Underground coal mine split type hydraulic deflecting drilling tool assembly and drilling method

A drilling tool assembly and split-type technology, which is applied to drilling equipment and methods, driving devices for drilling in boreholes, drilling equipment, etc., to achieve rapid disassembly and assembly, improved hole depth, and good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

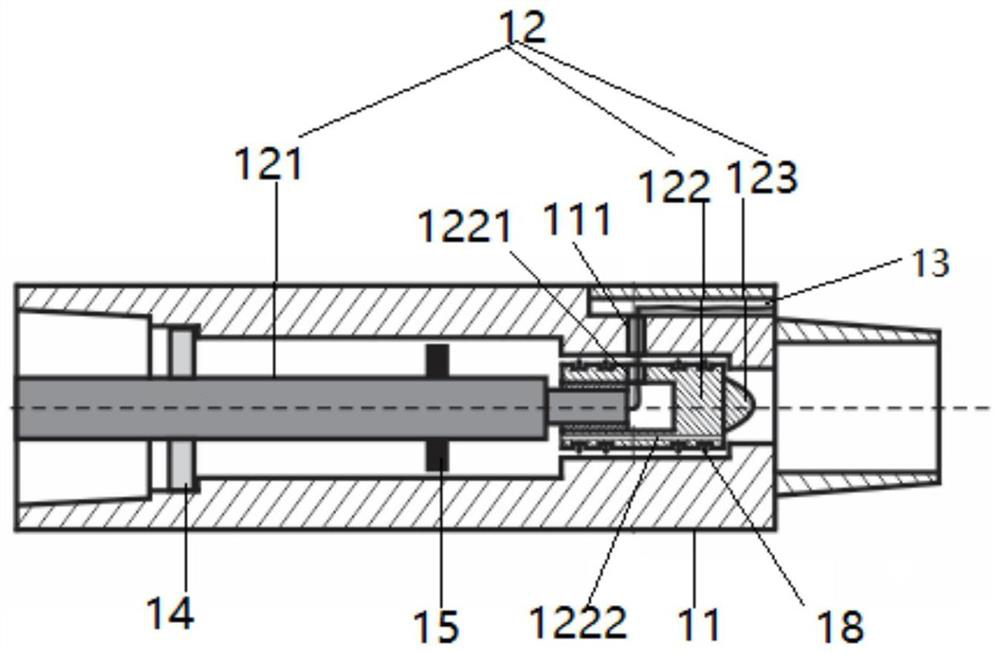

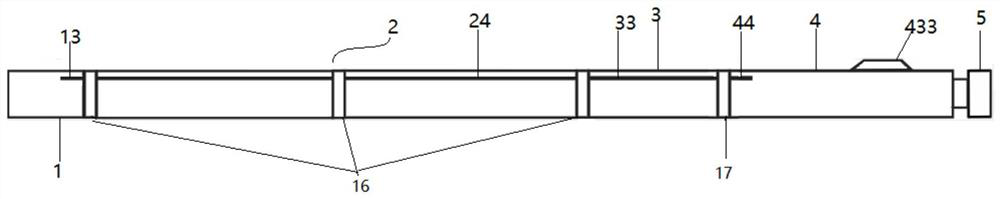

[0052] Such as Figure 1 to Figure 9 As shown, the present embodiment provides a coal mine split type hydraulic deflection drilling tool assembly, including a communication sub-section 1, a power unit 2, a universal sub-joint 3, a deflection sub-section 4 and a directional drill bit 5 arranged in sequence;

[0053] The communication sub-joint 1 includes the communication sub-joint outer tube 11, the communication measurement component 12 sleeved in the communication sub-joint outer tube 11, and the side wall to center cable 13 embedded in the communication sub-joint outer tube 11; in this implementation In an example, the sidewall-to-center cable 13 is arranged in a groove provided on the outer tube 11 of the communication nipple, and the groove is pressed and sealed with a sealing end cap.

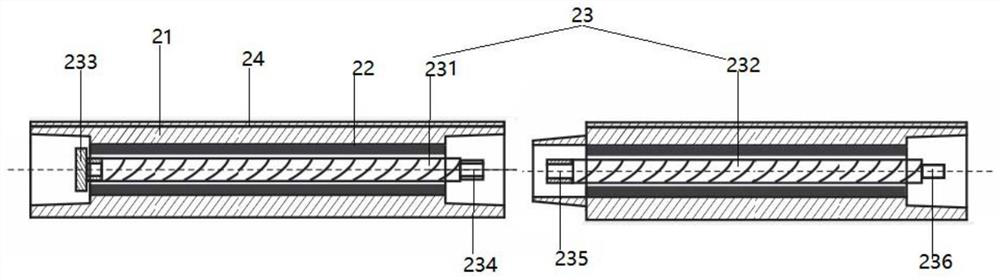

[0054] The power unit 2 includes a plurality of detachably connected power mechanisms. The power mechanism includes a motor nipple outer tube 21, a stator 22 arranged on the inner wall of...

Embodiment 2

[0079] This embodiment discloses a rotary directional drilling method, which is realized by the coal mine underground split type hydraulic deflection drilling tool assembly disclosed in Embodiment 1, and includes the following steps:

[0080] Step 1. Excavate the drill field in the underground roadway, use the hole drilling tool assembly to construct the hole section of the directional drilling in the rock formation, and then run the casing and solidify the hole;

[0081] Step 2. Run the drilling tool into the borehole, and complete the assembly of the communication nipple, power unit, universal nipple, and deflection nipple during the lowering process; complete the connection of the drilling tool with the measurement-while-drilling system and the high-pressure hose;

[0082] Step 3. Pump high-pressure water into the drilling tool assembly through the high-pressure rubber hose, and use the high-pressure water to push the drilling tool assembly forward along the preset drilling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com