Bagasse alkaline pulping method by pre-extracting hemicellulose and product thereof

A technology of hemicellulose and alkali pulping, which is applied in the directions of pulping with inorganic alkalis, fiber raw material treatment, chemical instruments and methods, etc., to achieve the effects of saving resources, huge social benefits, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

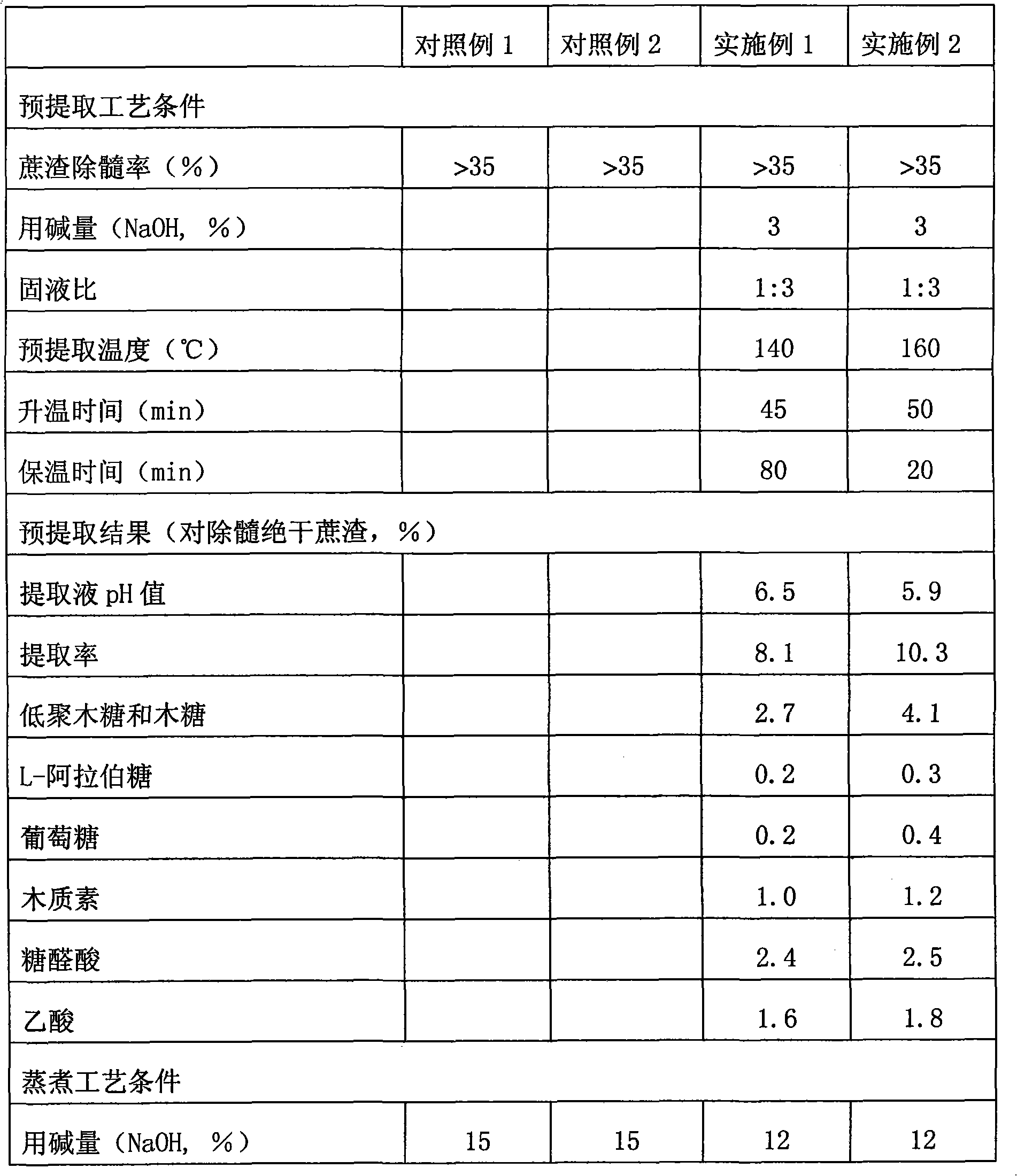

Embodiment 1

[0050] (1) bagasse is prepared, and bagasse is depitted and washed;

[0051] (2) Pre-extraction: carried out in steamed balls, the extraction solvent is sodium hydroxide solution, the amount of alkali used is 3%, the solid-to-liquid ratio is 1:3, and the pre-extraction temperature is 140 ° C. The time is 45 minutes, the incubation time is 80 minutes, and the pH value at the end of the reaction is 6.5;

[0052] (3) Liquid-solid separation and washing, collecting the filtrate to obtain an extract: the extraction rate of bagasse organic matter is 8.1%;

[0053] (4) Residue alkaline cooking and pulping: to the initial depitting and dry bagasse, in terms of NaOH, the amount of alkali used is 12%, the solid-to-liquid ratio is 1:3, the cooking temperature is 164 ° C, and the heating time is 50 minutes. The heat preservation time is 30 minutes, and the bagasse coarse pulp is obtained, the yield of the coarse pulp is 51-53%, and the hardness is KMnO 4 The value is 10-12, and the resi...

Embodiment 2

[0055] (1) bagasse is prepared, and bagasse is depitted and washed;

[0056] (2) Pre-extraction: carried out in steamed balls, the extraction solvent is sodium hydroxide solution, the amount of alkali used is 3%, the solid-to-liquid ratio is 1:3, and the pre-extraction temperature is 160 ° C. The time is 50 minutes, the incubation time is 20 minutes, and the pH value at the end of the reaction is 5.9;

[0057] (3) Liquid-solid separation and washing, collecting the filtrate to obtain an extract: the extraction rate of bagasse organic matter is 10.3%;

[0058] (4) Residue alkaline cooking and pulping: to the initial depitting and dry bagasse, in terms of NaOH, the amount of alkali used is 12%, the solid-to-liquid ratio is 1:3, the cooking temperature is 164 ° C, and the heating time is 50 minutes. The holding time is 20 minutes, and the bagasse coarse pulp is obtained, the yield of the coarse pulp is 51-53%, and the hardness is KMnO 4 The value is 10-12, and the residual alka...

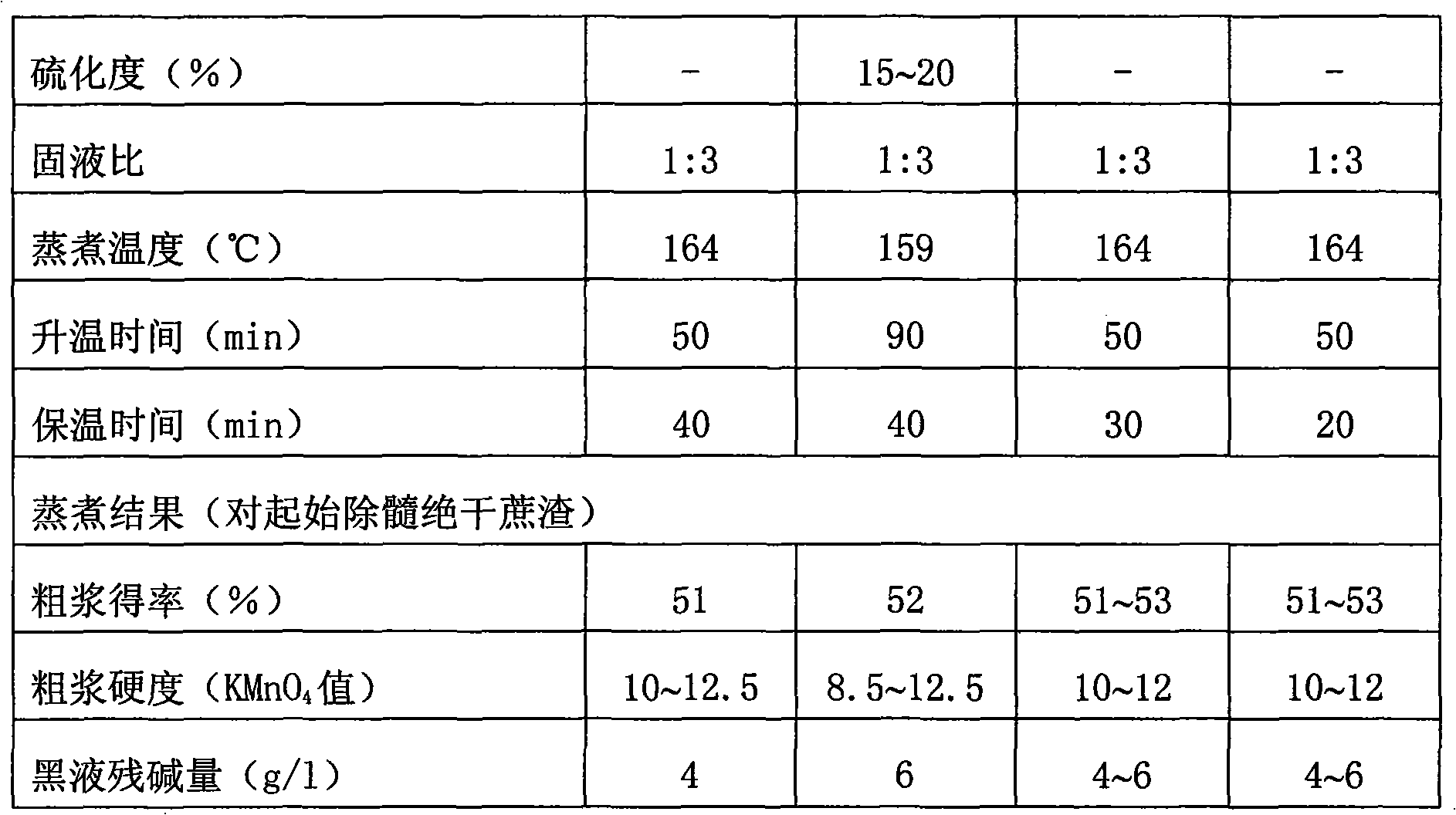

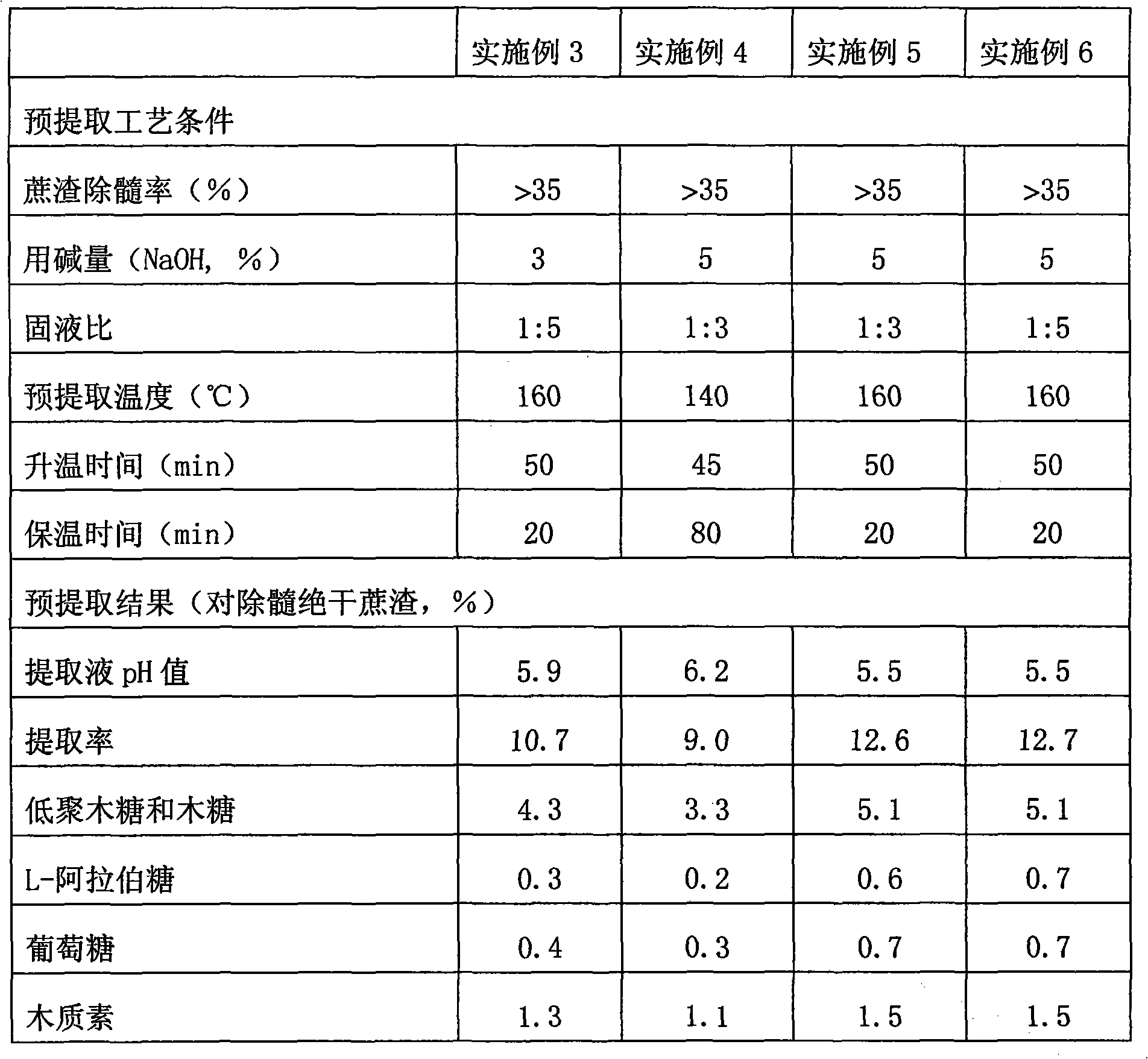

Embodiment 3

[0060] (1) bagasse is prepared, and bagasse is depitted and washed;

[0061] (2) Pre-extraction: carried out in a hydrolyzer, the extraction solvent is sodium hydroxide solution, and the amount of alkali used is 3%, the solid-liquid ratio is 1:5, and the pre-extraction temperature is 160° C. The time is 50 minutes, the incubation time is 20 minutes, and the pH value at the end of the reaction is 5.9;

[0062] (3) Liquid-solid separation and washing, collecting the filtrate to obtain an extract: the bagasse organic matter extraction rate is 10.7%;

[0063] (4) Residue alkaline cooking and pulping: for the initial depitting and dry bagasse, in terms of NaOH, the amount of alkali used is 12%, the degree of sulfidation is 15-20%, the solid-liquid ratio is 1:3, and the cooking temperature is 159 ℃, the heating time is 90 minutes, and the holding time is 15 minutes, the bagasse coarse pulp is obtained, the yield of the coarse pulp is 51-53%, and the hardness is KMnO 4 The value is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com