Integral type directional drill rod provided with helical groove

An integral, helical groove technology, applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of poor torsion resistance, bending resistance and tensile strength of drill pipes, increased drilling costs, and prone to rod breakage, etc. Achieve the effect of reducing drilling cost, improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

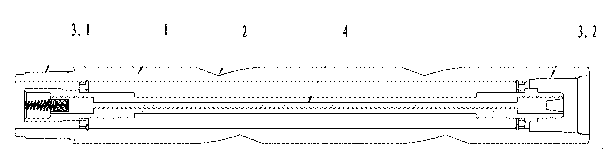

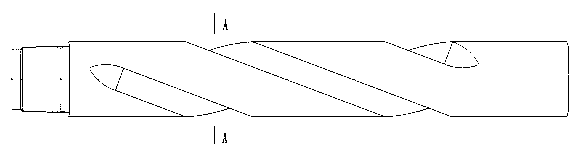

[0015] For ease of description, the integrated spiral groove directional drill rod of the invention will be described in detail below in conjunction with the accompanying drawings.

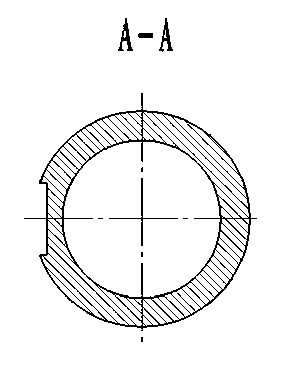

[0016] Such as figure 1 , 2 As shown, the integrated helical groove directional drill pipe includes a drill pipe body 1 and a central cable device 4 arranged at the inner axis of the drill pipe body 1. The ring is fixed at the axis position in the drill pipe body 1, and is used to transmit the signal at the bottom of the hole. The quick-connect joints provided at both ends of the drill pipe body 1 are respectively a male joint 3.1 and a female joint 3.2, and the male joint 3.1 is provided with external threads. The female joint 3.2 is provided with an internal thread for quick docking between two drill pipes, and the thread has a certain bending, torsion and tensile strength.

[0017] The outer wall of the drill pipe body 1 is provided with a helical groove 2. When the drill pipe needs to be rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com