Portable detachable ultrasonic vibration drilling machine and drilling method

A vibratory drilling rig, ultrasonic technology, applied in the direction of vibratory drilling, drill pipe, drill pipe, etc., can solve the problems of not being portable, difficult to maintain, difficult to operate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

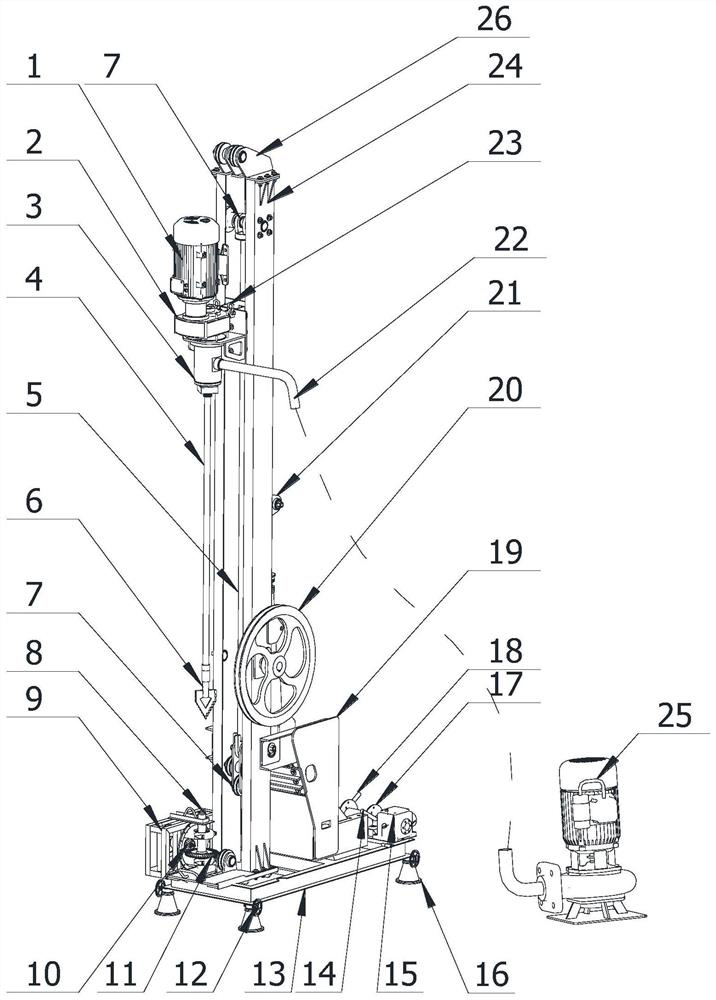

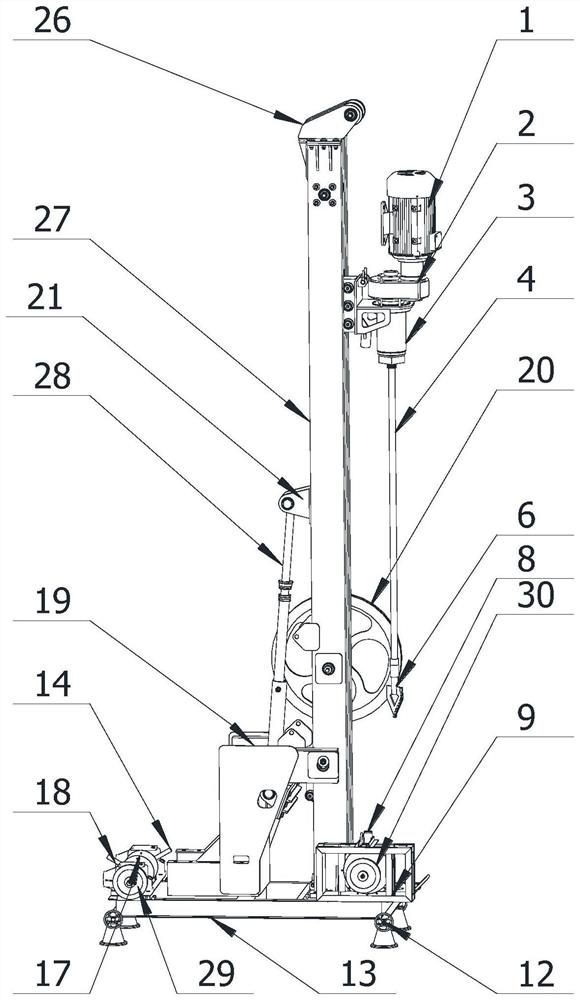

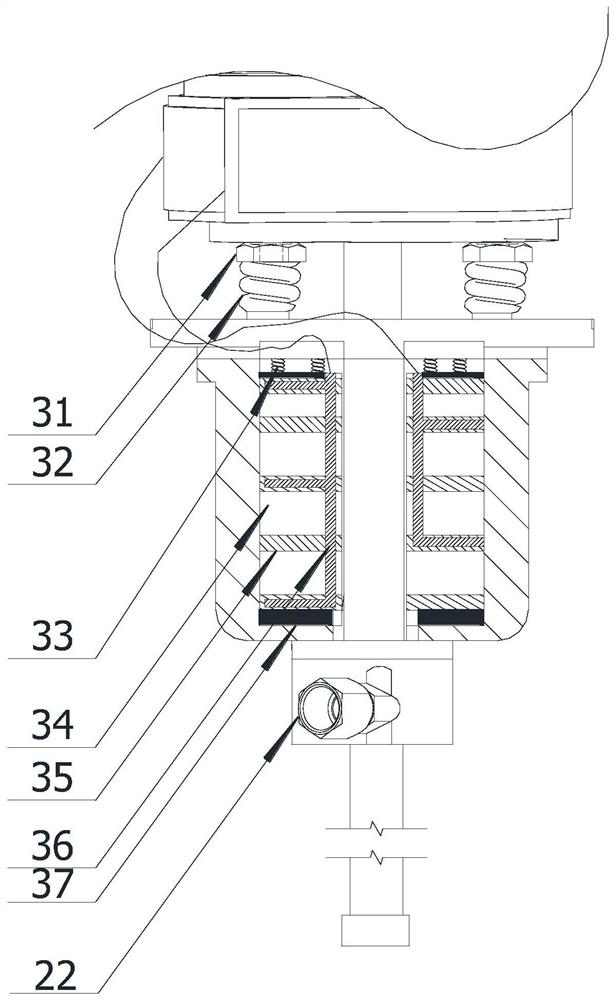

[0035] Example: see attached Figure 1-3 , a light and detachable ultrasonic vibration drilling machine, including a rotary mechanism, a feeding mechanism, a support mechanism, a hoisting mechanism and an ultrasonic vibrator 2; the rotary mechanism includes a drill rod 4 and a drill bit 6, and the drill bit 6 can rotate the drill Advance; one end of the drill rod 4 is connected to the drill bit 6, and the other end is connected to the faucet annular casing 3, the ultrasonic vibrator 2 and the driving device in turn; 25; the drill bit 6 is threaded to the drill pipe 4, and the top end of the drill pipe 4 is connected to a wire rope; the driving device is a diesel engine 1, and the base plate of the ultrasonic vibrator 2 is connected to the diesel engine 1. Connected by buffer springs 32 ; four stud bolts 31 are arranged on both sides of the upper seat plate of the ultrasonic vibrator 2 , and each stud bolt 31 is provided with two buffer springs 32 , constituting the external st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com