Apparatus for directional boring under mixed conditions

a technology of mixed conditions and apparatus, applied in the direction of directional drilling, borehole/well accessories, surveying, etc., can solve the problem that the pushing force of the drill string alone is insufficient to steer the tool in soft ground without rotation, and achieve the effect of better steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]While making and using of various embodiments of the present invention are discussed in detail below, it should be appreciated that the present invention provides many applicable inventive concepts which can be embodied in a wide variety of specific contexts. The specific embodiments discussed herein are merely illustrative of specific ways to make and use the invention and are not to delimit the scope of the invention. References to a numbered element shown in several alternative forms designated A, B etc. without such a letter are intended to refer to all of the alternative forms.

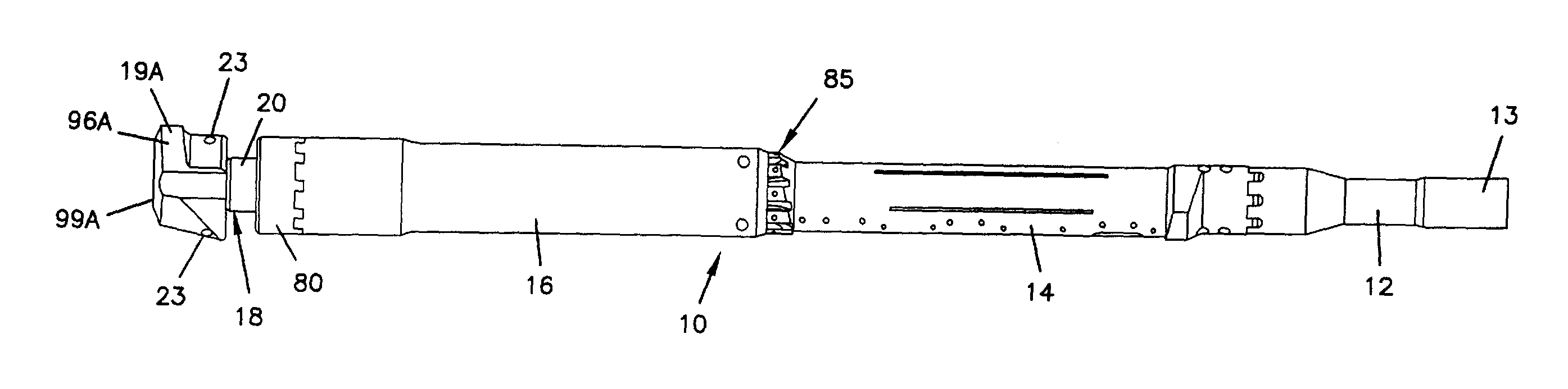

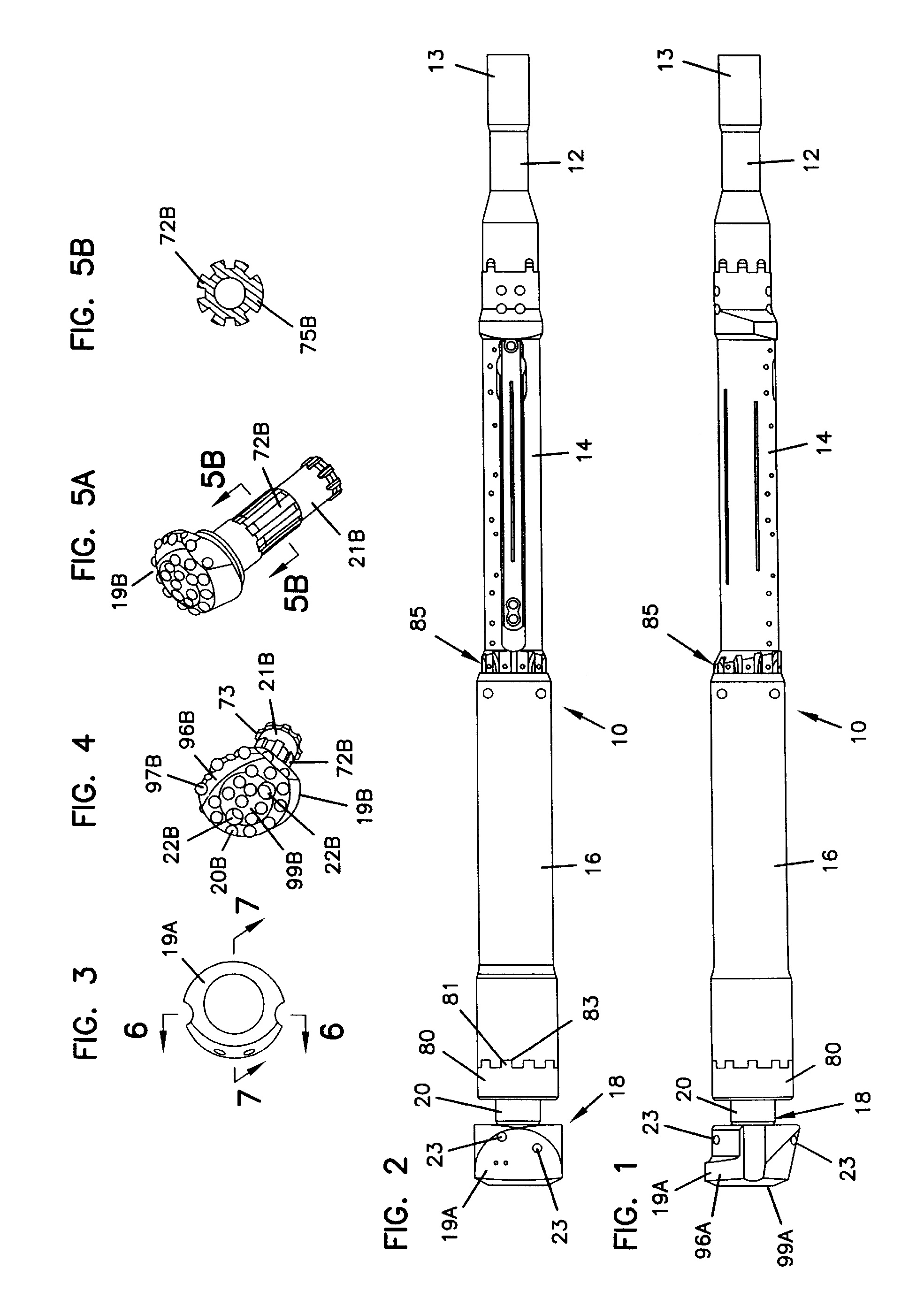

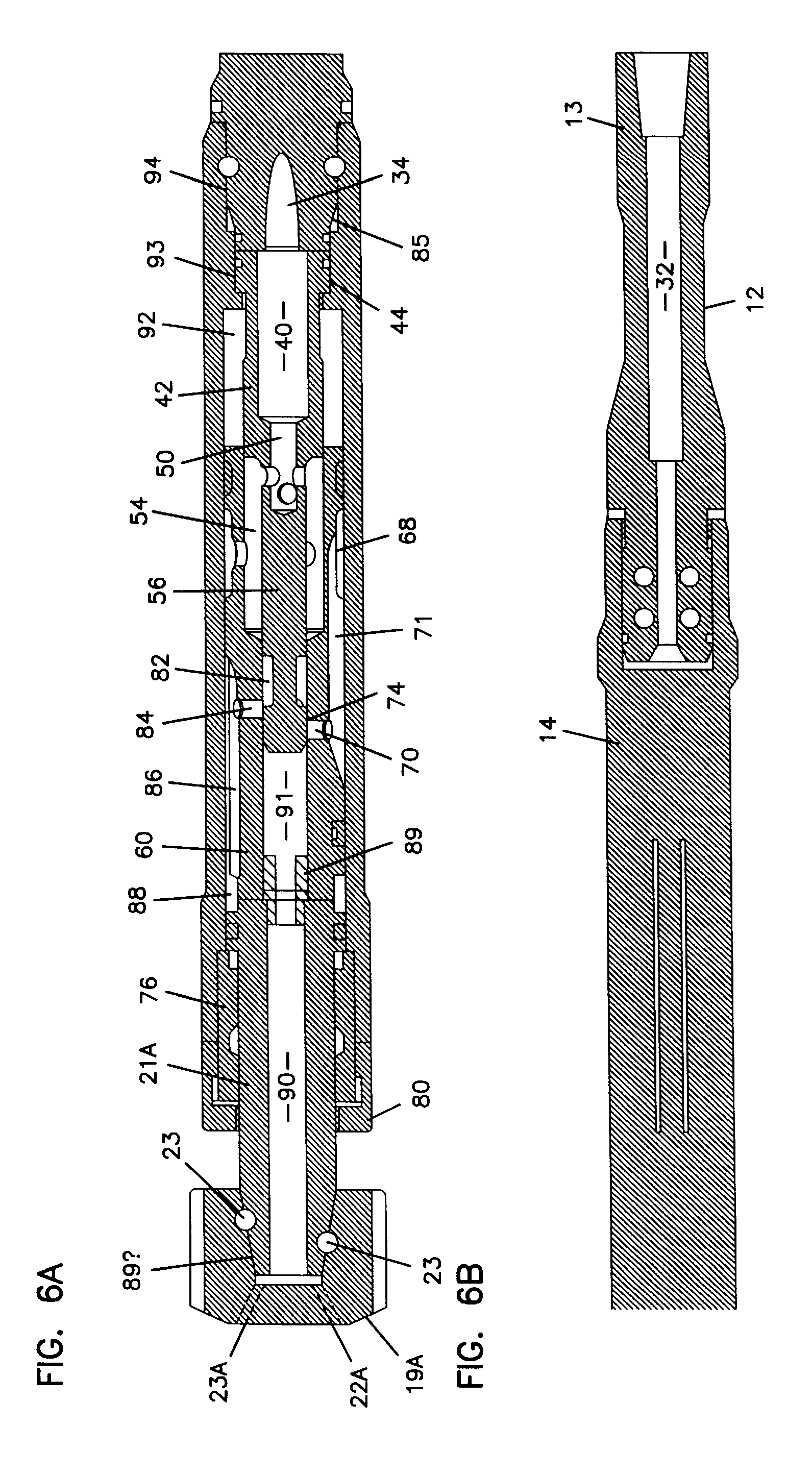

[0058]Referring to FIGS. 1-3, 6A-6B and 7A-B, a drill head 10 according to the invention includes, as general components, a sonde holder 14, pneumatic hammer 16 and bit assembly 18 connected head to tail as shown. As noted above, the drill head 10 can also include a starter rod 12. Starter rod 12 connects at its rear end 13 to a conventional drill string driven by a directional boring machine, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com