Method for increasing drilling rate of horizontal well tight oil reservoir

A technology for tight oil and horizontal wells, which is applied in drilling equipment and methods, directional drilling, earth-moving drilling, etc., which can solve the inconvenience of real-time adjustment of the drill bit direction, the difficulty in adjusting the drilling direction, and the lack of consideration of the phase change of the shale interlayer. Mudstone prediction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

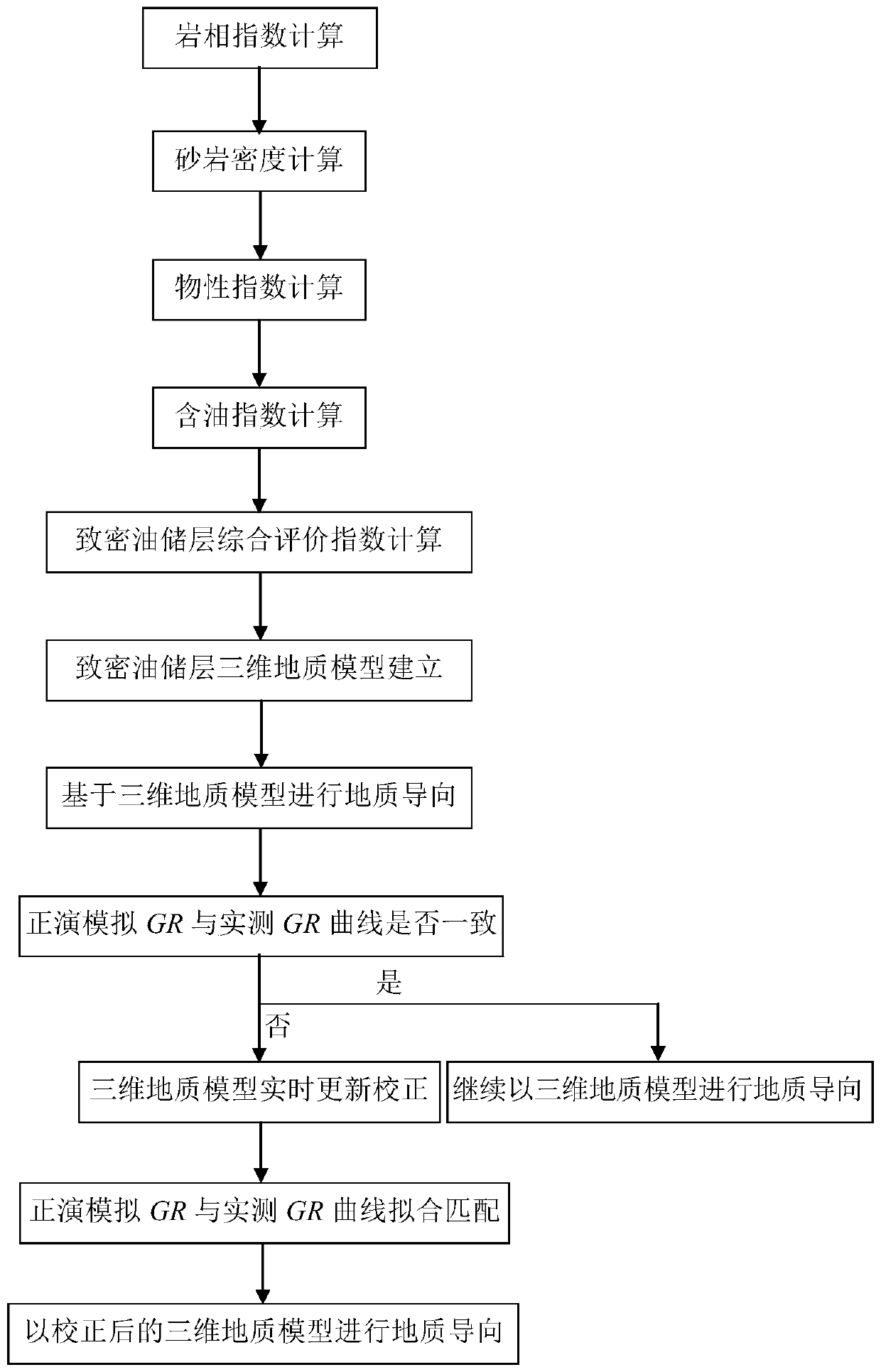

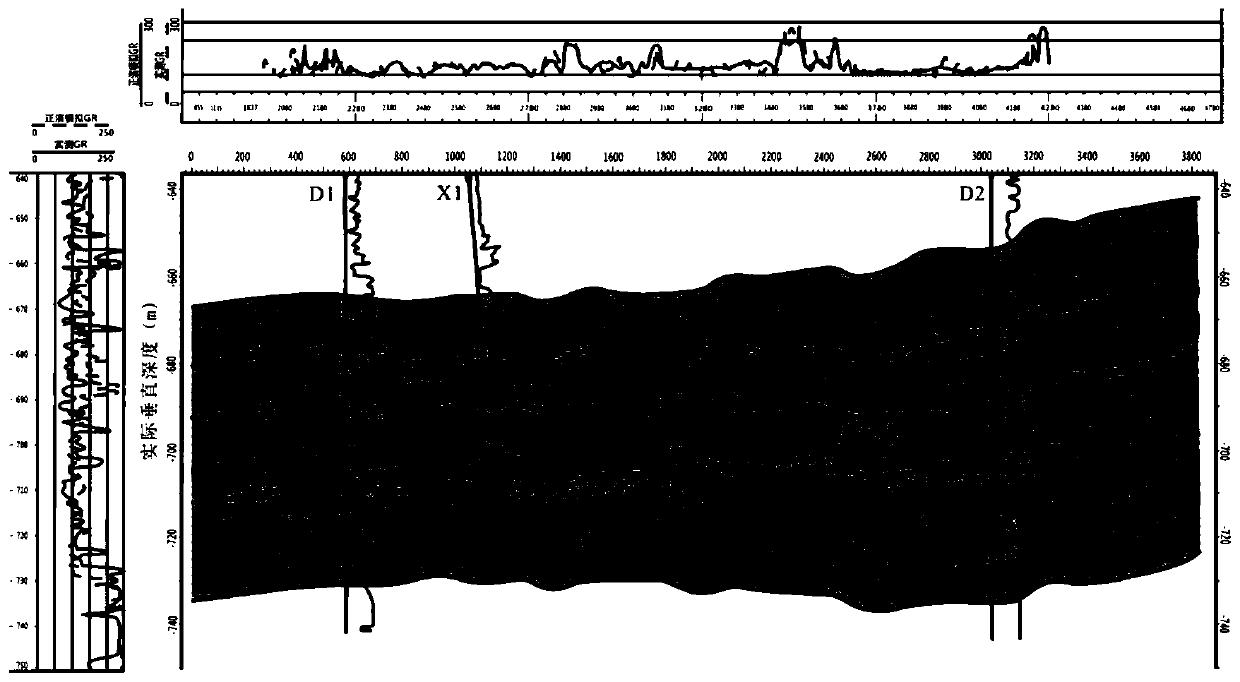

[0029] refer to figure 1 , a method for improving the drilling rate of tight oil reservoirs in horizontal wells, comprising the following steps:

[0030] Step 1. Calculating the lithofacies index: After calculating the relative natural gamma ray based on equation (1) using natural gamma ray logging, use equation (2) to calculate the lithofacies index, and use the lithofacies index to reflect the development characteristics of sandstone and mudstone. details as follows:

[0031]

[0032]

[0033] In the formula: ΔGR is relative natural gamma, dimensionless; GR max 、GR min Respectively, the maximum and minimum values of natural gamma, API; I ltih is the lithofacies index, which is dimensionless; GCUR is the Hirch index, which takes a value of 2 for old strata and 3.7 for new strata, and is dimensionless.

[0034] Step 2. Calculati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com