Patents

Literature

78 results about "Directional boring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Directional boring, also referred to as horizontal directional drilling (HDD), is a minimal impact trenchless method of installing underground utilities such as pipe, conduit, or cables in a relatively shallow arc or radius along a prescribed underground path using a surface-launched drilling rig. Directional Boring/HDD offers significant environmental advantages over traditional cut and cover pipeline/utility installations. The technique is routinely used when conventional trenching or excavating is not practical or when minimal surface disturbance is required.

Flexible directional drilling apparatus and method

A bottom hole assembly to directionally drill a subterranean formation includes a drill bit, a stabilizer assembly located proximate to and behind the drill bit, a drilling assembly comprising a drive mechanism and a directional mechanism, and a flex member. Optionally, the flex member may be located between the drilling assembly and the stabilizer assembly or an integral to a housing of the drilling assembly. A method to drill a formation includes positioning a stabilizer assembly behind a drill bit and positioning a flex member between an output shaft of a drilling assembly and the stabilizer assembly. The method preferably includes rotating the drill bit, stabilizer assembly, and flex member with a drilling assembly and directing the trajectory of the drill bit and stabilizer assembly with a directional mechanism of the drilling assembly.

Owner:SMITH INT INC

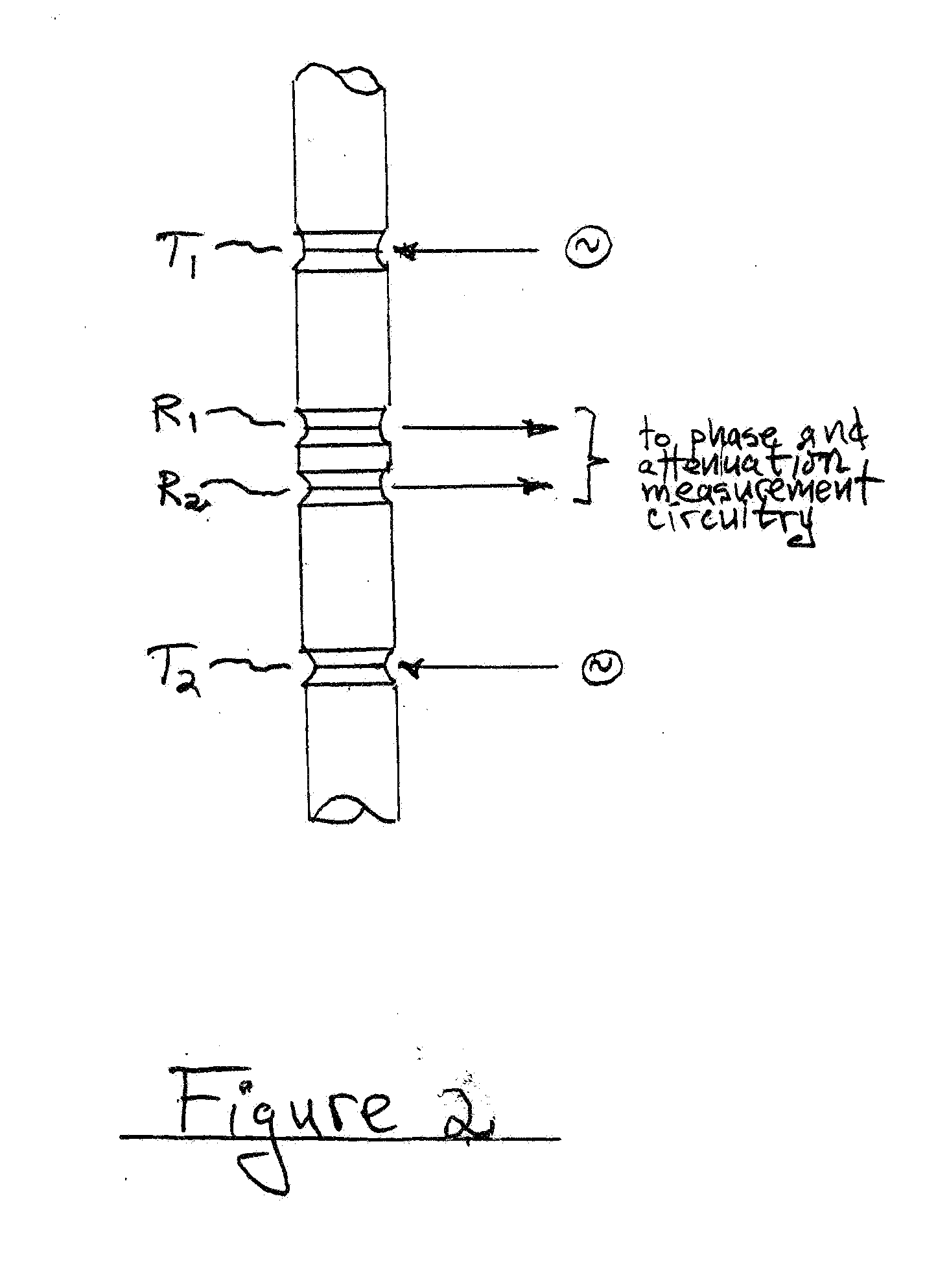

Methods For Characterization Of Formations, Navigating Drill Paths, And Placing Wells In Earth Boreholes

ActiveUS20120298420A1Electric/magnetic detection for well-loggingSurveyWell drillingLogging while drilling

A method for directing bore-hole drilling in a target earth formation includes the following steps: providing drilling equipment having a bottom hole assembly that includes a controllable directional drilling subsystem, and a logging-while-drilling directional measurement tool with a look-around and look-ahead capability; determining the presence of a predetermined type of formation characteristic in the target formation; and navigating a drill path in the target formation with the drilling equipment, including receiving measurement signals from the directional measurement tool, obtaining, from the received measurement signals, indications of formation parameters with respect to the formation characteristic in the target formation, and controlling the directional drilling subsystem to drill in a direction determined as a function of the obtained indication of formation parameters.

Owner:SCHLUMBERGER TECH CORP

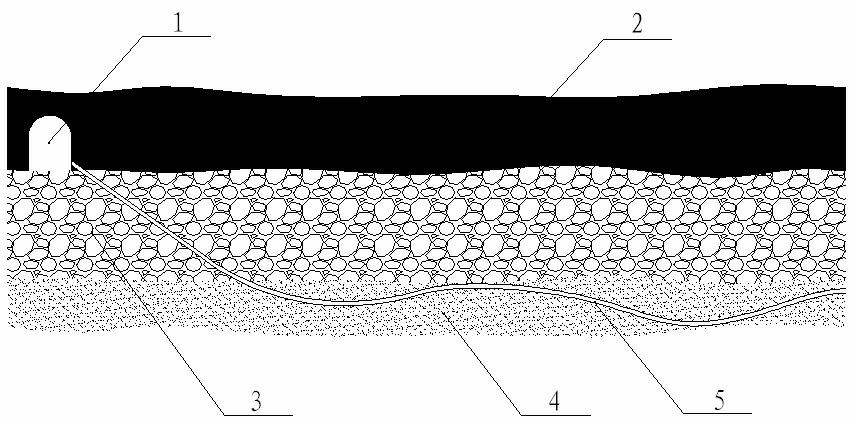

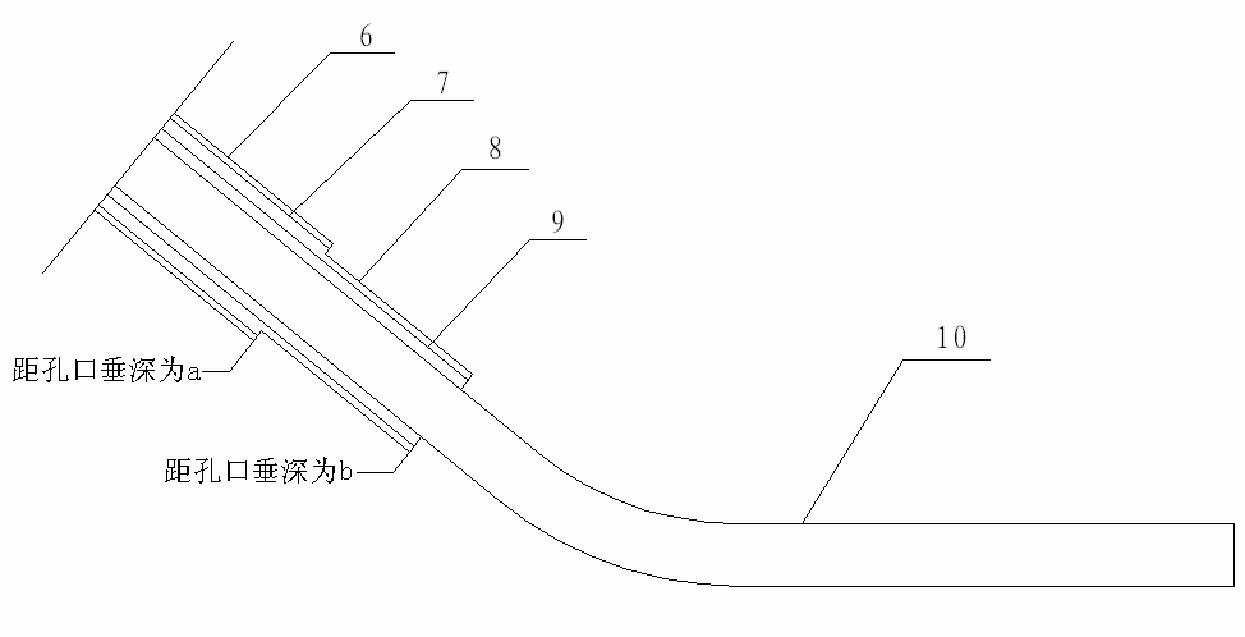

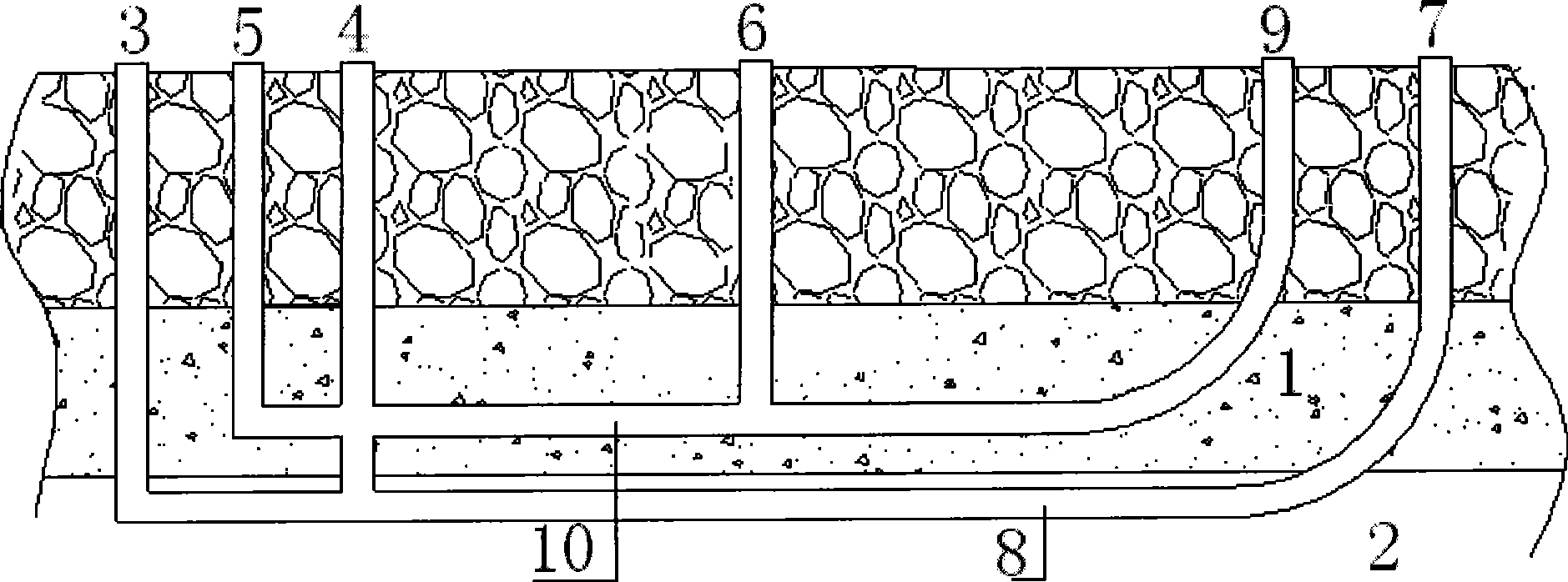

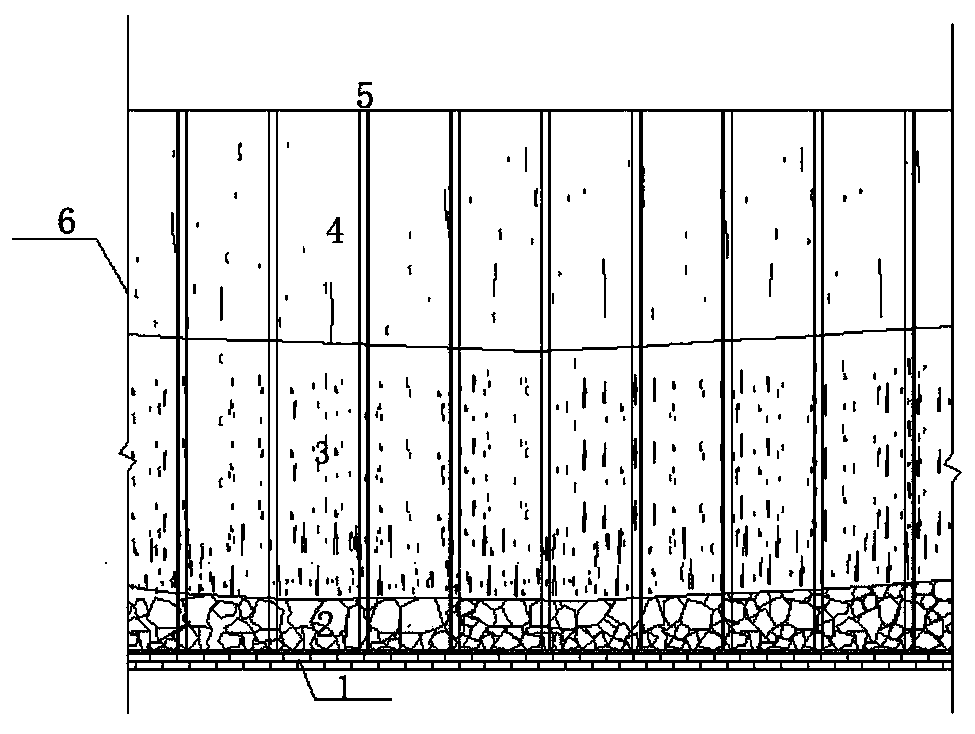

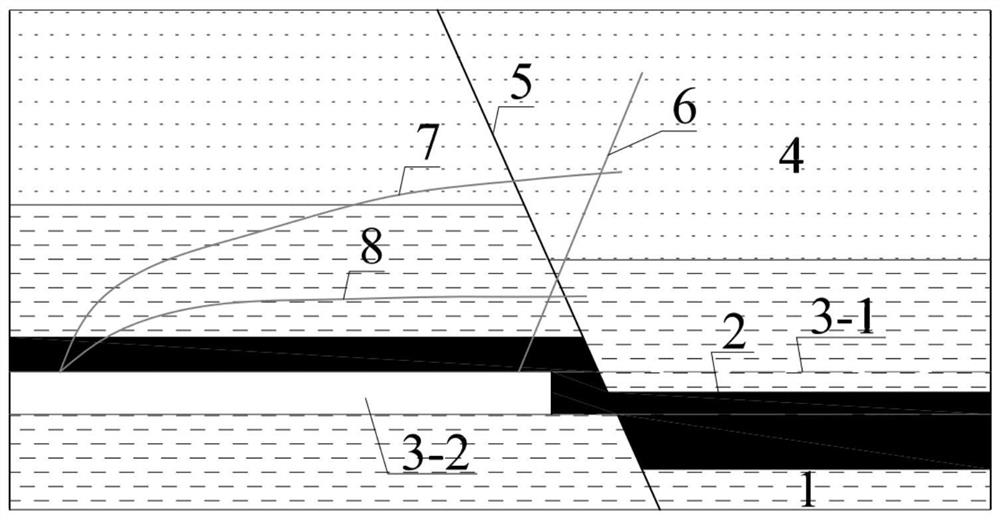

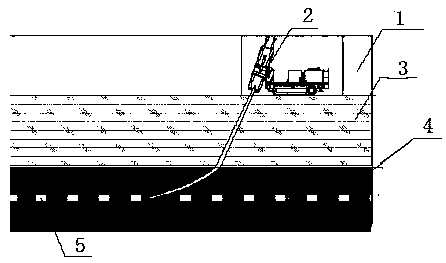

Construction method of consolidating horizontal directional drilling hole by grouting coal seam baseboard

ActiveCN102134967AAchieve consolidationAdjustable drilling directionSurveyDirectional drillingGeomorphologyBaseboard

The invention relates to a construction method of consolidating horizontal directional drilling holes by grouting a coal seam baseboard. Along with the continuous extension of coal mining depth and the continuous enlargement of the mining range, crustal stress is enlarged, and the number of abnormal geologic bodies is gradually increased, water pressure is gradually enhanced, hydrogeologic conditions become more and more complex, and water-inrush threat becomes more and more serious. The construction method provided by the invention comprises the following steps of: drilling holes in a coal seam by developing a drill field in a coal heading of a working surface, wherein the drilling direction points to a water resisting layer and a water bearing layer of the coal seam baseboard; rotatably drilling the coal seam baseboard for a certain depth to carry out hoist drilling and broaching, installing a primary hole sealing sleeve to seal the hole by grouting, cleaning the bottom of the hole after the grout is solidified; and then consolidating the hole by a primary sleeve, consolidating the hole by a secondary sleeve, and carrying out directional drilling to make the drilling hole extend along a preset consolidating layer according to the designed track to finally form the drilling hole. In the invention, the entire consolidation of the coal seam baseboard of the regional working surface is realized through designing the drilling hole track, determining the drilling hole consolidating radius and reasonably arranging the directional drilling according to the analysis to the water resisting layer and the water bearing layer.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

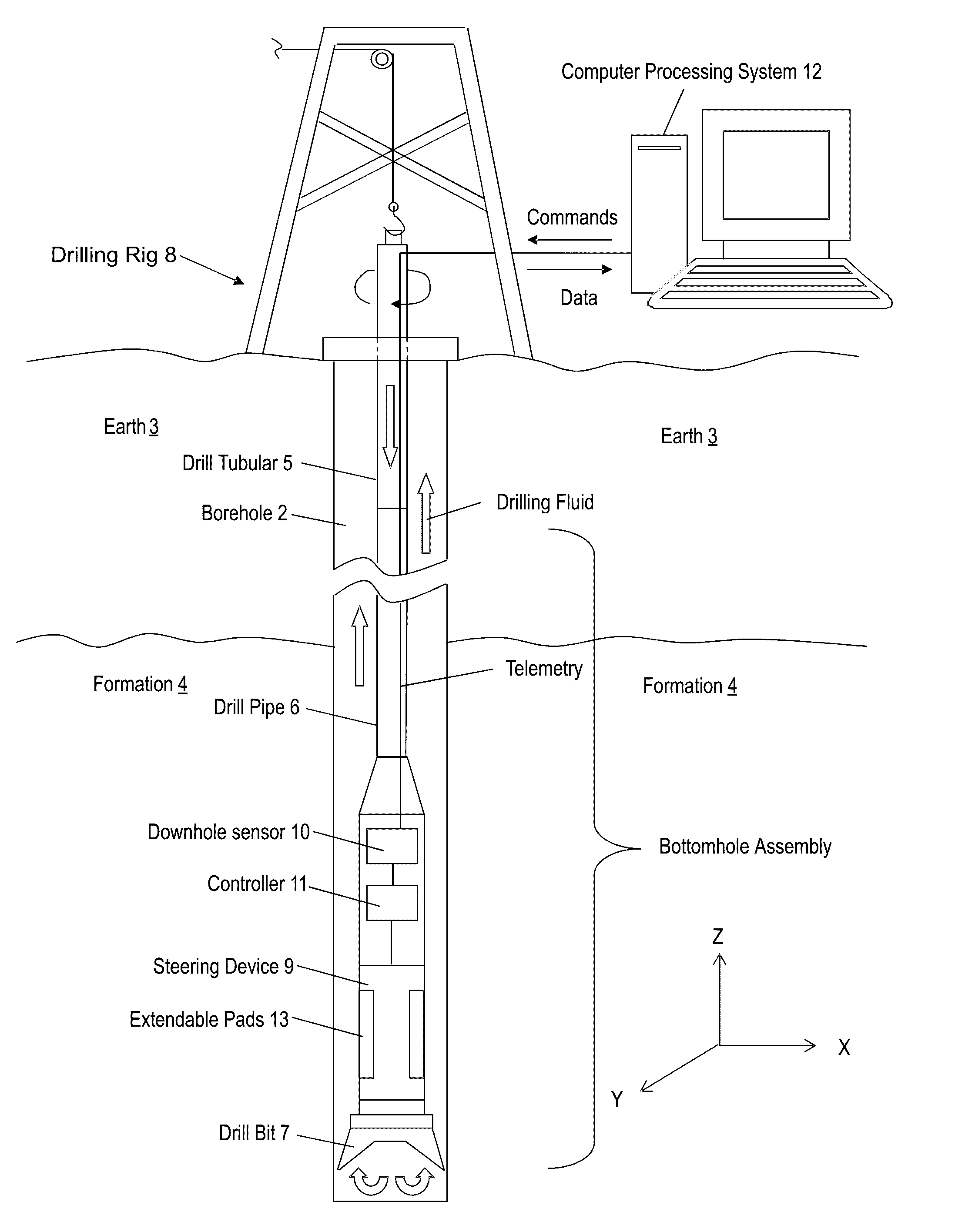

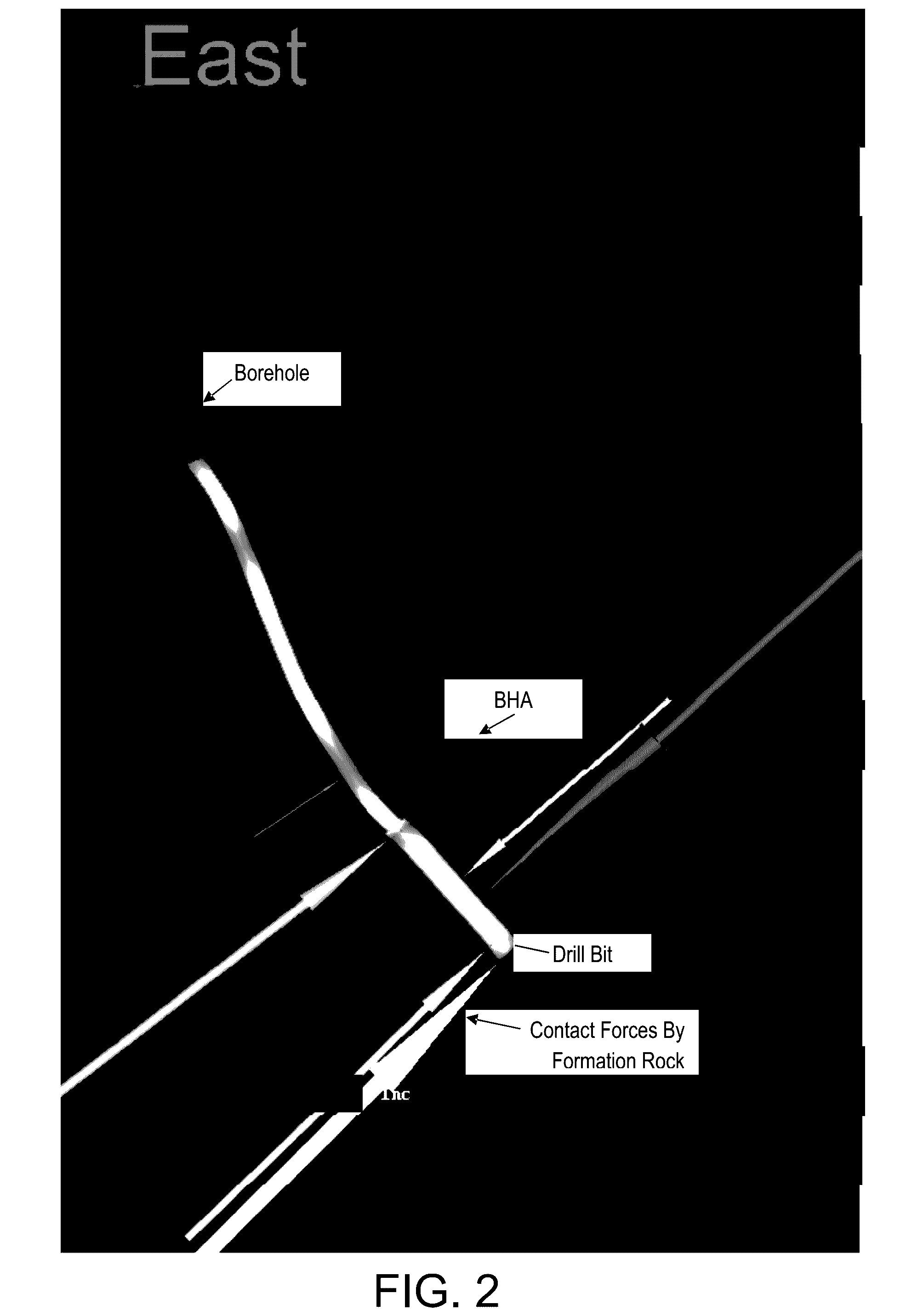

Methods of controlling drill bit trajectory by predicting bit walk and wellbore spiraling

A method of controlling drill bit trajectory in a subterranean formation includes receiving drilling parameters for operating a specific bottomhole assembly (BHA), constructing, with a computer processor, a directional drill-ahead simulator including a computer model of the BHA and the subterranean formation, calculating axial motion and lateral motion of a drill bit connected to a bottom end of the BHA using formation parameters and drilling parameters, predicting bit walk of the drill bit by accounting for and calculating contact forces and frictional forces between the BHA and a wall of a borehole in the subterranean formation using the computer model of the BHA, and determining an adjusted drill bit trajectory to account for the predicted bit walk. The method includes determining adjusted drilling parameters for operating the BHA to substantially follow the adjusted drill bit trajectory and operating the BHA according to the adjusted drilling parameters.

Owner:BAKER HUGHES INC

Novel underground coal gasification furnace

InactiveCN101382063AMeet craftFulfil requirementsConstructionsCoal gasificationEngineeringDirectional boring

The invention proposes a novel underground coal gasification furnace which is particularly suitable for the gasification of a coalbed containing water. An underground gasification furnace and a coalbed drainage passage integrated with each other are simultaneously constructed through a coalbed directional drilling process. The coalbed drainage passage can be effectively used for the coalbed drainage before gasification and the furnace body drainage during gasification, thereby ensuring the discharge of the water in the coalbed and consequently realizing the stable gasification of the coalbed containing water. The furnace has the advantages that the composite underground gasification furnace and the drainage passage are simultaneously constructed through the advanced coalbed directional drilling process, thereby bringing about easy execution and short construction period; as the drainage passage is positioned below the gasification passage, the drainage is smooth, and the problem of blockage does not easily happen; and the water in the drainage passage can be pumped out from a plurality of orientations, thereby bringing about rapid drainage. According to the requirements of furnace body drainage, the drainage holes of the gasification passage can be increased flexibly, thereby substantially solving the drainage problem of the coalbed containing water, and avoiding the impact of coalbed water inrush on coalbed gasification.

Owner:ENN COAL GASIFICATION MINING

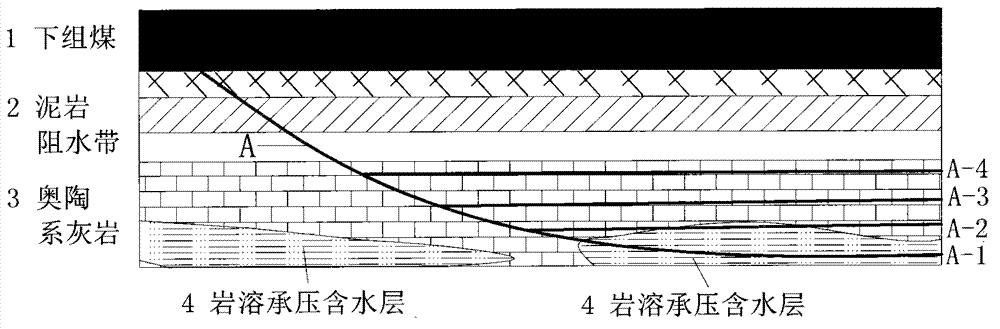

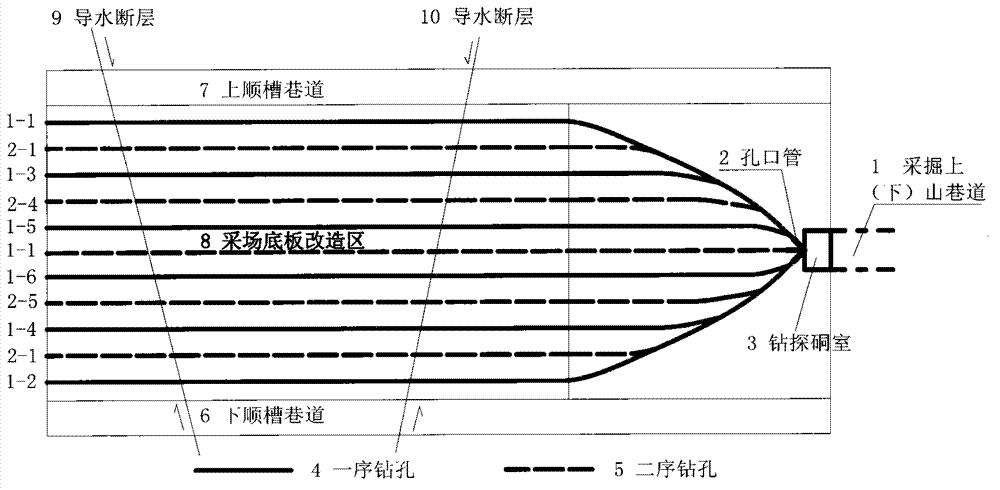

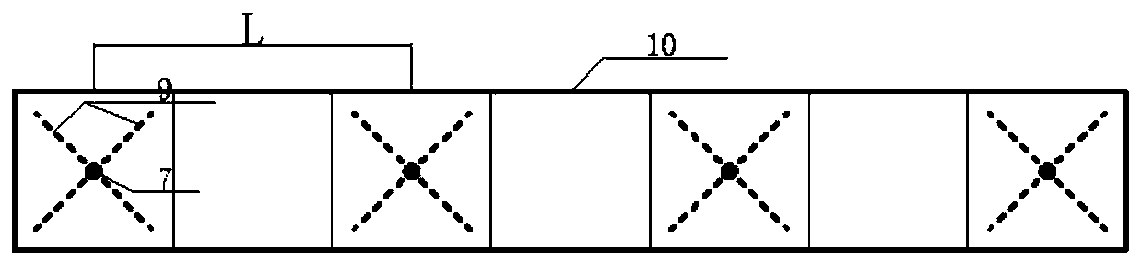

Method for modification and construction of top of Ordovician limestone of mine based on kilometer directional drilling technique

The invention discloses a method for modification and construction of top of Ordovician limestone of mine based on kilometer directional drilling technique. The method comprises the following steps: the drilling work for grouting modification of the top of the Ordovician limestone of the mine is applied through a kilometer directional drilling machine, a hole is drilled nonlinearly along the layer, a layout form of drilling the hole can be one perforated hole and multiple intersected holes, and advance grouting is adopted. According to the method for modification of the top of the Ordovician, the problem of safety mining under the conditions of insufficient thickness and strength of a water resisting layer when performing coal mining above a confined aquifer. An Ordovician limestone karst development structure and a hidden rupture structure are blocked in a large scale without occupying coal mining or driving face, a permeable layer at the top of the Ordovician limestone is converted to a water resisting layer in a certain range, so that ore resources threatened by the confined water are released, driving and recovery can be applied under the environment, no or few water prevention (separation) coal pillars can leave, and the resource recovery rate is improved.

Owner:SHANDONG ENERGY GRP

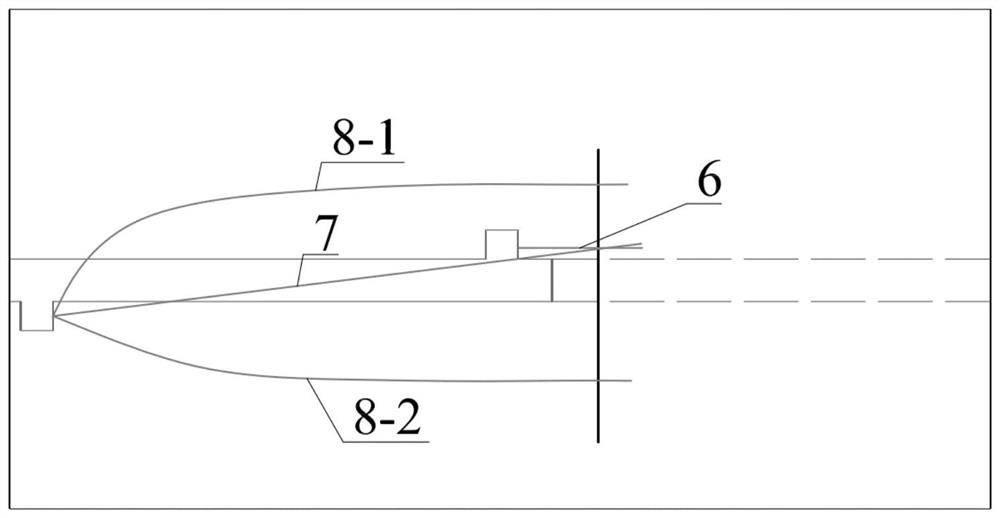

Drilling tool assembly used for directional hole-forming underground coal mine and provided with air screw motor and construction method

InactiveCN106869791AIncrease the encounter rateIncreased drilling depthDrilling rodsConstructionsMotor driveNon magnetic

Disclosed is a drilling tool assembly used for directional hole-forming underground a coal mine and provided with an air screw motor and construction method. The drilling tool assembly comprises a directional drill bit, the air screw motor, a lower non-magnetic drill rod, a wireless electromagnetic wave measurement while drilling short section, an upper non-magnetic drill rod, a middle drill rod and a blower which are connected in sequence. The drilling tool assembly can carry out composite drilling and sliding directional drilling for construction: when composite drilling is conducted, the air screw motor drives the directional drill bit to crush rocks in rotatably, meanwhile, the middle drill rod rotates to drive the air screw motor to rotate, boring mud at the bottom of a hole is discharged from the bottom of the hole by compressed air along an annular gap, and the middle drill rod can be used for auxiliary slagging; and when sliding directional drilling is conducted, the middle drill rod does not rotate, the directional drill bit is driven by the air screw motor driven by the compressed air to rotate to crush rocks, and the track of the hole is controlled by changing the elbow orientation of the air screw motor. Thus, according to the drilling tool assembly used for directional hole-forming underground the coal mine and provided with the air screw motor and construction method, the drilling depth of a soft coal seam and the coal seam drilling-encounter rate can be improved greatly, and the drilling gas extraction effect is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

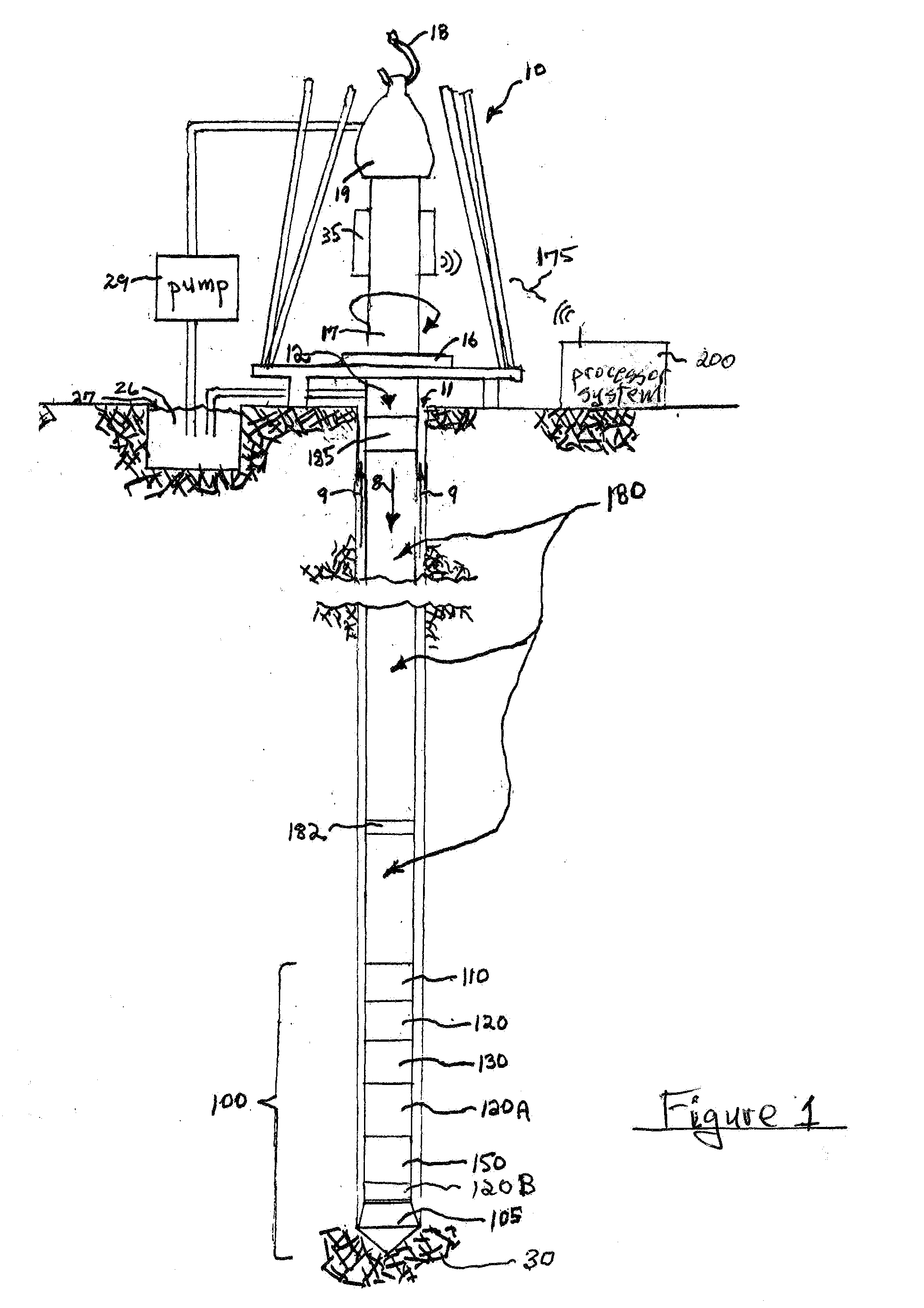

Method and apparatus for directional boring

InactiveUS6199643B1Improved directional stabilityEarth drilling toolsDirectional drillingEngineeringOrbit

Owner:TRACTO TECHN PAUL SCHMIDT SPEZIALMASCHEN

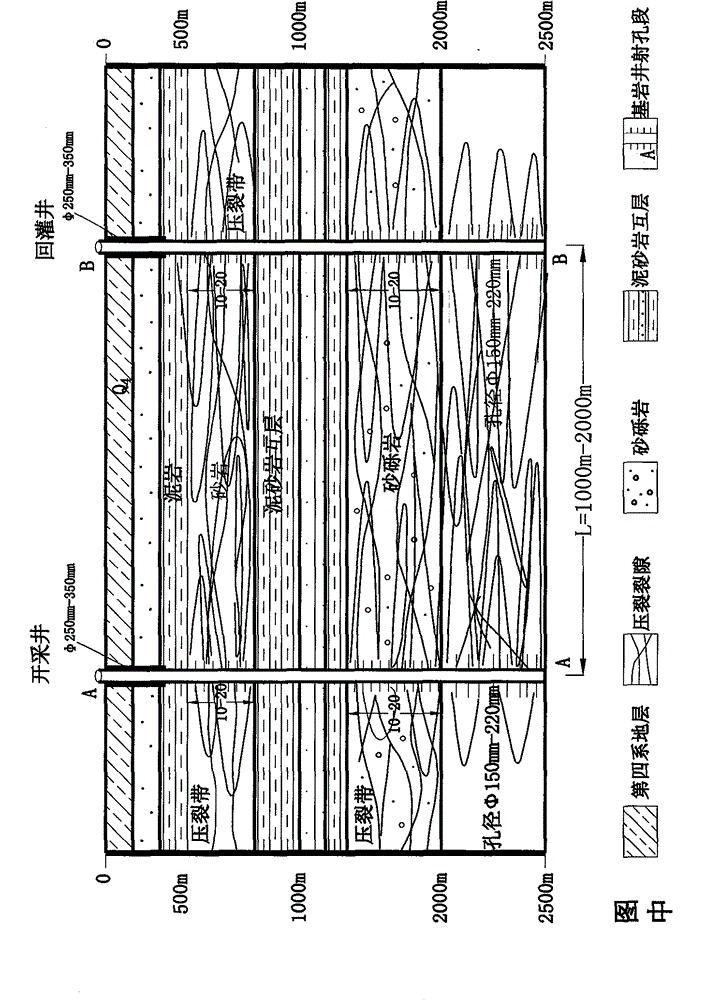

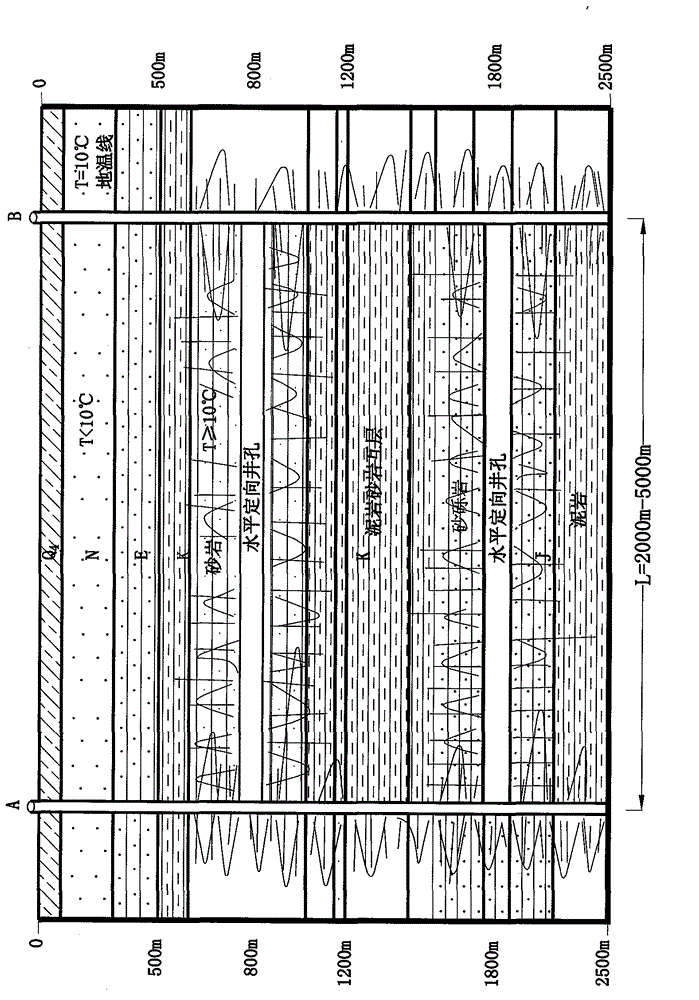

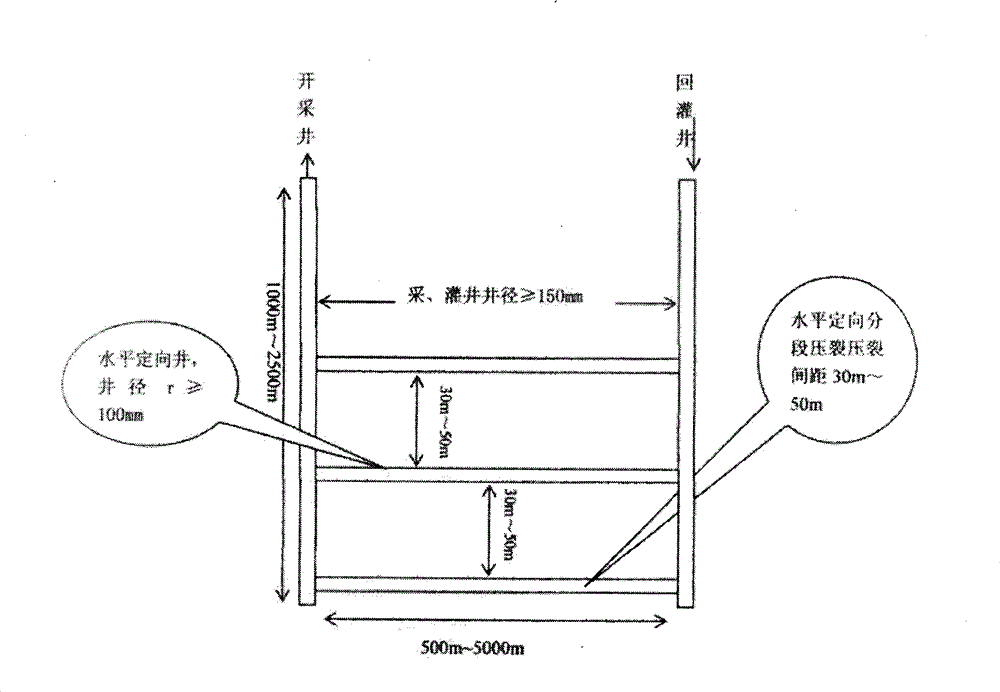

Low temperature geothermal energy production technique method

InactiveCN104695926ASolve the recharge problemIncrease heat storage spaceFluid removalHot springDirectional boring

The invention discloses a low temperature geothermal energy production technique method, and belongs to a geothermal energy utilization technique. According to the method, fracturing and communication are performed in a heat storage stratum section through drilling, fracturing and directional drilling techniques on the premise that geological environment stability is ensured according to a geothermic gradient theory, so that subsections of a heat storage stratum are communicated in a certain depth underground, a relatively independent fluid circulation space system is formed, and the purpose of low temperature geothermal energy production is achieved in an extraction and filling combined linkage manner. The method and techniques are scientific and reasonable, the production and utilization problems of low-temperature geothermal energy in a vast underground water area are solved, the technical target that hot springs exist anywhere is achieved, geothermal energy resources are sufficiently utilized, and the geological environment is not damaged.

Owner:王作韬

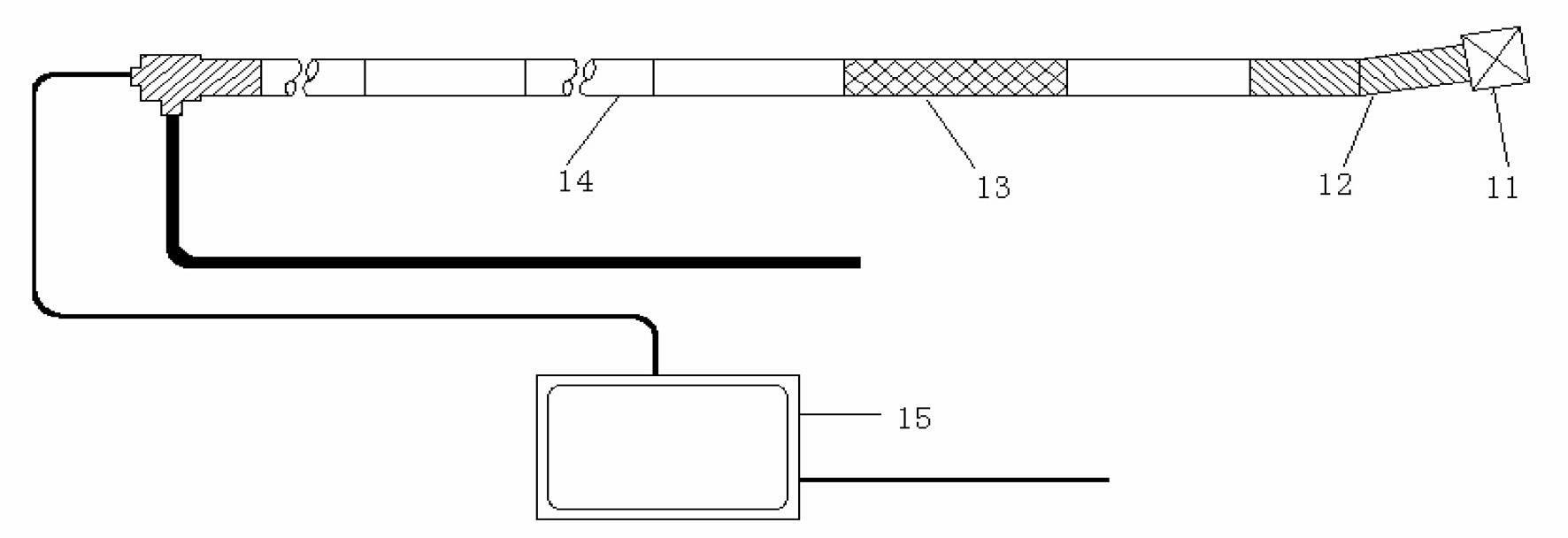

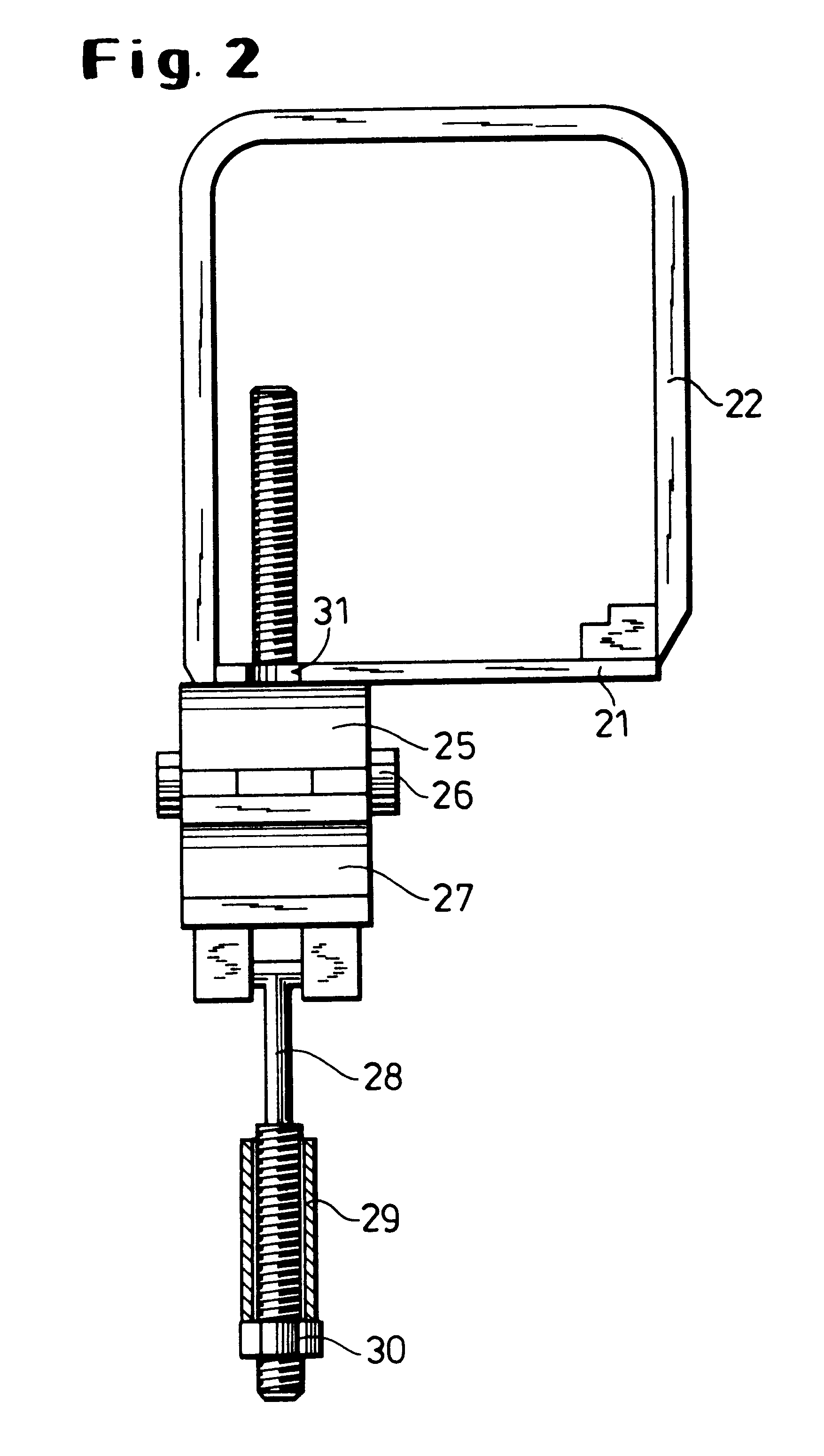

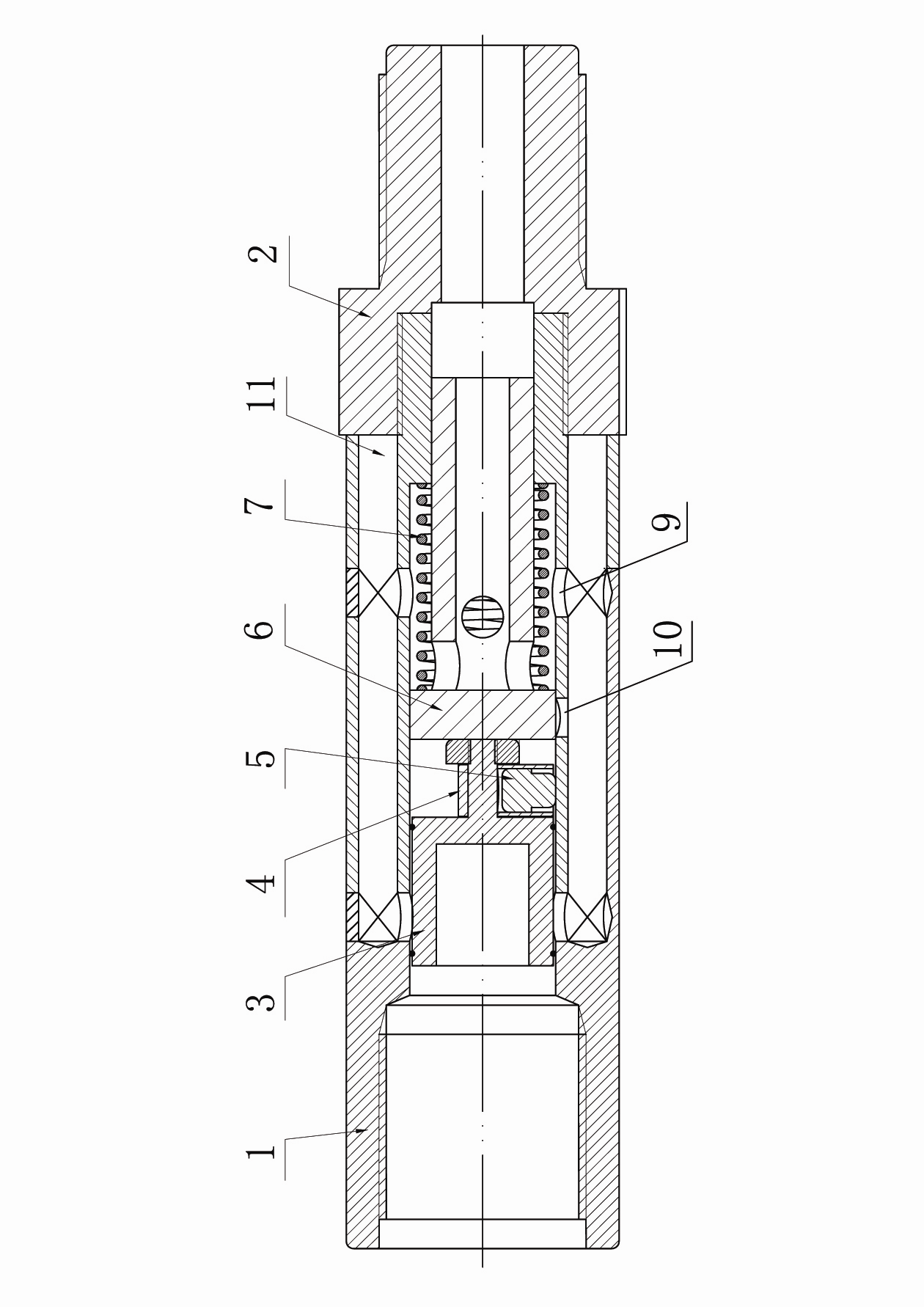

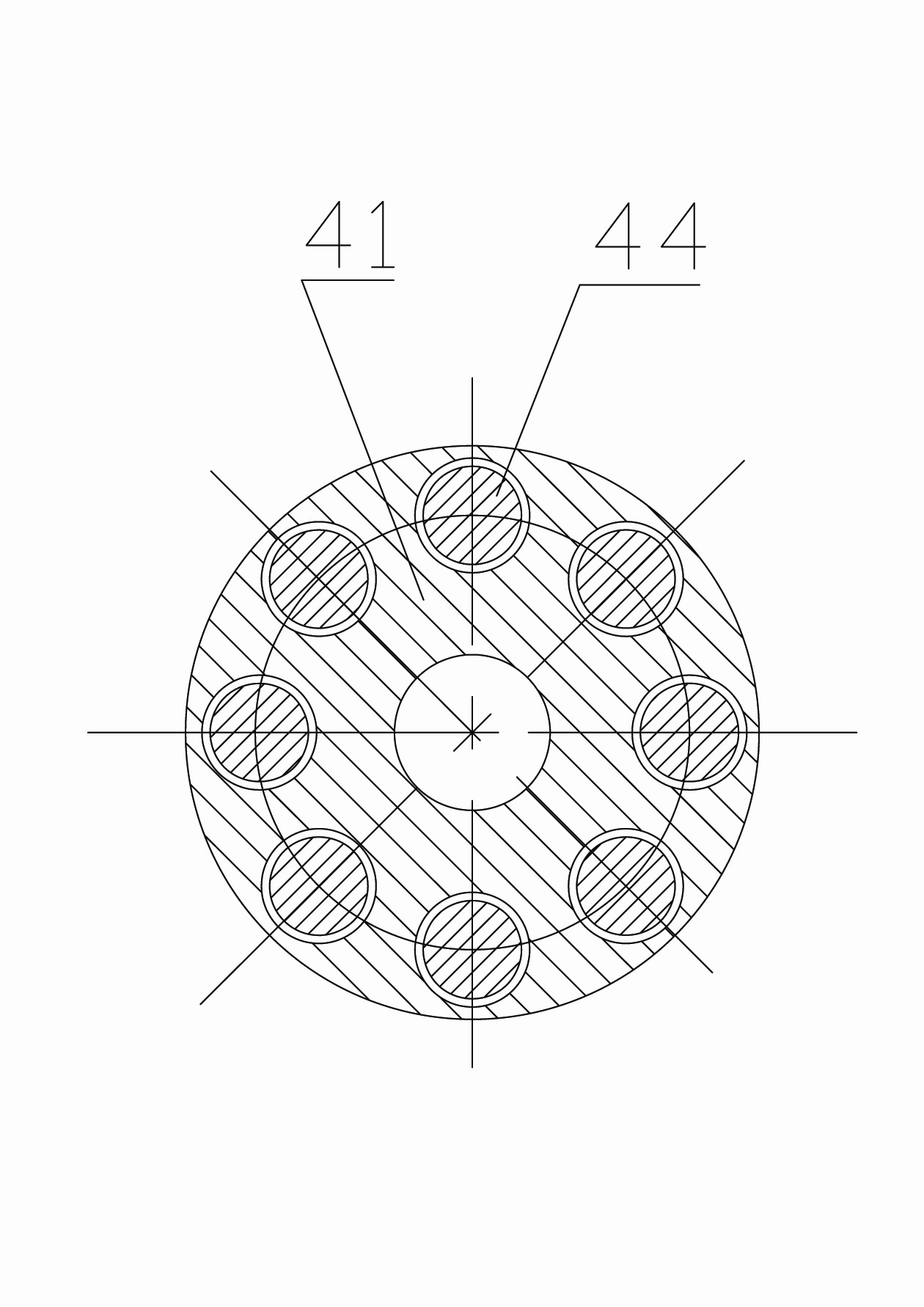

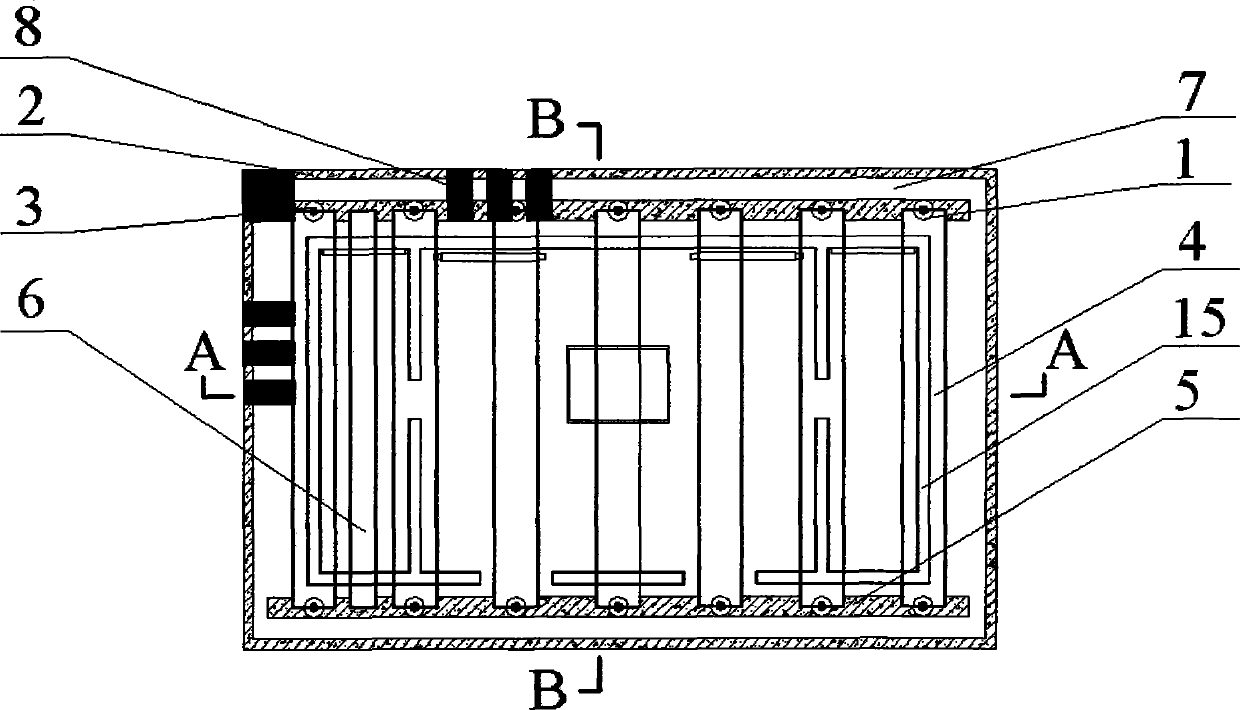

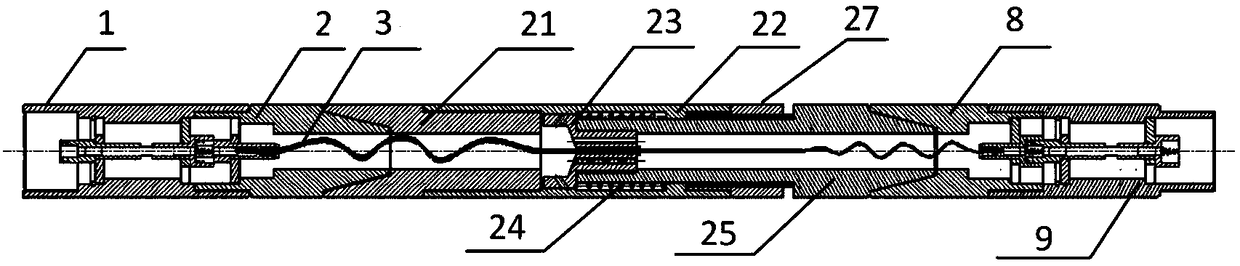

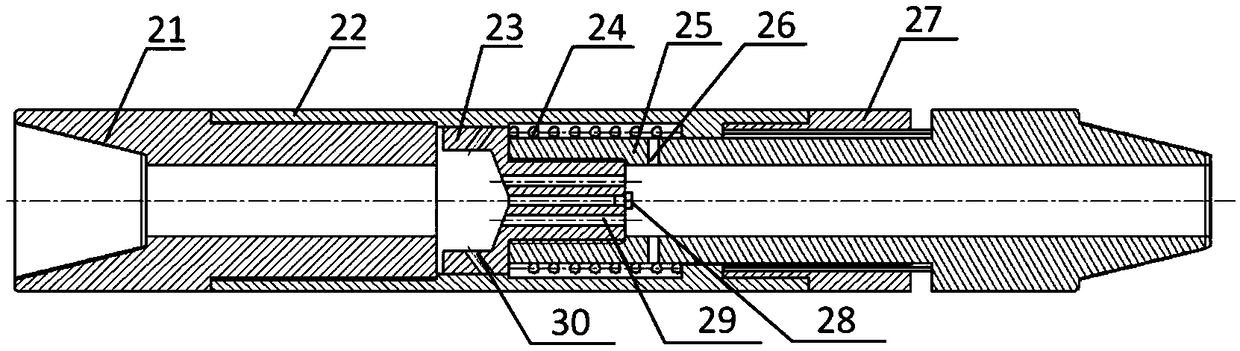

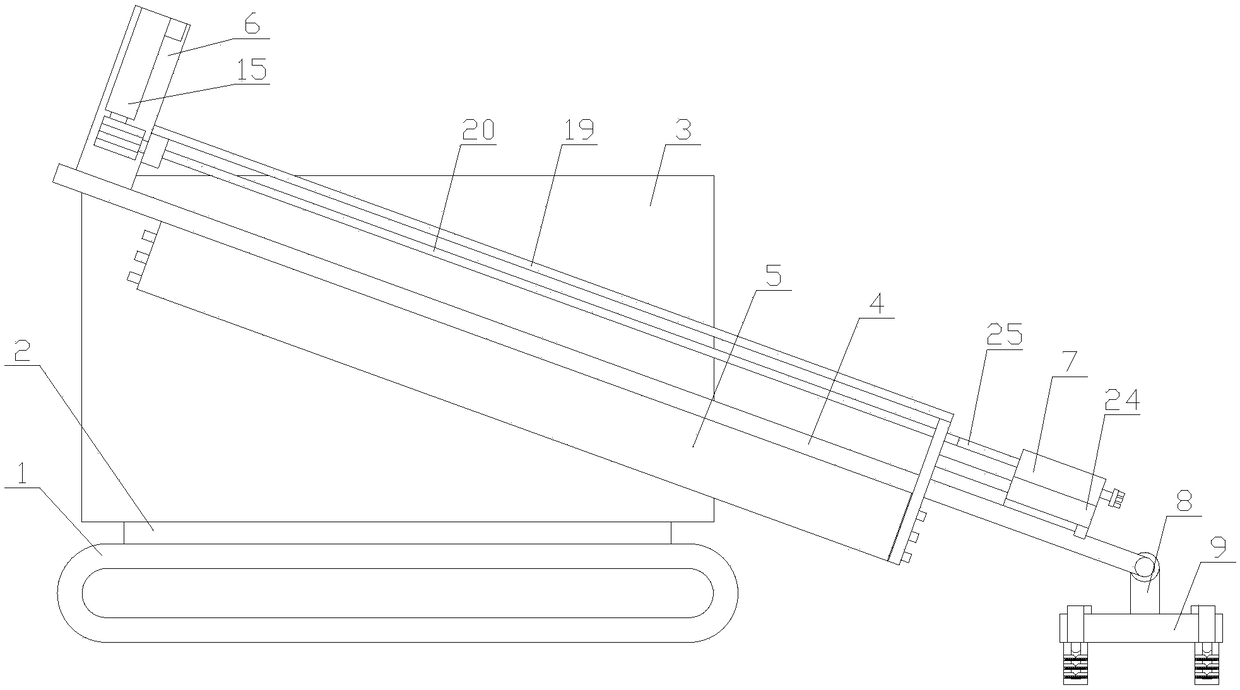

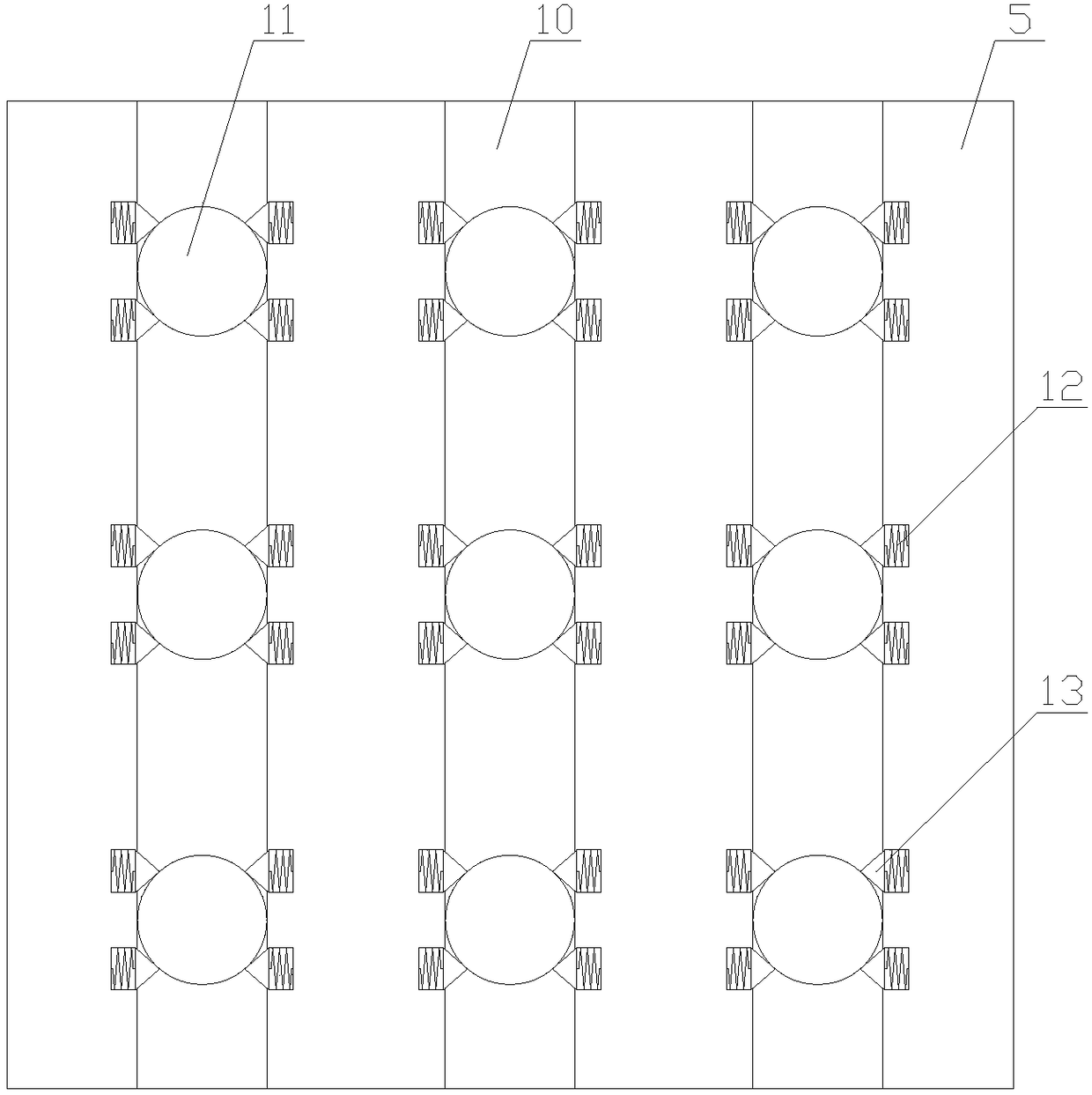

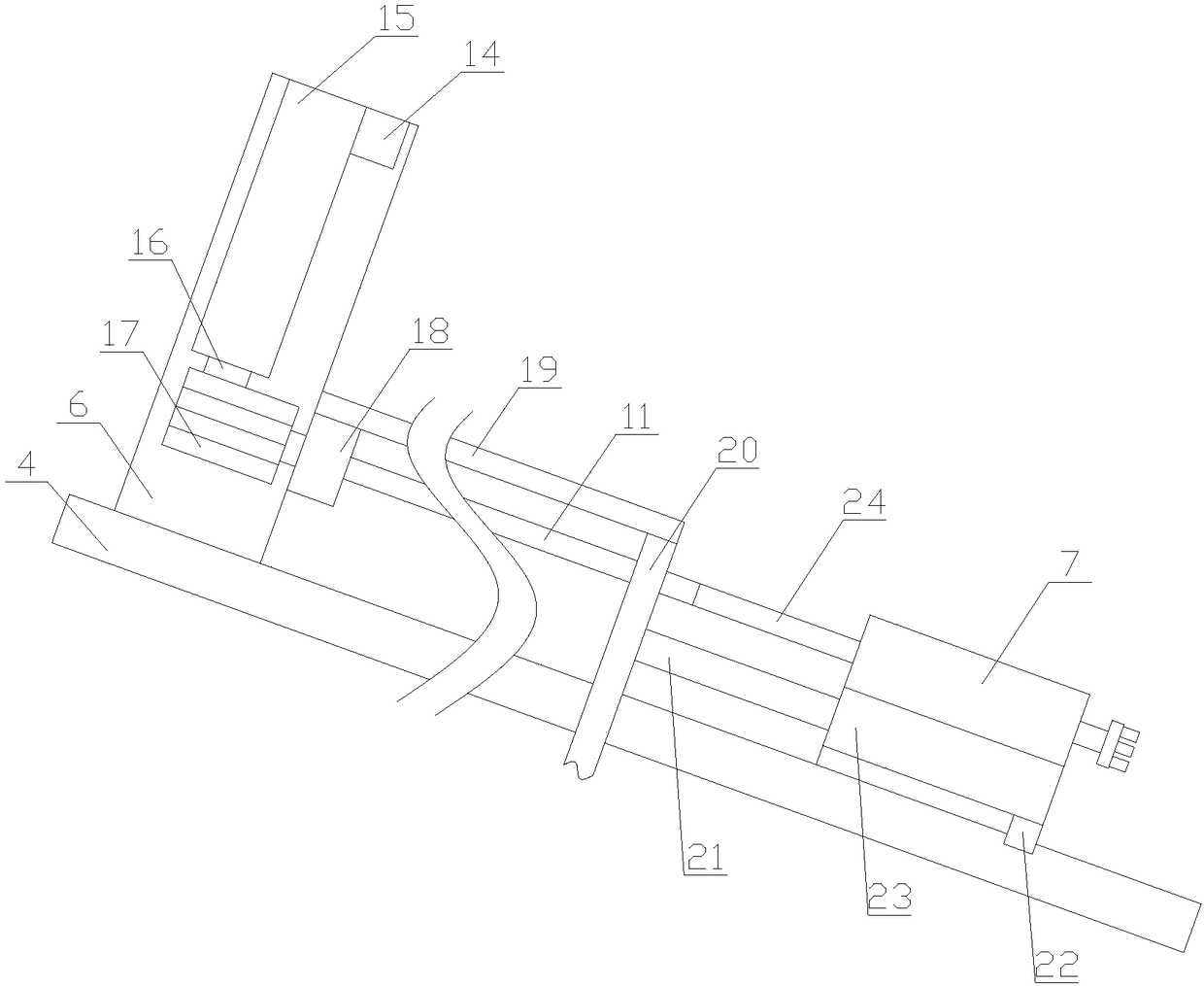

Continuous directional coring and deflecting machine tool with dual tubes for outer guiding and inner drilling and deflecting method thereof

ActiveCN102080503ASolve the technical problems of continuous coring and deflectionSurveyDrilling rodsEngineeringCoring

The invention discloses a continuous directional coring and deflecting machine tool with dual tubes for outer guiding and inner drilling and a deflecting method thereof, which belong to the technical field of continuous directional coring and deflecting. During the drilling in a directional drilling and deflecting segment, a drilling tool group special for continuous directional coring, deflecting and drilling is adopted, and the continuous directional coring, deflecting and drilling is performed by an inner tube coring drilling tool through the directional guiding deflection of an outer tube. The invention well solves the technical difficulty that the traditional domestic directional drilling and deflecting technique cannot perform coring, and provides a utility device and a deflecting method thereof for achieving the full-bore coring during the directional drilling in hydropower investigation projects. Meanwhile, the invention provides a reference for the directional drilling requiring continuous coring and deflecting in other industries of China.

Owner:POWERCHINA ZHONGNAN ENG +1

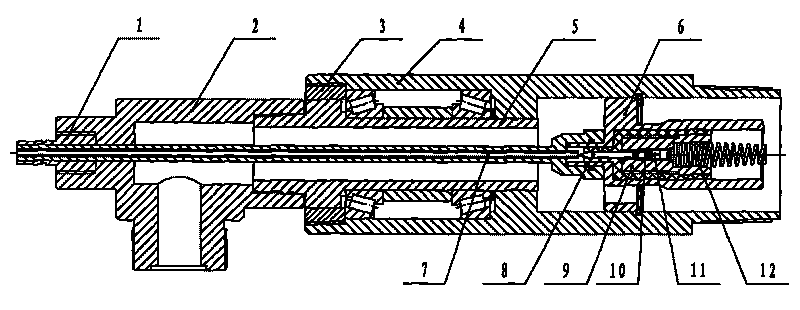

Hollow cable type directed water conveying device

The invention relates to a hollow cable type directed water conveying device. In the directional drilling of a coal mine underground tunnel and the controlled directional drilling of geology, a measuring system during drilling is a necessary tool for continuously monitoring the track of a drilling hole and timely correcting deviation. In the prior art, the water conveying device only can provide a washing medium to the inner part of a drilling rod but can not transmit a bottom hole measuring signal. The hollow cable type directed water conveying device has the following structure: the inner cavity of the existing directed water conveying device is provided with a hollow cable device which consists of a conducting wire, a probe needle, a probe head, a spring, a fixing bolt and a diameter-changing spring; the probe needle is fixed in the probe head by the spring and the fixing bolt; the probe head is provided with the diameter-changing spring; the probe needle is connected with a fast wiring column which is arranged at the other end of the directed water conveying device through the conducting wire; the diameter-changing spring is connected with the female connecting head of a hollow cable type large through hole drilling rode of an inner circular conical surface; and the fast wiring column is connected with a hole opening controller. The hollow cable type directed water conveying device can safely and reliably realize the wire measurement during drilling, and can simultaneously meet the requirements of two drilling technologies of the drilling with a bottom hole assembly drilling tool and the drilling with a bottom hole motor.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

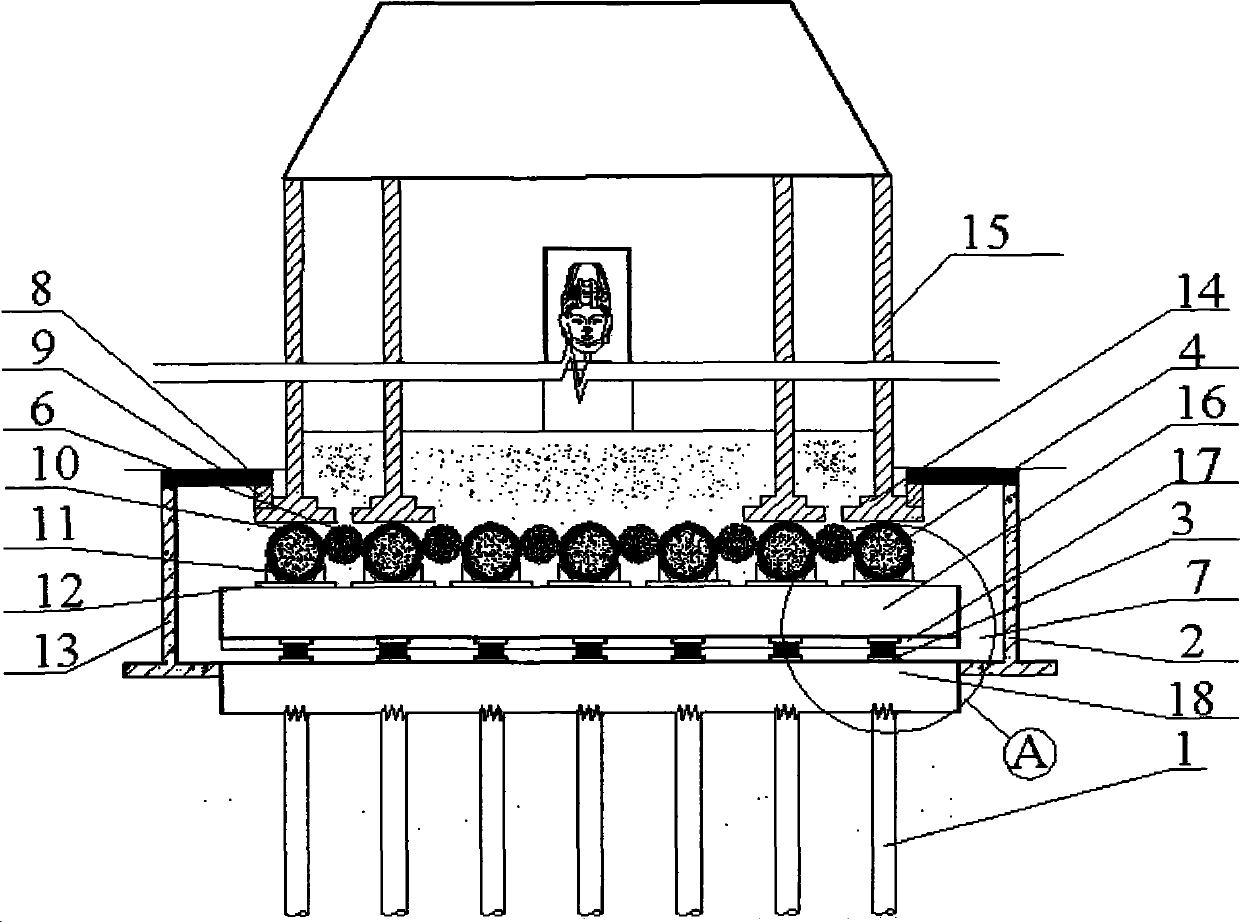

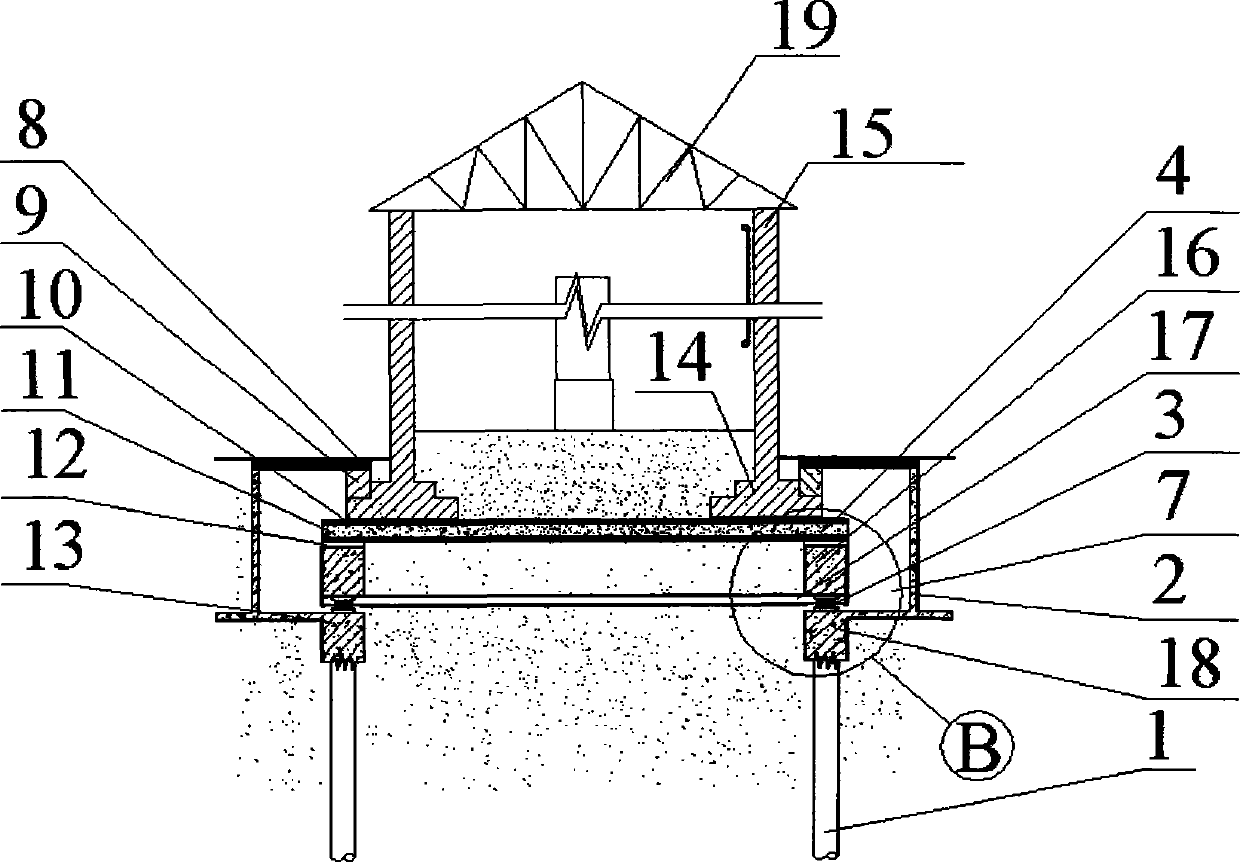

Integrated-tray, shock-insulation and reinforcing structure for historic building foundation and construction method thereof

InactiveCN103526781AReduce the overall heightReduce earthquake damageProtective foundationConcrete beamsVertical load

The invention relates to an integrated-tray, shock-insulation and reinforcing structure for a historic building foundation and a construction method thereof. The integrated-tray, shock-insulation and reinforcing structure comprises static pressure piles, oriented drilling steel tube concrete beams and shock-insulation pads. The static pressure piles are arranged on the outer side of the existing historic building, the bottom of a foundation horizontally penetrates through the oriented drilling steel tube concrete beams, the shock-insulation pads are arranged between the piles and the beams, and accordingly novel n-shaped shock-insulation foundation frames for the existing building is formed. In the longitudinal direction, the plurality of n-shaped shock-insulation foundation frameworks are integrally connected through connecting beams to form a shock-insulation foundation system of the whole building. In order to guaranteed connection between the steel tube concrete beams and an upper portion original foundation, necessary anchor rods are utilized to pull and knot. The steel tube beams can bear all vertical load of the original building and all load of indoor soil and structures above the bottom of the foundation. Gaps between the steel tube concrete beams are filled up with oriented drilling rear plain concrete to form an integrated supporting platform. The steel tube beams are supported by the piles at two ends through the shock-insulation pads. In earthquake, the shock-insulation pads can greatly reduce various effects of earthquake force on the upper portion buildings.

Owner:广州德科装饰设计工程有限公司

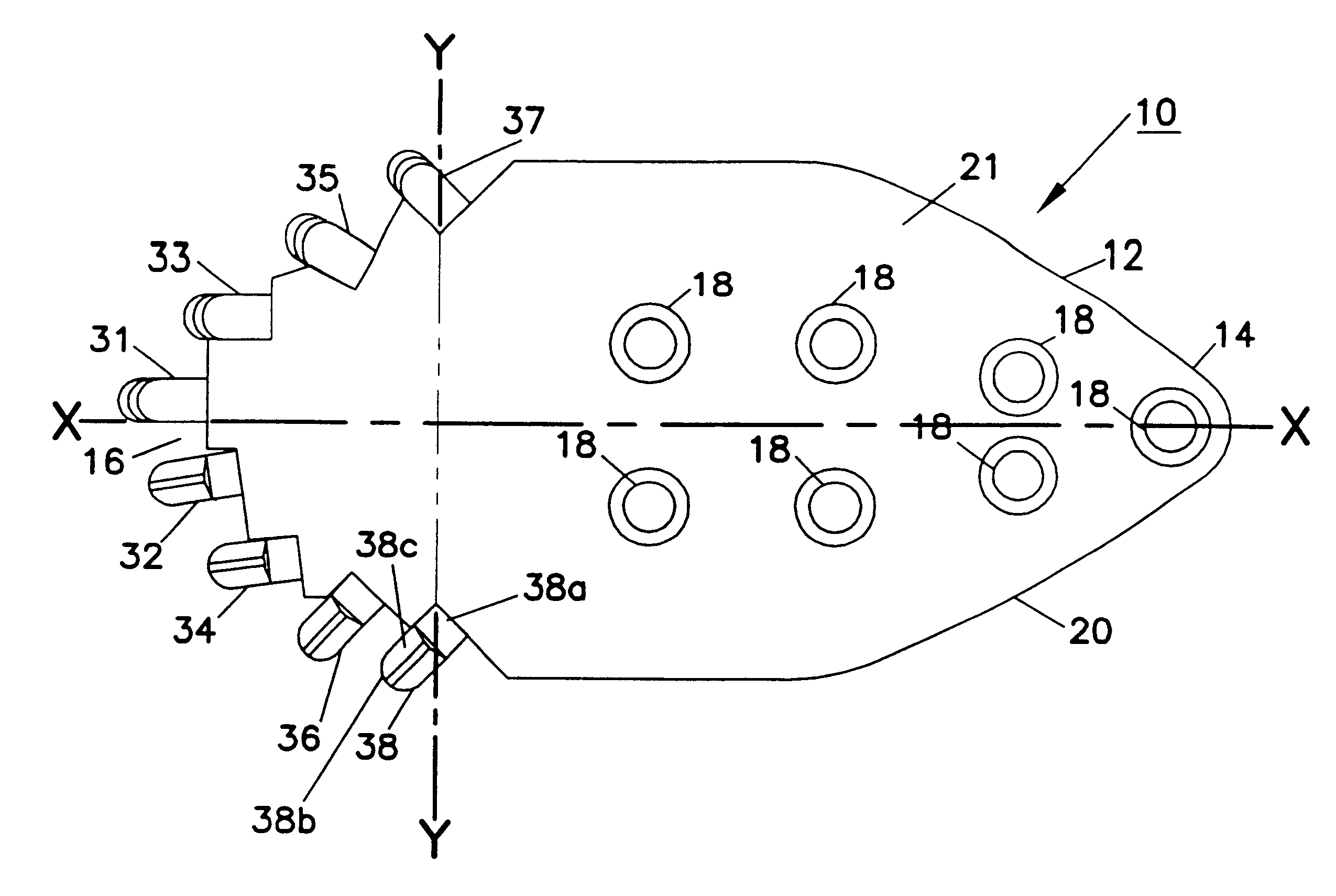

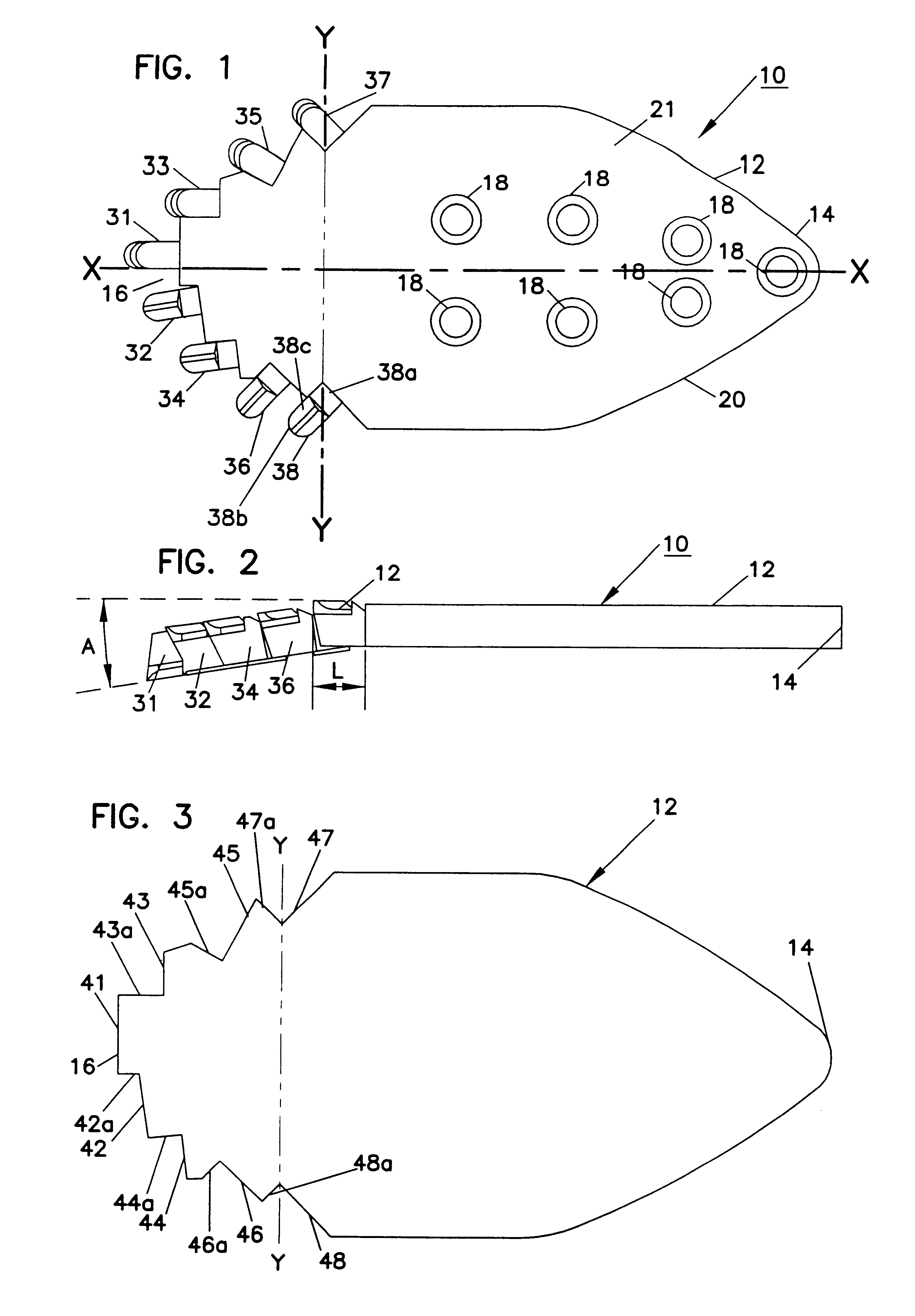

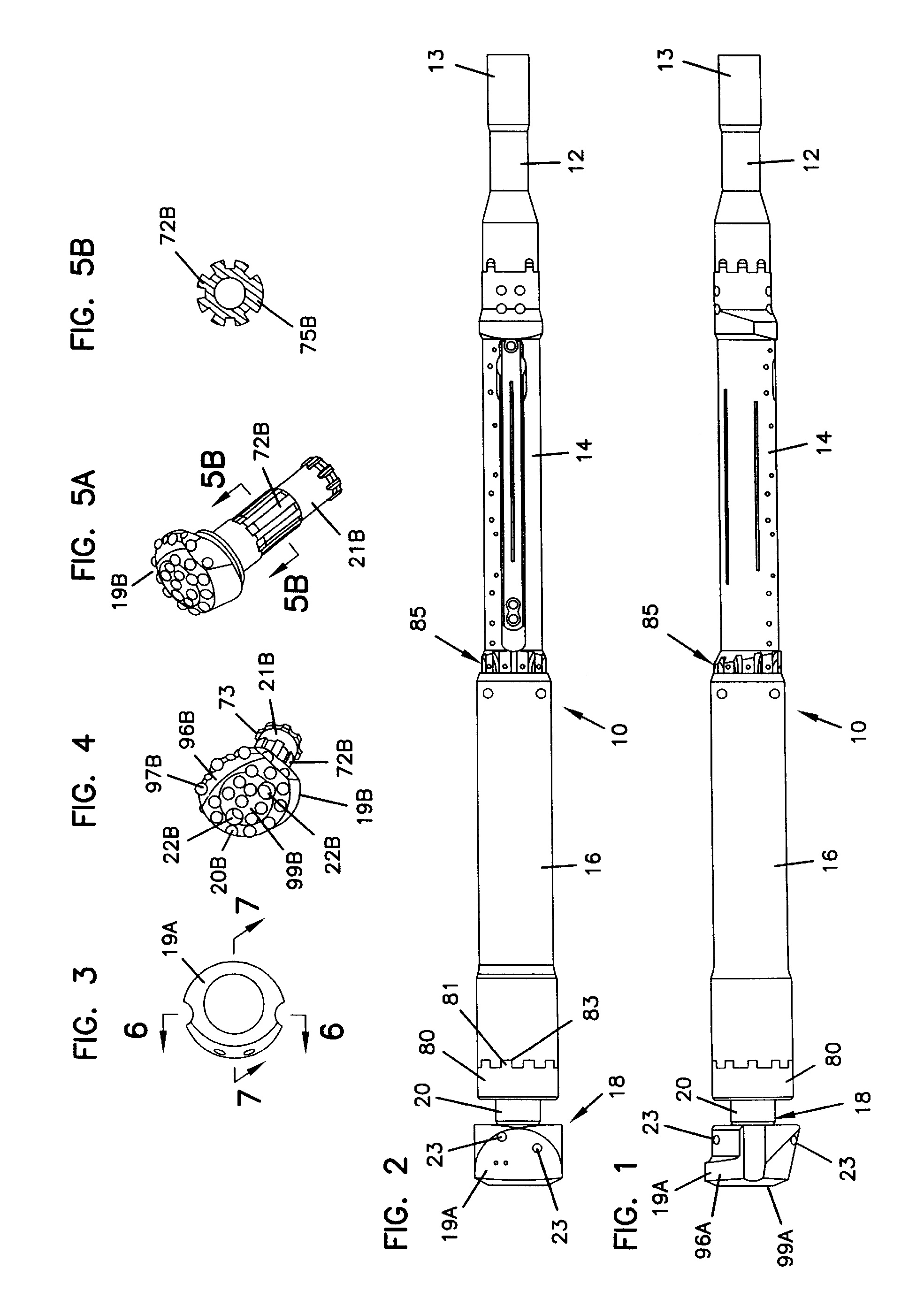

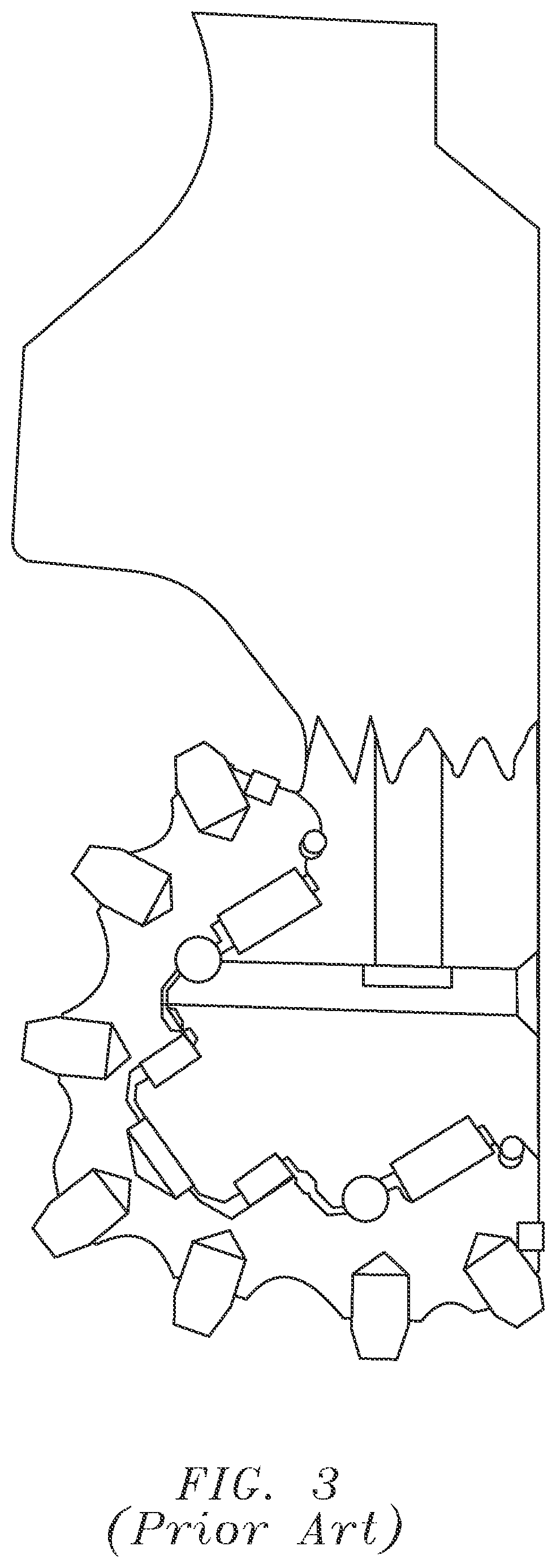

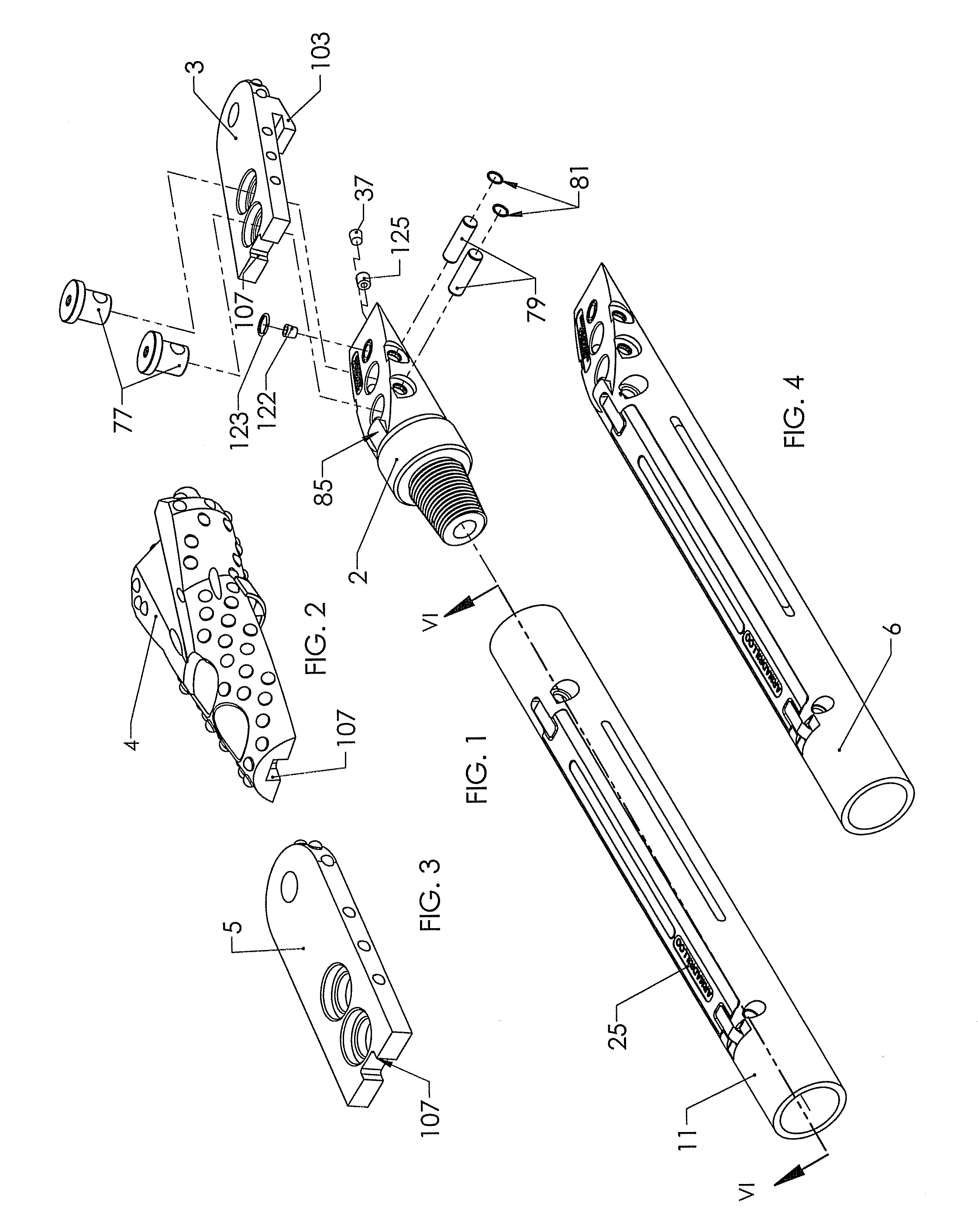

Duckbill with cutting teeth

A directing blade for a directional boring machine includes a blade body which extends along a longitudinal axis from an attachment end to a free end. The free end has a plurality of cutting teeth disposed in a non-symmetrical pattern relative to the longitudinal axis. The teeth are progressively spaced from a center portion of the leading end alternating from a first side to a second side of the body of the duckbill blade.

Owner:VERMEER MFG CO

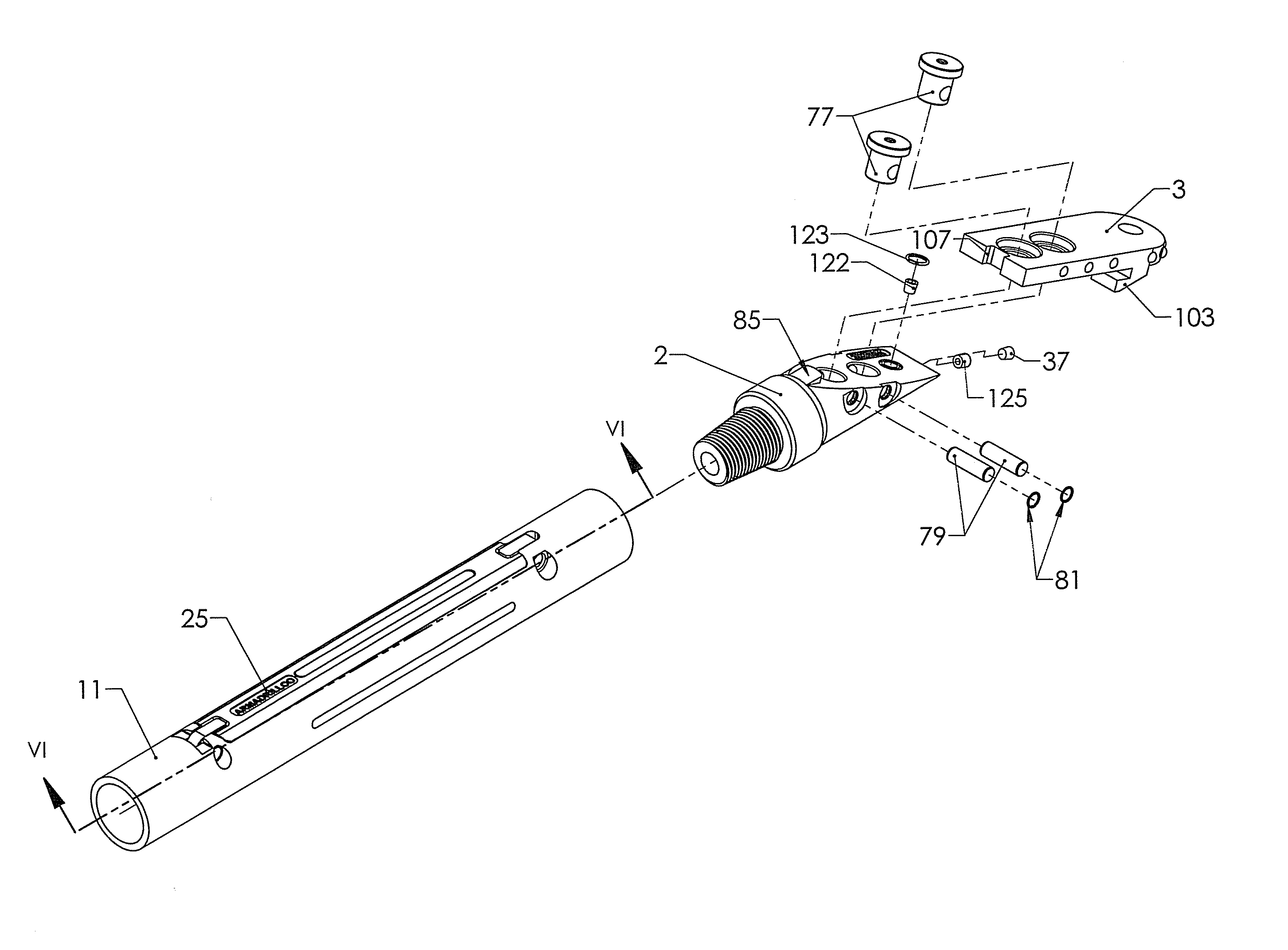

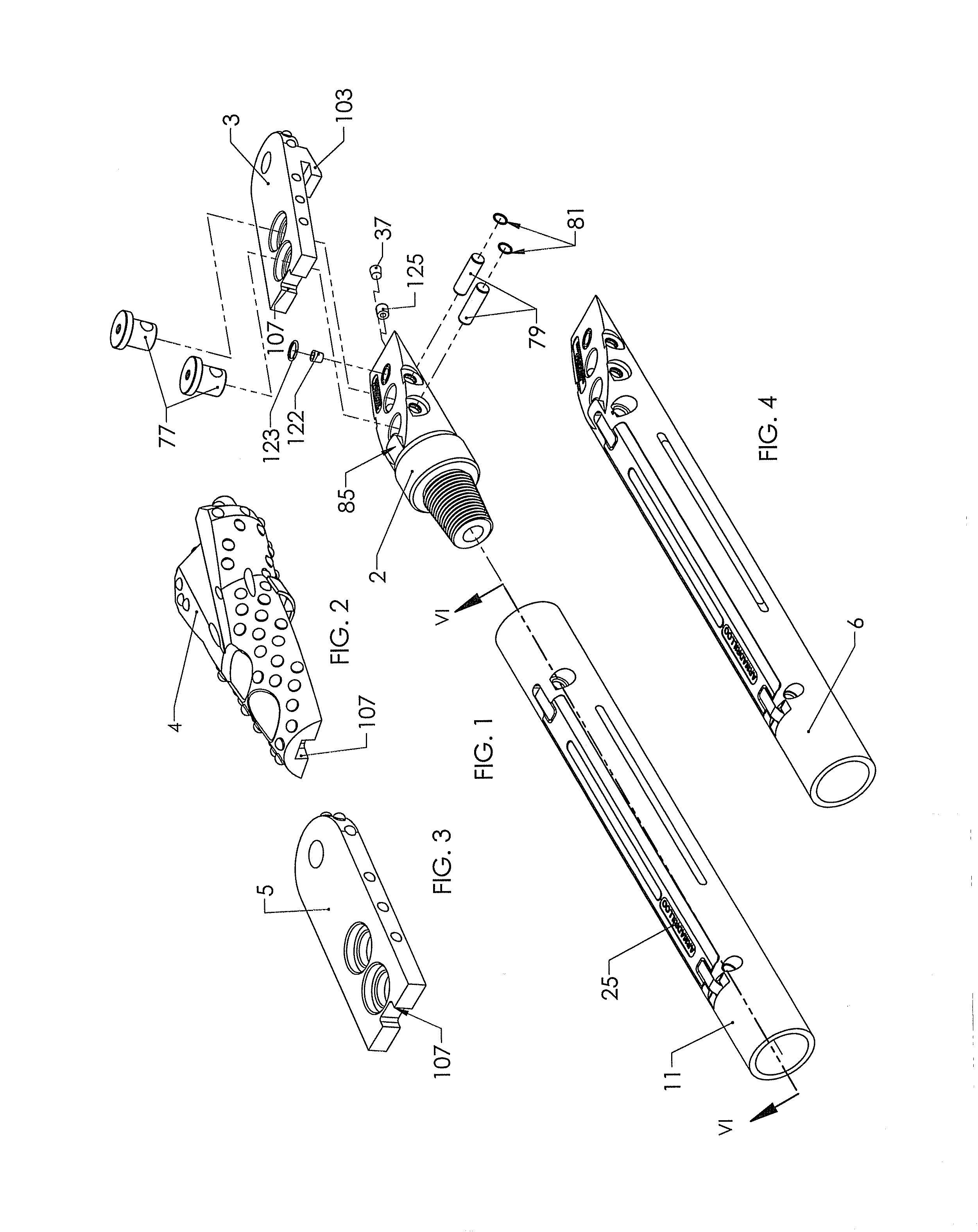

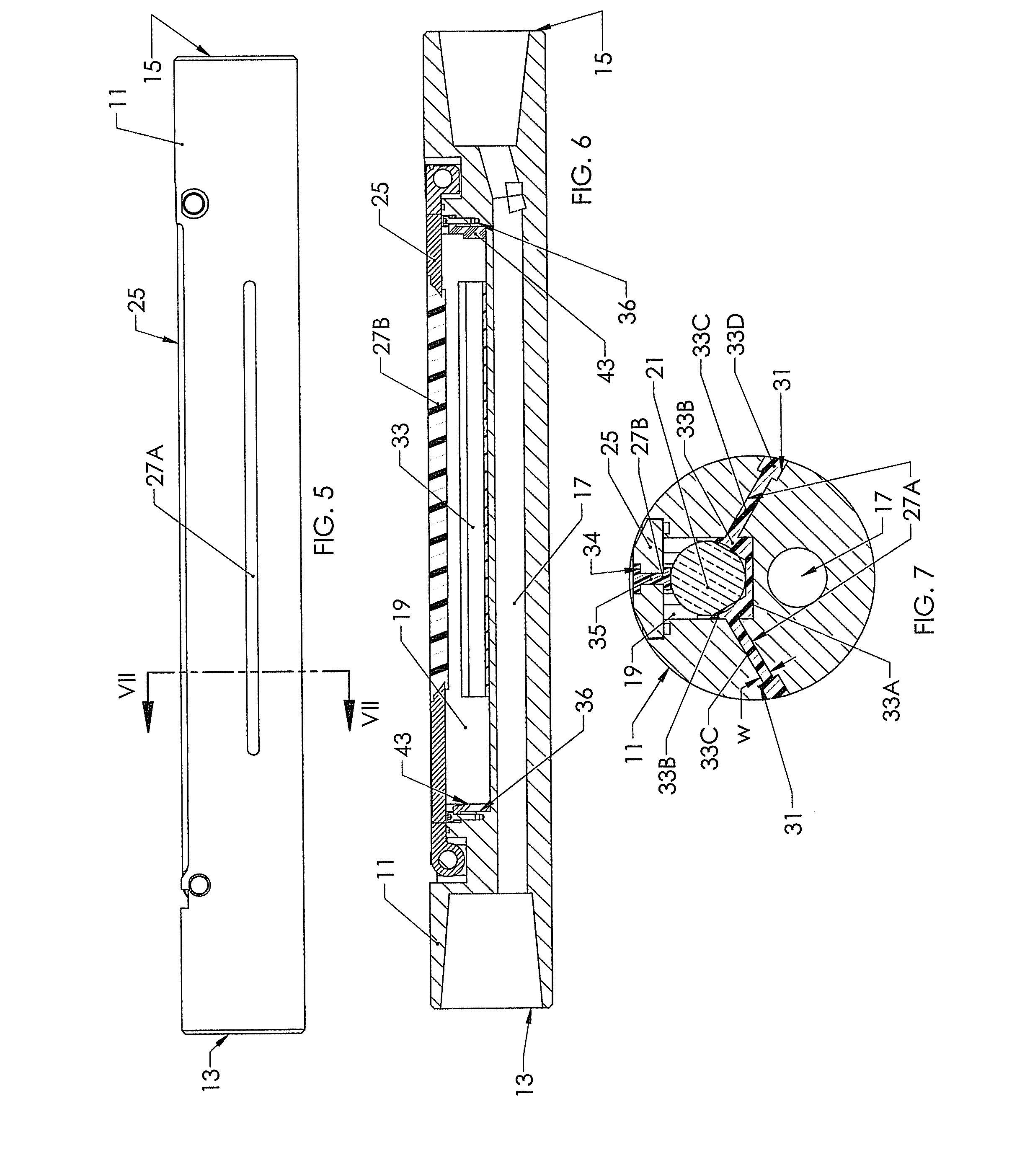

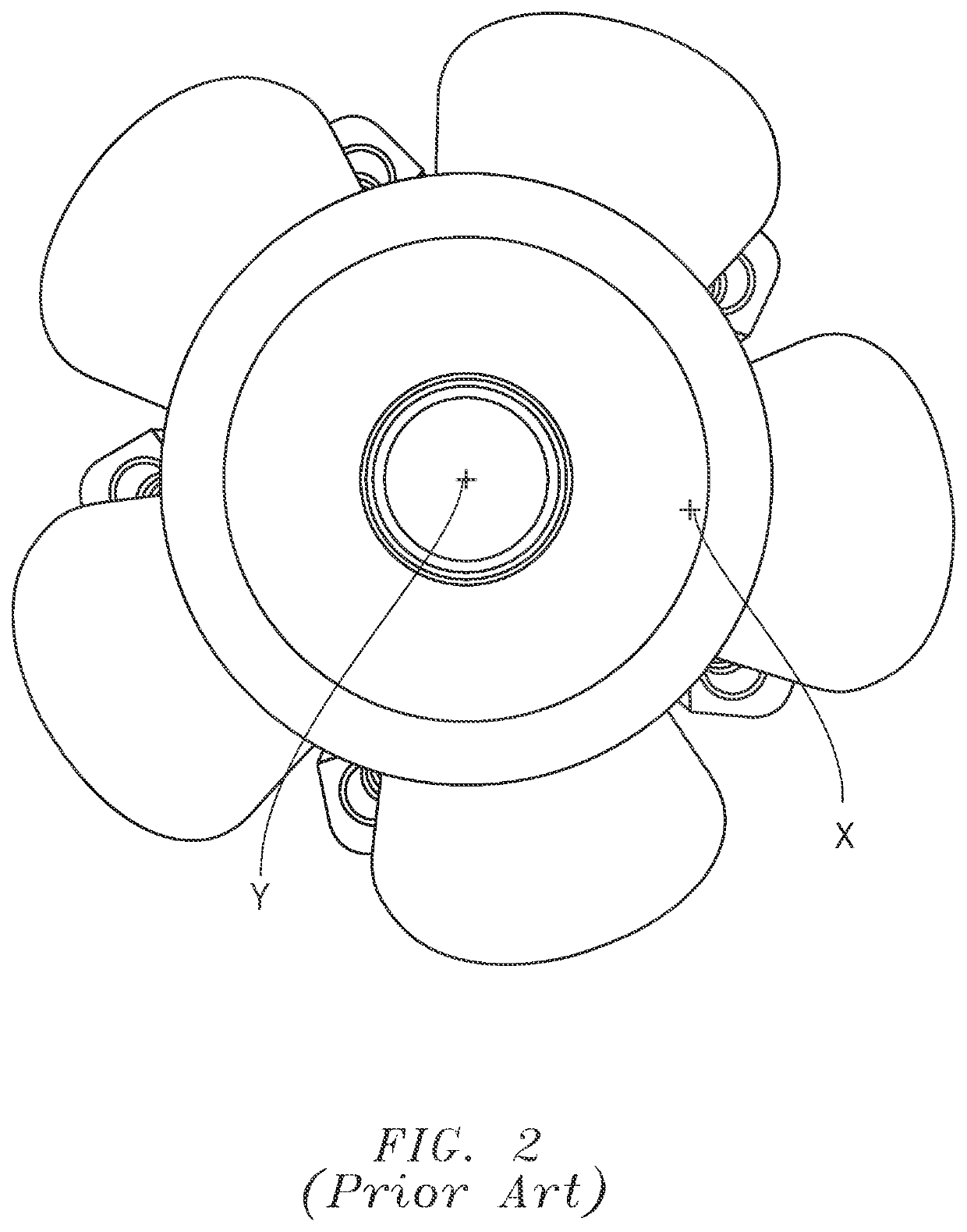

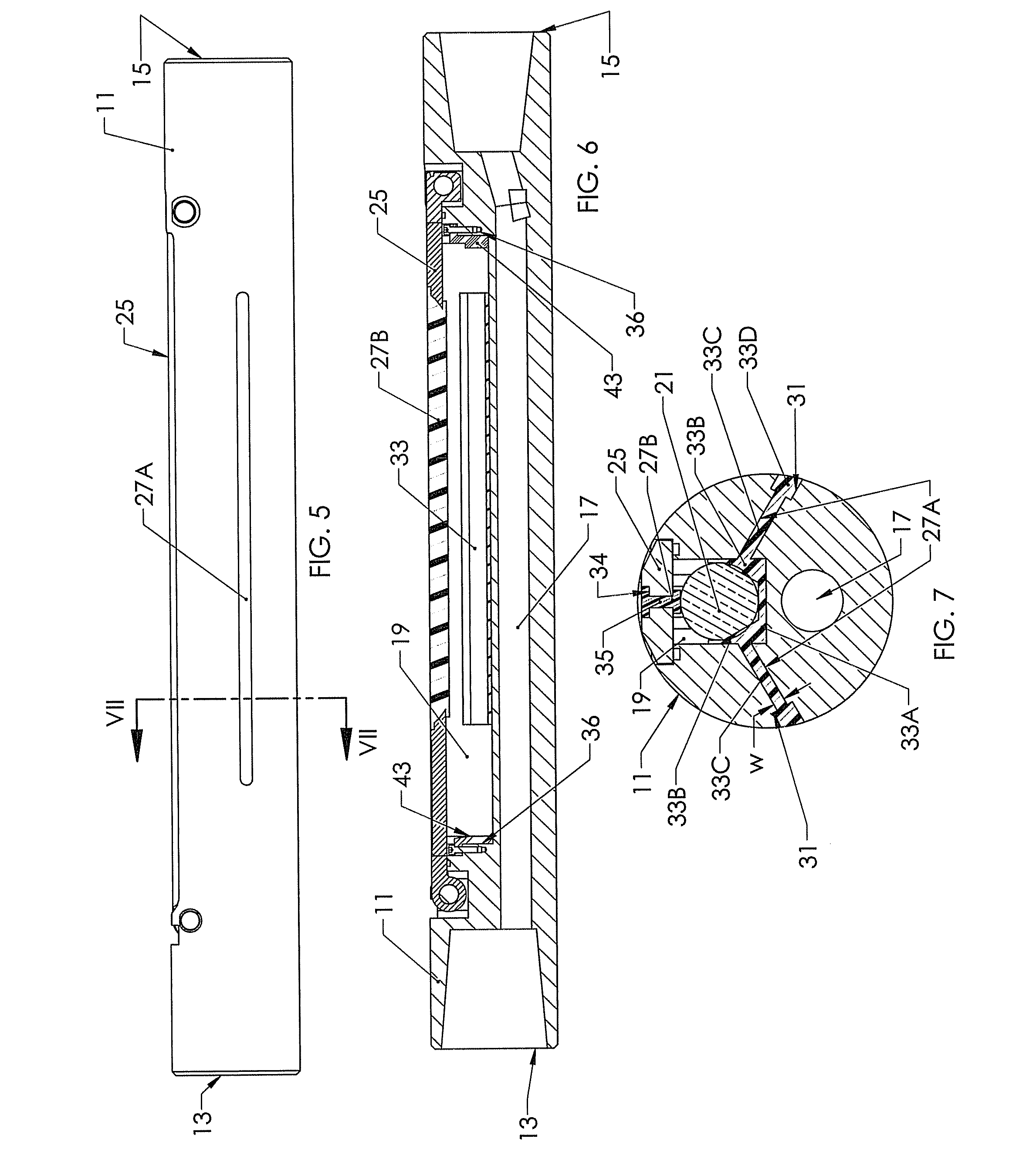

Sonde housing and bit body arrangement for horizontal directional drilling

InactiveUS20130168154A1Prevent movementDrill bitsDischarging arrangementClassical mechanicsMechanics

A horizontal directional drilling sonde housing has a cavity for receiving a sonde. Signal channels extend from the cavity to an exterior of the housing. A polymer lines at least part of the cavity and fills the signal channels. The drilling tool has a bit body and a drilling body. The two bodies have respective lateral surfaces which engage each other to prevent the transverse movement of the drilling body relative to the bit body during operations. The drill bit has a forward extending drill tooth, which drill tooth is removable from a bore. A spacer is located in the bore between the bottom end of the bore and the tooth. The drilling bit has buttons located on the side in a spiral configuration about a longitudinal axis of the bit.

Owner:STRAIGHTLINE HDD INC

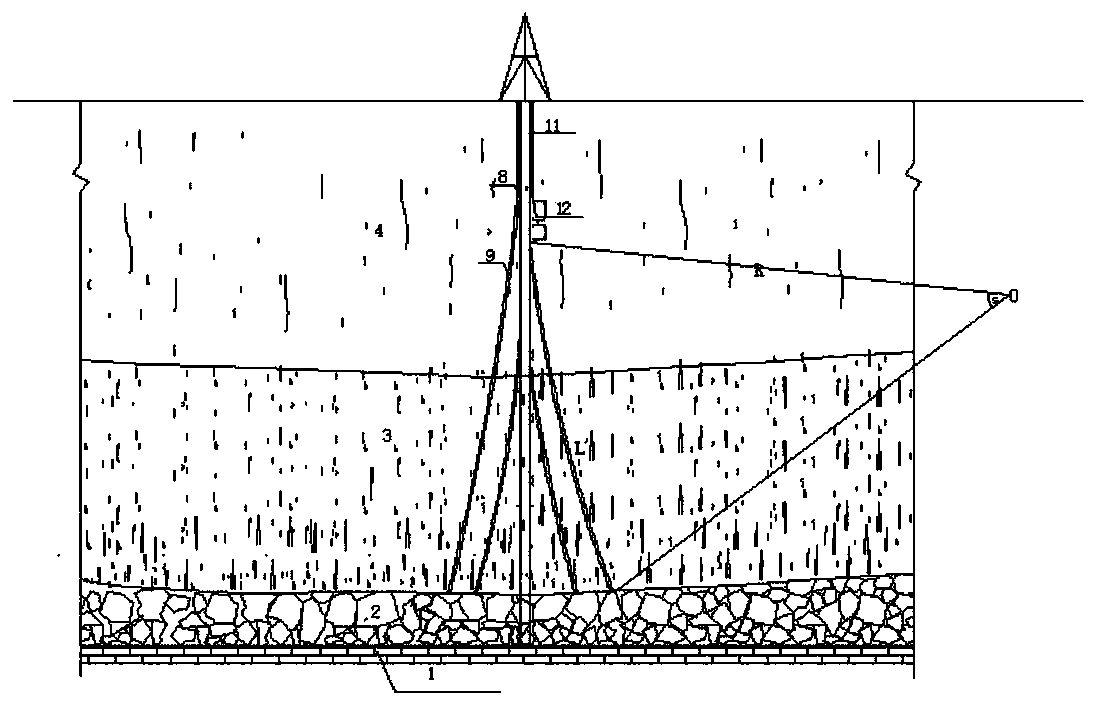

Fully mechanized mining goaf grouting method based on clustered arrangement multilateral well directional drilling

The invention discloses a fully mechanized mining goaf grouting method based on clustered arrangement multilateral well directional drilling. The method is applied to a fully mechanized mining goaf which is buried in depth of over 400 m. The method includes the following steps that (1) drilled holes are distributed, specifically, the positions and the number of clustered arrangement multilateral directional drilling are designed in a treatment area of the fully mechanized mining goaf; (2) a grouting material is determined and composed of cement, coal ash or clay and a setting accelerator; and(3) drilling and grouting operations of the plurality of clustered arrangement multilateral directional to-be-drilled holes are performed. Accordingly, the clustered arrangement multilateral directional drilled holes are flexibly applied to the field of geological disaster prevention and control of the fully mechanized mining goaf creatively, the drilling workload is substantially reduced, consumption is reduced, thus the drilling cost is effectively reduced, meanwhile by means of the advantage that the trajectory of the drilled holes can be controlled, the covering range of drilling and grouting is widened, the accuracy of drilling and grouting is improved, the repeated drilling work is avoided, the project efficiency is remarkably improved, and the better goaf treatment purpose is achieved.

Owner:中煤科工生态环境科技有限公司

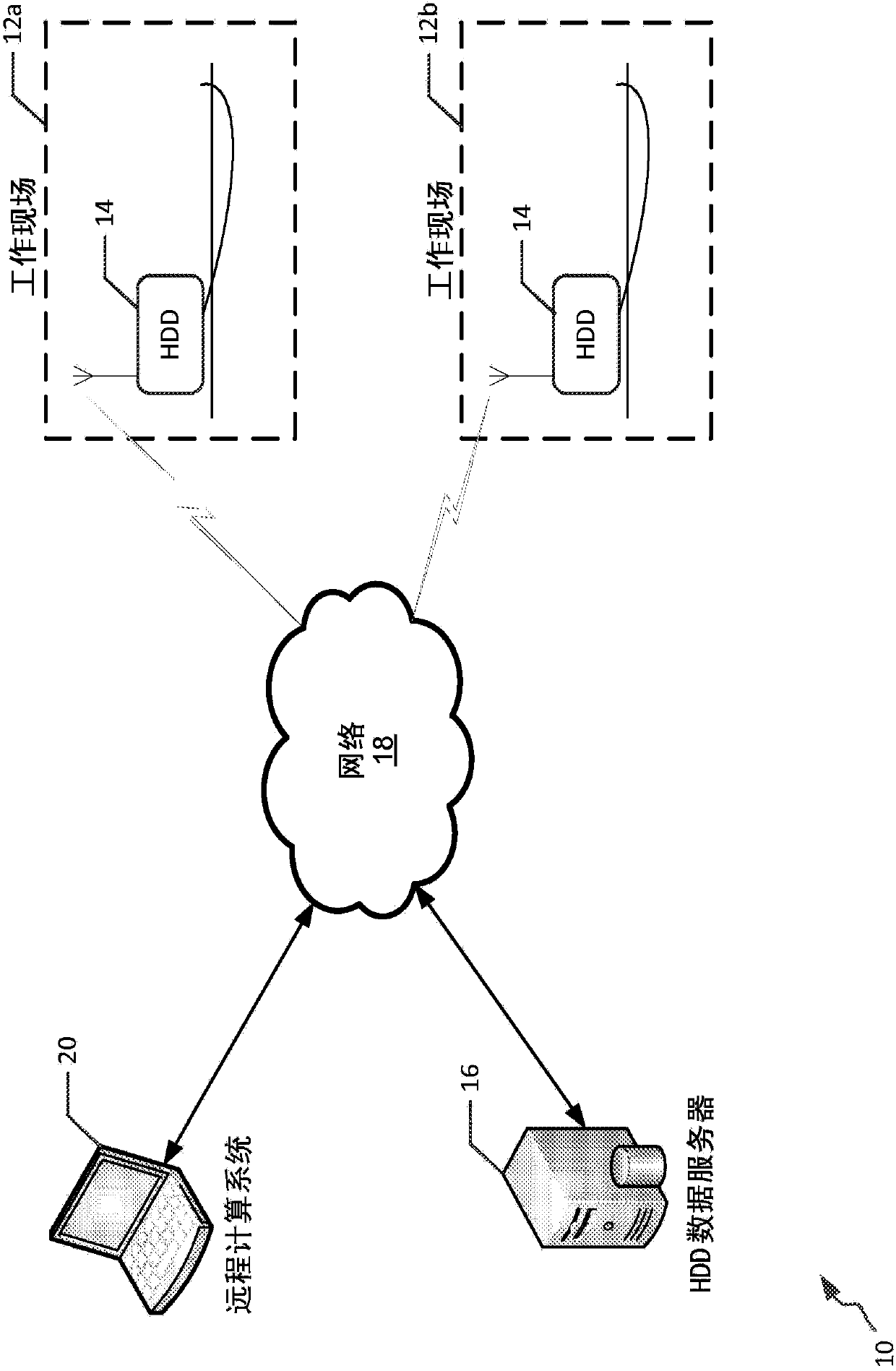

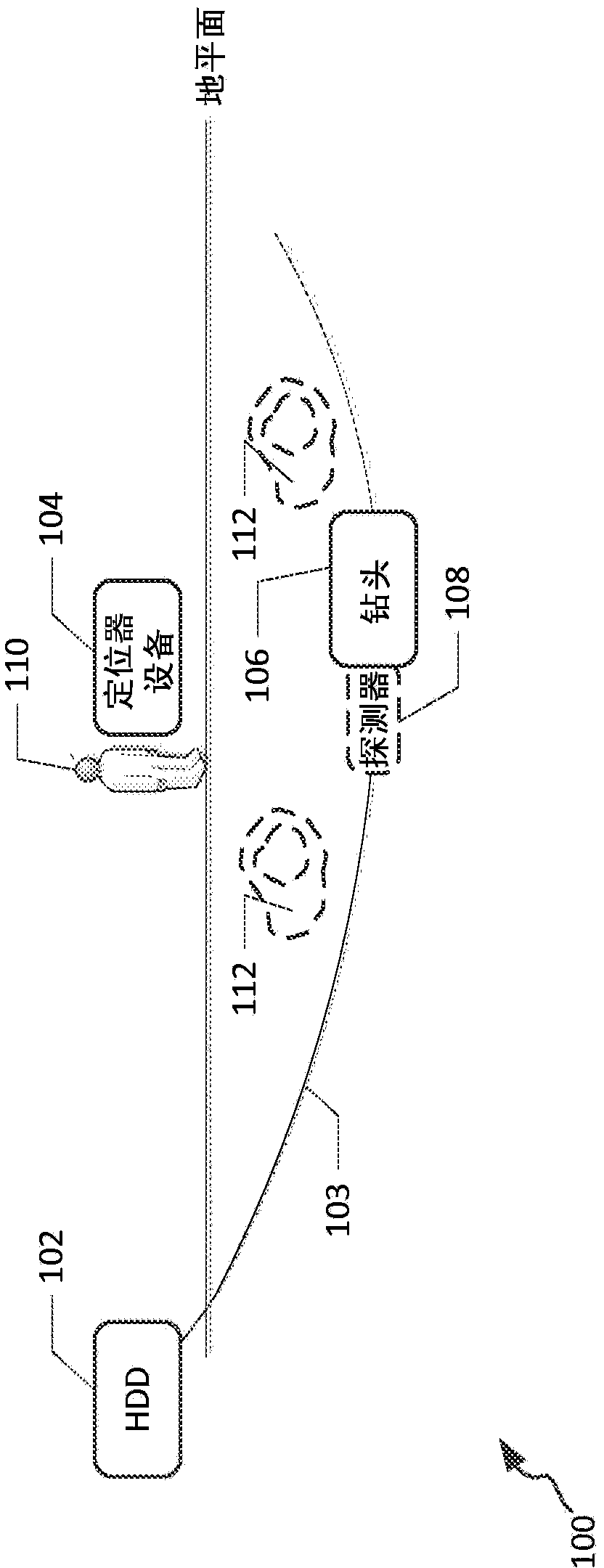

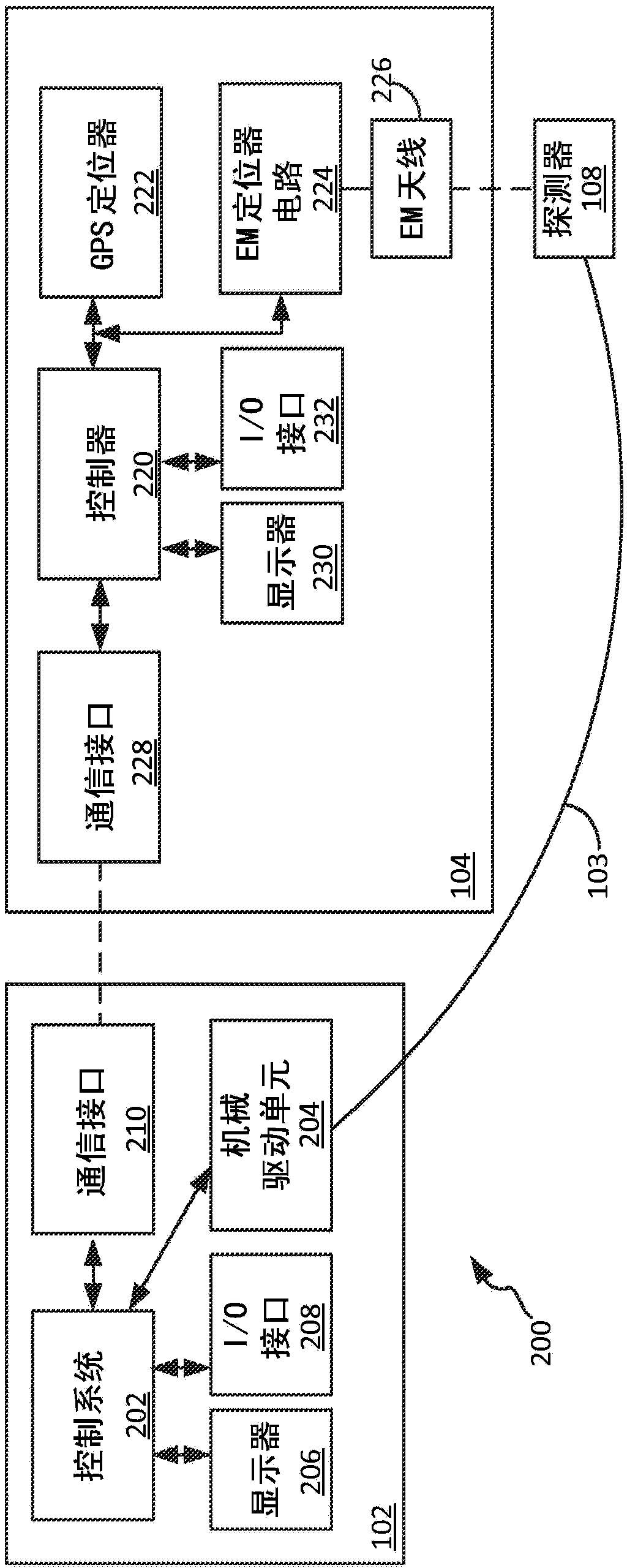

Horizontal directional drilling system including sonde position detection using global positioning systems

InactiveCN103748318AElectric/magnetic detection for well-loggingSurveyControl electronicsControl system

A locator device and methods of use are disclosed. The locator device includes a first locating system configured to generate to sense an electromagnetic field emanating from a sonde associated with a drill head, and a second locating system including a global positioning system. The locator device includes a display on the locating system configured to display a map of the area in which the locator device resides based on a location detected by the global positioning system. The locator device also includes control electronics configured to, upon receipt of an input from a user, record location data in a memory associated with the locator device for use by a horizontal directional drilling control system.

Owner:VERMEER MFG CO

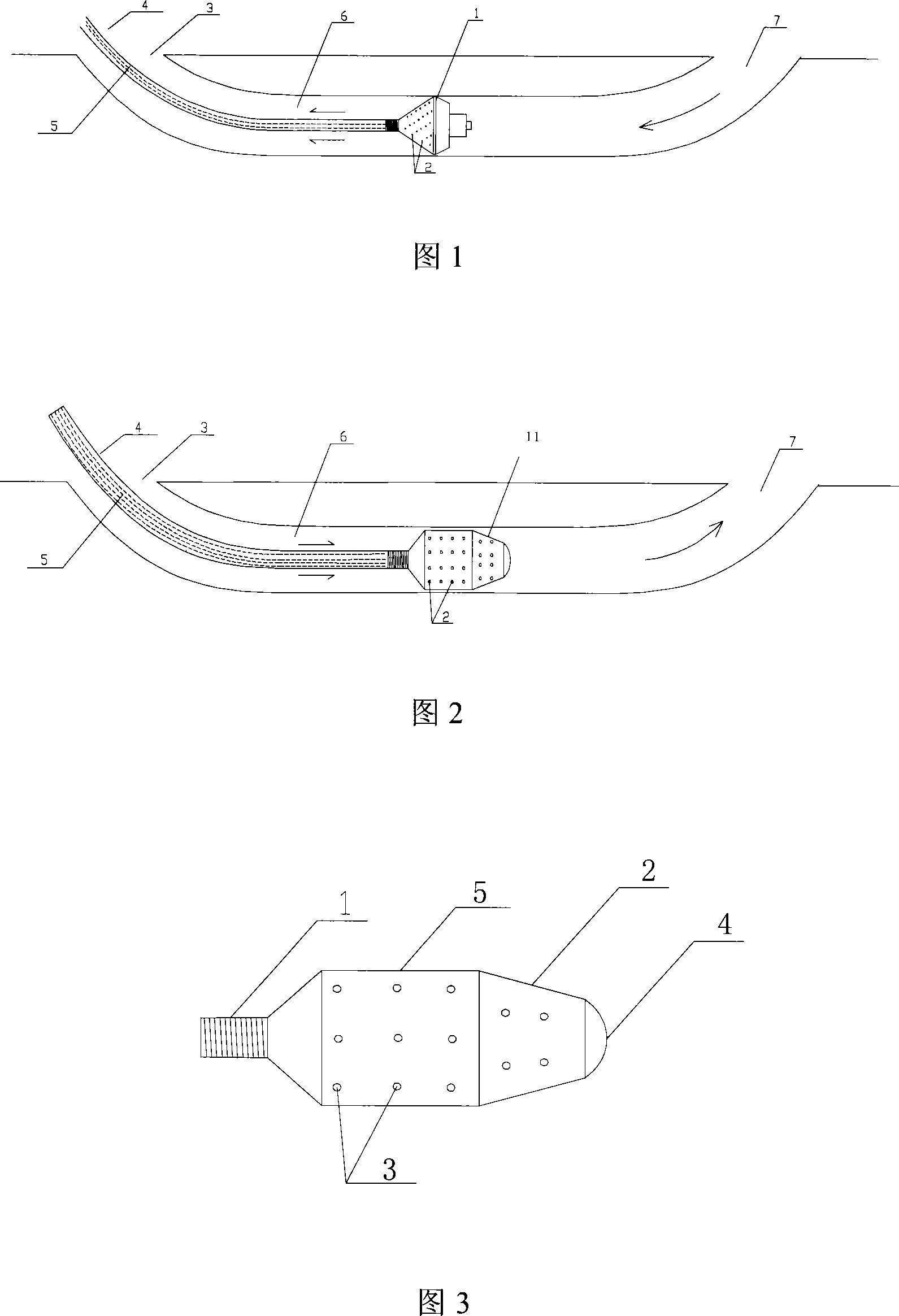

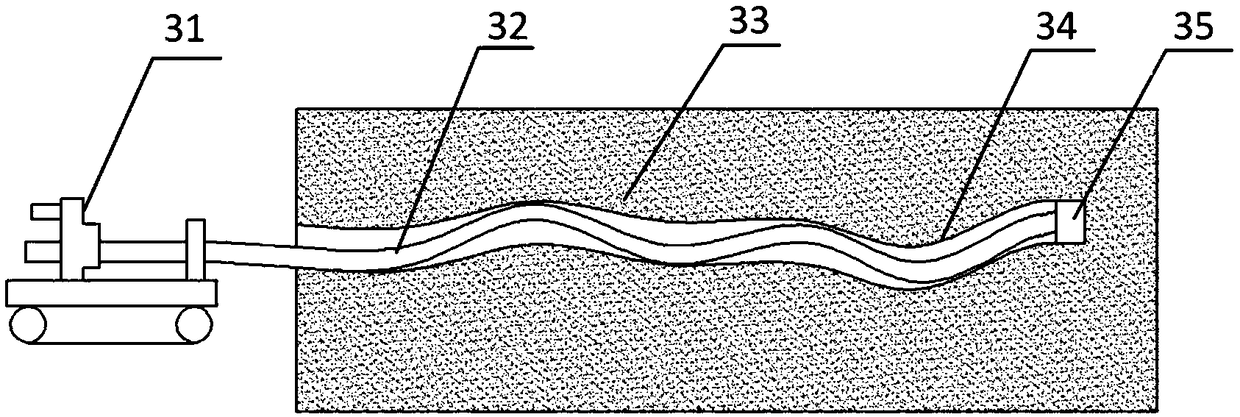

Prime hole reverse pushing construction method in horizontal orienting drilling and prime hole reverse pushing device

ActiveCN101158270AGood application effectOvercome the shortcomings of large site limitationsPipe laying and repairDirectional drillingEngineeringDirectional boring

The invention discloses a raw-hole reverse-pushing construction plan used for a horizontal directional boring. The plan includes the following: step 1, guiding hole boring procedure; step 2, reversing hole-enlarging procedure that a reverse-enlarger is connected with a tail end of a bore rod of a soil outlet end and the reverse-enlarger is used for reversely enlarging the hole from the soil outlet end to a soil inlet end; step 3, raw-hole reverse-pushing enlarging procedure that a reverse-pusher is connected with a tail end of the bore rod of the soil inlet end and a moving face of the reverse-pusher faces the soil outlet end, and the reverse-pusher is used for reversely enlarging the hole from the soil inlet end to a soil outlet end in the raw-hole channel; step 4, pipeline reverse-dragging procedure that when the hole channel diameter is larger than that of the reverser-dragging pipeline after enlarging, a reversely dragged pipeline is connected with a back end of the reverse-enlarger and a pipeline reverse-dragging work is carried out in the hole channel to realize a non-digging underground transmission of the pipeline. The invention can repeat the step 2 and the step 3. The invention overcomes a defect that a non-digging construction is always limited by a site condition of the soil outlet end and a practicality of the plan is enhanced. The invention also provides a raw-hole reverse-pusher used for the construction plan.

Owner:SHANGHAI MUNICIPAL GAS NO2 PIPELINES ENGINEERING CO LTD

Method for blocking water burst of high-pressure drill holes of underground fault fracture zone

ActiveCN111764863ASolve the problem of difficult to expose water inrush boreholesReduce construction riskFluid removalDirectional drillingFracture zoneStructural engineering

The invention discloses a method for blocking water burst of high-pressure drill holes of an underground fault fracture zone. An underground directional drilling technology is utilized to block waterburst of the high-pressure drill holed in the fault fracture zone, the problem that water burst drill holes are difficult to expose in conventional drilling drainage holes can be effectively solved, and the construction efficiency can be improved; and meanwhile, a safe area is selected to construct remote directional drainage holes so that an operator can be prevented from being exposed to a high-water-pressure and broken surrounding rock construction area by an in-hole intubation drainage grouting method, and the construction risk of the operator is effectively reduced. According to the method, the hole distribution mode comprehensively considers surrounding rock mass reinforcement and water gushing drilling drainage, meanwhile, the underground directional drilling technology with high drilling efficiency and accurate drilling control is utilized, so that the defects of complex procedures, long construction period and large number of drilled holes of drilling and grouting engineeringfor constructing conventional reinforcement holes are effectively overcome.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

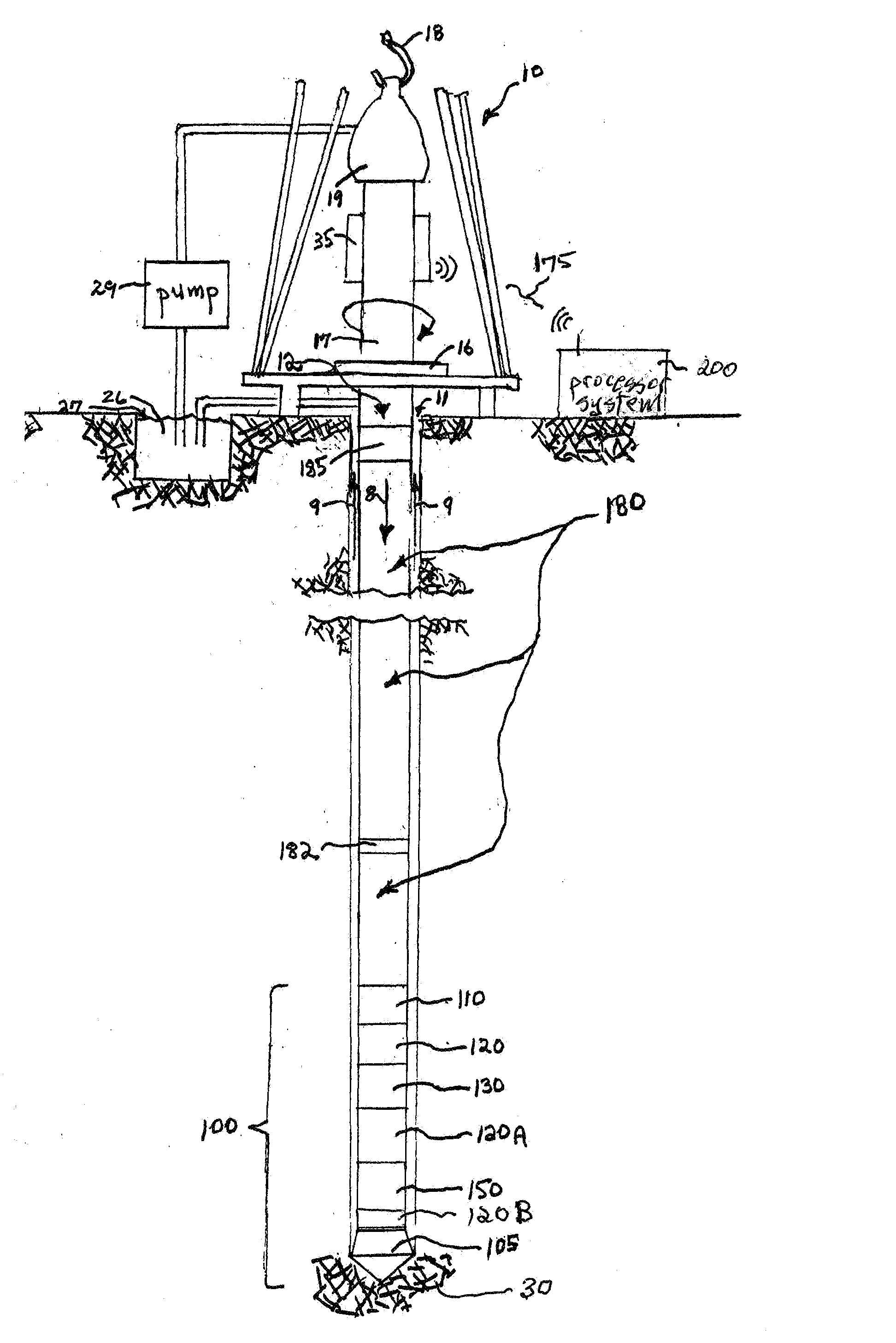

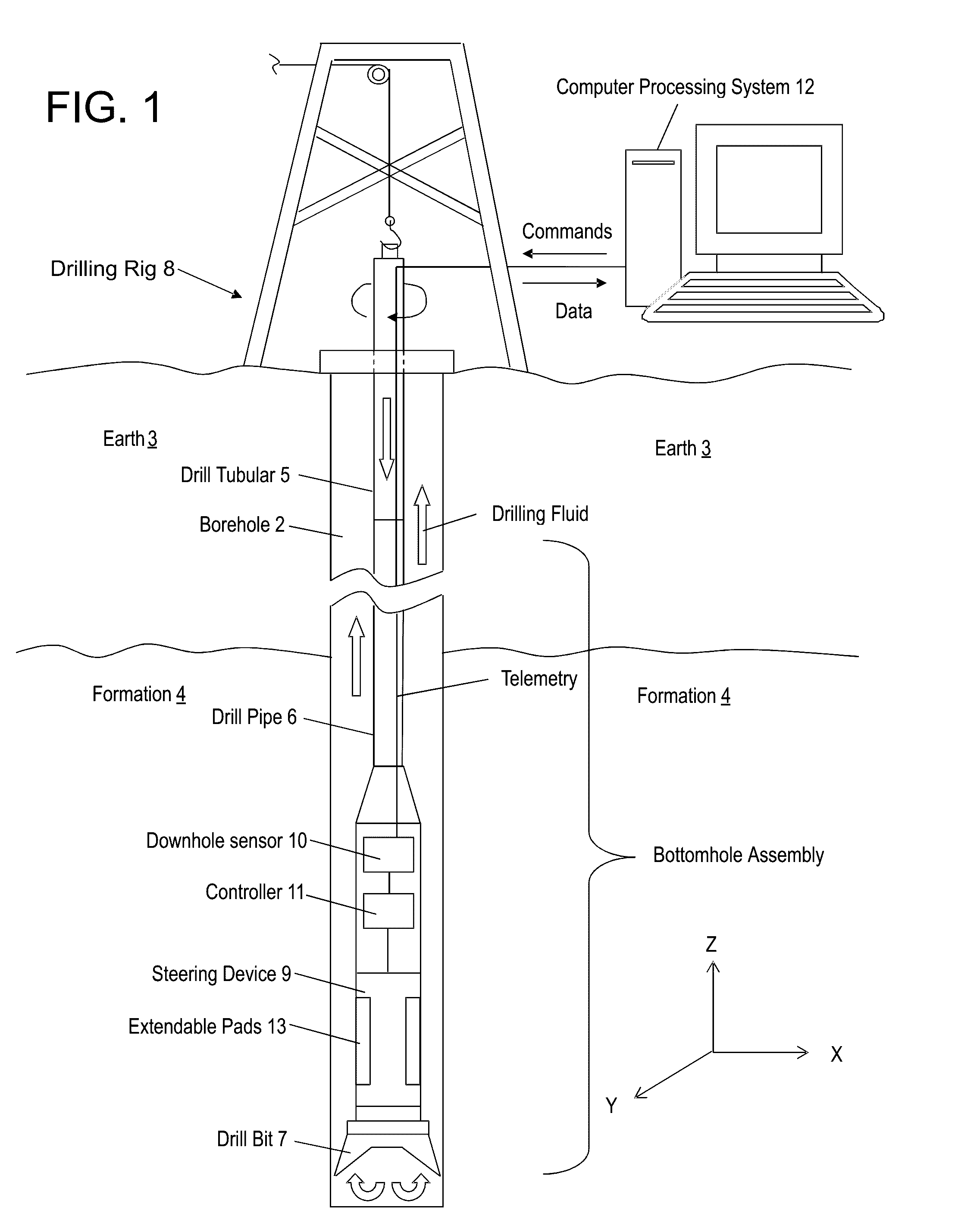

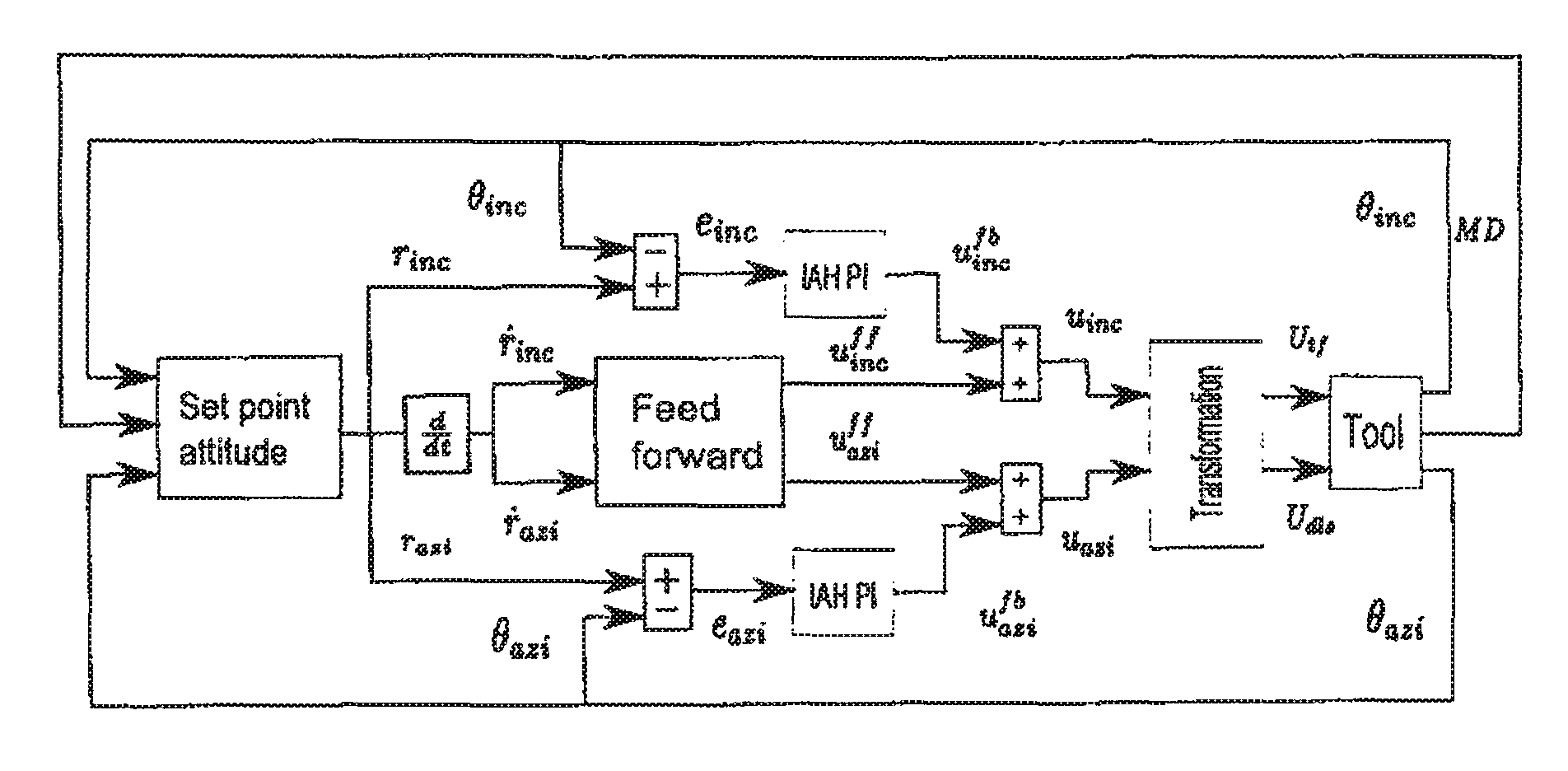

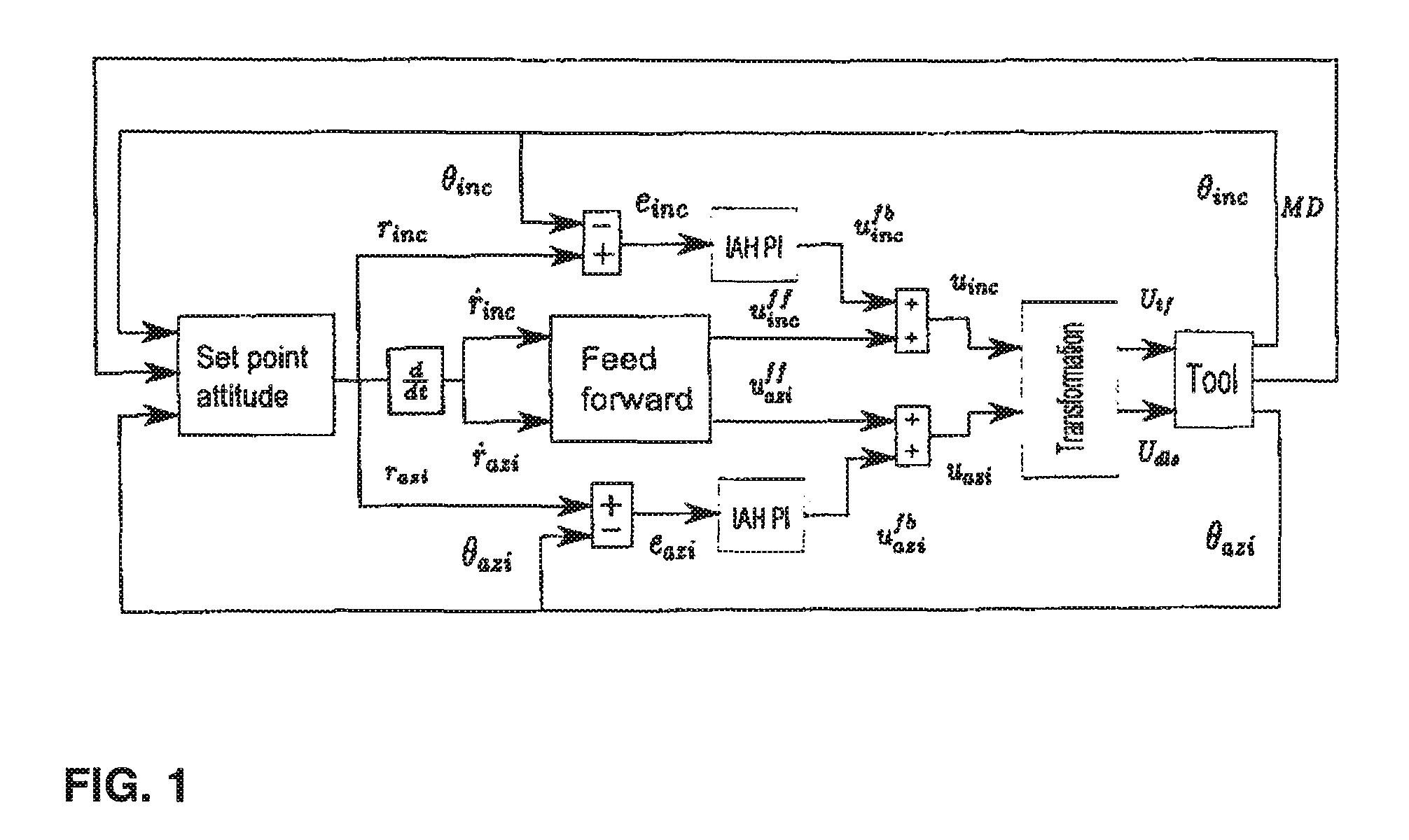

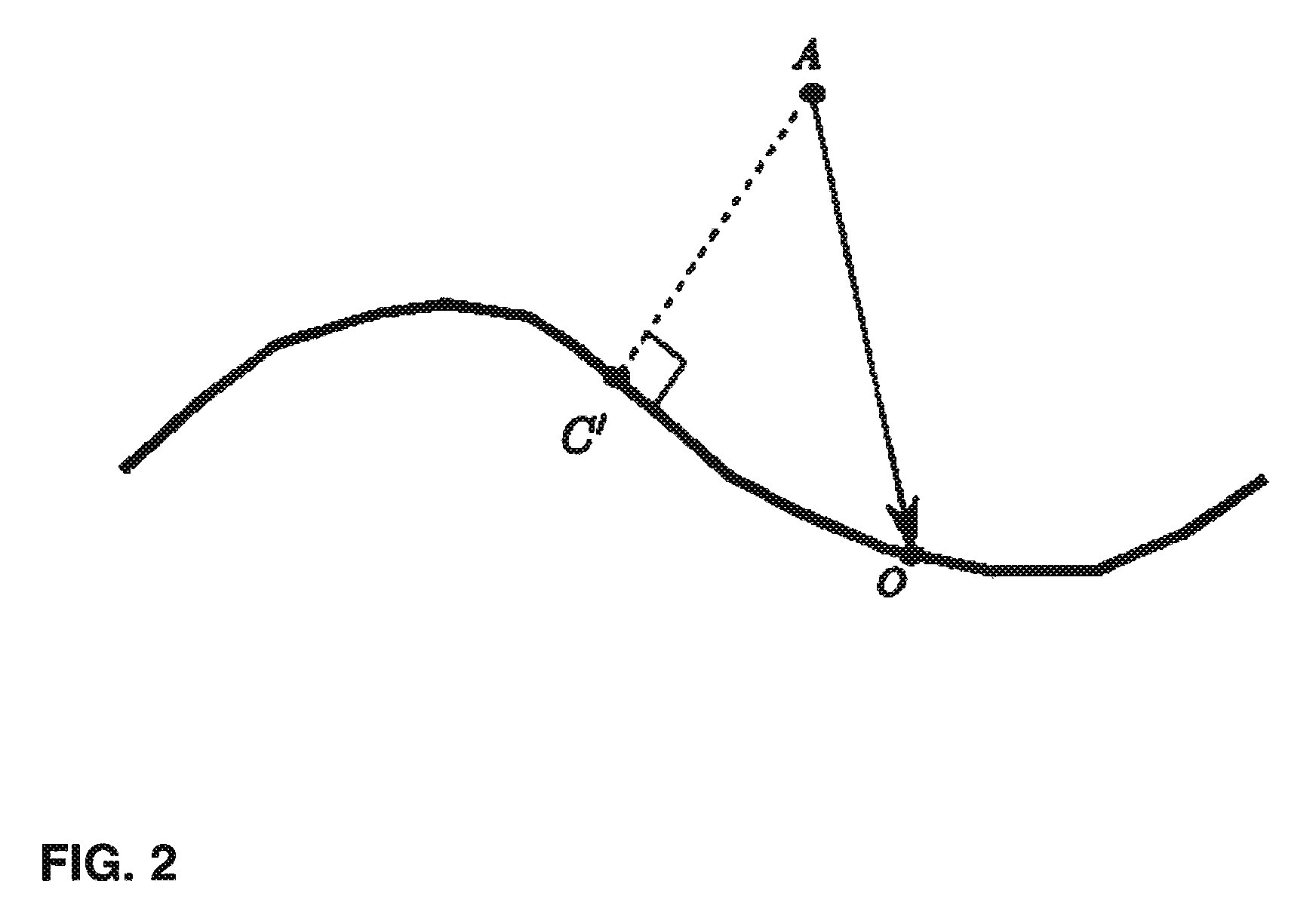

Path tracking for directional drilling as applied to attitude hold and trajectory following

A method for directional control of a drilling system includes generating a set point attitude on an outer loop to establish a path to be followed by the drilling system. The set point attitude may be generated using a surface controller based on inclination and azimuth measurements made at the drilling system and a measured depth of the drilling system. A downhole inclination and azimuth hold system is used on an inner loop to control drilling along the path established by the set point attitude. The inclination and azimuth hold system processes the set point attitude to compute a toolface control input and a dogleg severity control input which are applied to the drilling system to control the drilling system to drill along the established path.

Owner:SCHLUMBERGER TECH CORP

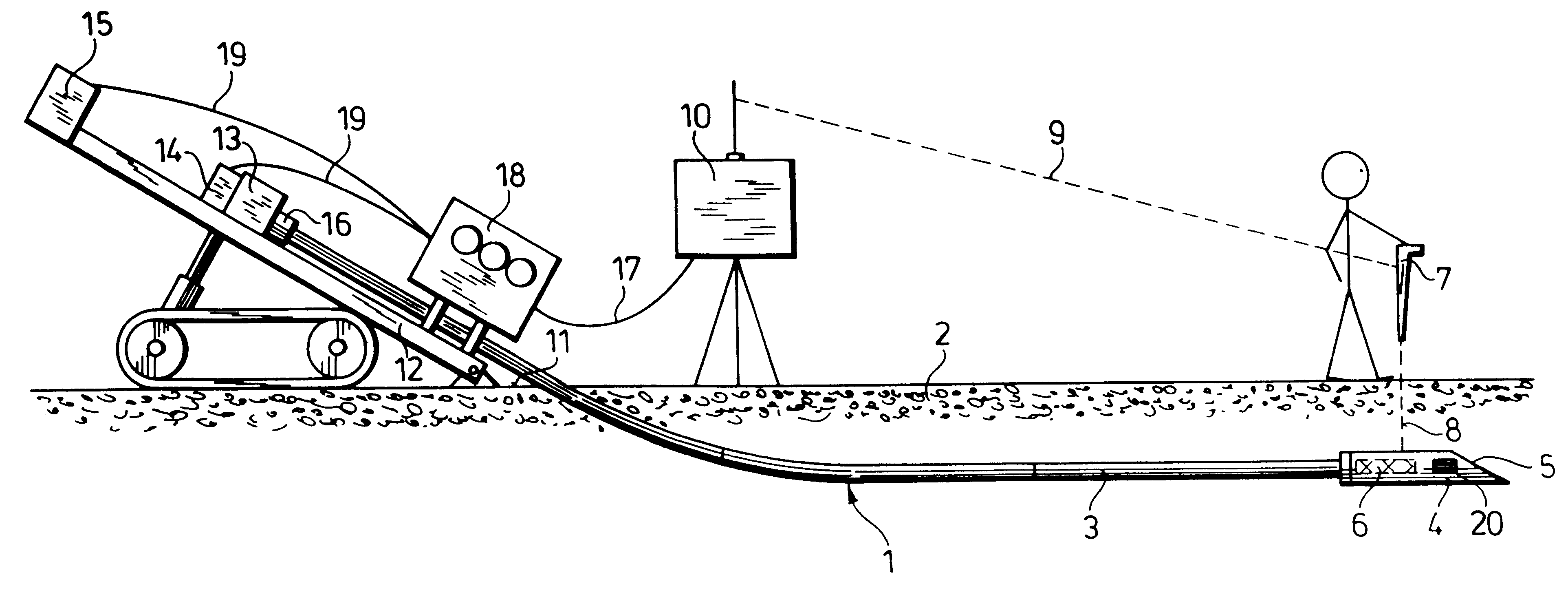

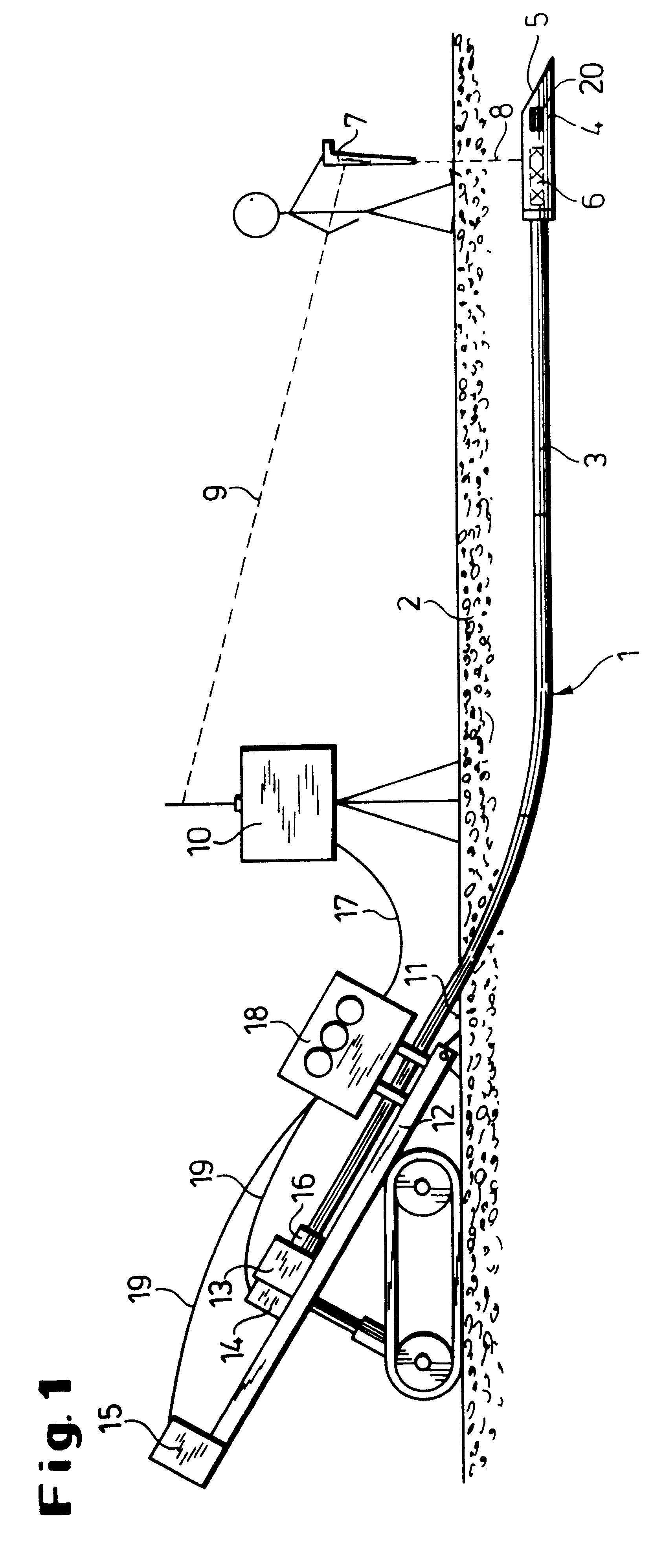

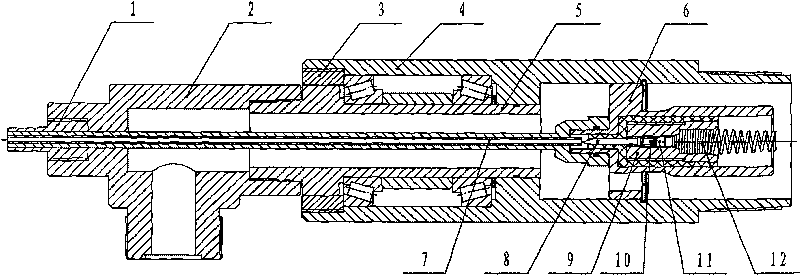

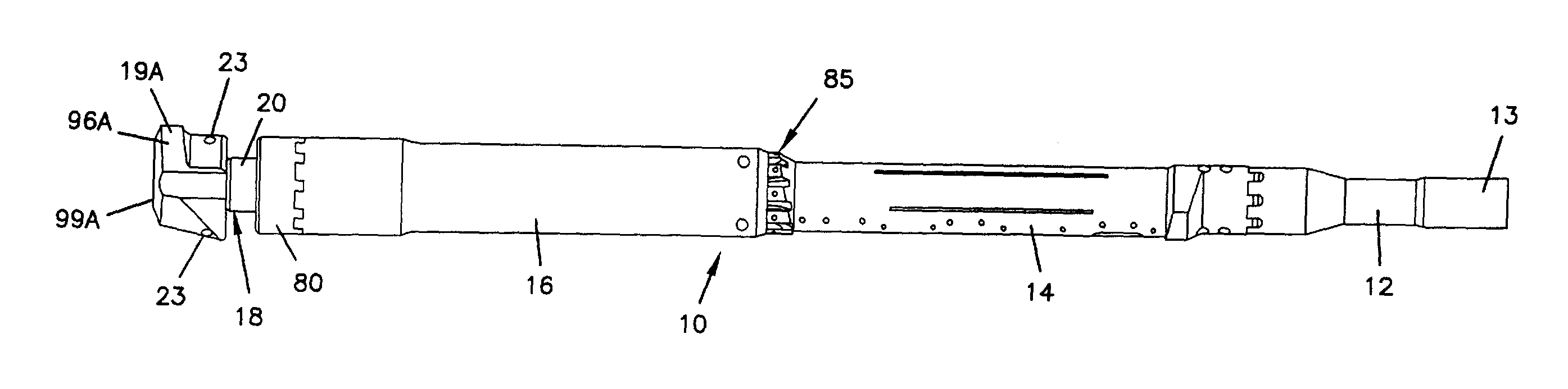

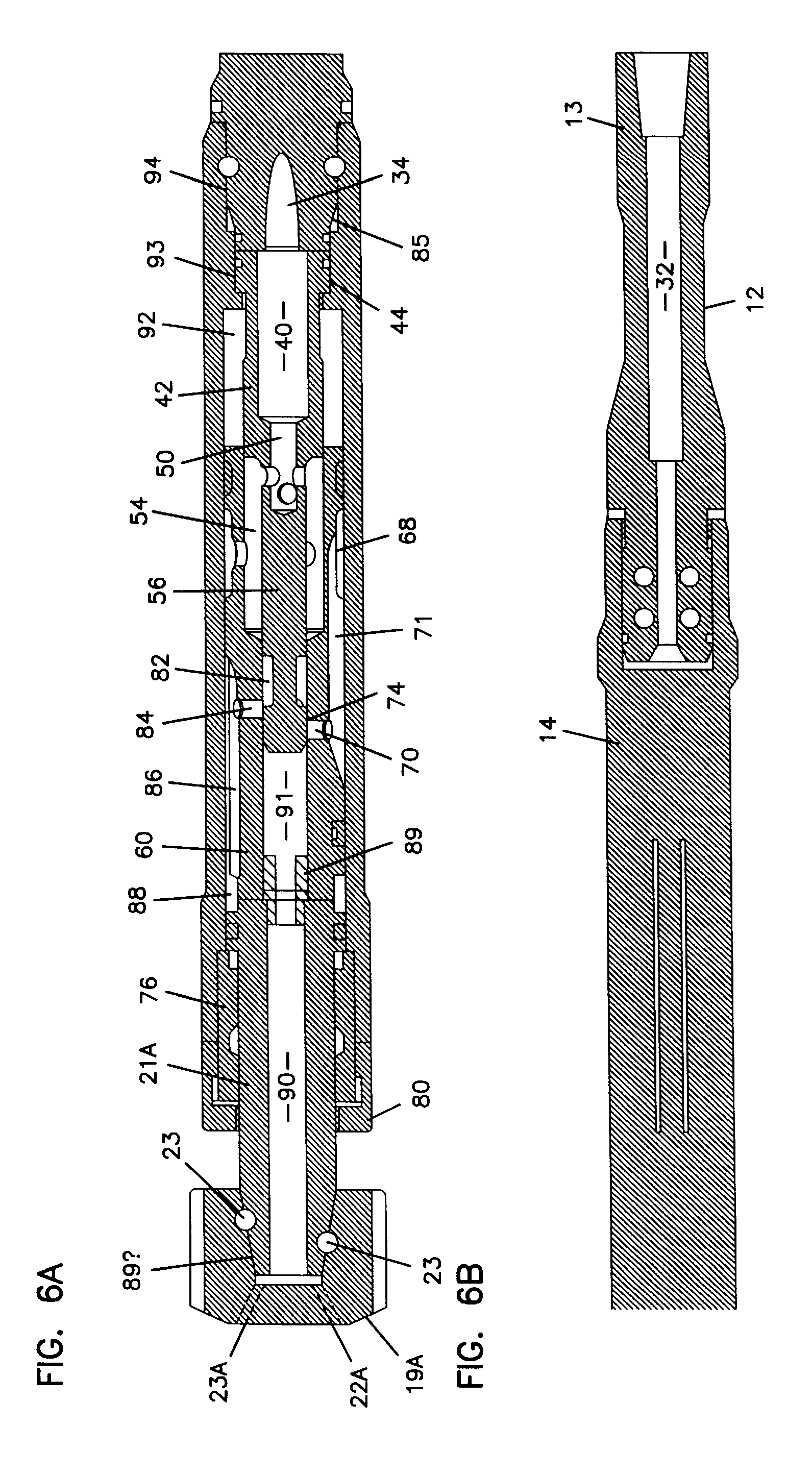

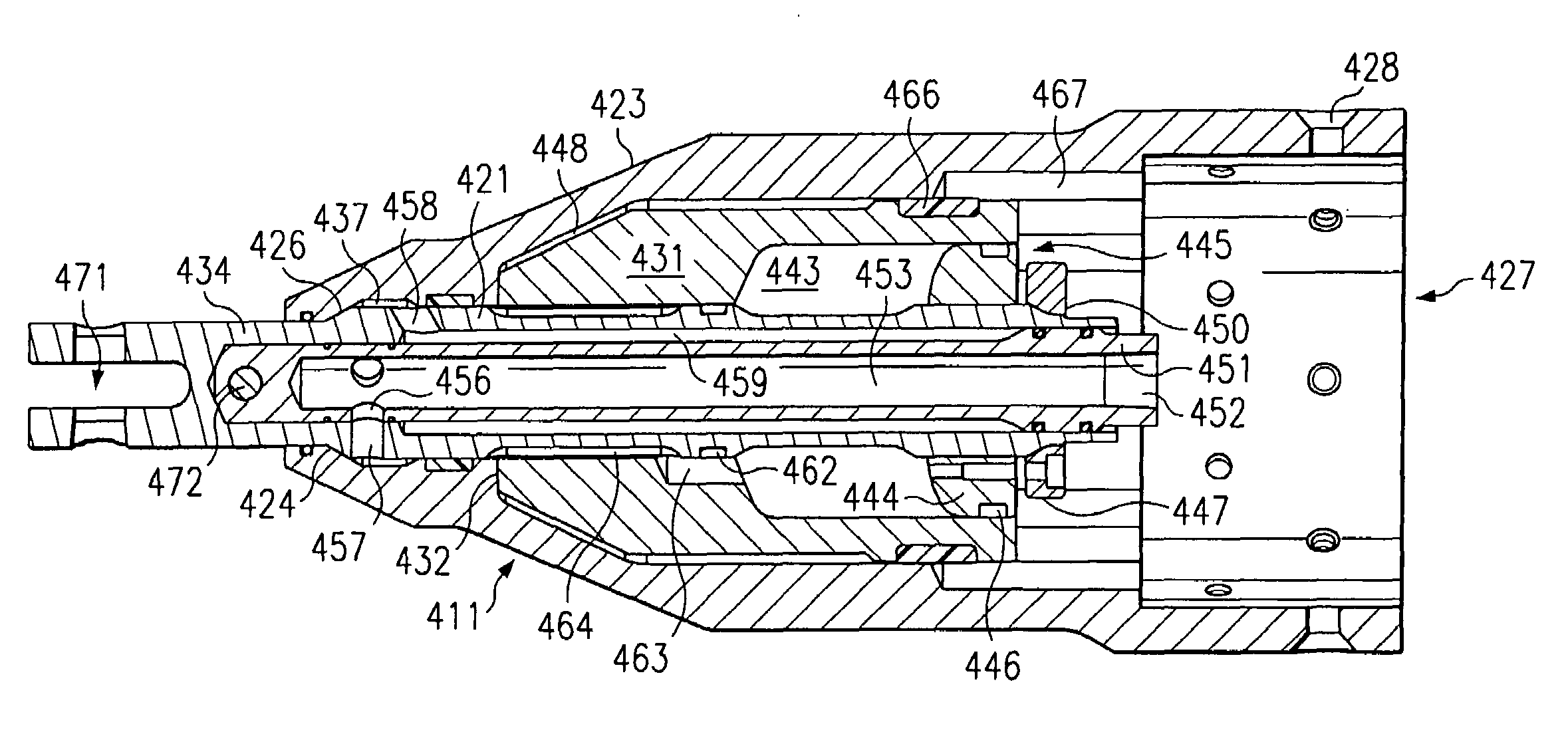

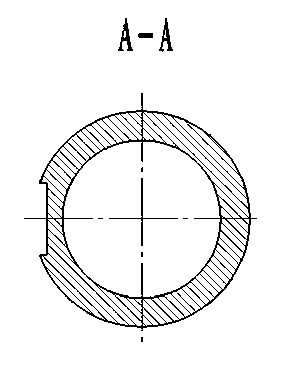

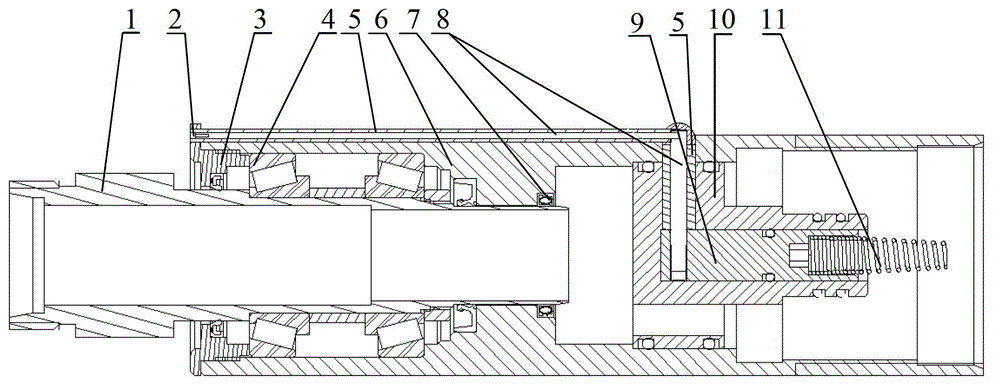

Apparatus for directional boring under mixed conditions

A drill head for an apparatus for horizontal directional drilling. The drill head includes a device for detecting angular orientation, a holder for the device for detecting angular orientation, the device for detecting angular orientation being disposed therein, a hammer driven by a liquid and a drill bit. The holder, the hammer and the drill bit are connected head to tail along a longitudinal axis of a drill string with the holder at a proximate end of the drill head and the drill bit at a distal end of the drill head.

Owner:VERMEER MFG CO

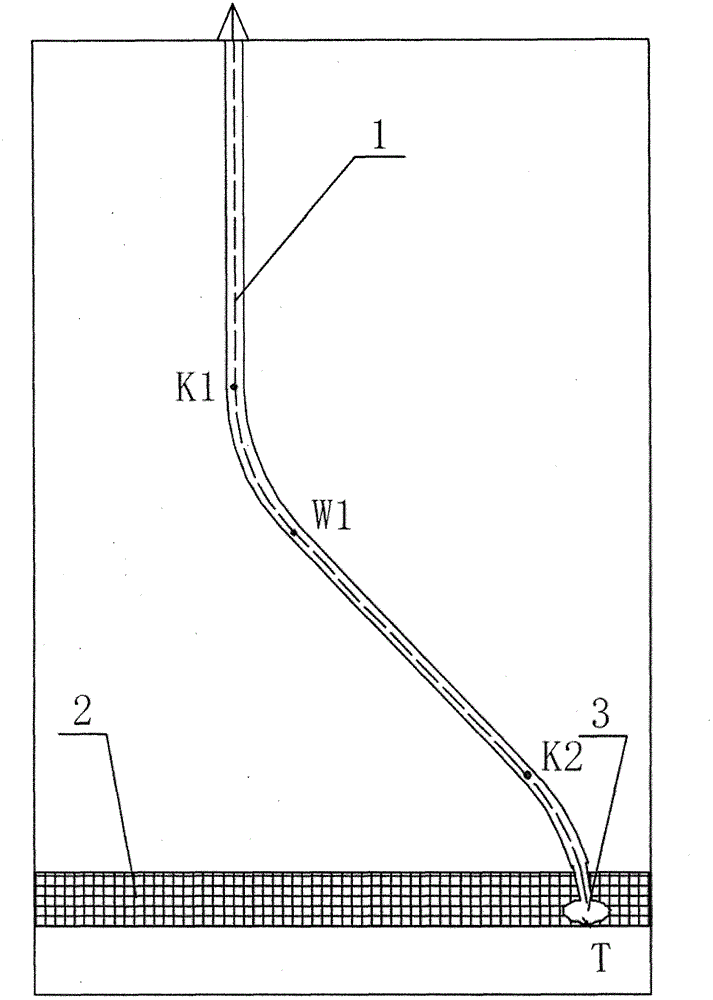

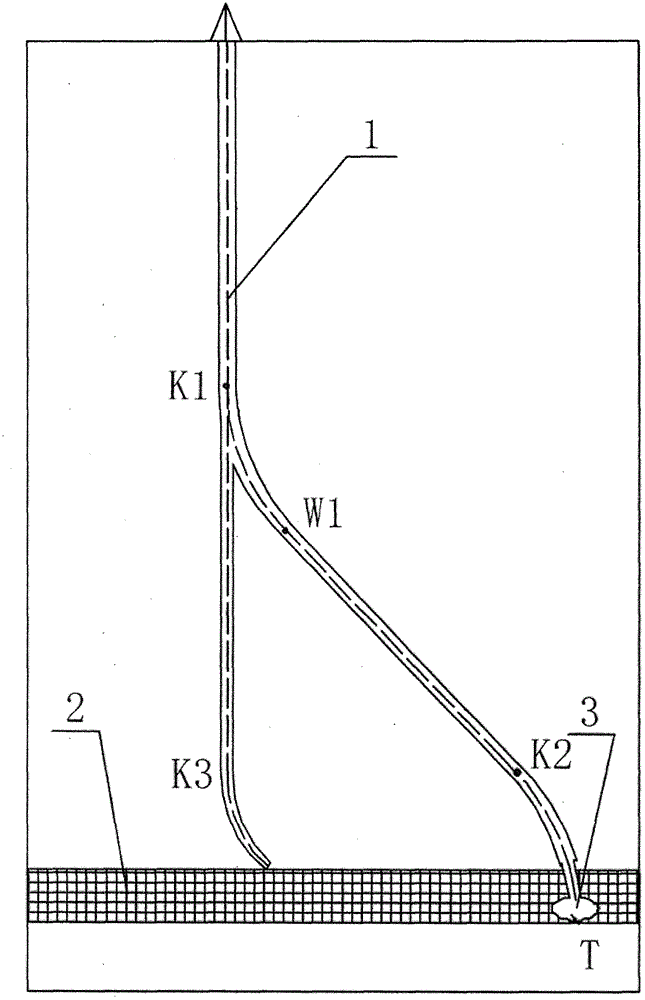

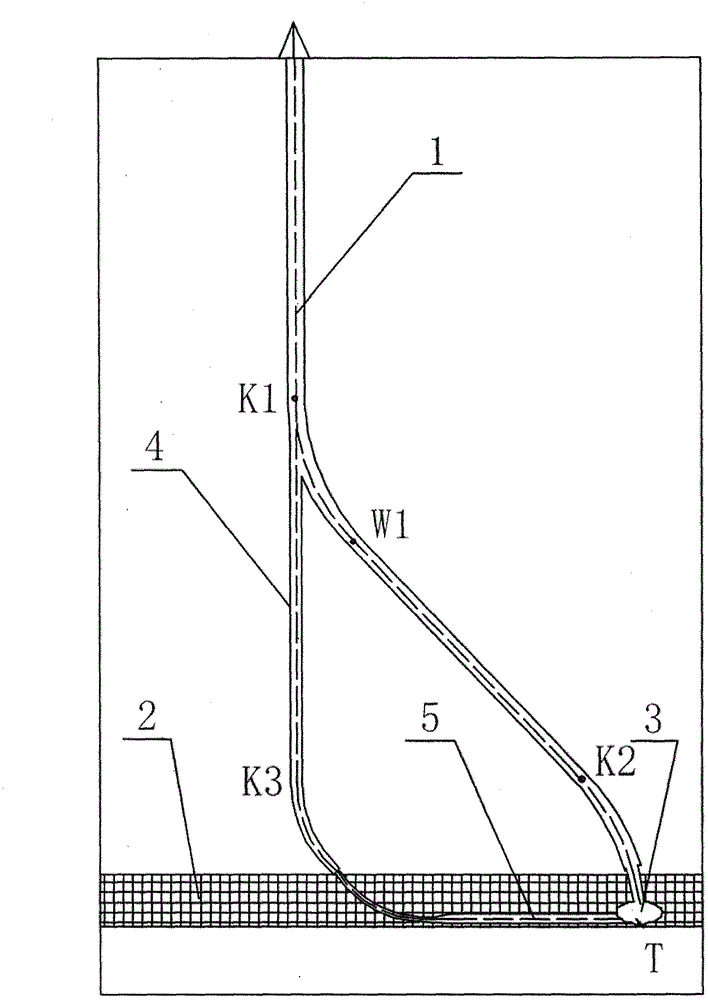

Single borehole multilateral directional butted well salt mining method

InactiveCN104612691AReduce mistakesSimplify Oriented DesignUnderground miningSurface miningWell drillingButt joint

The invention discloses a single borehole multilateral directional butted well salt mining method, which comprises the steps of: firstly conducting boring to a predetermined depth K1, then performing deflection by a directional drilling technology, boring out an inclined shaft through W1 and K2 points and reaching a T point in the ore bed, laying a casing pipe A to form a well, and conducting dissolution in the ore bed to build a small cave; in the same borehole, using a smaller level boring tool to pass through the deflecting point K1, carrying out boring downward vertically to a predetermined deflecting point K3, performing deflecting boring into the ore bed, laying a casing pipe B in the section of small-caliber borehole for well cementation; in the casing pipe B, using a smaller level boring tool to conduct further deflecting, boring a horizontal well section in the ore bed to realize butt joint with the small cave built in the first step; laying a center pipe in the casing pipe B, carrying out sealing connection on the center pipe end and the casing pipe B with a packer, and mounting well head equipment. The method provided by the invention utilizes directional boring and multilateral well technologies to build the horizontal butted well channel meeting brine mining at a smallest boring project amount.

Owner:中盐勘察设计院有限公司

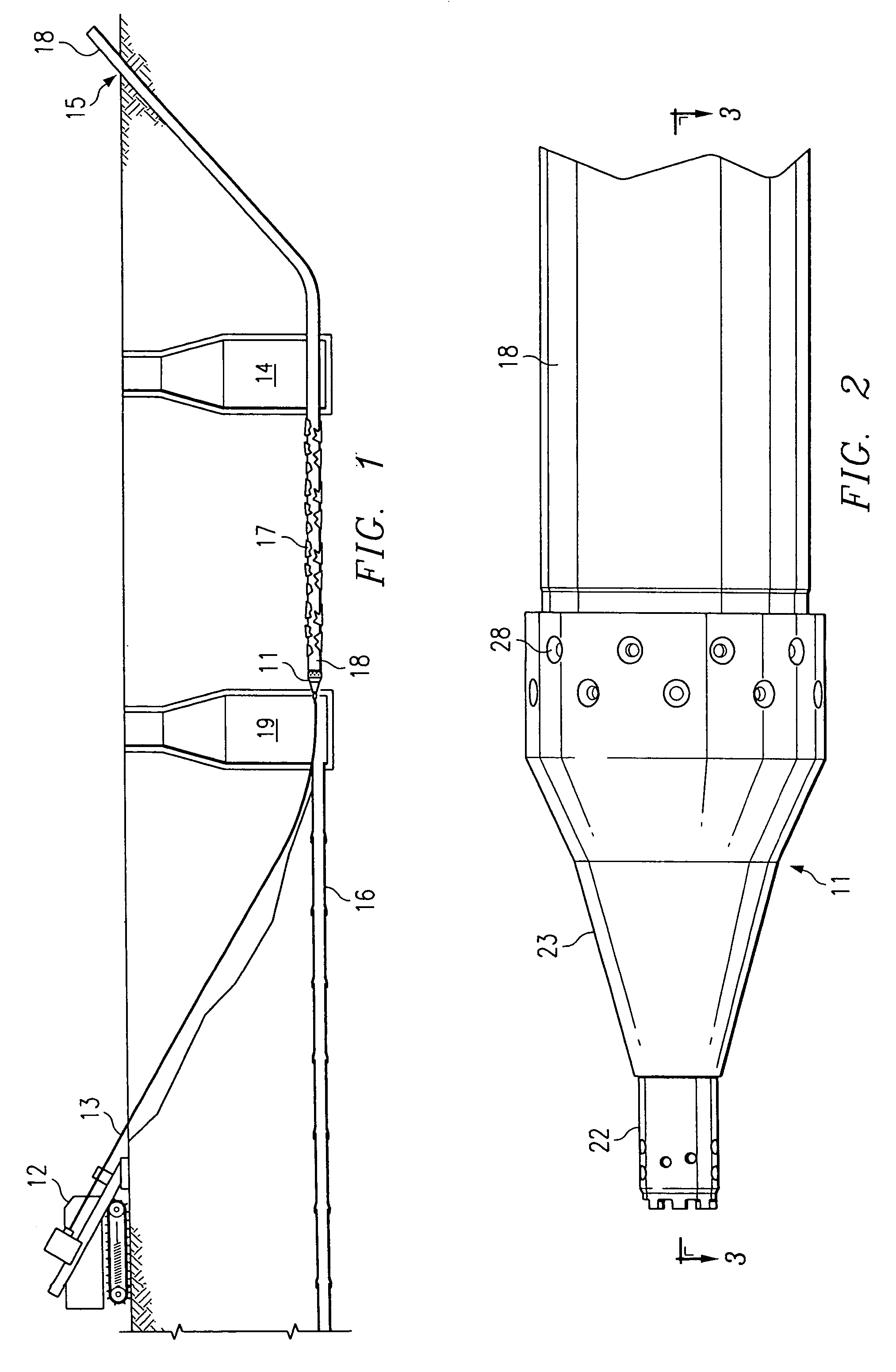

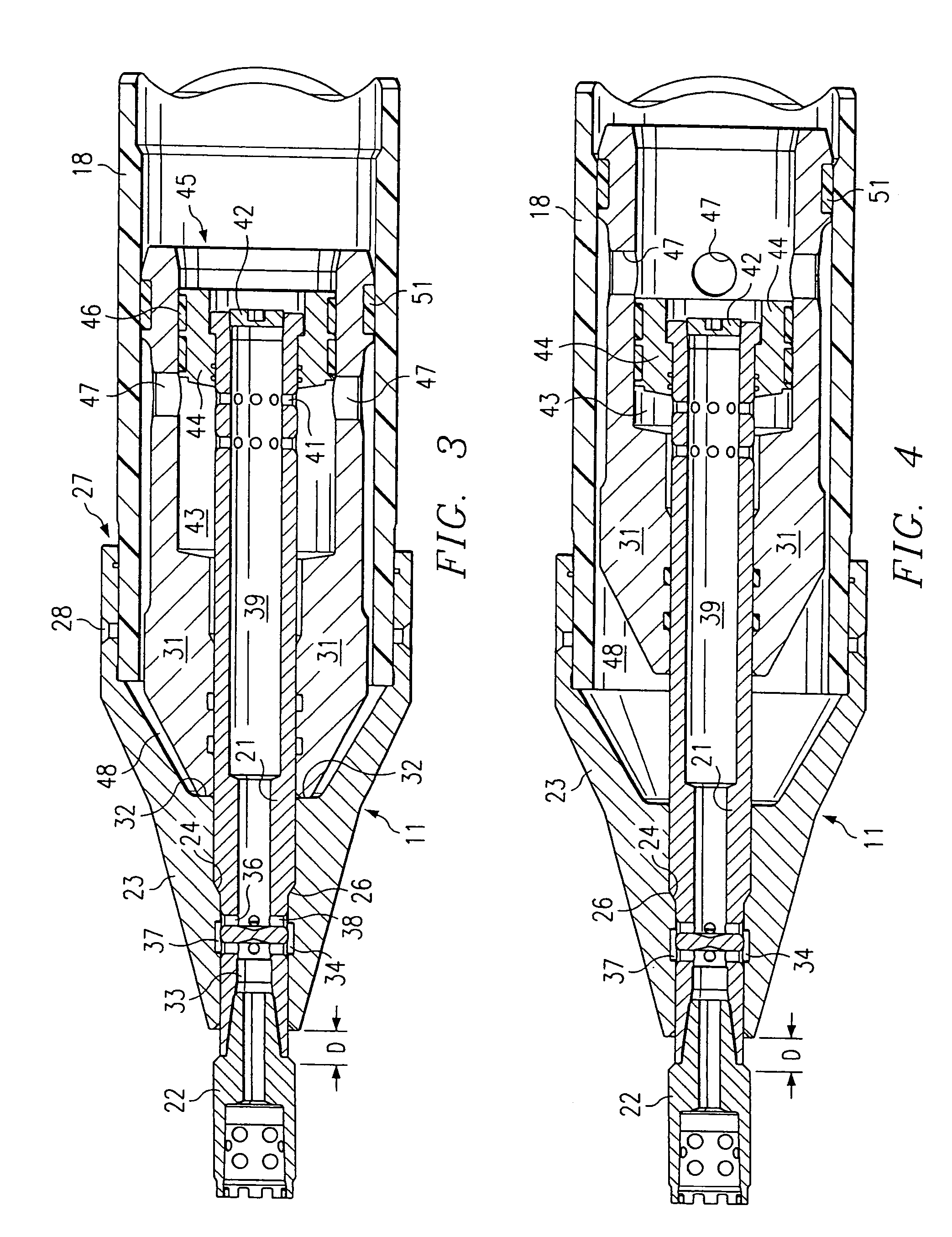

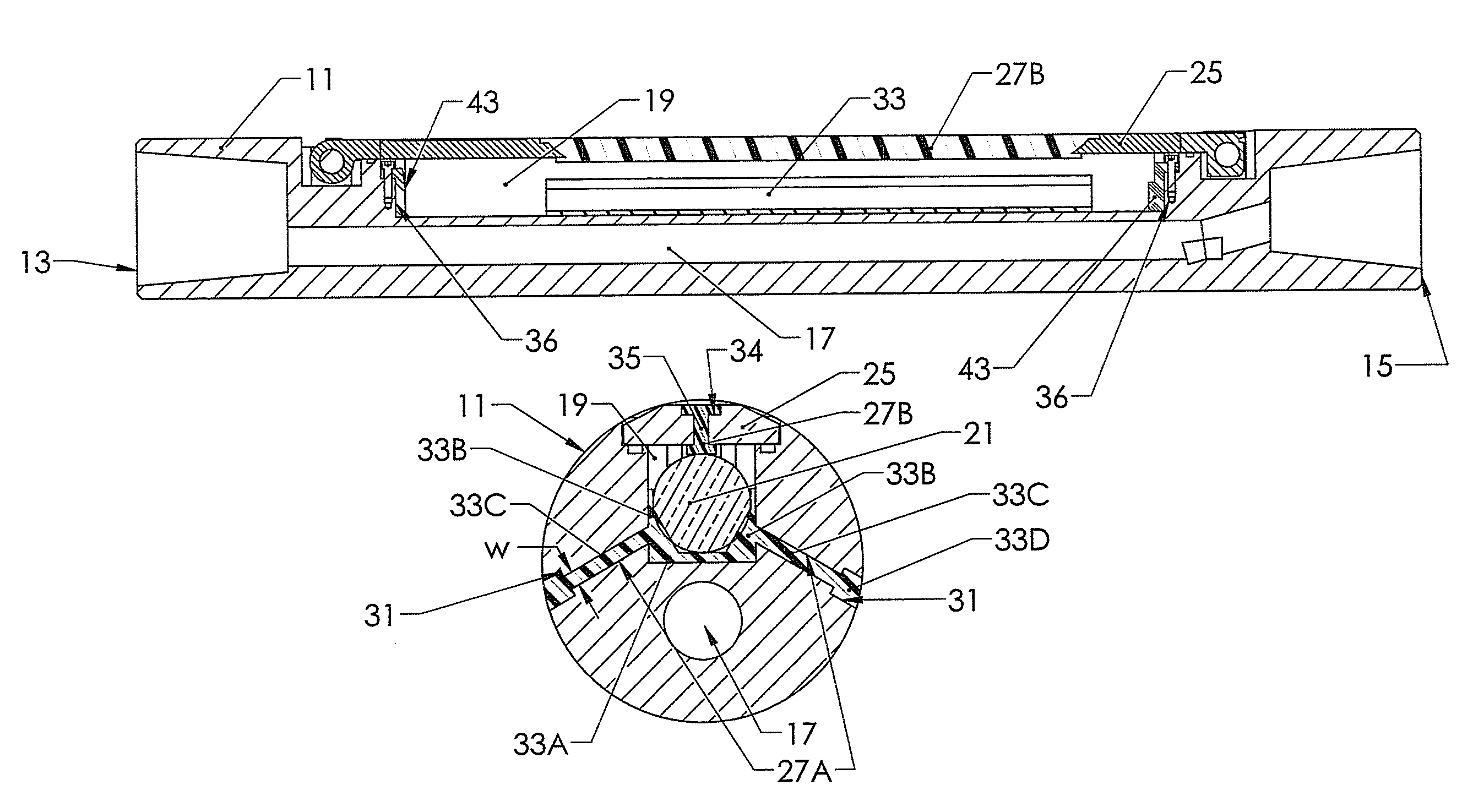

Method and apparatus for replacement of underground pipe

InactiveUS7055621B2Reduce stepsReduce impactDrilling rodsConstructionsPull forceReciprocating motion

An impactor for use with a directional boring machine for replacement of underground pipes includes a bursting head having a rearwardly opening recess and a front end opening that communicates with the recess. An inlet pipe is connected at its front end to a distal end of the drill string and extends into the recess of the bursting head through the front end opening. A striker is mounted for sliding movement along the inlet pipe, and a distributing mechanism responsive to pressure fluid supplied through the drill string and inlet pipe causes the striker to reciprocate in the rearwardly opening recess of the head to deliver forward impacts against the bursting head. The striker and distributing mechanism are mounted in a tubular housing, and a pulling connection is provided by which the impactor can be pulled by the drill string while the striker is delivering impacts against the head in the same direction as a pulling force exerted by the drill string. The bursting head is preferably slidably mounted on the inlet pipe and moves forward relative to the inlet pipe and drill string in response to an impact of the striker against the bursting head. The impactor can be readily used with existing directional boring machines.

Owner:EARTH TOOL L L C

Process method for directional drilling, punching and tunneling protection of coal mine high-level roadway

InactiveCN109252888AEfficient governanceEfficient extractionDirectional drillingGas removalPunchingControl area

The invention discloses a process method for directional drilling, punching and tunneling protection of a coal mine high-level roadway. The process method includes the following steps that S1, construction is carried out by a downward drilling machine to achieve directional horizontal drilling and punching, and drilling is carried out downward from the high-level rock roadway into a coal rock combination part; S2, when drilling is carried out on the combined part between rock and a coal layer, oblique drilling is controlled to be conducted on a coal rock segment by means of a drilling identification technology and the like; S3, after drilling is carried out in the middle of the coal layer, horizontal drilling is carried out by 80-130 meters; S4, according to specific situations or conditions, a forward punching mode or a backward punching mode is adopted for drilling in the middle of the coal layer, wherein the punching length is 1-5 meters, and the punching spacing is 8-10 meters; S5,construction from step S1 to step S4 serves as a loop, cyclic lap joint is completed by repeating steps S1, S2, S3 and S4, a whole gas control area is controlled, and the purposes of covering the tunneled roadway and removing a bottom drainage roadway are achieved. By obliquely drilling and punching the high-level roadway downward, gas control and gas extraction are achieved, gas can be effectively controlled, the extraction efficiency and concentration are high, and the cost is low.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD

Vibratory drag reduction method of drill column for directional drilling of approximate horizontal long drill holes of underground coal mine

ActiveCN108915591AReduce frictionReduce the risk of self-lockingDrilling rodsDirectional drillingStatic frictionFriction force

A vibratory drag reduction method of a drill column for directional drilling of approximate horizontal long drill holes of an underground coal mine comprises a conventional directional drilling, vibration generator installing position determination, vibratory drag reduction drilling construction method and the like. The size and material of the drill column are determined by (omitting) a vibrationgenerator installing position and according to a excitation force amplitude value, a front portion is caused, a rear portion drill column is driven to vibrate, meanwhile the stress waves produced invibration are transferred to an instrument for measurement while drilling and disappear in front of a hole bottom drill, and normal use of the instrument for measurement while drilling and the hole bottom drill is not affected. Therefore, a vibration function of the drill column during directional drilling of deep holes of the underground coal mine is achieved, a static friction force is convertedinto a movable friction force, buckling deformation of the drill column can be effectively decreased, accordingly the drilling friction resistance is remarkably decreased, signal transmission with existing mature cabled communication drill rods can be achieved, and the vibratory drag reduction method has the great significance in improvement of directional drilling depth and directional drillingefficiency of deep holes.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

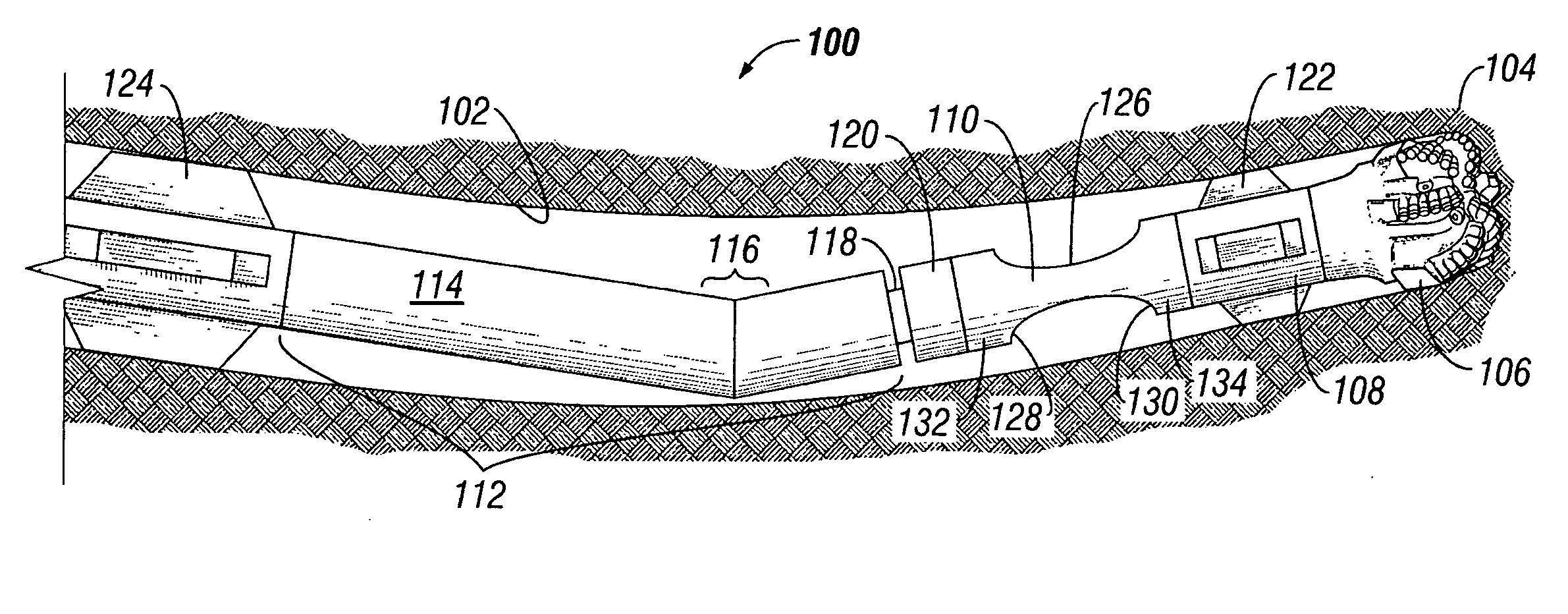

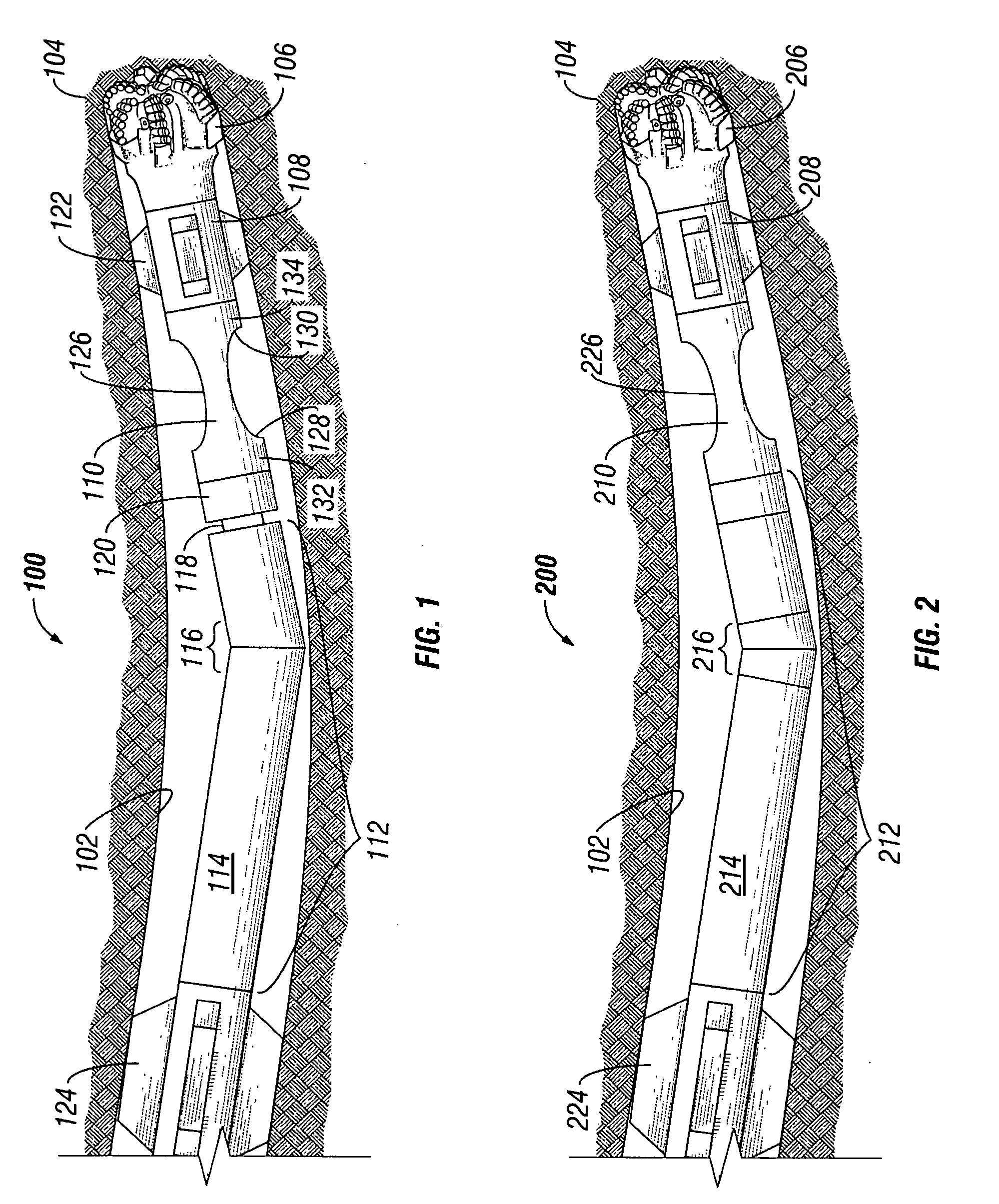

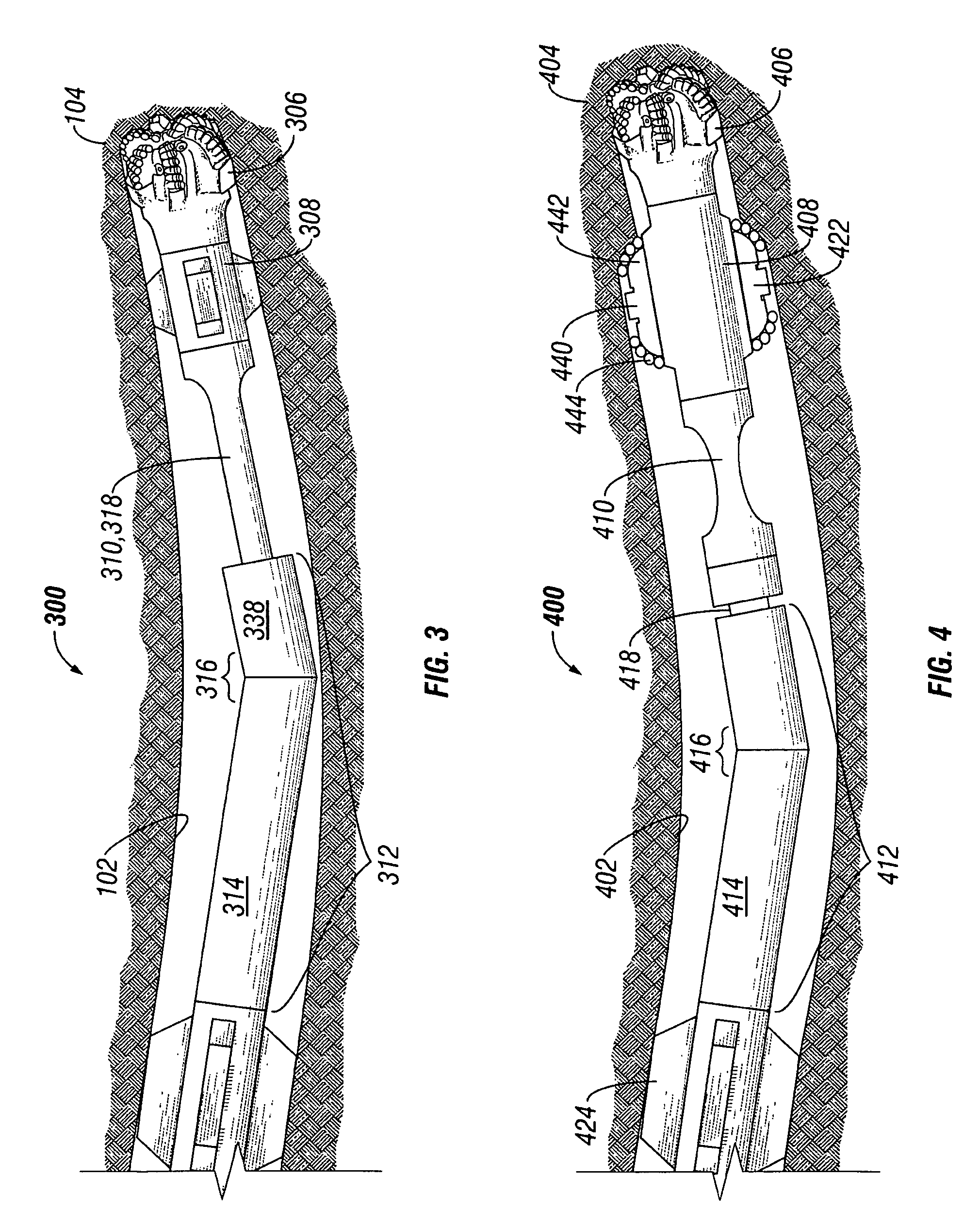

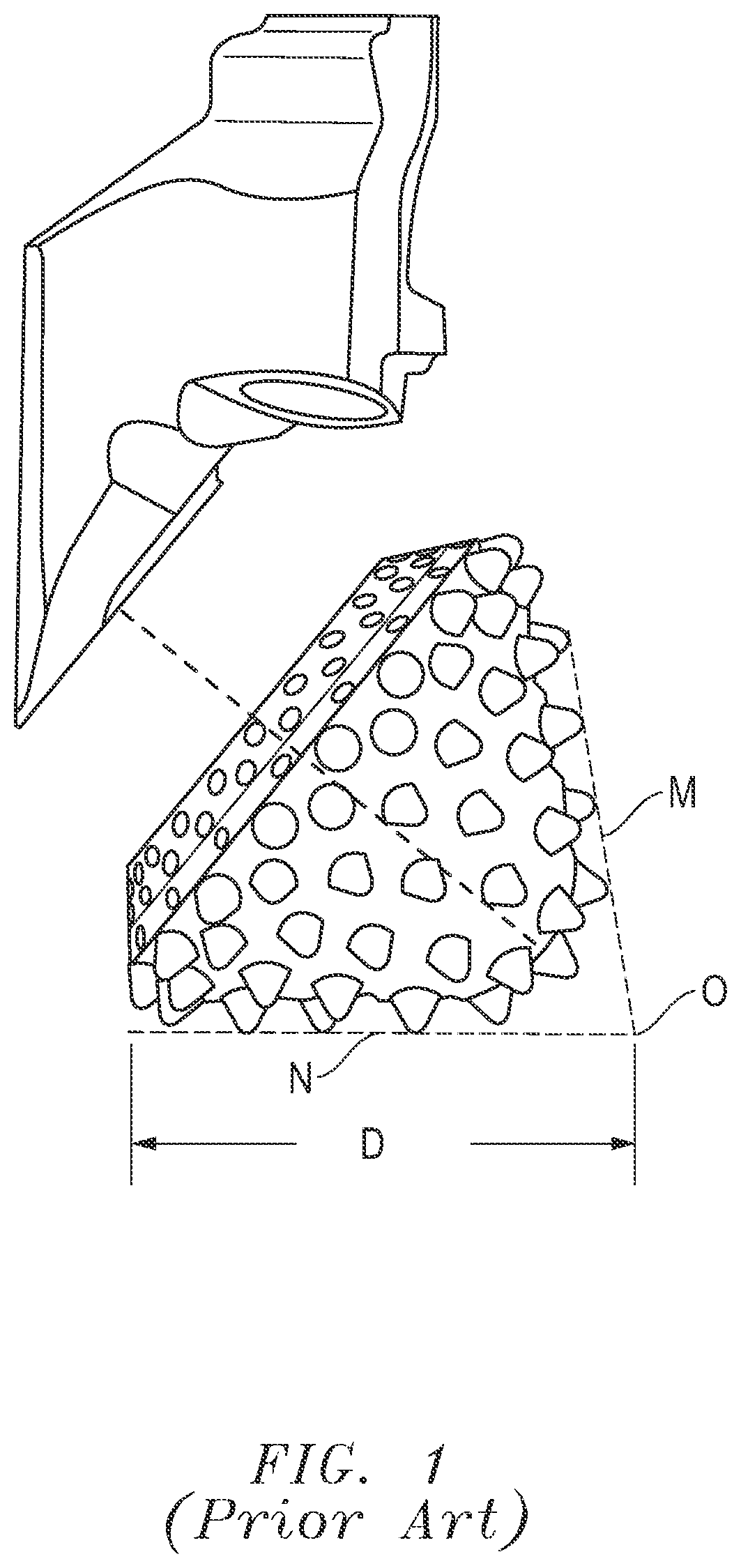

Horizontal Directional Reaming

The disclosure relates to embodiments of horizontal directional drilling equipment and methods for horizontal directional drilling techniques including a reamer head comprising a frustoconical body, wherein the frustoconical body defines a cavity configured to receive at least one bearing; and a plurality of teeth mounted to the frustoconical body. An imaginary apex of the frustoconical body is superimposed on the centerline of a reamer or reaming apparatus for reaming of an underground arcuate path. In another embodiment the reamer head is a progressive independently segmented reaming head. A plurality reaming heads are mounted to a reaming apparatus for reaming of an underground arcuate path.

Owner:QUANTA ASSOC

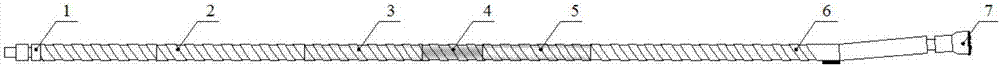

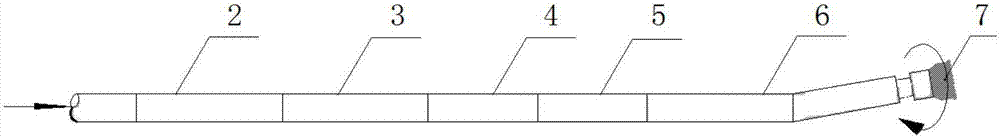

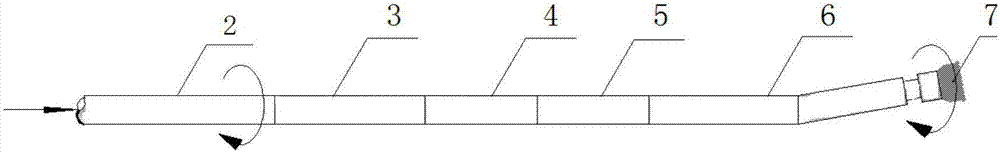

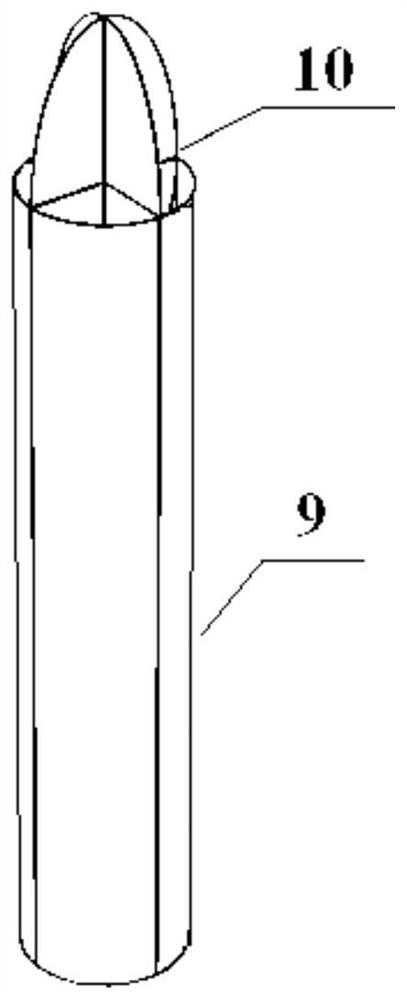

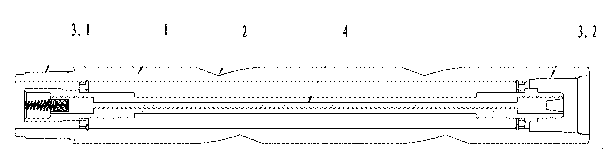

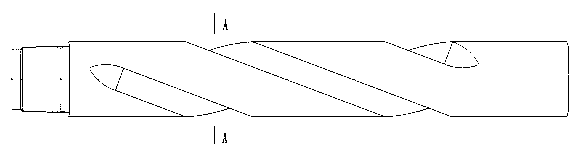

Integral type directional drill rod provided with helical groove

InactiveCN103015916AIt has the function of auxiliary powder dischargeEffective solutionSurveyDrilling rodsDirectional boringDrill hole

The invention relates to an integral type directional drill rod provided with a helical groove and used for directional drilling construction of soft outburst coal seams and broken coal seams of underground coal mine. The purpose of the invention is to provide the integral type directional drill rod with the helical groove, which not only can transmit a down-hole signal accurately in real time but also can be used for effectively handling drilling accidents such as bit jamming, bit burying and the like at the same time. The invention adopts the following technical scheme: the directional drill rod provided with the helical groove comprises a drill rod body and a central cable connection device arranged at a shaft line in the drill rod body, wherein quick connectors are arranged at the two ends of the drill rod body respectively; the helical groove is formed in the outer wall of the drill rod body; and the drill rod body, the helical groove and the quick connectors form an integral type structure. The directional drill rod has the benefits as follows: the twisting, bending and tensile strength of the drill rod is improved; the production efficiency is improved and the production cost is reduced; and the down-hole signal can be transmitted accurately in real time, and the drilling accidents such as bit jamming, bit burying and the like can be effectively handled at the same time, so that the drilling cost is lowered.

Owner:SHANDONG JIUSHANG ENG MACHINERY

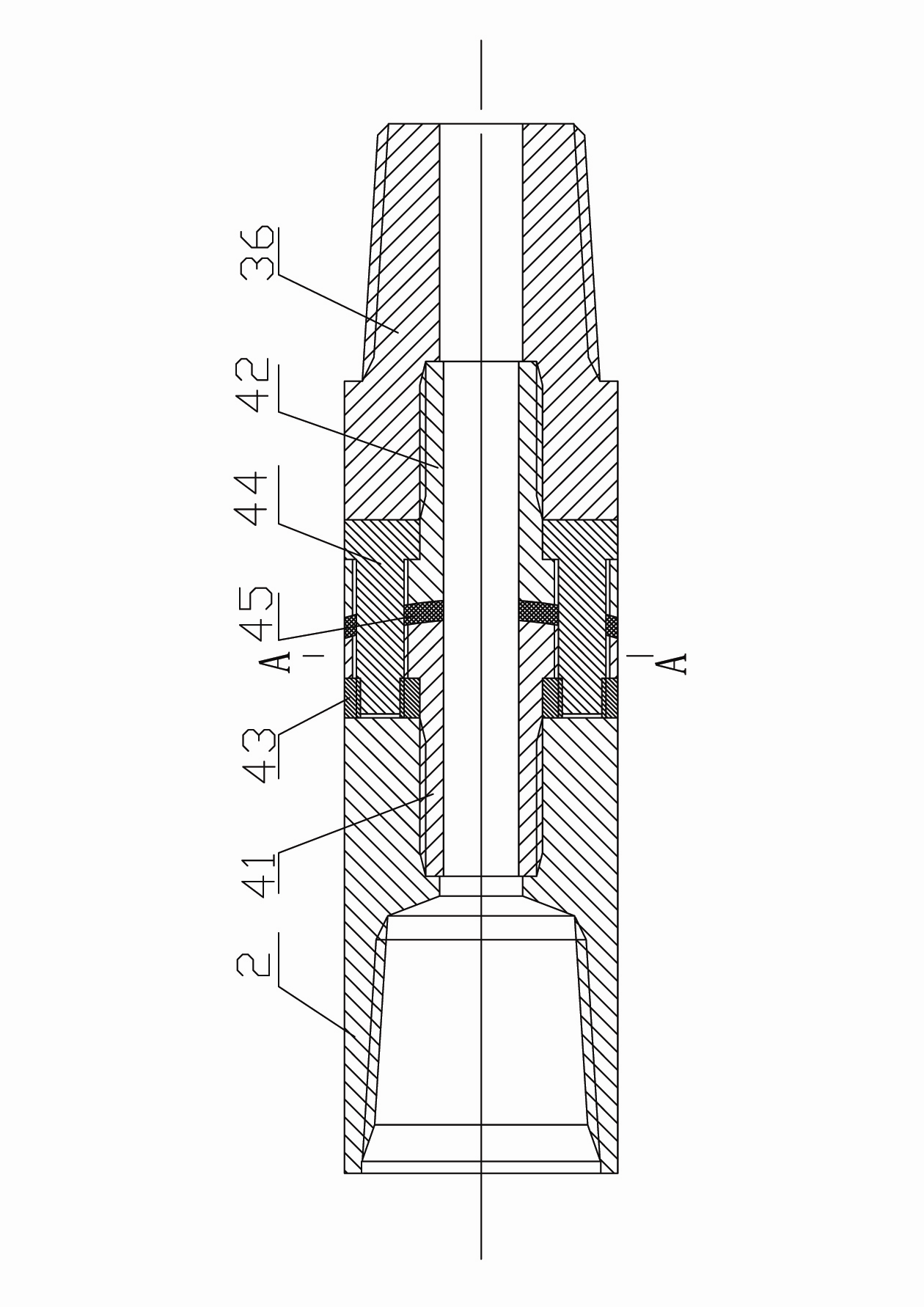

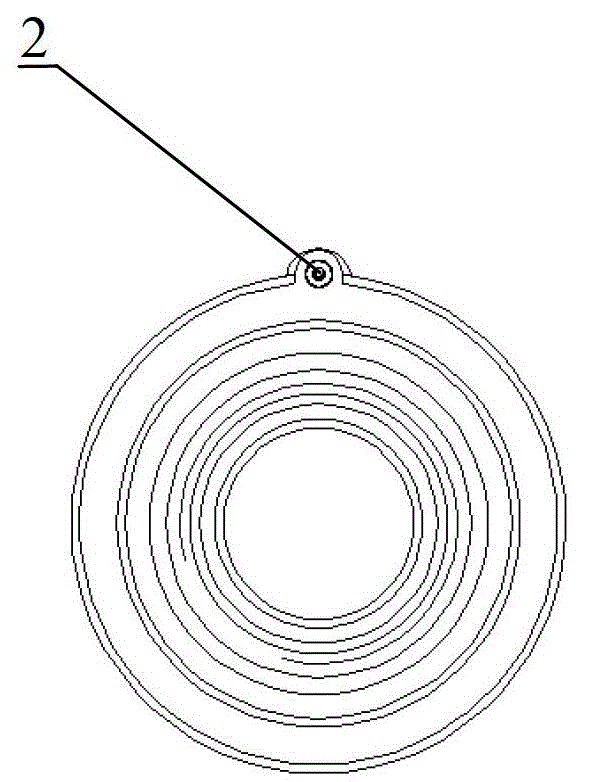

Directional water feeder and directional drilling rig

ActiveCN102926686BMeet the use requirementsRealize measurement while drillingDirectional drillingFlushingEngineeringDirectional boring

The invention discloses a directional water feeder and a directional drilling machine, wherein the directional water feeder comprises a shaft, a bearing, an outer pipe and a central cable-traverse device; the shaft is connected with the outer pipe through the bearing; and the central cable-traverse device is arranged on the outer pipe. Thus, the directional water feeder disclosed by the invention can solve the problems of inconvenient measurement signal and unreliable measurement and obviously increase the drilling efficiency of a drill hole of the directional drilling machine.

Owner:益阳市科技成果转化服务中心 +1

Sonde housing and bit body arrangement for horizontal directional drilling

A horizontal directional drilling sonde housing has a cavity for receiving a sonde. Signal channels extend from the cavity to an exterior of the housing. A polymer lines at least part of the cavity and fills the signal channels. The drilling tool has a bit body and a drilling body. The two bodies have respective lateral surfaces which engage each other to prevent the transverse movement of the drilling body relative to the bit body during operations. The drill bit has a forward extending drill tooth, which drill tooth is removable from a bore. A spacer is located in the bore between the bottom end of the bore and the tooth. The drilling bit has buttons located on the side in a spiral configuration about a longitudinal axis of the bit.

Owner:STRAIGHTLINE HDD INC

Stable horizontal directional drilling equipment with automatic pipeline connection function

InactiveCN108060895AFast connectionFirmly connectedDirectional drillingBorehole/well accessoriesDirectional boringRotating disc

The invention relates to stable horizontal directional drilling equipment with an automatic pipeline connection function. The stable horizontal directional drilling equipment includes a crawler, a supporting block, a working box, a supporting plate, a pipe storing box, a moving box, a fixed block, a connecting rod, a fixed plate and a connecting mechanism. The fixed plate is provided with four fixing mechanisms. The connecting mechanism includes a driving unit, a motor, a rotating block, a sliding rod, a moving plate, a moving unit, a drilling rod and a rotating disc. Each fixing mechanism comprises a compression unit, a limiting block and three telescopic units. According to the stable horizontal directional drilling equipment with the automatic pipeline connection function, through the connecting mechanism, a new drilling pipe can be automatically connected with and fixed to an original drilling pipe, the working intensity of workers is reduced, not only that, through the fixing mechanisms, the horizontal directional drilling equipment can ensure that the heading direction of the drilling pipe cannot be off the predetermined route in the drilling process, so that the drilling pipe is avoided from being stuck underground.

Owner:南京卓茨机电科技有限公司

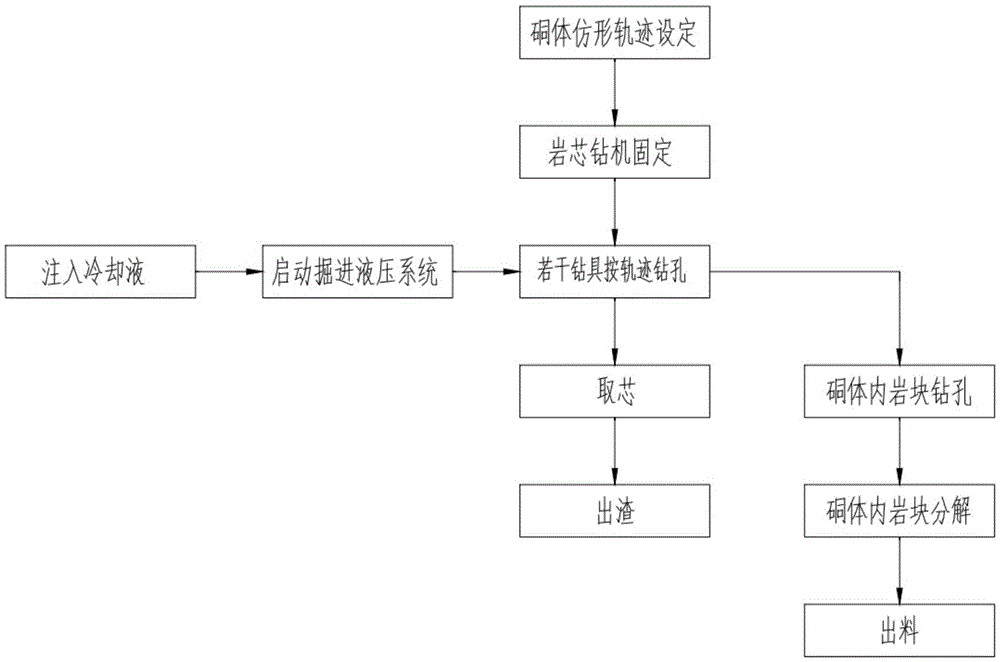

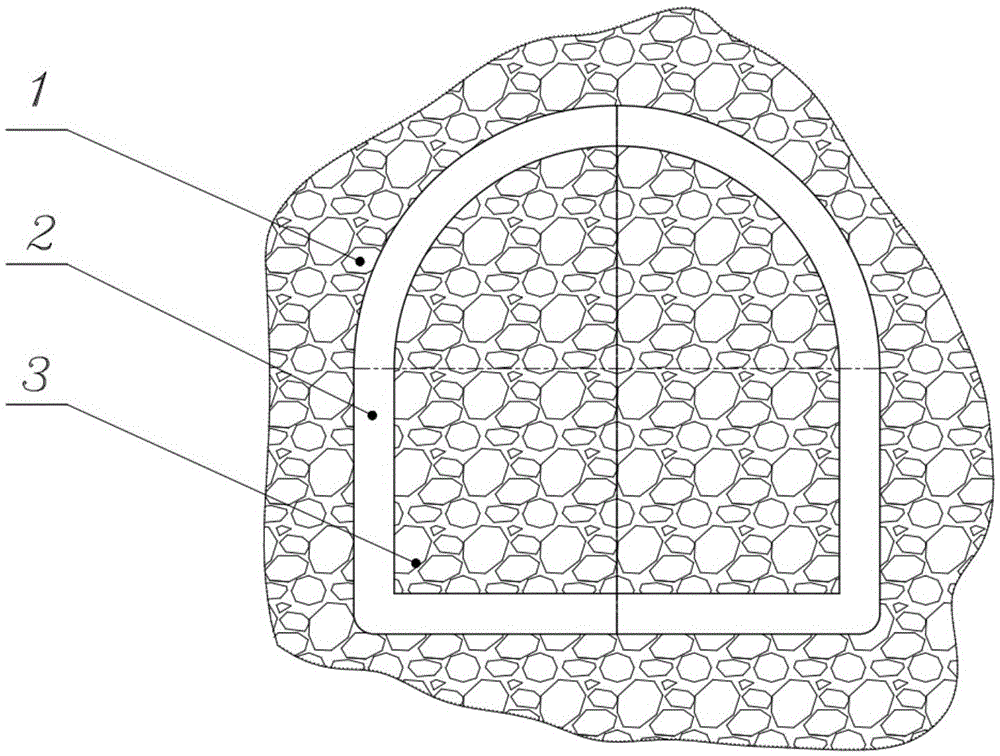

Directional drilling and rock splitting chamber forming method

InactiveCN105649633ATake advantage ofSimplify the construction processDisloding machinesTunnelsRock coreSlag

The invention relates to a drilling method, in particular to a directional drilling and rock splitting chamber forming method, and belongs to the technical field of tunnel construction. The method includes the following steps that firstly, a hole body profiling track is designed; secondly, a drilling device and a rock splitting device are fixed; thirdly, holes are drilled according to the hole body profiling track; and fourthly, the drilling device drills a stratum inside a hole body, a rock core is separated from the inside of the stratum, and slag is discharged; the rock splitting device splits the hole body, and broken rocks inside the hole body are discharged until a chamber is formed. The directional drilling and rock splitting chamber forming method has the beneficial effects that the construction process is simple, the design is novel, the efficiency is improved, the cost is lowered, and the directional drilling and rock splitting chamber forming method is suitable for being widely popularized in the market.

Owner:NANJING HAIJIE MACHINERY MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com