Continuous polymerization production process of high-viscosity polyamide 6

A production process, polyamide technology, applied in the field of polyamide 6 continuous polymerization production process, which can solve the problems of high-viscosity polyamide 6 chip internal quality evaluation, retention, and application impact, and achieve stable and reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

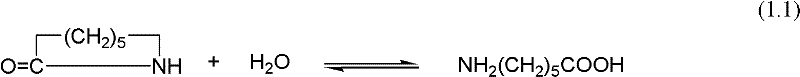

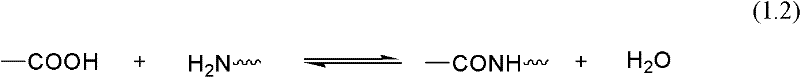

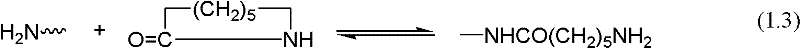

Method used

Image

Examples

Embodiment 1

[0035] Example 1: After the solid caprolactam is melted in the melting tank or directly from the caprolactam manufacturer’s liquid caprolactam and 1-4% deionized water, it is poured into the caprolactam intermediate tank, mixed uniformly and stored in the intermediate tank, and used The feed pump preheats the mixed caprolactam to 200℃ through the preheater and then transports it to the prepolymerizer (VK tube) for hydrolysis and ring opening and prepolymerization of caprolactam. The pressure of ring opening and prepolymerization is 2.50bar and the temperature is 275℃, the flow rate of caprolactam is 2000kg / h, and then the polymer is discharged by the front polymer discharging pump to the rear polymerizer; the pressure of post polymer is 0.2bar, the temperature is 245~270℃, and the polymer melt is melted with the discharging gear pump. Discharge outward; polymer melt is sliced after polymer filter, casting head, underwater pelletizer, and vibrating screen; put slices into pre-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com