Track while drilling control method of shali shale oil horizontal well

A trajectory control, horizontal well technology, applied in the field of oil exploration, to achieve the effect of precise time-depth relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0058] The first embodiment: as Figure 1-7 As shown, the present embodiment adopts the following technical scheme: a method for controlling the trajectory while drilling a thin-bed shale oil horizontal well, comprising the following steps:

[0059] 1) Determine the optimal artificially synthesized seismic trace, and generate the seismic sweet spot time window according to the seismic velocity of the sweet spot section of the horizontal well;

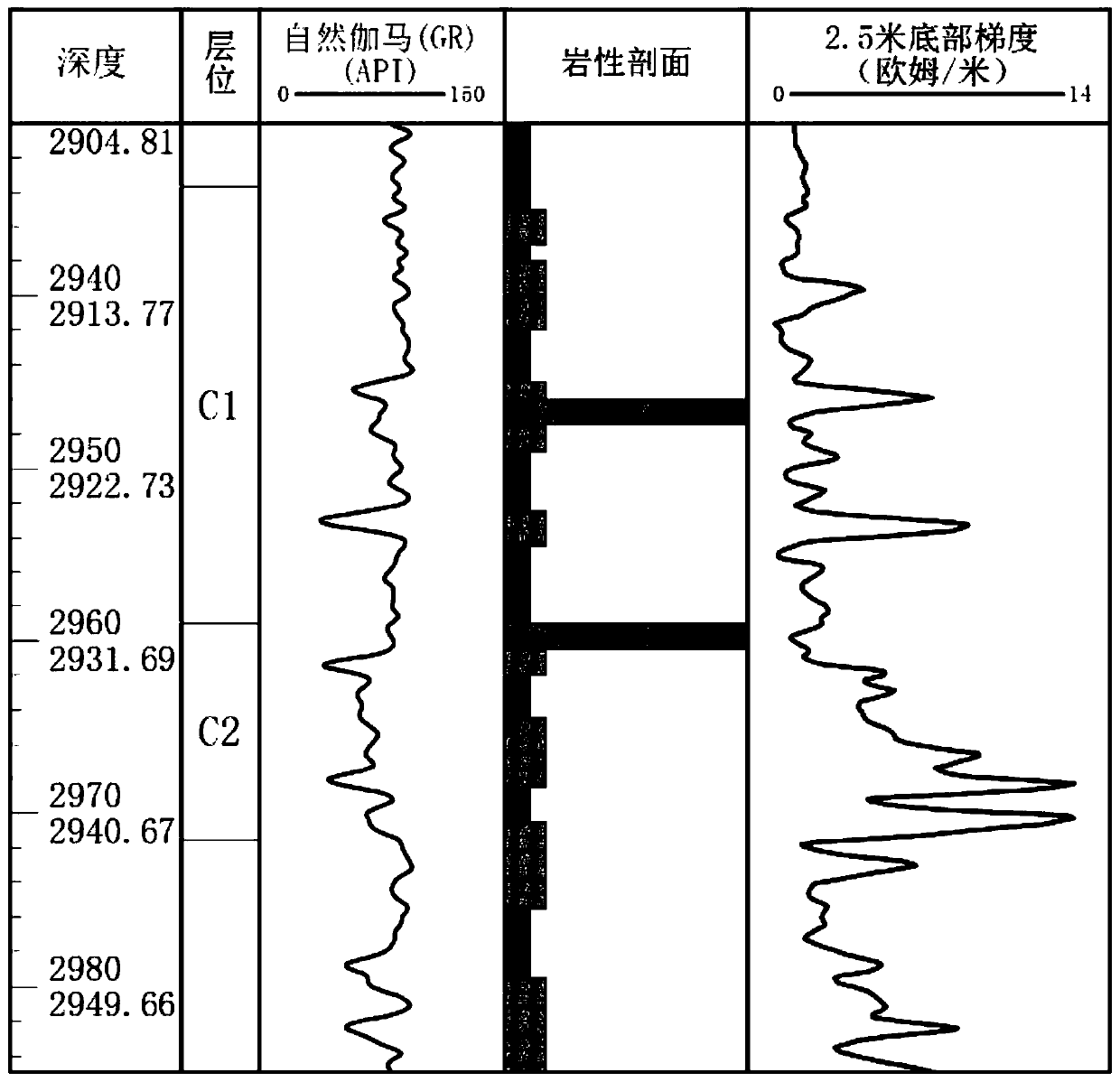

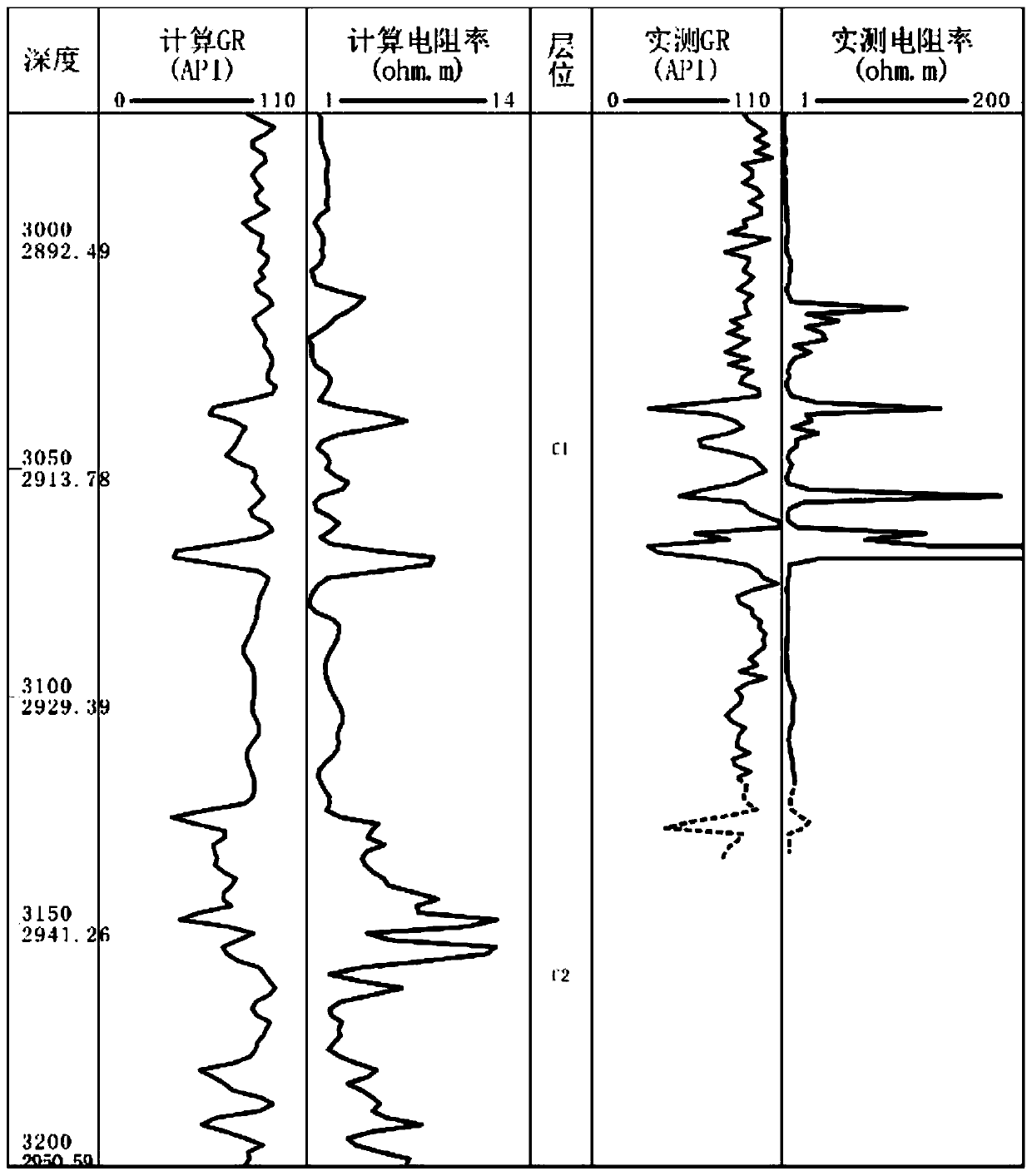

[0060] 2) Establish the standard logging response curve of the sweet spot section by using the corresponding shape of the well logging curve of the known well, and generate the predicted logging curve according to the design trajectory of the shale oil horizontal well;

[0061] 3) During the process of drilling, adjust the trajectory while drilling in time according to the real-time logging curve and refer to the logging absolute value and variation range of the marked interval.

[0062] Wherein, in the step 1), the optimal artificiall...

no. 2 example

[0095] 1) Determine the optimal synthetic seismic trace, and generate the seismic sweet spot time window according to the seismic velocity of the horizontal well sweet spot section.

[0096] ① Well seismic calibration for all intervals.

[0097] a. Determine the optimal synthetic seismic trace.

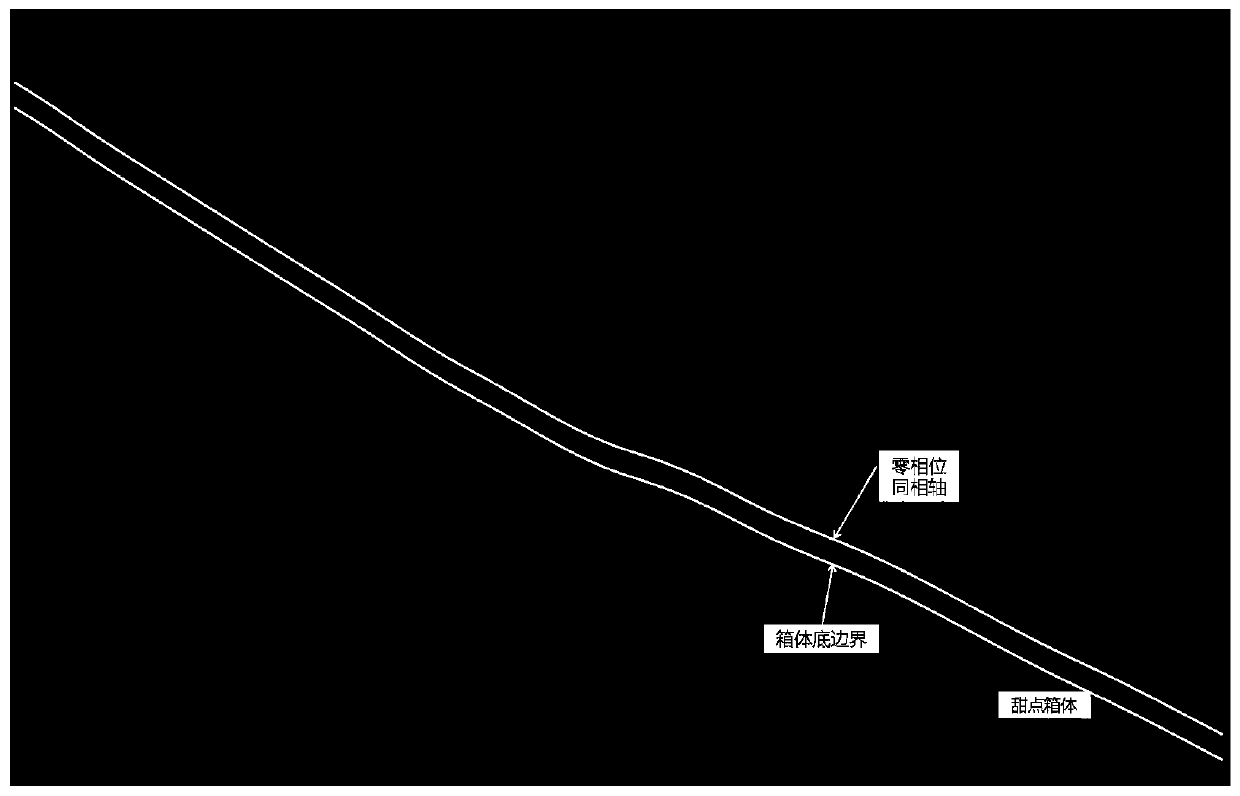

[0098] G 1 , G 2 and G 3 There are 3 geological layers in total, and the seismic traces are artificially synthesized using the acoustic time difference logging curve (AC), and the corresponding time depth is G t1 , G t2 and G tn , the seismic interpretation interface is numbered T from top to bottom corresponding to the time and depth 1 , T 2 and T n , as attached figure 1 -A shown.

[0099] Define the well-seismic fit degree DF formula:

[0100] Among them, G t1 , G t2 ,...,G tn is the time depth corresponding to the synthetic seismic trace, T 1 , T 2 ,...,T n Interpret interfaces for seismicity corresponding to time-depth.

[0101] Search the minimum value of DF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com