Directional drilling and rock splitting chamber forming method

A technology of directional drilling and drilling device, which is applied in the field of drilling and directional drilling and rock splitting, which can solve the problems of waste of resources, tree disturbance, short life of cutting tools and seals, etc., and achieve simple construction process and high efficiency. Economic benefits and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

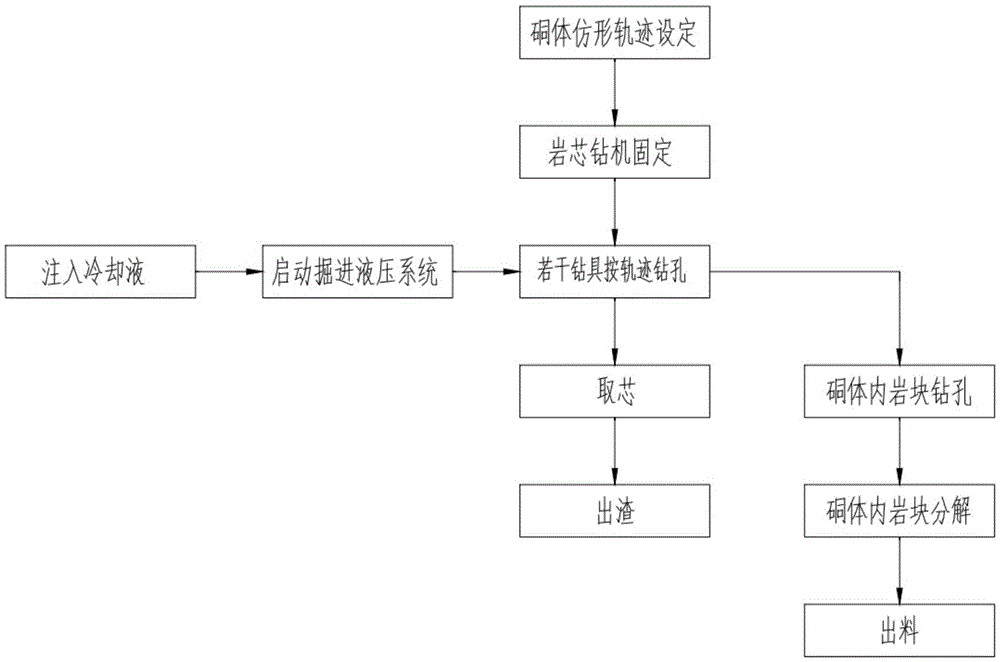

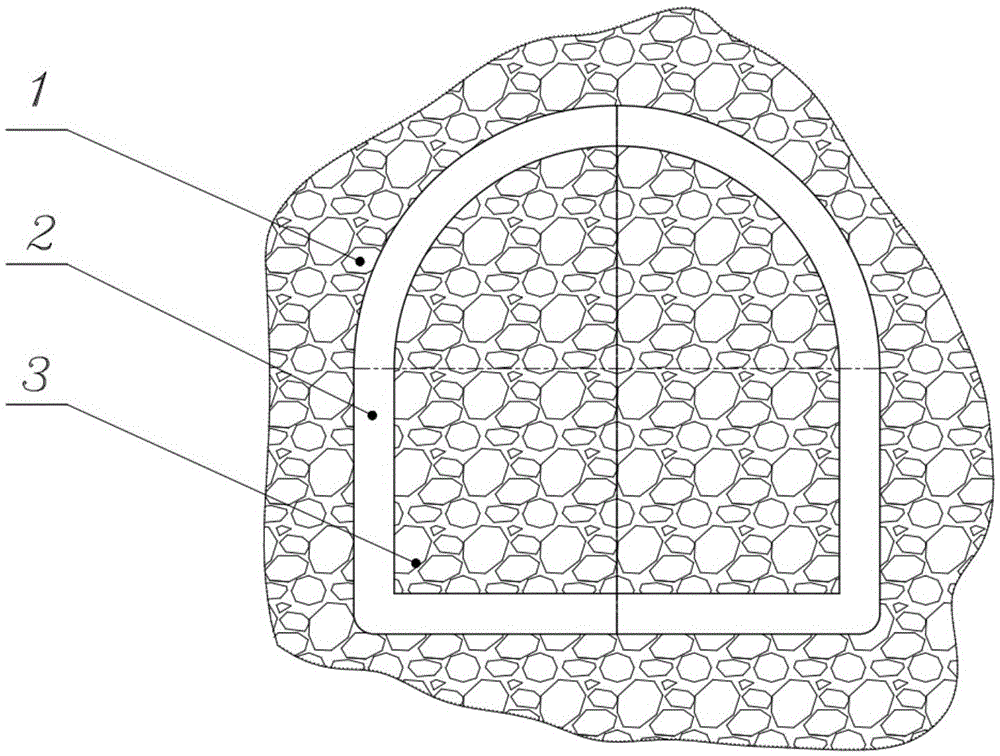

[0032] In this embodiment, the construction flow chart of the method of directional drilling and splitting rock is as follows: figure 1 As shown, the directional drilling rock-splitting method consists of setting the trajectory of the tunnel body, fixing the core drilling rig, injecting coolant, starting the drilling rig, drilling with several core drilling tools according to the set trajectory, and taking cores to form a core circle. , Drilling of rock blocks in the cave, decomposition of rock blocks in the cave, discharging, slag discharging and other steps. Firstly, according to the requirements of the design plan, the profiling trajectory of the required cave body is adjusted, and the working surface is divided into three parts: bedrock, core ring and cave body to meet the design requirements. Proceed as follows: first step, design the profiling trajectory of the chamber, set the width of the chamber as D, the horizontal height of the chamber as B, the diameter of the dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com