Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

A high-outburst coal seam and layer-penetrating technology, which is applied in earthwork drilling, gas discharge, safety devices, etc., can solve the problems of small effective range of single-hole gas drainage, inability to effectively solve gas hazards, and heavy drilling workload. , to achieve the effect of solving the difficulty of coal roadway support, reducing the amount of gas emission, and promoting the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

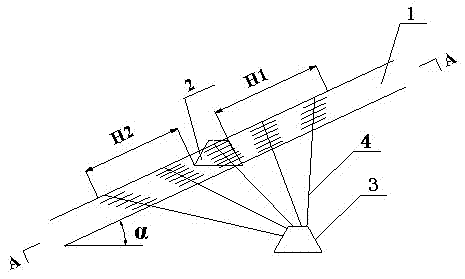

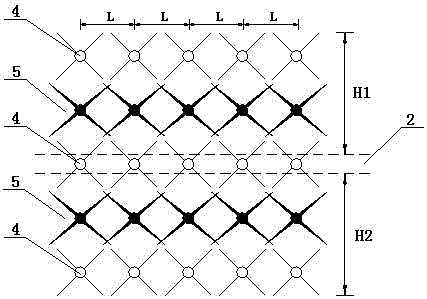

[0017] Such as figure 1 As shown, the soft and high outburst coal seam piercing slits of the present invention relieve pressure and increase permeability and fast tunneling method, at first according to the geological information parameters: coal seam thickness, coal seam dip angle α, coal seam direction, gas parameters, hydrological conditions and other in construction There are required parameters, and a detailed implementation plan is formulated. Do a good job in the preparatory work before implementation, and consider dealing with cracks, faults, water and other risk factors. Arrange the bottom pumping roadway 3 along the direction of the working face in the floor rock layer of the coal seam 1, and determine the influence radius of the slot hole through the slotting test; after completion, arrange a drilling site every 6~8m in the bottom pumping 5~7 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com