Drilling method and system

A drilling and drill bit technology, which is applied in the field of drilling methods and systems applying the method, can solve the problems of different structural complexity, low drilling rate of high-quality shale, and failure to reflect the drill bit in time, so as to achieve the effect of increasing the drilling rate

Active Publication Date: 2018-05-11

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in practical applications, due to the lack of high-precision 3D seismic data in low-exploration areas, it is difficult to achieve a good prediction of the distribution characteristics of underground high-quality shale

At the same time, the structural complexity of each exploration area is different, and there are difficulties such as prominent well-seismic contradictions and large deviations between the geological design and the actual drilled formation. A slight deviation in its prediction will cause the horizontal well trajectory to deviate from the best quality shale section

In addition, the measurement while drilling instrument has a measurement blind area of 5-15 meters from the bottom of the well, which cannot reflect the geological data of the position of the drill bit in time. Adjust, and then adjust the trajectory back to the high-quality shale, the actual deviation from the horizontal section of the high-quality shale has reached 20-50 meters, resulting in a low drilling rate of the overall high-quality shale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0060] The drilling system in the second embodiment can be used to implement the drilling method, therefore, since the details have been described in the first embodiment, the description will not be repeated in the embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

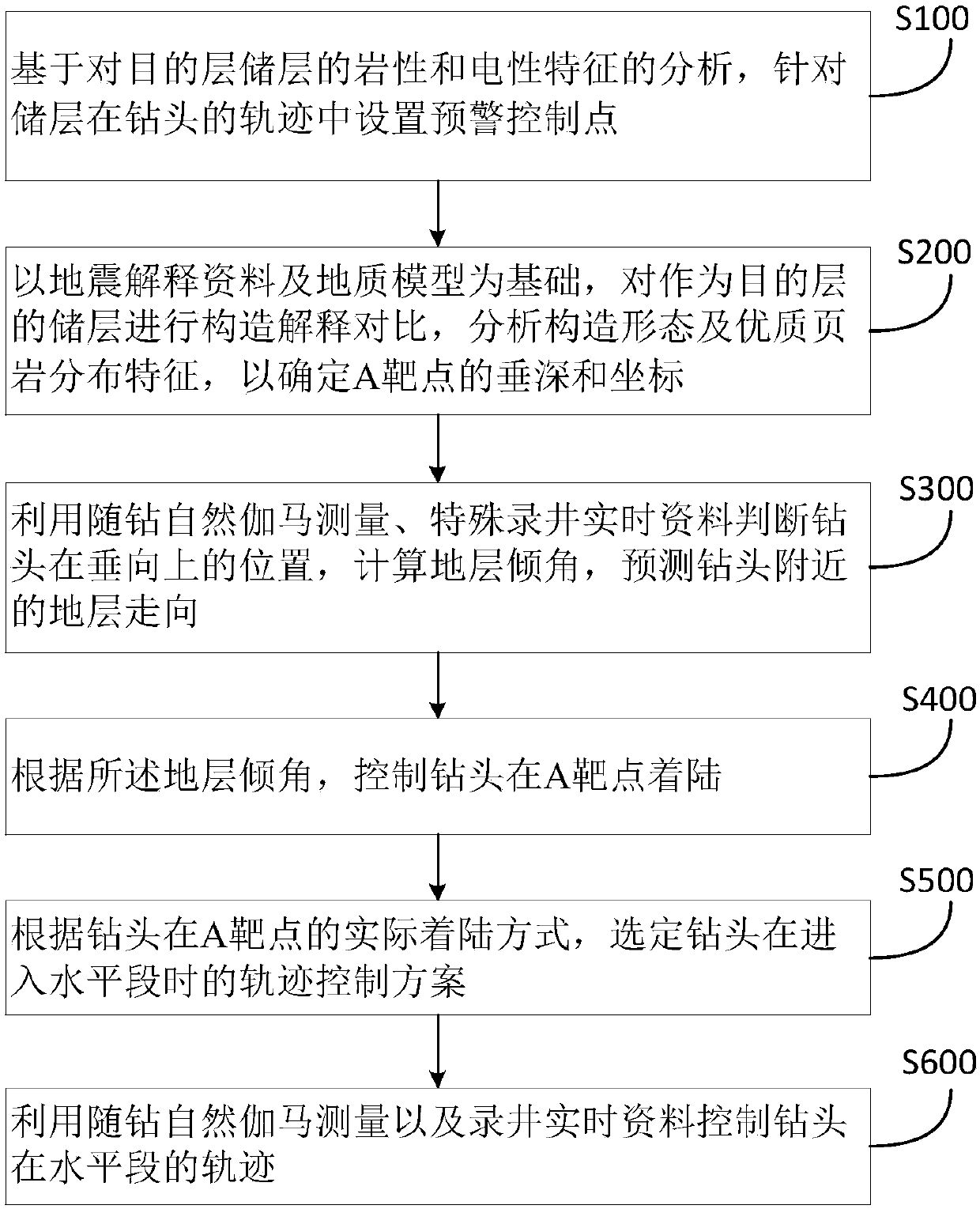

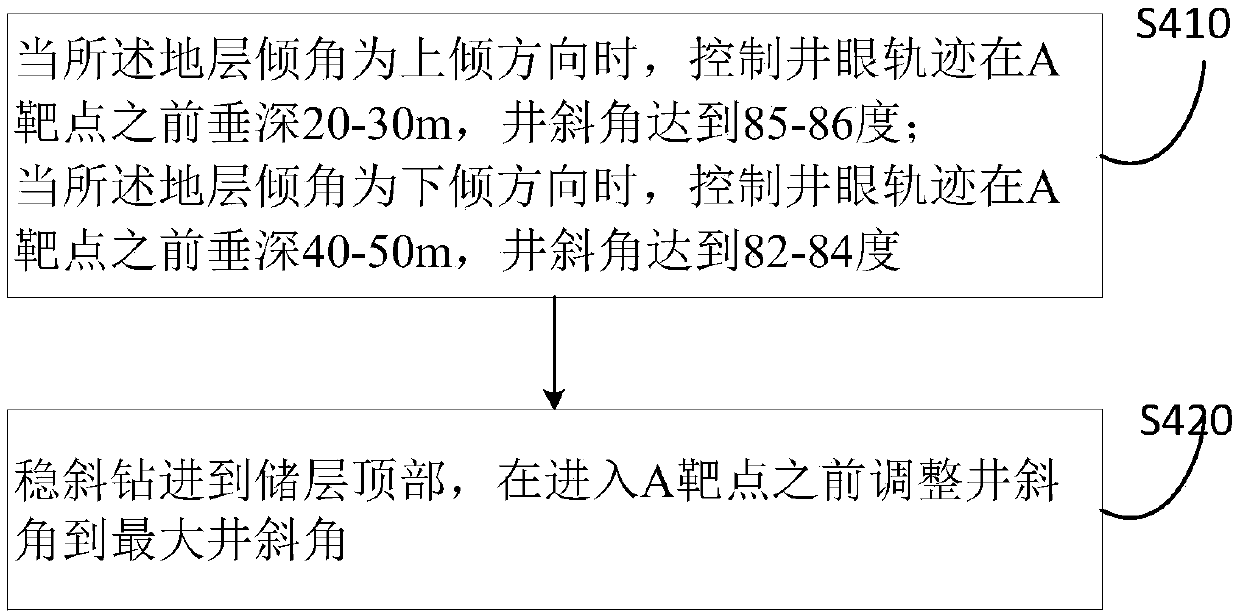

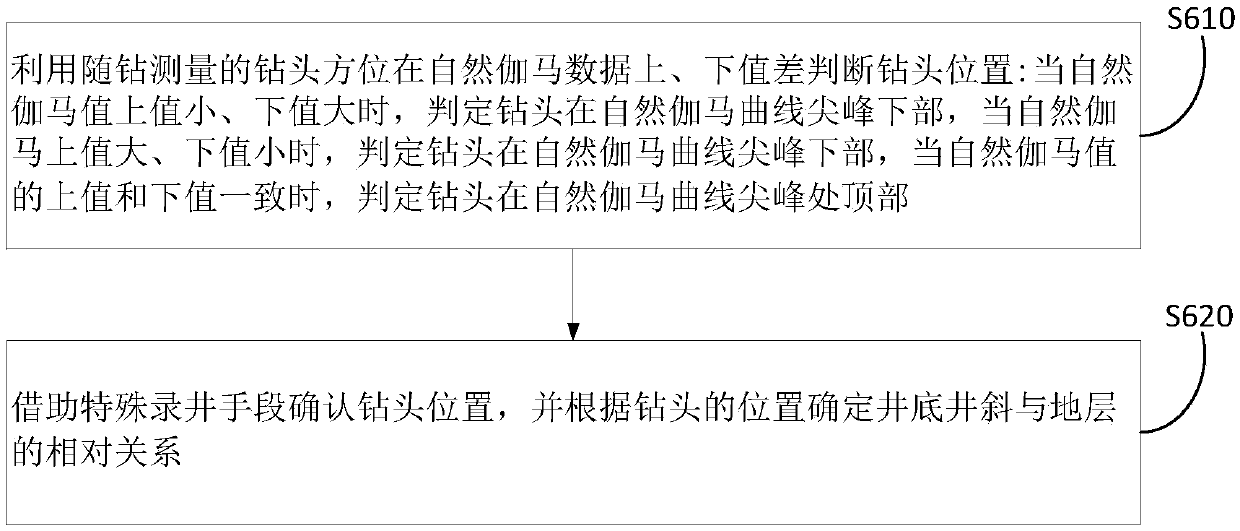

The invention relates to the field of petroleum and natural gas exploration and provides a drilling method and system. The drilling method comprises the steps that based on the analysis of the lithologic characters and the electric characteristics of a reservoir of a target stratum, forewarning control points are arranged in the track of a drill bit aiming at the reservoir; on the basis of seismicinterpretation data and a geological model, structure interpretation comparison is conducted on the target stratum, and the structure form and the excellent shale distribution characteristics are analyzed so as to determine the vertical depth and coordinates of an A target point; the position of the drill bit in the vertical direction is judged through while-drilling natural gamma measurement andspecial logging real-time data, the stratum dip angle is calculated, and the strike of a stratum near the drill bit is predicted; according to the stratum dip angle, the drill bit is controlled to land at the A target point; according to the actual landing mode of the drill bit at the A target point, the track control scheme of the drill bit at the time of entering the horizontal section is selected; and through the while-drilling natural gamma measurement and logging real-time data and according to the gamma values of the forewarning control points, the track of the drill bit on the horizontal section is controlled.

Description

technical field [0001] The invention relates to the field of oil and natural gas exploration, in particular to a drilling method and a system applying the method. Background technique [0002] In recent years, horizontal well technology has been widely used in the exploration and development of shale gas in China. The development and production of shale gas fields are realized by increasing the drainage area of reservoirs through horizontal wells. The long horizontal section increases the productivity of shale gas and reduces the cost of shale gas exploitation. In order to meet the production needs of shale gas horizontal wells, the designed horizontal section is relatively long, generally around 1400-1500m. The horizontal well section must ensure that it passes through relatively optimal reservoirs. The high-quality shale drilling rate after entering the horizontal section is a measure The key indicator of the quality and success of horizontal wells. Therefore, ensuring ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B7/04

CPCE21B7/046

Inventor 熊亮张克银董晓霞史洪亮陈维孔选林谢刚平张全林周维娜张天操马如辉

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com