Trimming code generation circuit, trimming system and method based on successive approximation principle

A technology of successive approximation and circuit generation, which is applied in the field of trimming system and trimming code generation circuit, which can solve the problems such as inability to accurately obtain trimming codes, achieve the effects of reducing the number, avoiding accidental power-off, and reducing chip costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

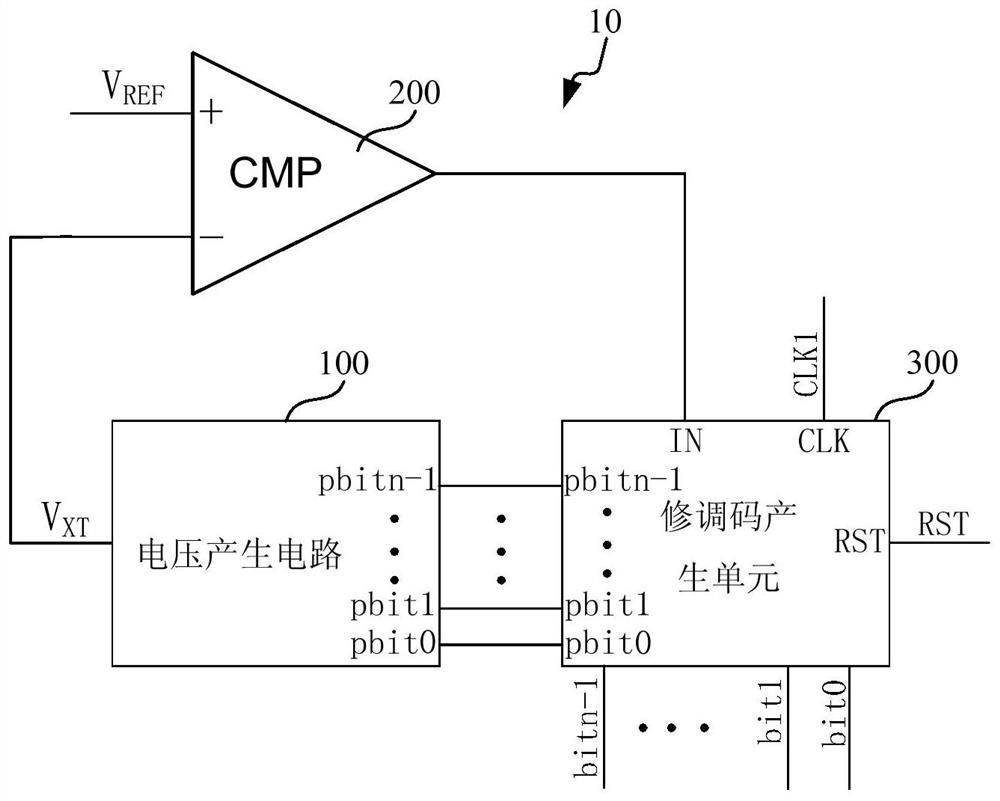

[0071] Such as image 3 As shown, the present embodiment provides a trimming code generating circuit based on the principle of successive approximation. The trimming code generating circuit 10 includes: a voltage generating circuit 100, a comparator 200, and a trimming code generating unit 300. The trimming A code generating unit 300 is connected between the comparator 200 and the voltage generating circuit 100;

[0072] The trimming code generating unit 300 outputs a pre-modifying code (pbit0 to pbitn-1) to the voltage generating circuit 100, and the voltage generating circuit 100 outputs a pre-modifying code (pbit0 to pbitn-1) according to the preset Trimming voltage V XT to said comparator 200;

[0073] The comparator 200 compares the pre-trimming voltage V XT and reference voltage V REF and output a comparison result to the trimming code generating unit 300; and

[0074] Based on the first clock signal CLK1 and / or the comparison result, the trimming code generation un...

Embodiment 2

[0094] Such as Figure 7 As shown, the present embodiment provides a trimming system based on the principle of successive approximation, and the trimming system includes:

[0095] The trimming code generating circuit 10 as described in Embodiment 1 is used to generate and output a trimming code (bitn-1 to bit0);

[0096] The programming controller 20 is connected to the trimming code generation circuit 10, and is used to perform trimming operations on the N fuses according to the trimming codes (bitn-1 to bit0) and the second clock signal CLK2, so as to N fuses are state solidified.

[0097] As an example, such as Figure 8 As shown, the programming controller 20 includes: a single high level generating circuit 21, a trim enabling signal generating circuit 22 and N fuse trimming units 23, the trim enabling signal generating circuit 22 and The single high level generating circuit 21 is connected, and the N fuse trimming units 23 are respectively connected to the trimming ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com