Slotting and fracturing cooperation networking permeability increasing method for low-permeability coal seam

A gas permeability and slitting technology, which is applied in the directions of earth-moving drilling, gas discharge, and exploitation of fluids, etc., can solve the problems such as the difficulty in controlling the expansion direction of fracturing cracks, the small influence range of slitting and drilling, and shorten the gas pre-extraction time. , the effect of increasing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] The specific steps of the low-permeability coal seam slotting and fracturing collaborative network anti-permeability method of the present invention are as follows:

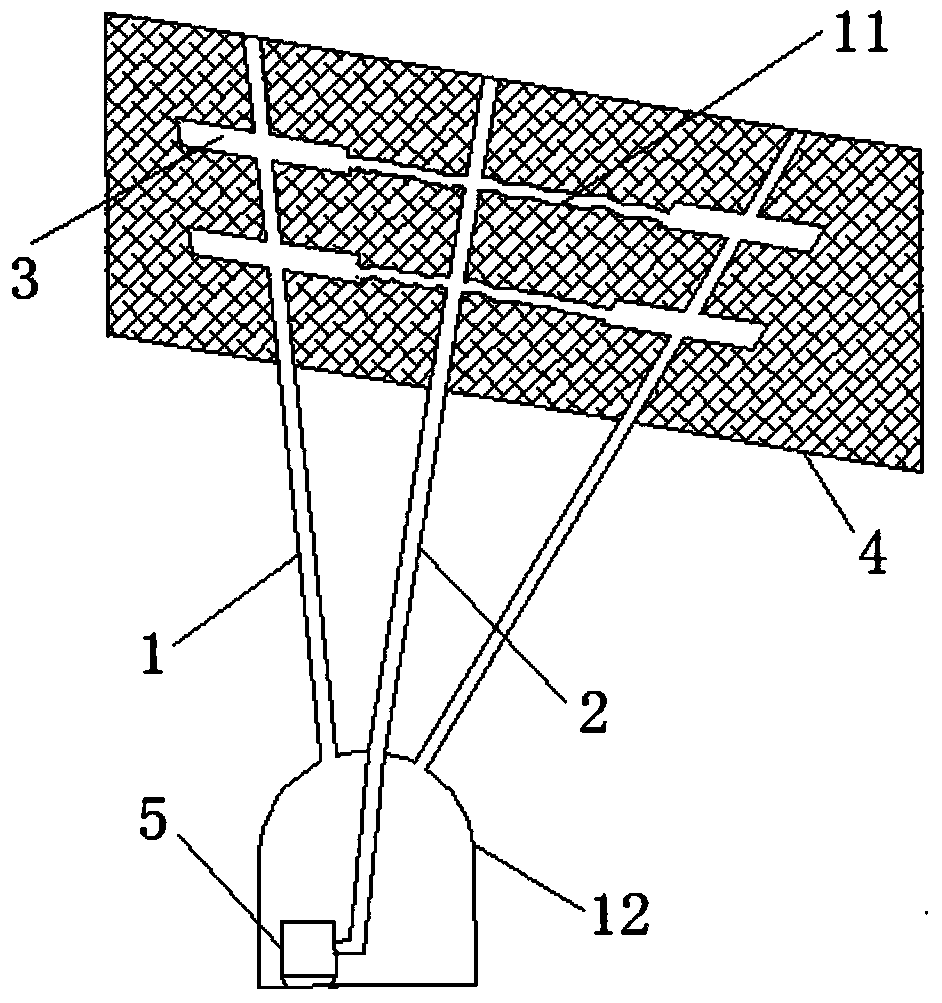

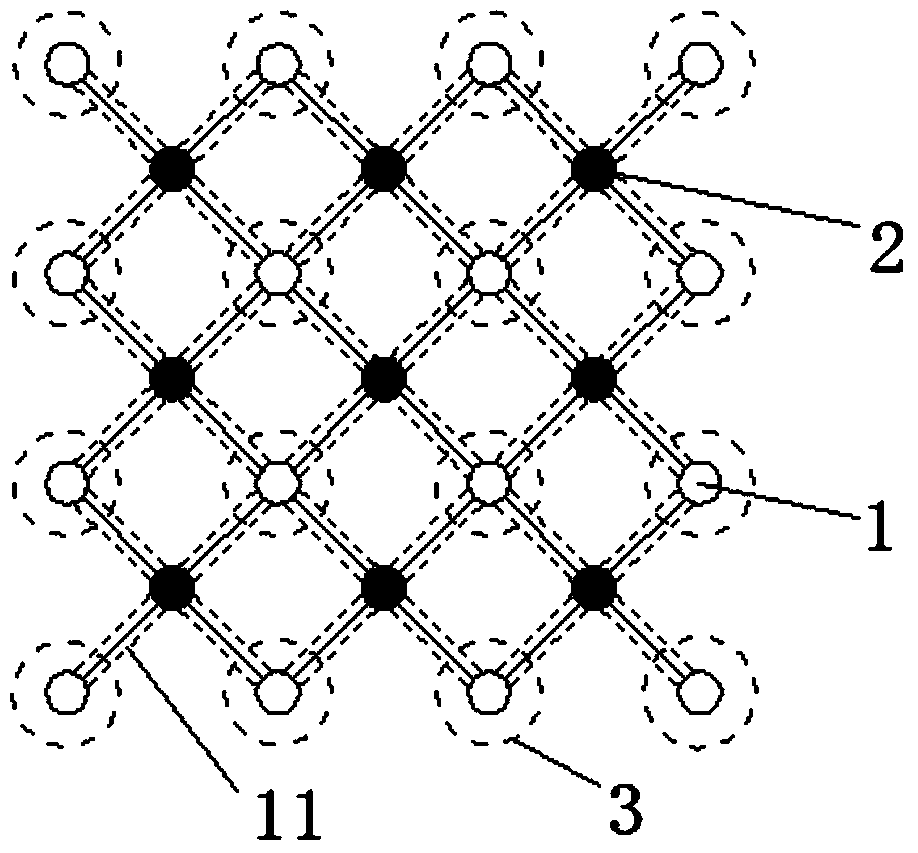

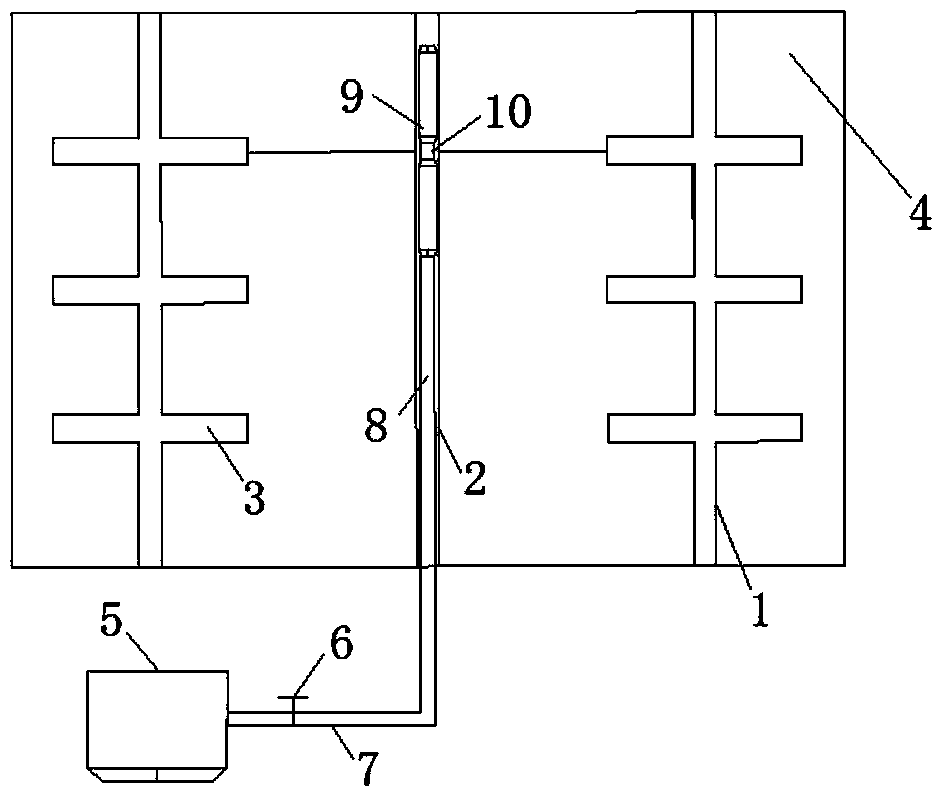

[0020] a. Alternately arrange a plurality of slotted drill holes 1 and fracturing drill holes 2 in the direction of the coal seam 4 in the bottom pumping roadway 12, and the distance between the coal penetration points of adjacent drill holes is 5-10m, such as figure 2 shown;

[0021] b. Construct each slotted borehole 1 one by one, and use high-pressure water jet to slit each slotted borehole 1. The bottom of each slotted borehole 1 is 0.6-1.0m away from the coal seam roof to start slotting, and the thickness is 0.3 -0.5m annular slot 3, the radius of annular slot 3 is 0.6-1.5m, then drill outwards, and construct an annular slot 3 with a thickness of 0.3-0.5m every 1.0-1.5m until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com