Method for improving conversion efficiency of lignocellulose through combined treatment and method for efficiently preparing ethyl alcohol

A lignocellulose and combined treatment technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of unsatisfactory and low conversion rate of enzymatic hydrolysis, so as to reduce the dosage, increase the conversion rate of sugar, The effect of simple and easy preprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for joint treatment to improve lignocellulose conversion efficiency, comprising steps as follows:

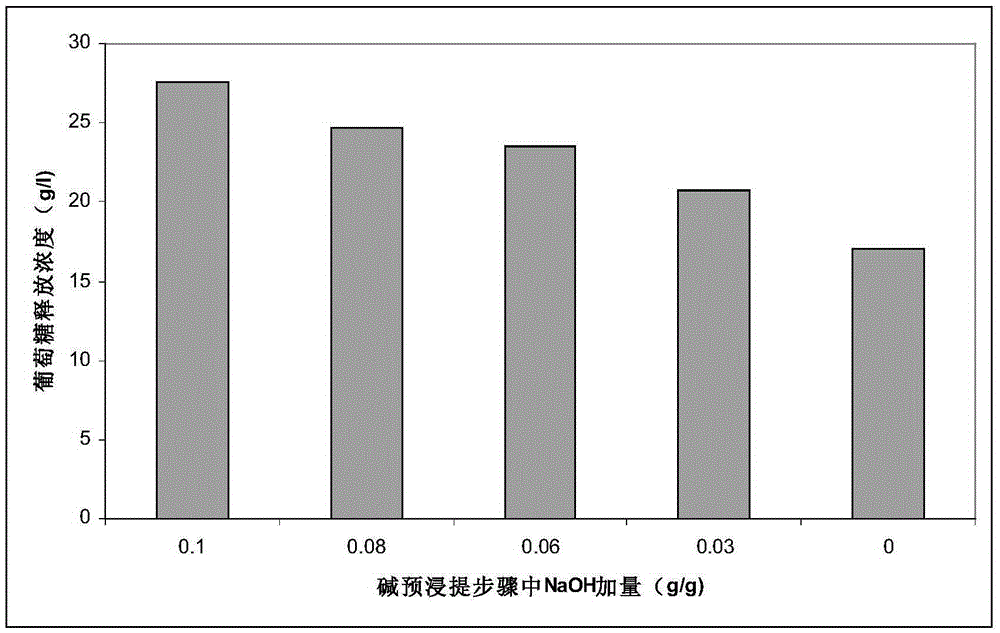

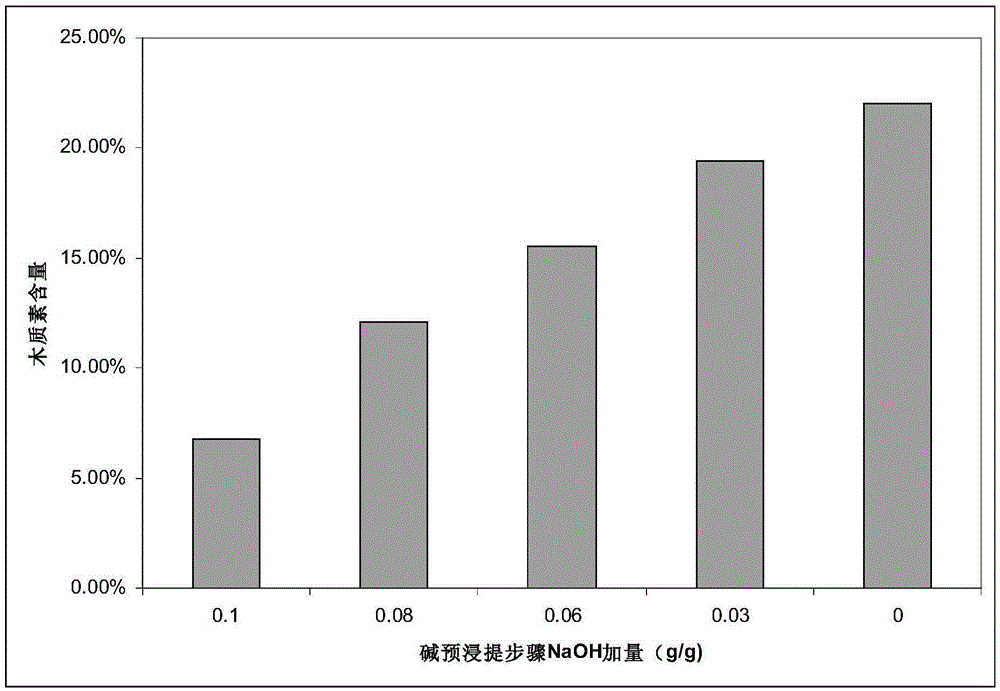

[0045] 1) Alkali preleaching: soak corn stalks in NaOH solution and keep warm at 80°C for 1 hour. The ratio of the mass of corn stalk to the volume of water is 5:100, unit: g / mL. The amount of NaOH added is 0.03gg / g corn stover. After preleaching, the insoluble corn stover was washed with 2 volumes of deionized water to remove all soluble matter. The liquid is removed by extrusion and the solid matter is retained, which is the corn stalk after pre-leaching.

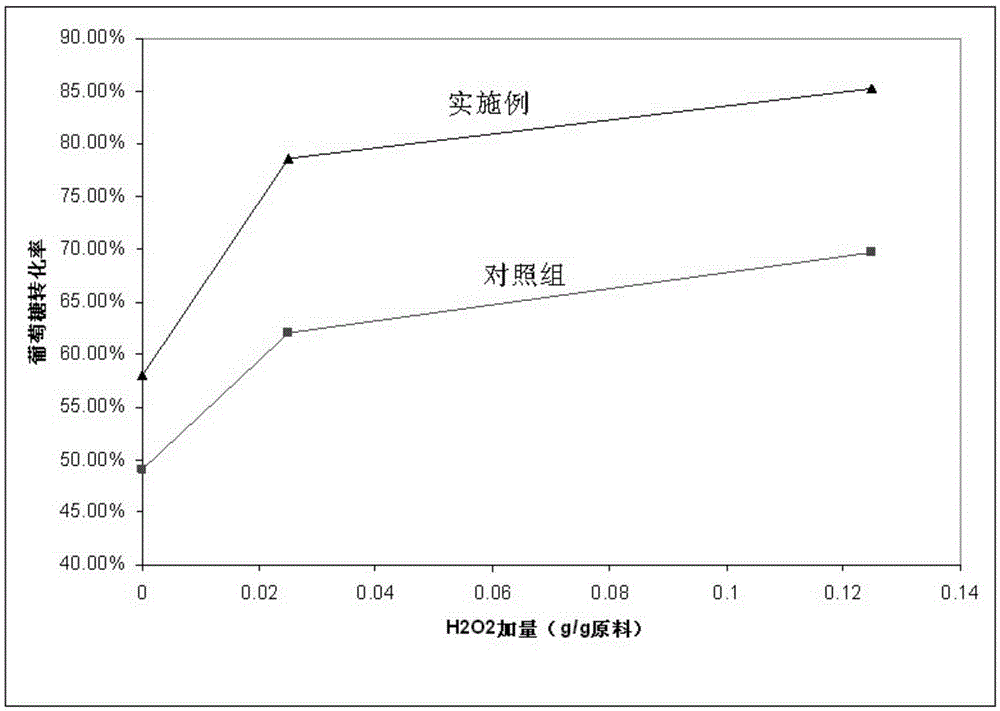

[0046] 2) Basic H 2 o 2 Treatment: Combine the pre-soaked corn stover with H 2 o 2 mix, h 2 o 2 The addition amount is 0.025 g / g corn stalks, and the pH is adjusted to 11.7 with 5 mol / l NaOH, and placed in a shaker at 30° C. at 180 rpm for 24 hours. the basic H 2 o 2 Processed rice straw.

[0047] 3) Enzymatic hydrolysis: the basic H 2 o 2 The treated rice straw was adjusted to pH 5.2 with 72% ...

Embodiment 2

[0050] The method for improving lignocellulose conversion efficiency through joint treatment described in Example 1 is different in that the amount of NaOH added is 0.06 g / g corn stalks.

Embodiment 3

[0052] It is the same as the method for improving lignocellulose conversion efficiency by joint treatment described in Example 1, except that the amount of NaOH added is 0.08 g / g corn stalks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com