Measurement while drilling and precise control ultrashort radius horizontal drilling method

A technology of precise control and measurement while drilling, applied in drilling equipment and methods, measurement, drilling equipment, etc., can solve the problems of short drilling distance, inability to monitor wellbore trajectory, and inability to realize measurement while drilling, etc., to improve drilling distance and the effect of the oil layer drilling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and embodiments.

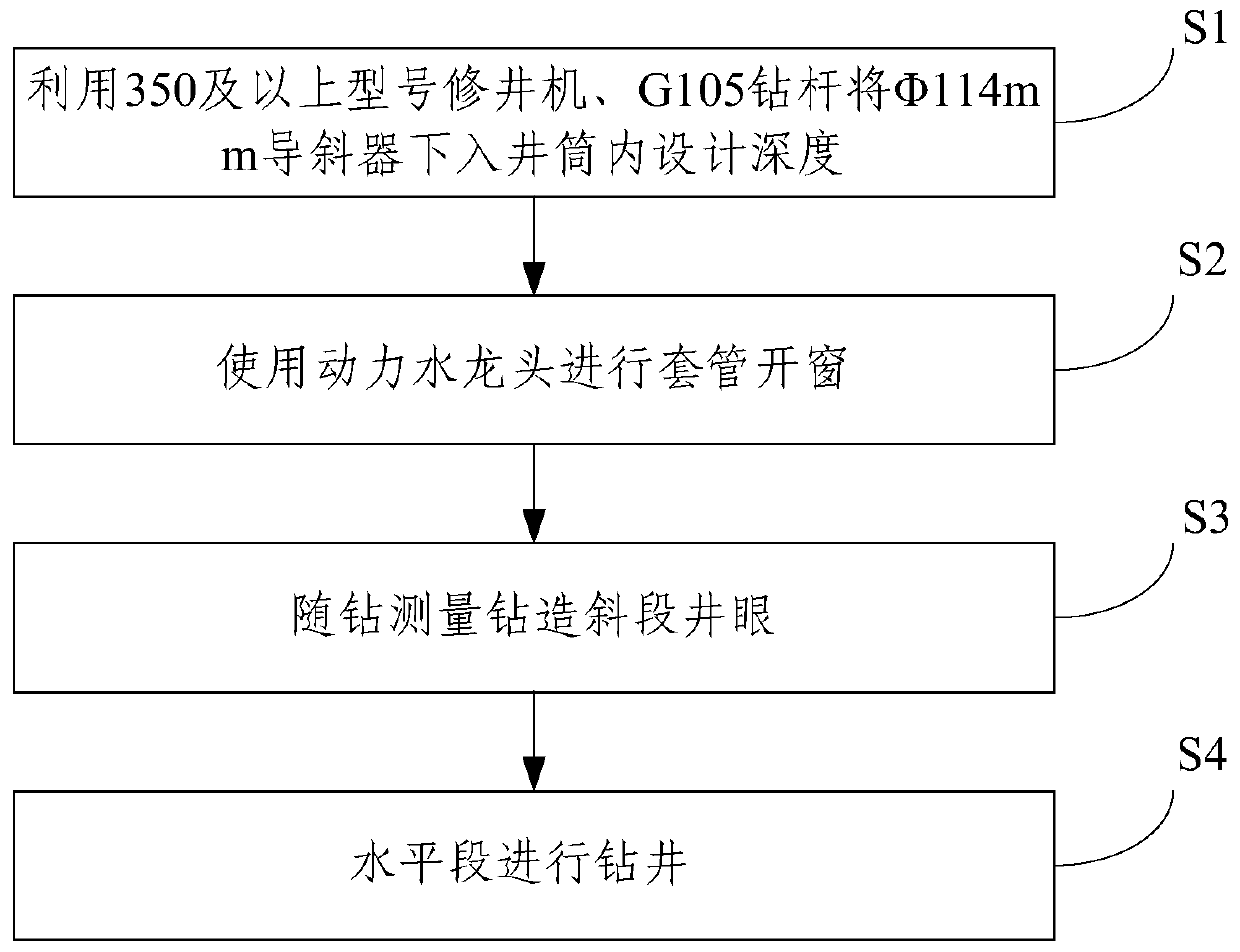

[0022] Such as figure 1 As shown, the embodiment of the present invention provides an ultra-short radius horizontal drilling method for measuring while drilling and performing precise control, including:

[0023] Step S1: Use the workover rig 350 or above and G105 drill pipe to lower the Φ114mm deflector into the design depth of the wellbore.

[0024] In this step, it specifically includes:

[0025] Step S11, depth control;

[0026] The depth control includes: depth reference system; Party A provides the depth reference system as the standard, and provides the blueprint of the original well. Drilling tool management: Effectively manage all drilling tools to ensure accurate drilling tool length and lowering the whipstock to the designed depth. Re-test the original well: Log the cased well, compare the original logging blueprint, and determine the depth position of the reserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com