Process method for directional drilling, punching and tunneling protection of coal mine high-level roadway

A technology of directional drilling and process method, which is applied in directional drilling, drilling equipment and method, drilling equipment, etc., can solve the problems of difficult treatment, low drainage concentration, long construction period, etc., and achieve scientific and reasonable process method, The effect of high extraction efficiency and high extraction concentration

Inactive Publication Date: 2019-01-22

HENAN TIEFULAI EQUIP MFG CO LTD

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the difficult problem of underground gas control, many gas control technologies have emerged at present, such as floor rock roadway through-bed drilling and coal seam drilling. Although the immediate problem has been solved, the effect is not ideal. The cost of drilling is high, the construction period is long, the amount of work is large, the concentration of drainage is low, the effect of pre-drainage is not ideal, the rate of drilling holes along the bedding is low, and the drainage effect is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

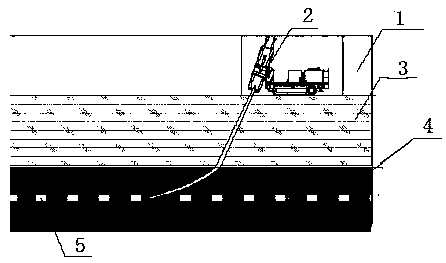

Login to View More Abstract

The invention discloses a process method for directional drilling, punching and tunneling protection of a coal mine high-level roadway. The process method includes the following steps that S1, construction is carried out by a downward drilling machine to achieve directional horizontal drilling and punching, and drilling is carried out downward from the high-level rock roadway into a coal rock combination part; S2, when drilling is carried out on the combined part between rock and a coal layer, oblique drilling is controlled to be conducted on a coal rock segment by means of a drilling identification technology and the like; S3, after drilling is carried out in the middle of the coal layer, horizontal drilling is carried out by 80-130 meters; S4, according to specific situations or conditions, a forward punching mode or a backward punching mode is adopted for drilling in the middle of the coal layer, wherein the punching length is 1-5 meters, and the punching spacing is 8-10 meters; S5,construction from step S1 to step S4 serves as a loop, cyclic lap joint is completed by repeating steps S1, S2, S3 and S4, a whole gas control area is controlled, and the purposes of covering the tunneled roadway and removing a bottom drainage roadway are achieved. By obliquely drilling and punching the high-level roadway downward, gas control and gas extraction are achieved, gas can be effectively controlled, the extraction efficiency and concentration are high, and the cost is low.

Description

technical field The invention relates to the technical field of coal mines, in particular to a process method for directional drilling of high-level roadways in coal mines to create holes and cover excavations. Background technique Underground coal and rock gas control is the biggest problem in coal mines. Most coal seams in my country have poor air permeability, high gas content, high gas pressure, and great outburst risks. Poor drillability, accidents such as injection holes, top drilling, and drilling are prone to occur during the drilling construction process, poor stability after the drilling is formed, and hole wall collapse and blockage are prone to occur, low gas drainage efficiency, poor drainage effect, gas Governance is difficult. For a long time, due to the low permeability of soft coal seams and poor drilling stability, it is difficult to control gas in soft and high gas coal seams, and the fatality rate of coal mine gas accidents remains high. Therefore, soft ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21F7/00E21B7/04

CPCE21B7/04E21B7/046E21F7/00

Inventor 武国胜张志晶李伟伟胡金星

Owner HENAN TIEFULAI EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com