Synthesizing method for molybdenum-nickel ore

A comprehensive treatment, molybdenum-nickel ore technology, applied in the direction of process efficiency improvement, etc., can solve the problems of SO2 pollution, acid and ammonia consumption and leaching rate difficult to balance, no oxidant and purification scheme, etc., to achieve cheap chemical raw materials, eliminate Potential safety hazard, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

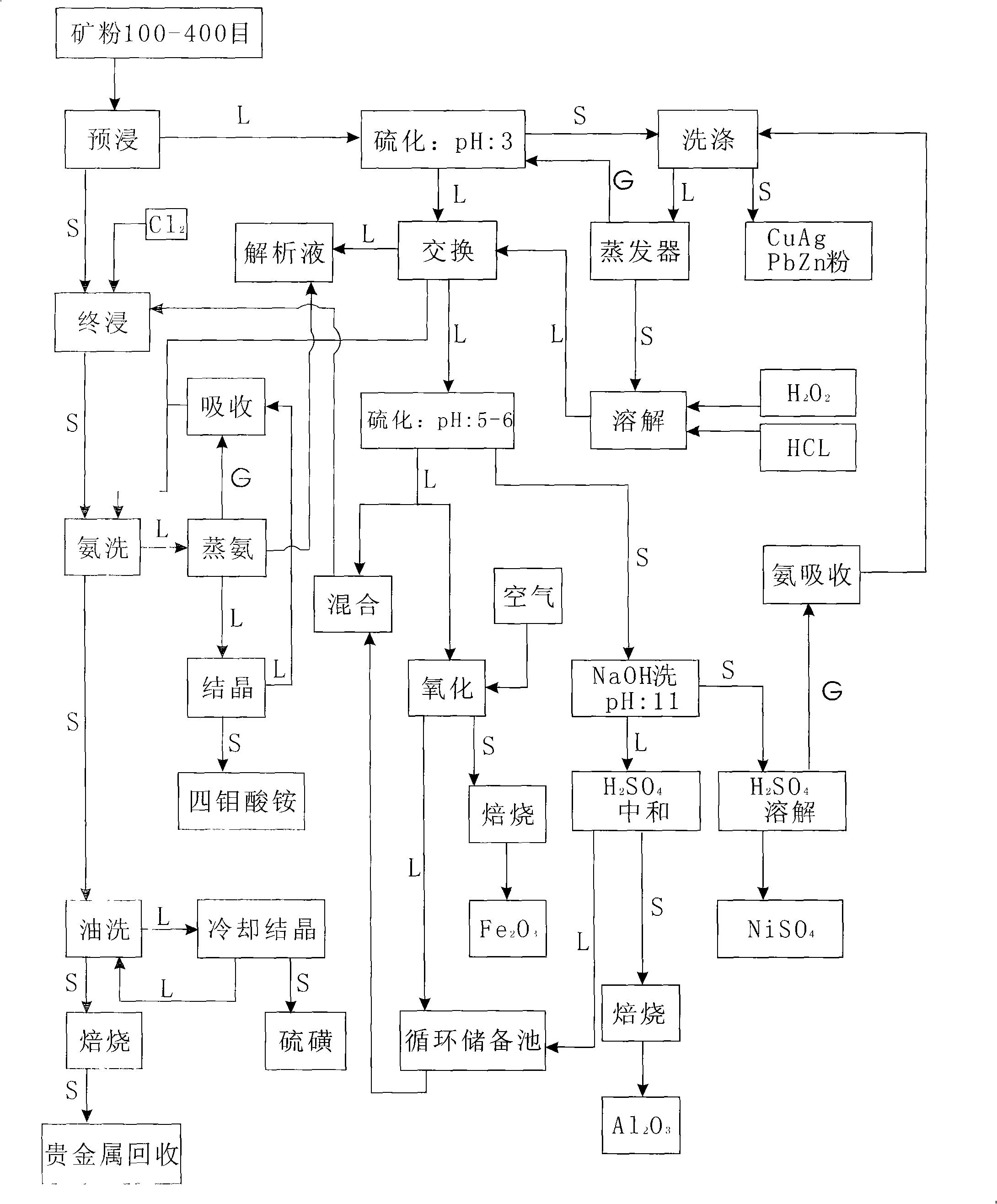

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. like figure 1 As shown, the process route S represents the solid phase, L represents the liquid phase, and G represents the gas phase. The method for comprehensive treatment of molybdenum-nickel ore of the present invention is a process for processing carbonaceous molybdenum-nickel ore, which includes three process sections: leaching of raw ore, treatment of leaching slag, and separation of pre-soaking liquid.

[0017] 1. The leaching of raw ore includes the following steps:

[0018] 1. Raw ore materials are ground to 100-400 mesh, preferably 320 mesh;

[0019] 2. Use the specific gravity d of the final immersion solution to be 1.0-1.2 to pre-soak the ore material. The final immersion solution composition is: molybdenum 5-25g / l, nickel 3-25g / l, chlorine 50-300g / l, pre-soaked The process conditions are: the mass ratio of the raw ore material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com