Gas extraction equipment and method for low coal penetration layer

A coal seam gas and drainage technology, which is applied in the field of low-permeability coal seam gas drainage equipment, can solve the problems of small borehole spacing, poor gas permeability of coal reservoirs, and poor pre-extraction effect of gas, so as to increase and reduce the distance between gas drainage The amount of drilling work and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

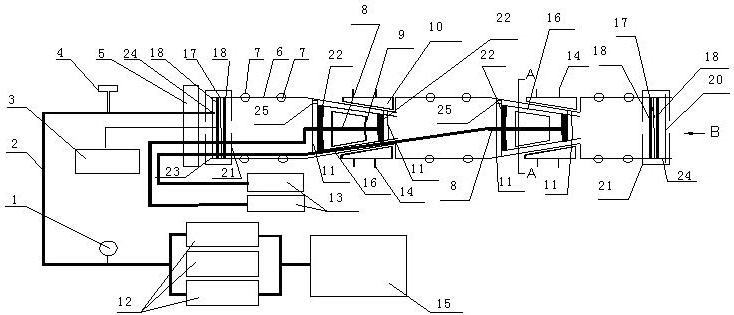

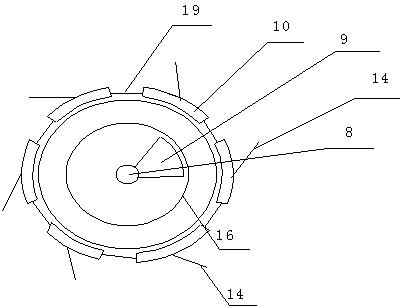

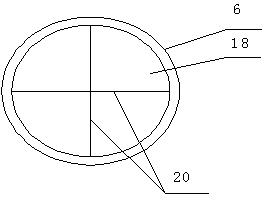

[0023] Depend on Figure 1-Figure 3 The shown low-permeability coal seam gas drainage equipment includes a hollow drill pipe 6, the end of the drill pipe 23 is connected to a high-pressure water pump 12 through a pipeline, and the high-pressure water pump 12 is connected to a water tank 15. The pipeline includes a high-pressure hose 2, and the high-pressure water pump 12 to the high-pressure hose 2 at the end of the drill rod 23, a control valve 4 and a flow meter 1 are arranged in sequence. Nozzles 7 are arranged at intervals on the drill pipe 6, and a vibrator is arranged in the drill pipe 6. The vibrator includes an eccentric block 9 driven by a motor 13 through a rotating shaft. The motor 13 is located outside the drill pipe 6. The axial section of the eccentric block 9 is Trapezoidal and the small end is towards the front end 24 of the drill pipe 6, the cross-section of the eccentric block 9 is in the shape of a 45° fan, and the radial section of the drill pipe part of th...

Embodiment 2

[0025]The low-permeability coal seam gas drainage method is realized on the basis of the low-permeability coal seam gas drainage equipment described in Embodiment 1. First set up the low-permeability coal seam gas drainage equipment as described in Example 1, send the drill pipe 6 into the borehole, inject water into the water tank 15, and choose whether to open the vibrator according to the coal structure. If it is a soft coal seam, it can be opened first. The vibrator vibrates the coal seam, and then sends high-pressure water to the drill pipe 6 through the high-pressure water pump 12 and sprays the coal seam through the nozzle 7; The nozzle 7 acts on the coal seam, or can carry out water jet and open the vibrator to vibrate the coal seam at the same time. When the vibrator is turned on, a steel bar 14 extending radially and obliquely is arranged around the hole wedge 10, and the steel bar 14 is inserted into the coal body. At this time, by rotating the drill pipe 6, while t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com