Prime hole reverse pushing construction method in horizontal orienting drilling and prime hole reverse pushing device

A construction method and horizontal directional technology, which is applied in directional drilling, pipeline laying and maintenance, pipes/pipe joints/fittings, etc. It can solve problems such as poor site conditions at the excavation end of directional drilling, difficulty in circulation transportation, and long construction time, etc. Achieve the effect of overcoming the shortage of drill pipes, meeting technical requirements, and simple and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides a construction method of original hole pushback in horizontal directional drilling, which includes the following steps:

[0026] Step one is the process of drilling pilot holes. The rig drills along the designed trajectory from the input end to the discharge end; generally, the pilot hole curve is as smooth as possible to facilitate subsequent pre-expanding construction and pipeline drag-back construction.

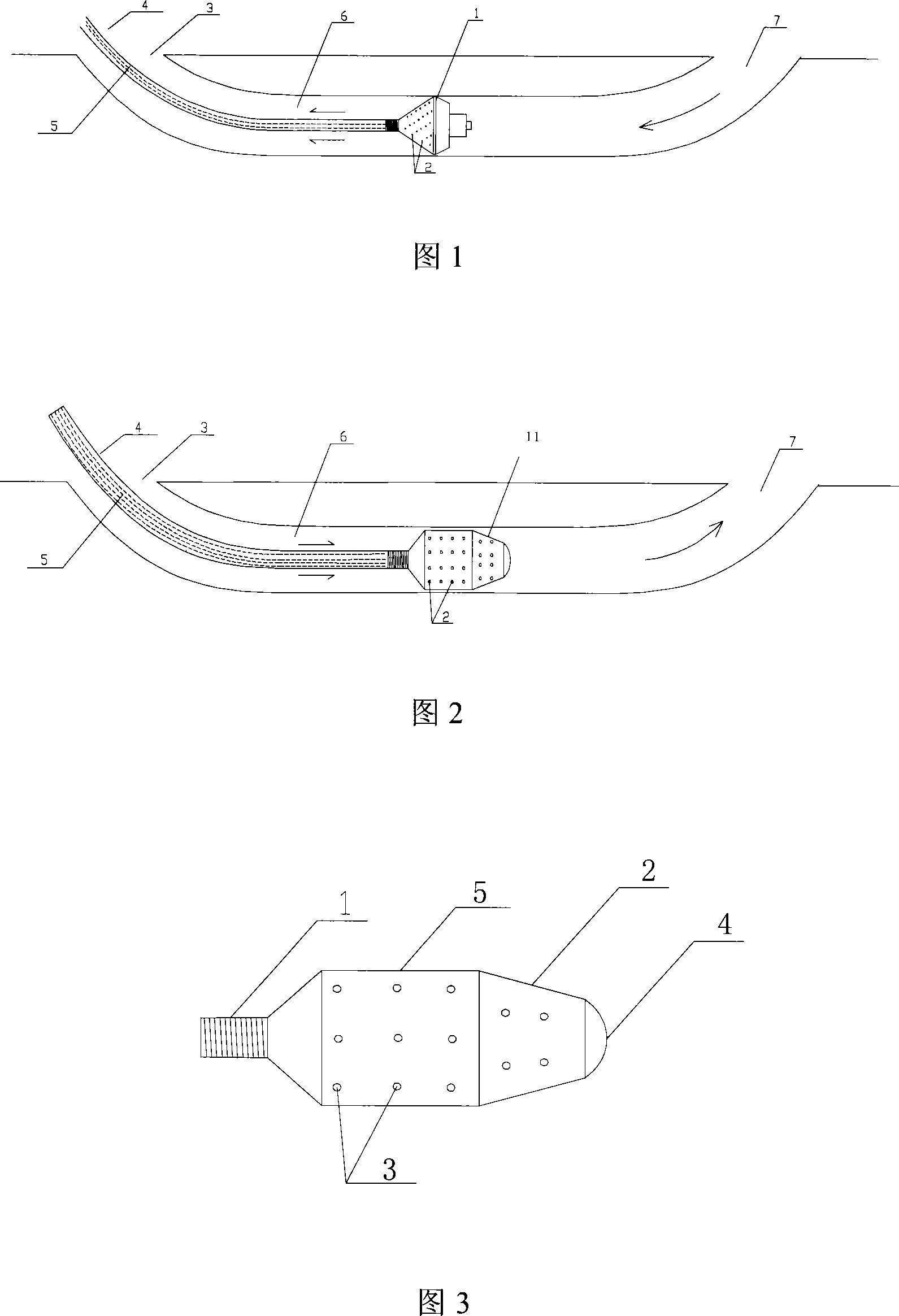

[0027] Step two, back-expanding process, as shown in Figure 1, the end of the drill pipe 4 of the unearthed end 3 is connected to a back expander 1, and the back expander 1 is used to expand the borehole 6 from the unearthed end 7 to the soil-entry end 3. The back expander 1 is fixedly connected with the drill rod 4 by a threaded fastener only at one end of the traveling surface. As in the prior art construction method, both the drill pipe 4 and the back expander 1 are hollow, and the back expander 1 is provided with a plurality of mud holes 2. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com