Underground progressive gas pre-extraction and directional hole drilling system and method for broken and soft coal seam

A soft coal seam, directional hole technology, applied in directional drilling, gas discharge, drill pipe, etc., can solve the problems of large drilling engineering volume and long construction period gas extraction time to meet the standard, so as to increase the depth of the hole and reduce the period of reaching the standard. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

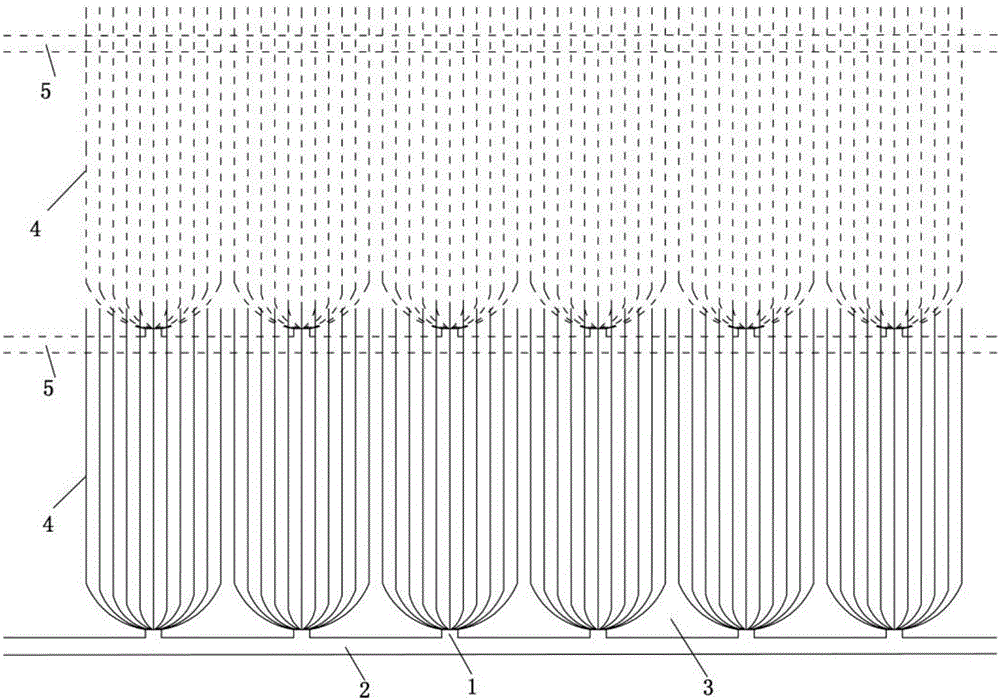

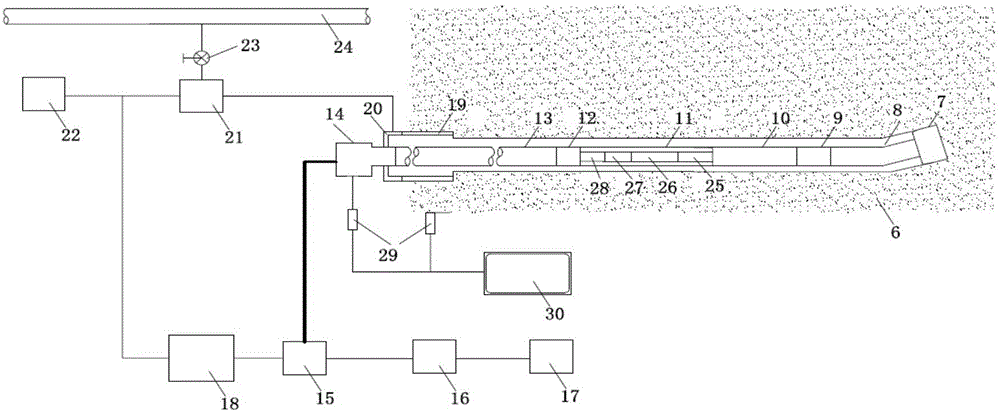

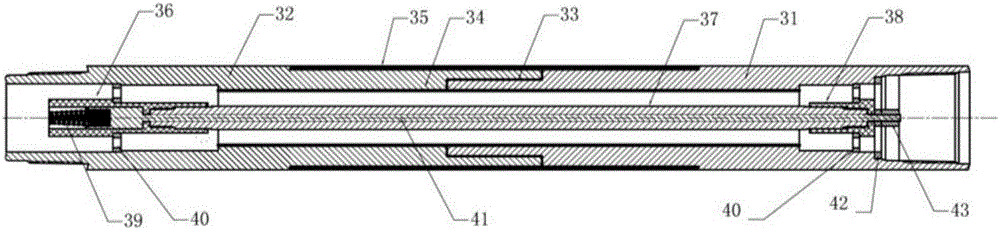

[0037] see figure 1 According to the present invention, the underground progressive gas pre-pumping directional hole drilling method in broken soft coal seams comprises the following working steps:

[0038] Step 1: Drill site 1 layout. The drilling site 1 is arranged in the coal mining roadway 2, close to the side of the working face 3 to be mined, and the distance between the drilling sites 1 is 30-50m;

[0039] Step 2: Orientation hole 4 design. The directional hole 4 is perpendicular to the coal mining roadway 2, the opening point is located in the drilling site 1, and the stabilizing hole sections are arranged in parallel at intervals of 5m; The displacement fluctuates with the ups and downs of the broken and soft coal seam 6, the length of the directional hole 4 ≥ the width of the working face 3 to be mined + the width of the coal roadway 5 to be excavated + the lead distance; the inclination and azimuth of the trajectory design of the directional hole 4 every 3m from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com