr fractional ext...

Embodiment 2

[0049] The mixture of lightly burned magnesia and calcium oxide obtained by roasting dolomite at 800-850°C for 2 hours is digested and mixed with water. The liquid-solid weight ratio is 100:1, and then carbon dioxide gas (concentration is 40%) is introduced. React at 20° C. for 40 minutes, and obtain pure aqueous solution of magnesium bicarbonate and calcium bicarbonate (MgO+CaO: 0.92%) through clarification and filtration.

[0050] Magnesium bicarbonate and calcium bicarbonate aqueous solution are added at a flow rate of 6.4L / min, lanthanum cerium chloride solution (0.665mol / L) is at a flow rate of 1.5L / min, and 1.3mol / L P204 organic phase is added at a flow rate of 6L / min Extraction is carried out in 12-stage pre-extraction tanks, the mixing time is 25 minutes, and after 6-stage co-current and 6-stage countercurrent extraction, a loaded organic phase containing lanthanum and cerium is obtained. The rare earth content REO is 0.165mol / L, and the pH value of the raffinate aqueou...

Embodiment 3

[0053] Calcium oxide obtained by calcining limestone at 800-850°C for 2 hours, digested with water to adjust the slurry, the liquid-solid weight ratio is 16:1, and then pass through carbon dioxide gas (concentration is 60%), react at 70°C for 30 minutes, after After clarification and filtration, a pure aqueous solution of calcium bicarbonate (CaO: 6.25%) was obtained.

[0054] Add the calcium bicarbonate aqueous solution at a flow rate of 1.12L / min, the lanthanum nitrate solution (0.744mol / L) at a flow rate of 1.5L / min, and the 1.5mol / L P507 organic phase at a flow rate of 6L / min into the 8-stage pre-extraction tank Carry out extraction, the mixing time is 25 minutes, after 5 stages of co-current and 3 stages of countercurrent extraction, a loaded organic phase containing refractory rare earth ion lanthanum is obtained, the rare earth content REO is 0.185mol / L, and the pH value of the raffinate aqueous phase is 4.5. REO content 0.0016mol / L.

[0055] The loaded organic phase w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com