Fixing device and adjusting method for a circular track

A technology of circular track and fixing device, applied in the direction of track system, transportation and packaging, load hanging components, etc., can solve the problems of small adjustment and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

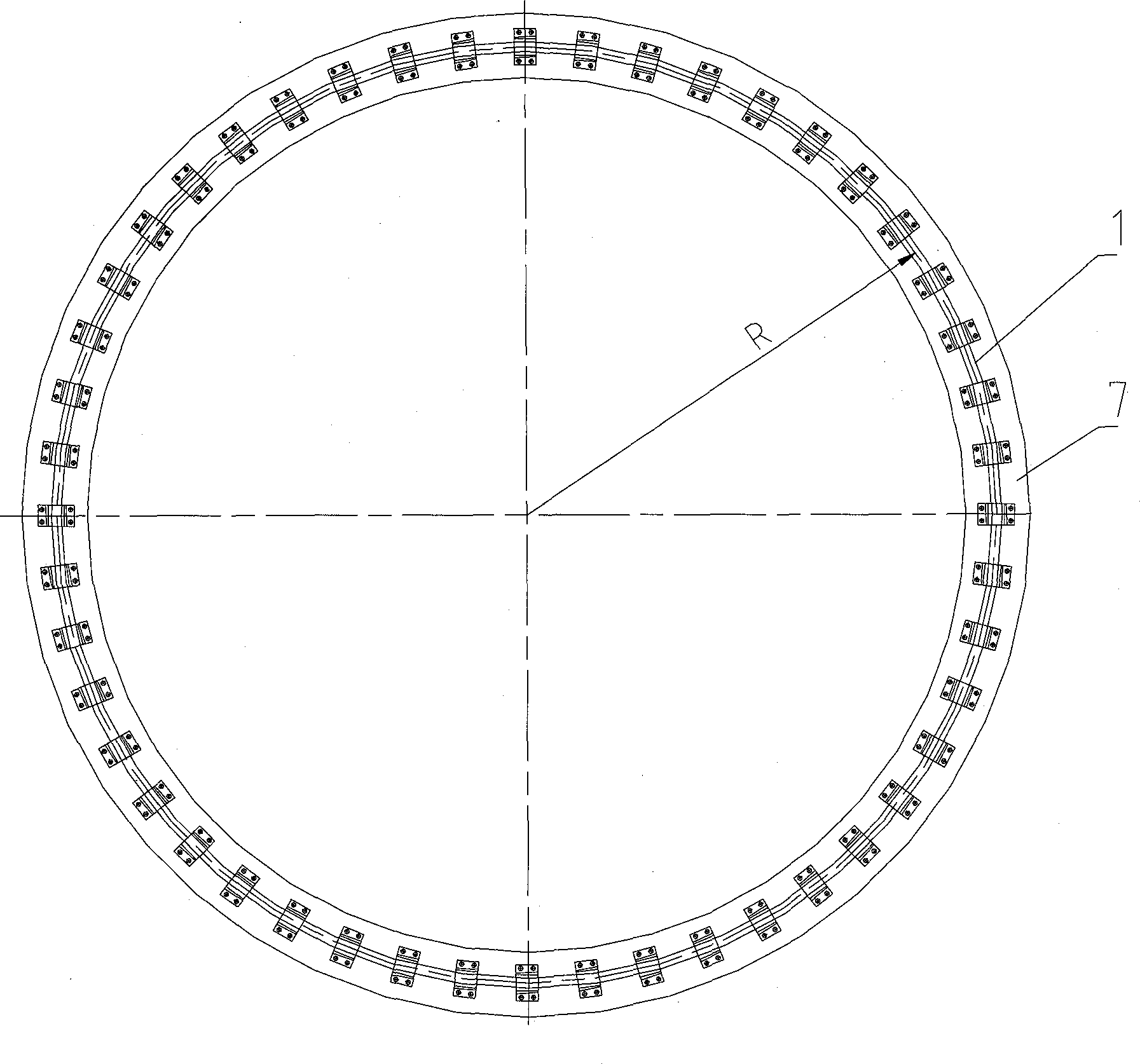

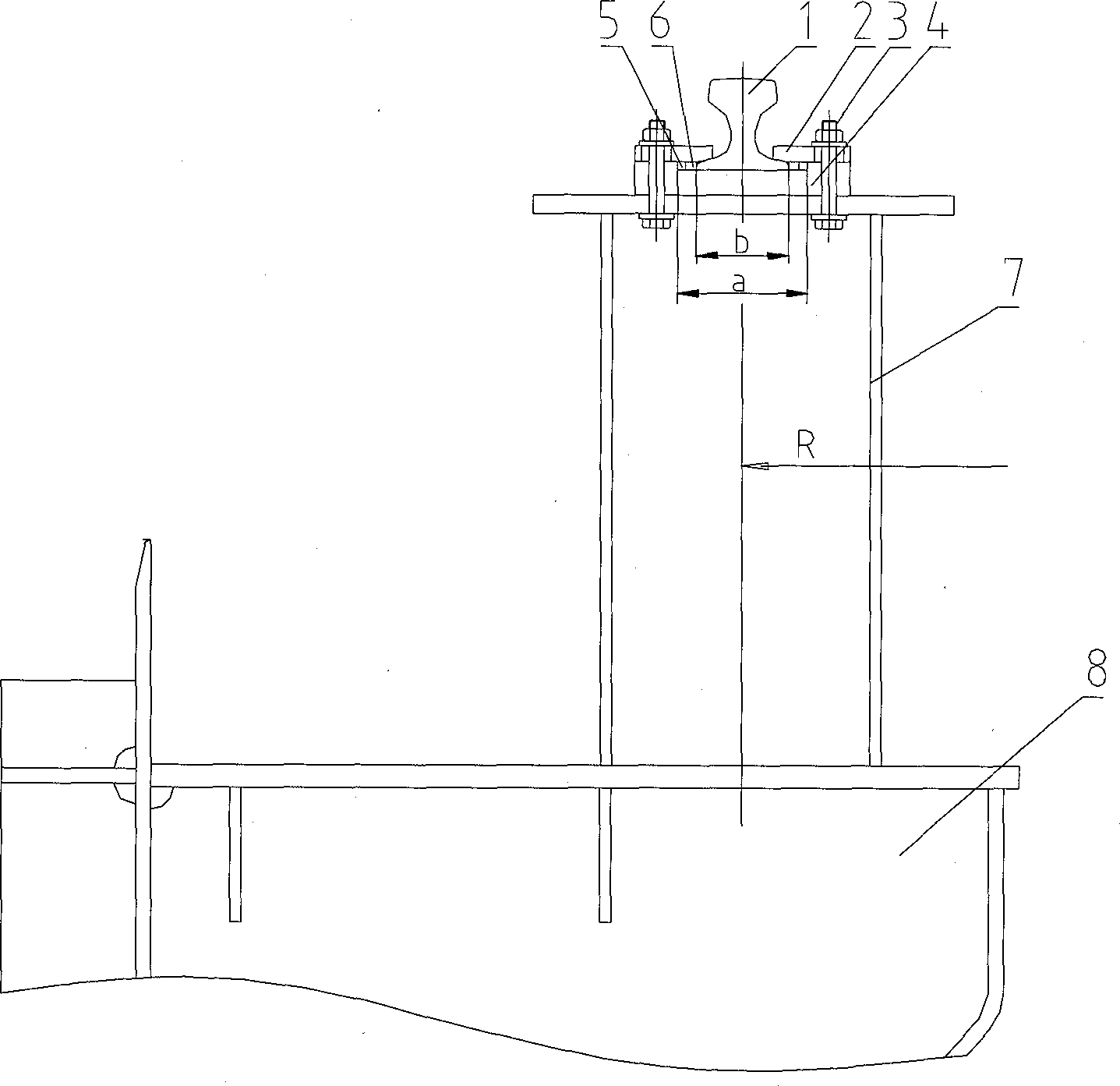

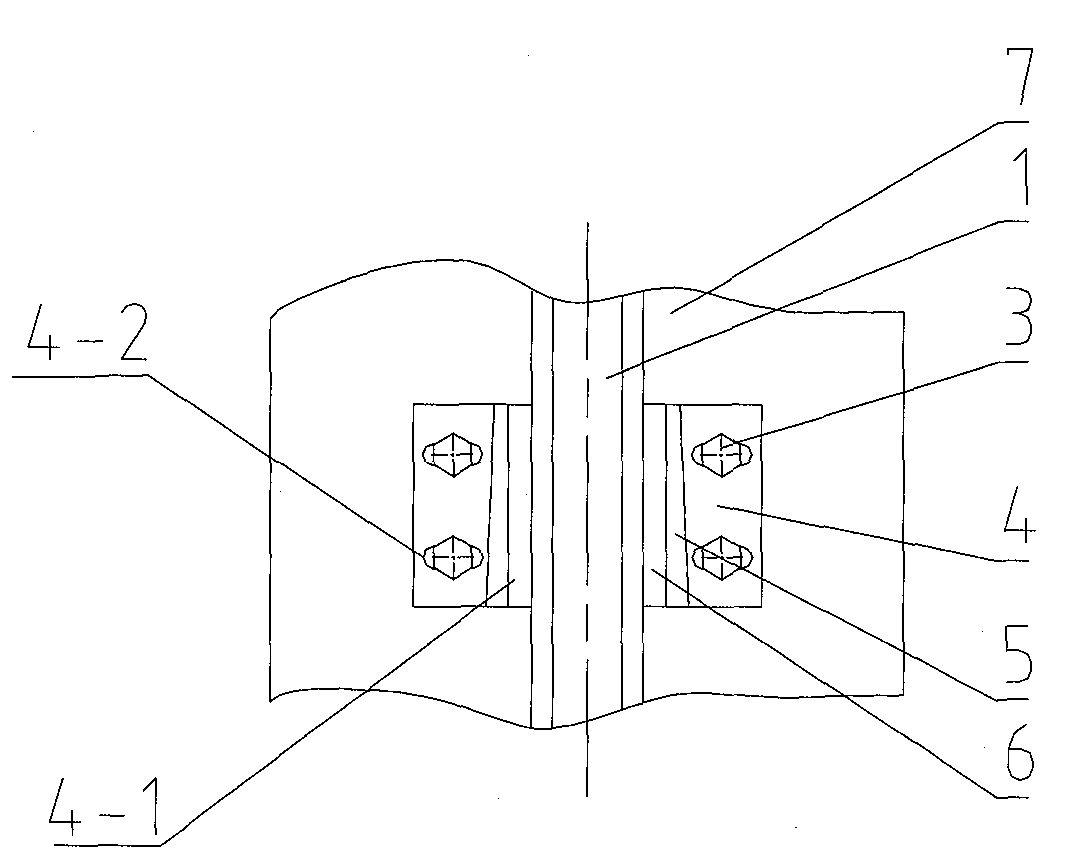

[0026] Such as figure 1 , 2 , shown in 3, a kind of fixing device of ring track, comprises: ring track 1, track clamping plate 2, bolt assembly 3, ring bearing beam 7 that are made up of several sections of tracks, ring track 1 uses track clamping plate 2, bolt assembly 3 It is connected with the ring bearing beam 7; a number of track backing plates 4 are placed between the ring track 1 and the ring bearing beam 7, and a mounting groove 4-1 is opened in the middle of each track backing plate 4, and each piece of Both ends of the track backing plate 4 are provided with oblong bolt holes 4-2 in the radial direction of the track; the width dimension a of the installation groove 4-1 is 20-40mm larger than the width dimension b of the circular track 1; The center of the installation groove 4-1 coincides with the theoretical centerline of the ring track 1, the ring track 1 is placed in the center of the installation groove 4-1, and in the installation groove 4-1, the ring track 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com