Fully mechanized mining goaf grouting method based on clustered arrangement multilateral well directional drilling

A multi-branch and goaf technology, which is applied in the direction of earthwork drilling, mining equipment, filling, etc., can solve the problems of pipe fixing work, large material consumption, difficulty in vertical drilling and relocation, and increase in project cost. Avoiding areas that are difficult to drill, reducing the amount of drilling work and reducing the cost of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

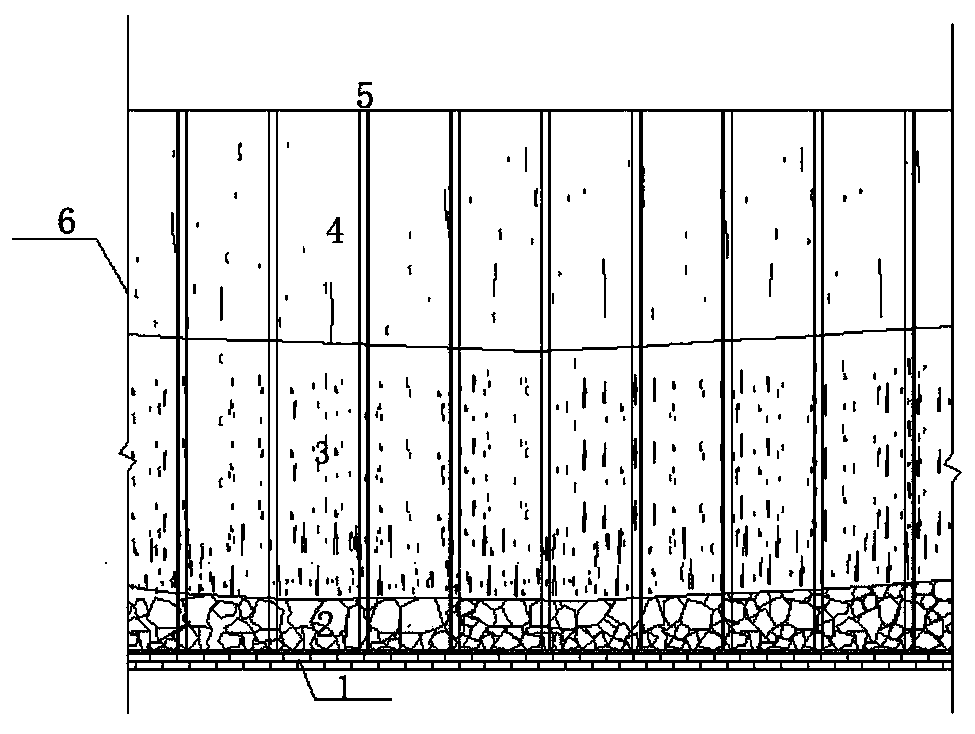

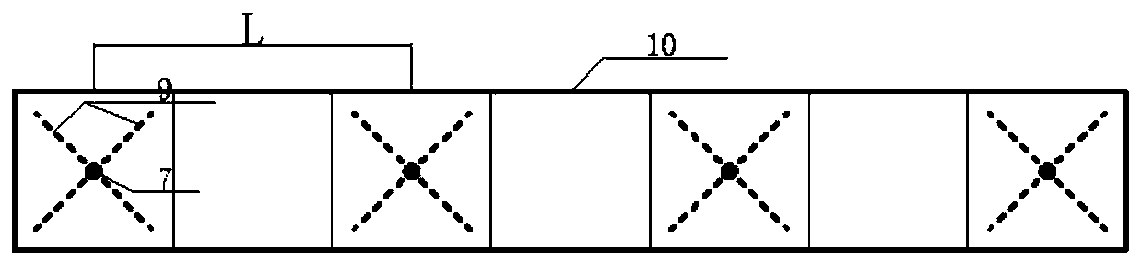

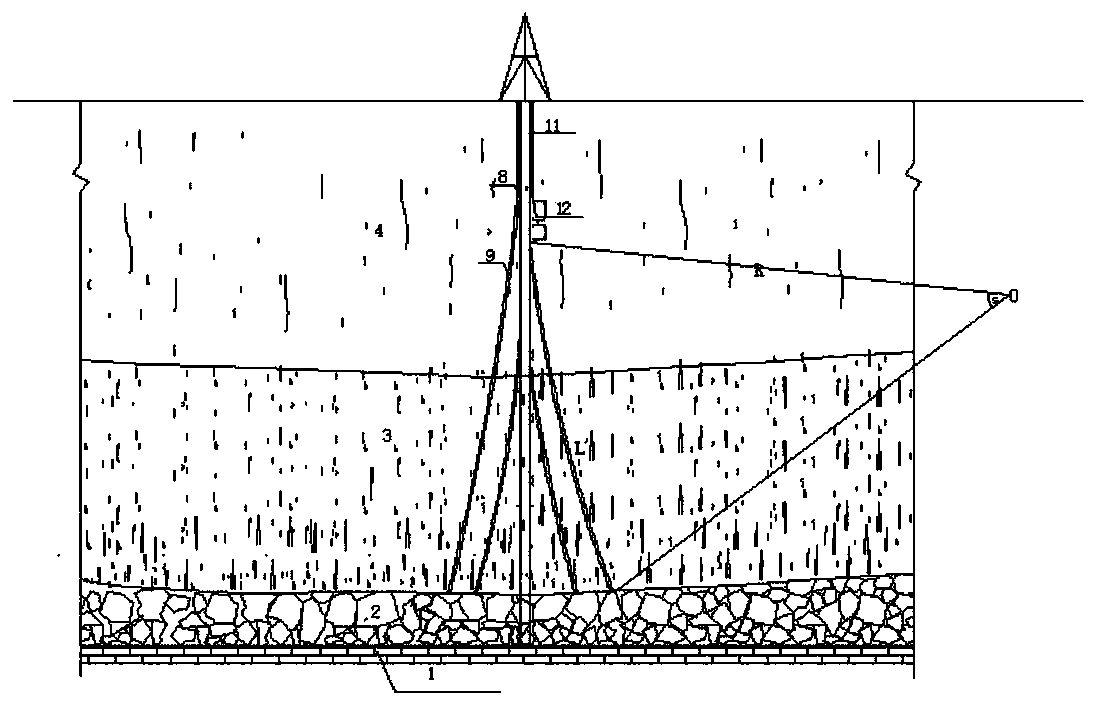

[0022] see figure 2 and 3 , shows the method for grouting in fully mechanized gobs based on the directional drilling of cluster multi-branch wells of the present invention.

[0023] The fully-mechanized goaf grouting method based on the directional drilling of cluster multi-branch wells is also aimed at the fully-mechanized goaf as figure 1 As shown, it is applied to the fully-mechanized goaf with a buried depth of more than 400m, and the fully-mechanized goaf is successively composed of a caving zone 2, a fissure zone 3, and a curved subsidence zone 4 on the coal seam floor 1 within the control area boundary 6 , there are a large number of rockfalls of different sizes in the caving zone 2, and the caving zone carries a fissure zone 3 and a curved subsidence zone 4. In order to realize smooth grouting in the fully mechanized goaf, the pioneering The construction of cluster-type multi-branch well directional drilling is applied. Specifically, the gob grouting method includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com