Lignocellulose pretreatment method and system

A lignocellulosic pretreatment technology, applied in fiber raw material treatment, biomass pretreatment, biomass post-treatment, etc., can solve the problems of excessive power cost consumption, low hydrolysis rate of semi-fiber, long reaction time, etc. Achieve the effects of increasing the conversion rate of hemicellulose, reducing the conversion rate of cellulose enzymatic hydrolysis, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

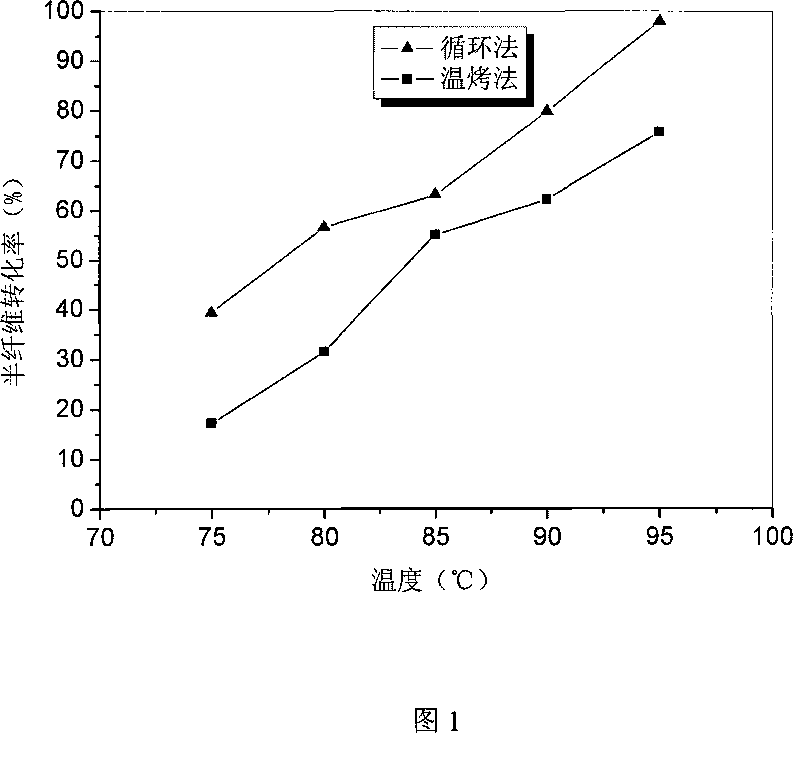

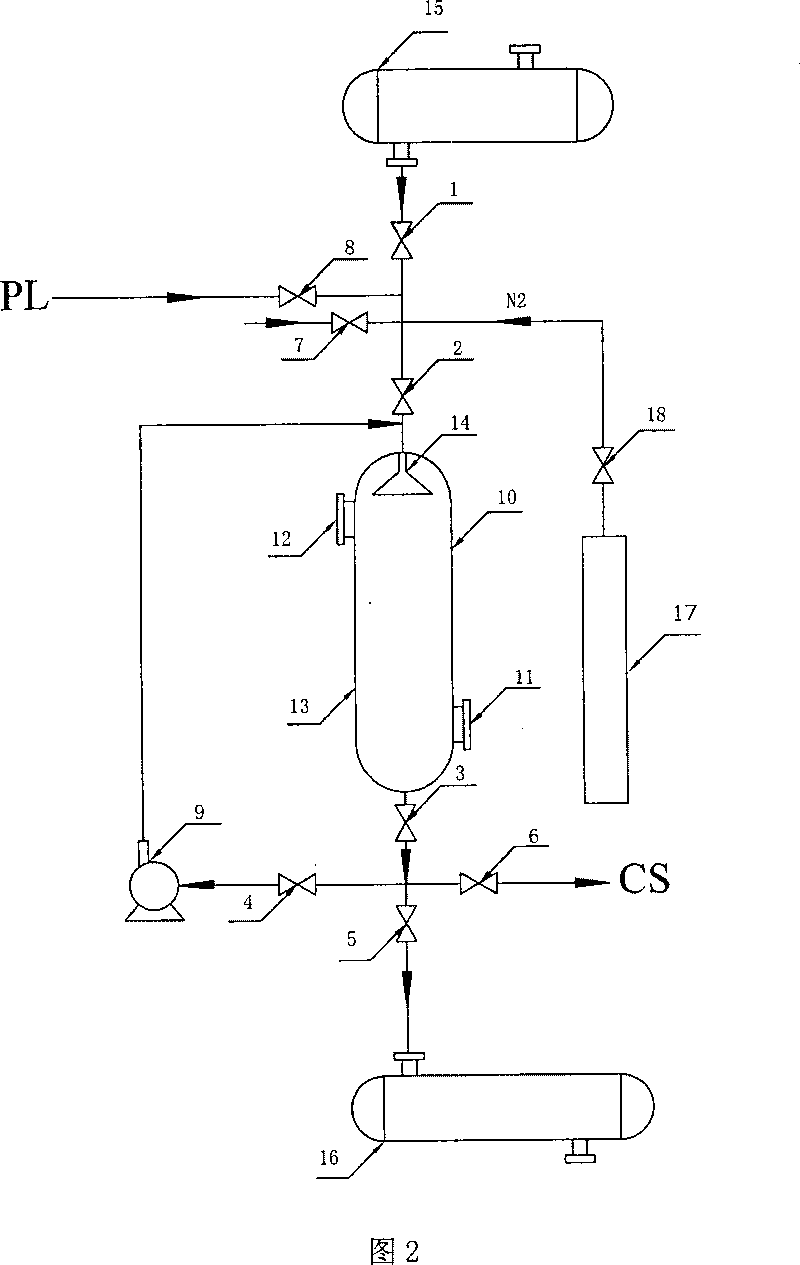

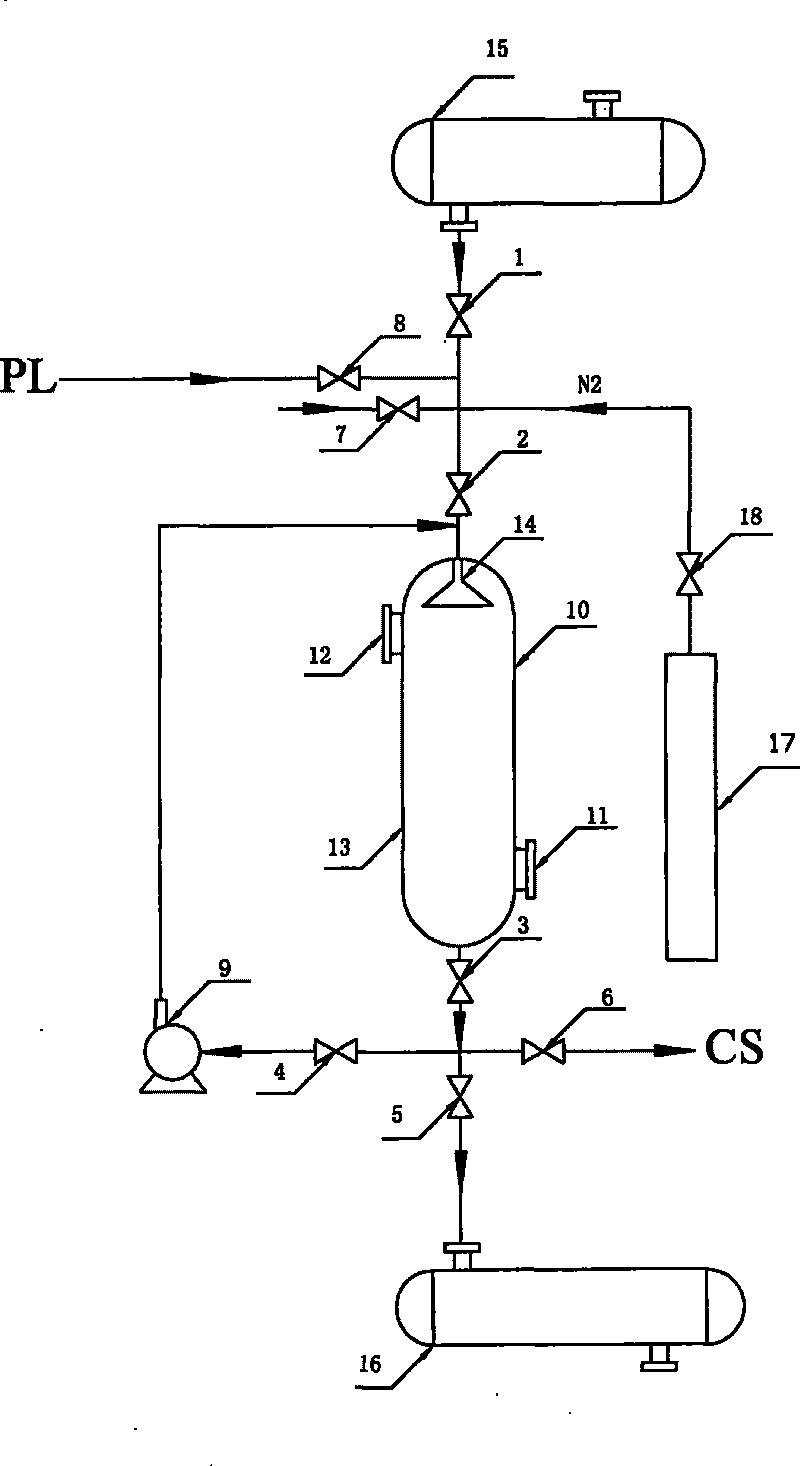

[0024] Corn stalks (moisture 12.82%, benzene alcohol extract 17.44%, cellulose 40.08%, hemicellulose 20.03%, lignin 19.95%, ash 5.52%) are air-dried and crushed, and then charged into the dilute acid cycle from the inlet 12 Device 10, open valve 1 and valve 2, and inject 0.8% dilute H from acid storage tank 15 2 SO 4 In the reactor, corn stover and dilute H 2 SO 4 The solid-liquid ratio is 1:10; open valve 3, valve 4, close valve 1, valve 2, start circulating pump 9, the flow rate is set to 10L / min, the liquid level is located at the upper end of the filter plate 13 during the reaction, at 95 ℃ Circulate the reaction for 4 hours. During the reaction, the liquid part is circulated through the filter plate 13, and the solid material part is blocked by the filter plate 13 and left in the reactor. The liquid part passes through the pump 9 and then returns to the reactor by spraying through the spray head 14 Medium; after the reaction is over, close valve 4 and pump 9, open valve 2, ...

Embodiment 2

[0026] Corn stalks (moisture 12.82%, benzene alcohol extract 17.44%, cellulose 40.08%, hemicellulose 20.03%, lignin 19.95%, ash 5.52%) are air-dried and crushed, and then charged into the dilute acid cycle from the inlet 12 Device 10, open valve 1 and valve 2, and inject 0.8% dilute H from acid storage tank 15 2 SO 4 In the reactor, corn stover and dilute H 2 SO 4 The solid-liquid ratio is 1:10; open valve 3, valve 4, close valve 1, valve 2, start the circulating pump 9, the flow is set to 10L / min, the liquid level is located at the upper end of the filter plate 13 during the reaction, at 90 ℃ Circulate the reaction for 4 hours. During the reaction, the liquid part is circulated through the filter plate 13, and the solid material part is blocked by the filter plate 13 and left in the reactor. The liquid part passes through the pump 9 and then returns to the reactor by spraying through the spray head 14 Medium; after the reaction is over, close valve 4 and pump 9, open valve 2, v...

Embodiment 3

[0028] Corn stalks (moisture 12.82%, benzene alcohol extract 17.44%, cellulose 40.08%, hemicellulose 20.03%, lignin 19.95%, ash 5.52%) are air-dried and crushed, and then charged into the dilute acid cycle from the inlet 12 Device 10, open valve 1 and valve 2, and inject 0.8% dilute H from acid storage tank 15 2 SO 4 In the reactor, corn stover and dilute H 2 SO 4 The solid-liquid ratio is 1:10; open valve 3, valve 4, close valve 1, valve 2, start circulating pump 9, the flow is set to 10L / min, the liquid level is located at the upper end of the filter plate 13 during the reaction, at 85 ℃ Circulate the reaction for 4 hours. During the reaction, the liquid part is circulated through the filter plate 13, and the solid material part is blocked by the filter plate 13 and left in the reactor. The liquid part passes through the pump 9 and then returns to the reactor by spraying through the spray head 14 Medium; after the reaction is over, close valve 4 and pump 9, open valve 2, valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com