Hollow cable type directed water conveying device

A central cable and water feeder technology, applied in directional drilling, measurement, borehole/well components, etc., can solve the problem of inability to transmit the measurement signal at the bottom of the hole, and achieve the effect of safe and reliable wired measurement while drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

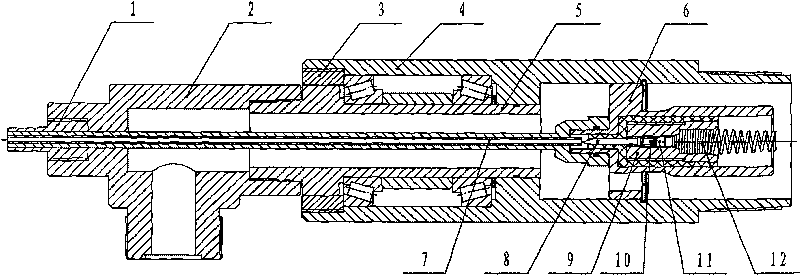

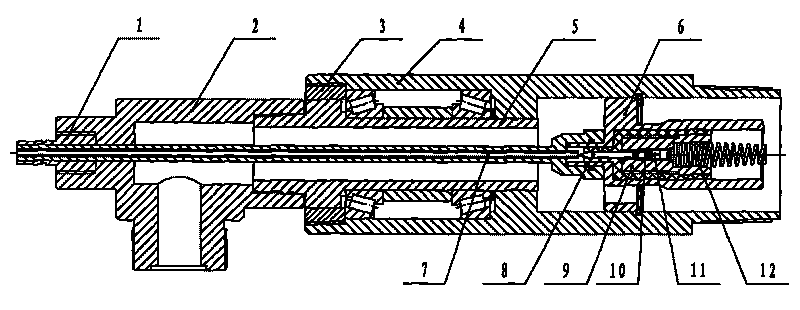

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] see figure 1 , the present invention includes a joint 2, a retaining ring 3, an outer tube 4, a shaft 5, a sheath 6, a central cable device, and the central cable device includes a wire 7, a probe 8, a probe 9, a spring 10, a set screw 11 and The variable diameter spring 12, the joint 2 and the outer pipe 4 are connected by the shaft 5, the retaining ring 3 is arranged between the outer pipe 4 and the shaft 5, and the sheath 6 is arranged at one end of the outer pipe 4 to form a directional water feeder, and the central cable device is arranged on Orientate the inner cavity of the water feeder. The probe 8 is fixed inside the probe 9 by a spring 10 and a set screw 11. The spring 10 has a certain amount of pre-compression. It will automatically compensate to ensure that the probe 8 is kept in contact with the wire 7, and the wire 7, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com