Novel underground coal gasification furnace

A technology of underground gasification and gasifier, which is applied in coal gasification, underground mining, construction and other directions to achieve the effect of solving drainage problems, short construction period and rapid drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

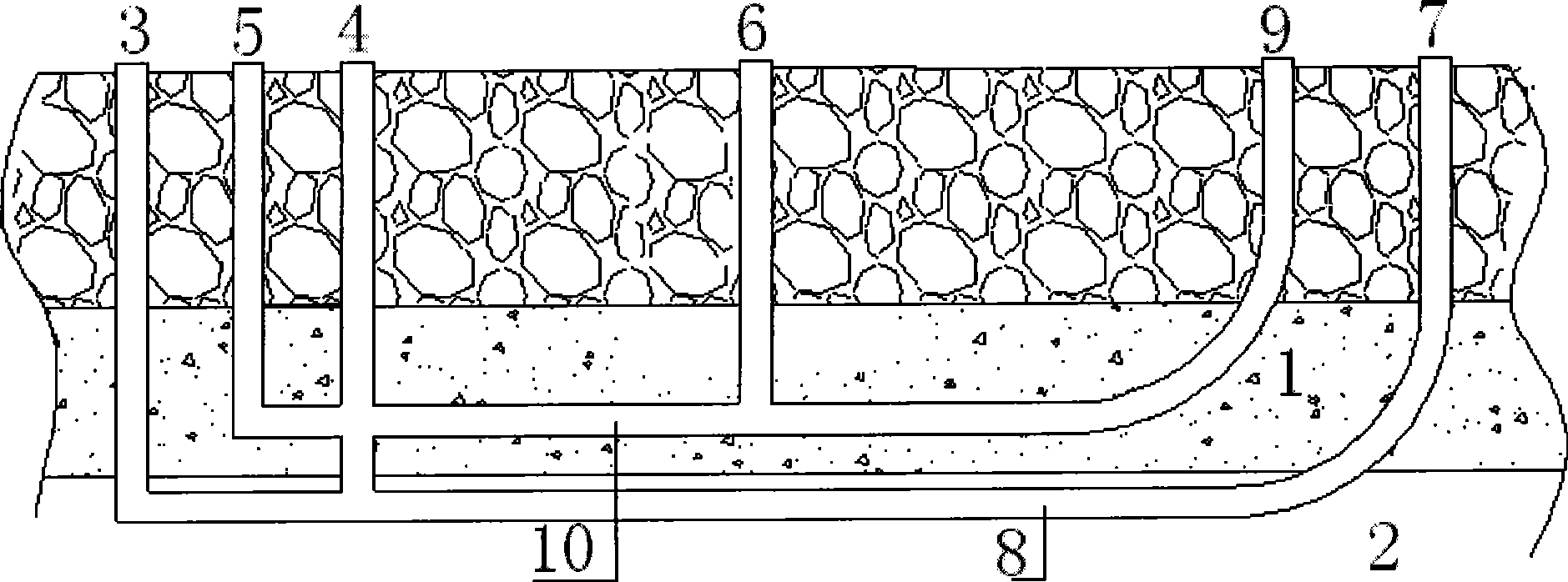

[0014] With reference to the diagram and according to the layout of the furnace type and the functions of each drilling hole, the construction and implementation process of the new type of underground coal gasification furnace is as follows:

[0015] 1. Construct vertical boreholes 3 and 4 to the bottom plate 2 of coal seam 1 at a certain distance from the ground (the diameter is determined according to actual needs, the same below), and the boreholes penetrate the bottom plate 2 about 1 to 2 meters;

[0016] 2. Choose a point between boreholes 3 and 4 (the distance from boreholes 3 and 4 depends on the ability of the directional drilling tool to find the target point and the pressure-bearing capacity of the borehole) as the position of the vertical borehole 5 to build a borehole toward the coal seam , And go deep to a distance of 0.5 to 1 meter from the coal seam floor;

[0017] 3. Choose a point on the straight line where boreholes 3 and 4 on the ground are located to construct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com