Drilling tool assembly used for directional hole-forming underground coal mine and provided with air screw motor and construction method

A technology of screw motor and drilling tool assembly, which is applied in directional drilling, driving devices for drilling in boreholes, drill pipes, etc., can solve the problems that hydraulic power cannot be used as flushing medium, and reduce the possibility of accidents in holes and increase Drilling rate of coal seam and the effect of avoiding blind areas in extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

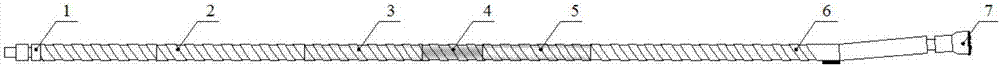

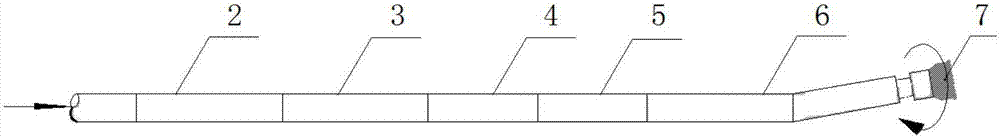

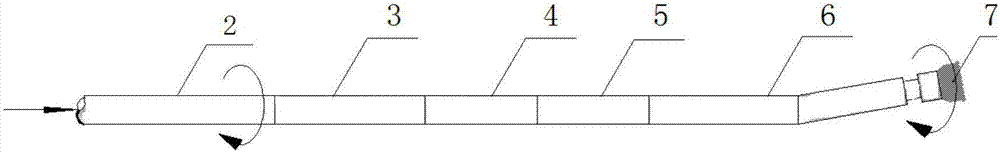

[0033] see Figure 1 to Figure 3 , shows the coal mine underground air screw motor directional drilling tool assembly and construction method of the present invention.

[0034] Such as figure 1 As shown, the coal mine underground air screw motor directional drilling tool assembly includes a directional drill bit 7 connected in sequence, an air screw motor 6, a lower non-magnetic drill rod 5, a wireless electromagnetic wave measurement while drilling nipple 4, and an upper non-magnetic drill rod 3. The middle drill pipe 2 and the air blower 1, the drilling tool combination can carry out two methods of composite drilling and sliding directional drilling: during composite drilling, the directional drill bit 7 is driven by the air screw motor 6 to rotate and break the rock At the same time, the middle drill pipe 2 rotates to drive the air screw motor 6 to rotate, and the drilling slag at the bottom of the hole is discharged from the bottom of the hole along the annular gap to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com