Patents

Literature

109 results about "Steel casing pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel casing pipe, also known as encasement pipe, is most commonly used in underground construction to protect utility lines of various types from getting damaged. Such damage might occur due to the elements of nature or human activity.

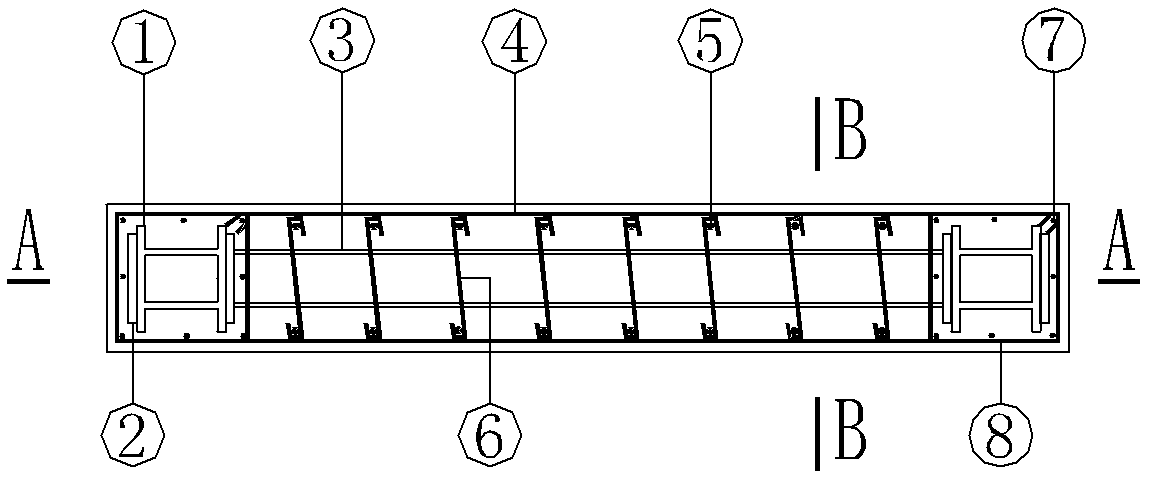

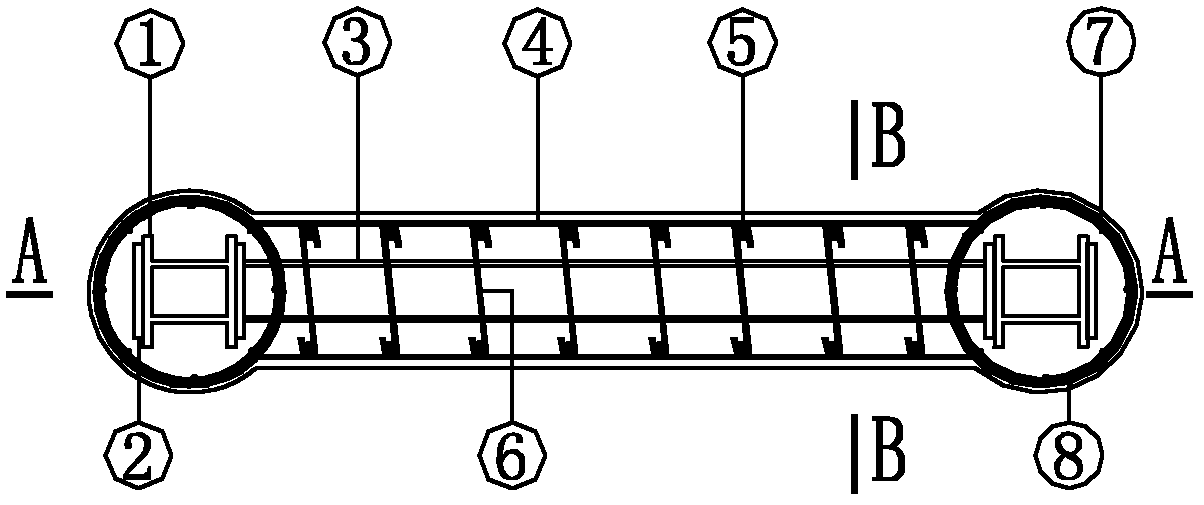

Bottom double composite section steel shear wall with reinforced concrete frame and inside-hidden steel plate as well as manufacturing method

InactiveCN102409783AImprove seismic performanceImprove performanceStrutsWallsReinforced concrete columnUltrasound attenuation

The invention relates to a bottom double composite section steel shear wall with a reinforced concrete frame and an inside-hidden steel plate as well as a manufacturing method. The shear wall comprises a steel reinforced concrete composite frame column, a mild steel energy-consuming steel plate and a shear wall steel plate, which is a double composite column comprising the composite of the externally-adhered mild steel energy-consuming steel plate and a concrete filled steel tube column and the composite of the concrete filled steel tube and a reinforced concrete column and is a multiple combination body comprising the combination of a reinforcing bar and concrete, the combination of a steel plate and the concrete and the combination of a steel reinforced concrete frame column and a steel plate shear wall. Compared with a conventional shear wall, the shear wall provided by the invention has the advantages of high initial stiffness, high bearing capacity, slow bearing capacity and stiffness attenuation, good whole anti-seismic energy-consuming performance and relatively stable later-stage anti-seismic performance; the bottom shear-slip damage is little; and after a mild steel casing pipe is added, the outer mild steel casing pipe is firstly surrendered so as to consume the energy in the structure input by earthquake and can give play to the effects of resistance and ductility till being destroyed, therefore, the premature damage and destroy of the high-strength steel plate can be prevented and delayed.

Owner:BEIJING UNIV OF TECH

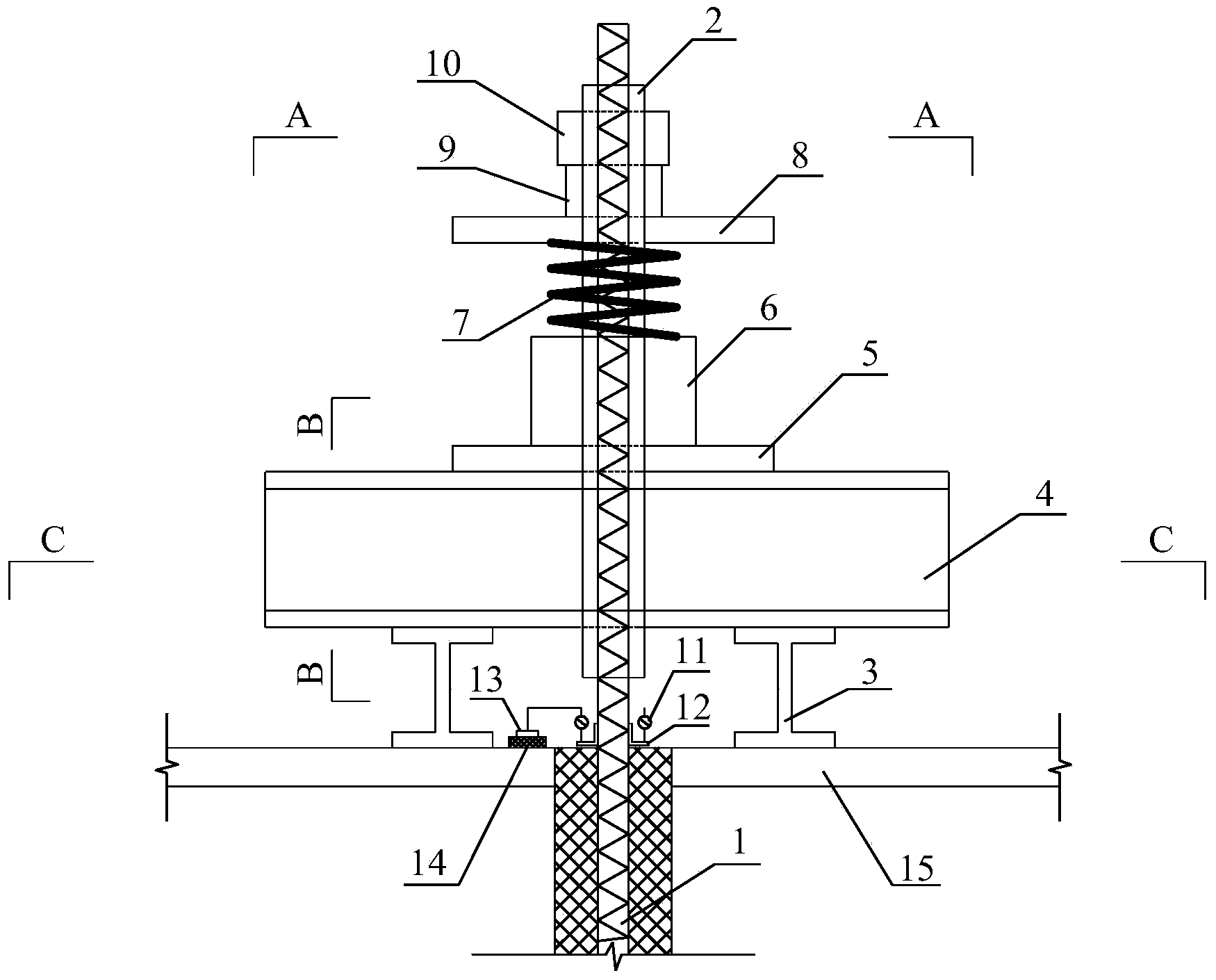

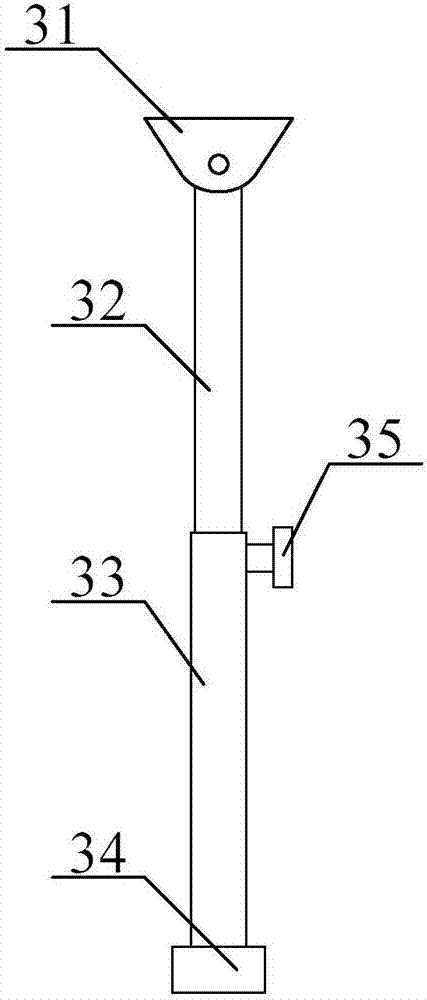

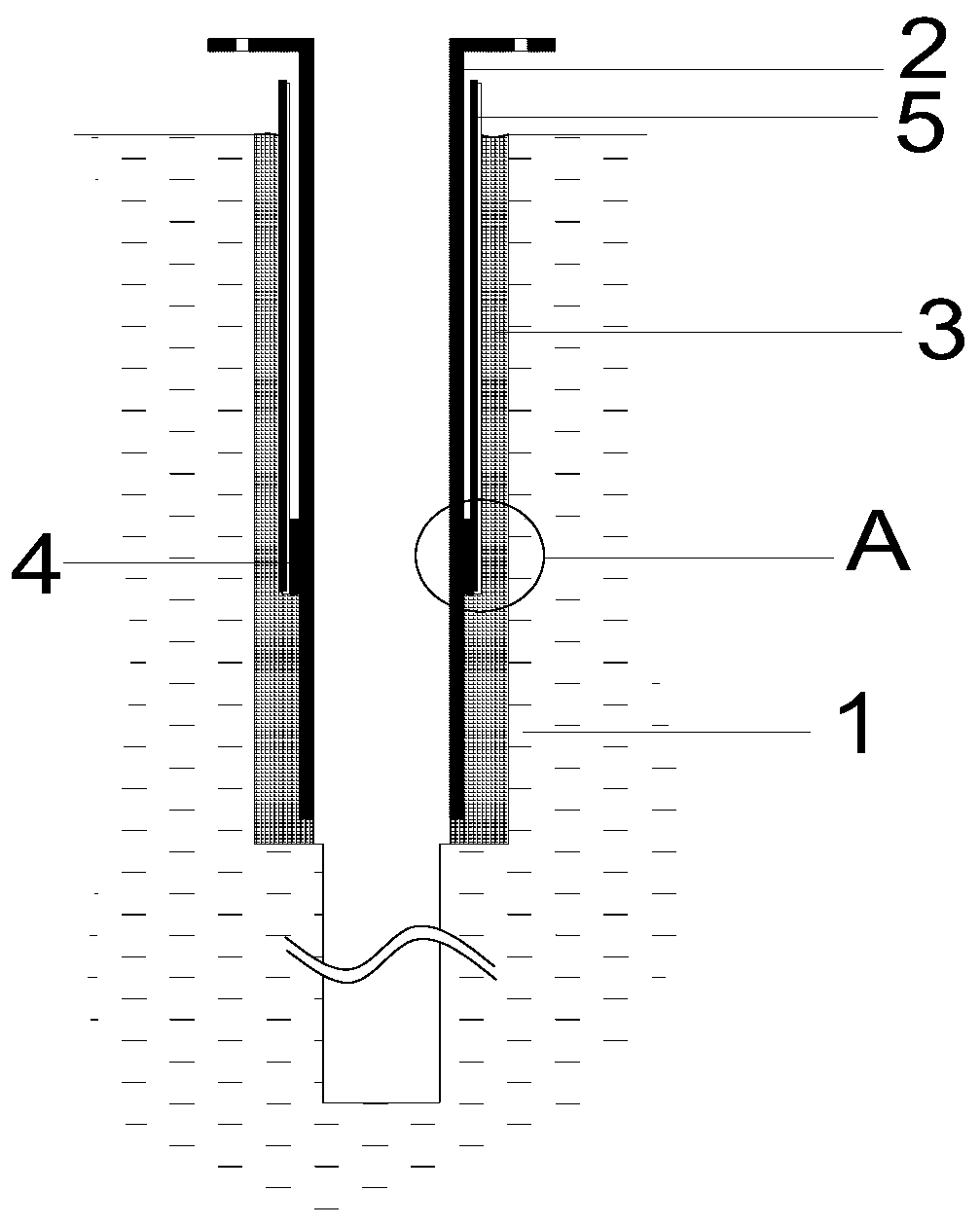

Creep test loading device for non-metal anti-floating anchor

The invention belongs to the technical field of in-situ test equipment and relates to a creep test loading device for a non-metal anti-floating anchor. An anchor body is of a solid rod-shaped structure and is bonded with a steel casing pipe. H-shaped steel is perpendicular to a concrete cushion layer and is symmetrically arranged on the two sides of the anchor body. A counterforce beam is a box-type section formed by welding two pieces of H-shaped steel. The counterforce beam is provided with a steel base plate. The steel base plate, a penetrating jack, a spring, a steel plate, an anchor cable axial force meter and an anchorage device are stacked on the counterforce beam and arranged outside the steel casing pipe in a sleeved mode. The anchorage device is welded to the outside of the steel casing pipe. A dial indicator is arranged on L-shaped organic glass in an erecting mode. The L-shaped organic glass is arranged on the interface of the concrete cushion layer and the anchor body. A magnetic indicator base of the dial indicator is arranged on a standard beam arranged on a concrete buttress. The concrete buttress is arranged on the concrete cushion layer. The creep test loading device is simple in overall structure, convenient to install, high in testing precision and high in operability.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

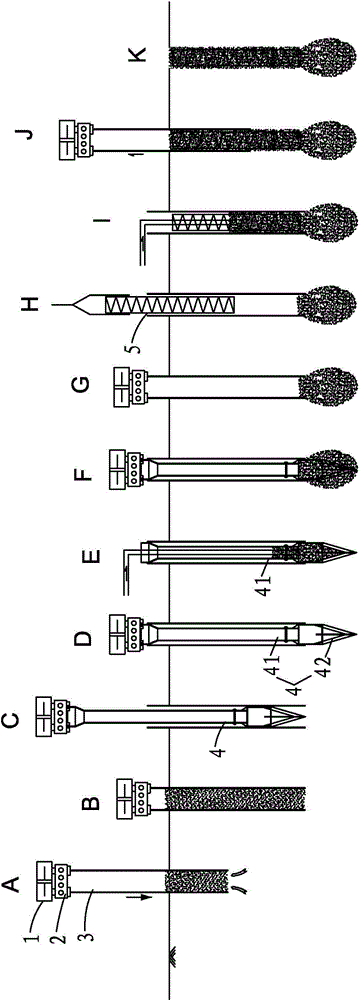

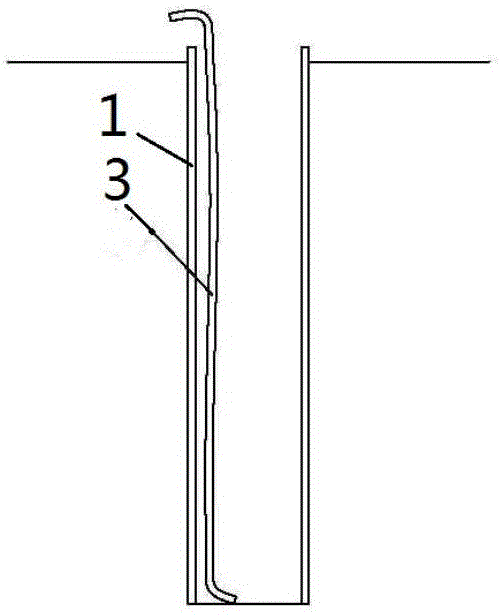

Full casing pipe soil taking vibration construction method for squeezed and expanded cast-in-place pile

InactiveCN104631442AReduce dosageImprove vertical bearing capacityDrill bitsBulkheads/pilesEngineeringVertical load

A full casing pipe soil taking vibration construction method for a squeezed and expanded cast-in-place pile includes the steps that a steel casing pipe is sunk to the design elevation by a high-frequency vibration hammer through a clamper; soil is taken mechanically or manually; a special hole expander is put in the pipe for vibration hole expansion; concrete is poured into the special hole expander, and vibration hole expansion and concrete pouring are repeatedly performed; a steel reinforcement cage is lifted and put, and concrete is poured into the steel reinforcement cage; the steel casing pipe is pulled out in a vibrating mode to form the squeezed and expanded cast-in-place pile. As the fill concrete is poured while the special hole expander is used for vibration squeezing and expanding, foundation soil of the bottom expanding part can be more compact, a formed expanding head can substantially increase the end resistance of the pile, and the vertical bearing capacity of the pile is improved substantially; when the same vertical load is borne by a single pile, the needed pile length is small, the usage amount of the concrete is small, and the foundation project cost can be substantially reduced.

Owner:FUJIAN UNIV OF TECH

Method for correcting deviation of building in miniature pile hole earth taking manner

ActiveCN105178368AAvoid the shortcomings of excessive water rectification and easy loss of controlLow costFoundation engineeringSteel casing pipeCement mortar

The invention discloses a method for correcting the deviation of a building in a miniature pile hole earth taking manner. The method includes the following steps that firstly, a miniature pile hole is drilled in the upper portion of the seriously-settled side of a building foundation; secondly, a steel reinforcement cage or a steel pipe is suspended in the drilled hole and the hole is filled with cement mortar; thirdly, a miniature pile hole is drilled in the upper portion of the slightly-settled side of the building foundation and meanwhile the wall is protected through a steel casing pipe; when a soft soil layer is drilled, the steel casing pipe enters the top of the soft soil layer to take soil, and therefore surrounding soft soil collapses towards the drilled hole; fourthly, in the soil taking forced settlement process of the third step, the settlement change of the whole building is observed, and when the forced settlement side of the foundation is settled to the elevation close to that of the sealed portion of the foundation, the hole is continuously drilled to a hard soil layer; and fifthly, a steel reinforcement cage or a steel pipe is suspended in the drilled hole, the hole is filled with cement mortar and then sealed, and the forced settlement process of the side is stopped. The characteristic that continuous settlement can be stopped by sealing the upper end of a miniature pile is used for guaranteeing that the deviation correcting process is accurate and easy to control.

Owner:SHANDONG JIANZHU UNIV

Steel-pipe-insertion local strengthening trenchless repair method for drainage pipeline with large pipe diameter

InactiveCN102032416AEasy constructionRepair material savingsPipe elementsEngineeringSteel casing pipe

Aiming at the problem existing in the current method for repairing a mountain city pipeline and the inadaptability of a method for repairing a drainage pipeline with large pipe diameter, the invention provides a steel-pipe-insertion local strengthening trenchless repair method for a drainage pipeline with large pipe diameter. In the method, one steel pipe is inserted into a pipeline to be repaired at a distance, and the upper side of the middle of a steel casing pipe is additionally provided with a crescent rib to improve the strength. When used by matching with a coating repair method, the method can be used for non-structural repair of the pipeline and can also be used for structural repair of the pipeline. The method is more convenient for construction without large-scale construction equipment, materials are saved, and the repair price is cheep. The method is suitable for repairing the pipeline with a pipe diameter of more than 800mm.

Owner:CHONGQING UNIV +1

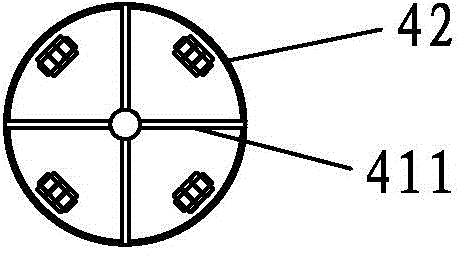

Clasping device for fitting up steel pipe sleeve and construction method thereof

InactiveCN102320519AWon't breakEasy to useAssembly machinesLoad-engaging elementsEngineeringSteel casing pipe

The invention discloses a clasping device for fitting up a steel pipe sleeve, which comprises internal pipe clasps and external pipe clasps, wherein the internal pipe clasps are fixed through a fastening bolt I and the external pipe clasps are fixed through a fastening bolt II; the internal pipe clasps are provided with two symmetrical hosting holes I; the external pipe clasps are provided with two symmetrical hosting holes II; and lifting devices are arranged on the hosting holes I and the hosting holes II. The clasping device has a simple structure and is convenient to use; and internal pipes of the steel pipe sleeve can be arranged in an external sleeve sequentially through the lifting devices so that less machines are needed in the construction, the internal pipes are pulled into the external sleeve at a uniform speed, the stress direction of the internal pipes is consistent to the central line of a pipeline, and supports on the internal pipes cannot be damaged.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

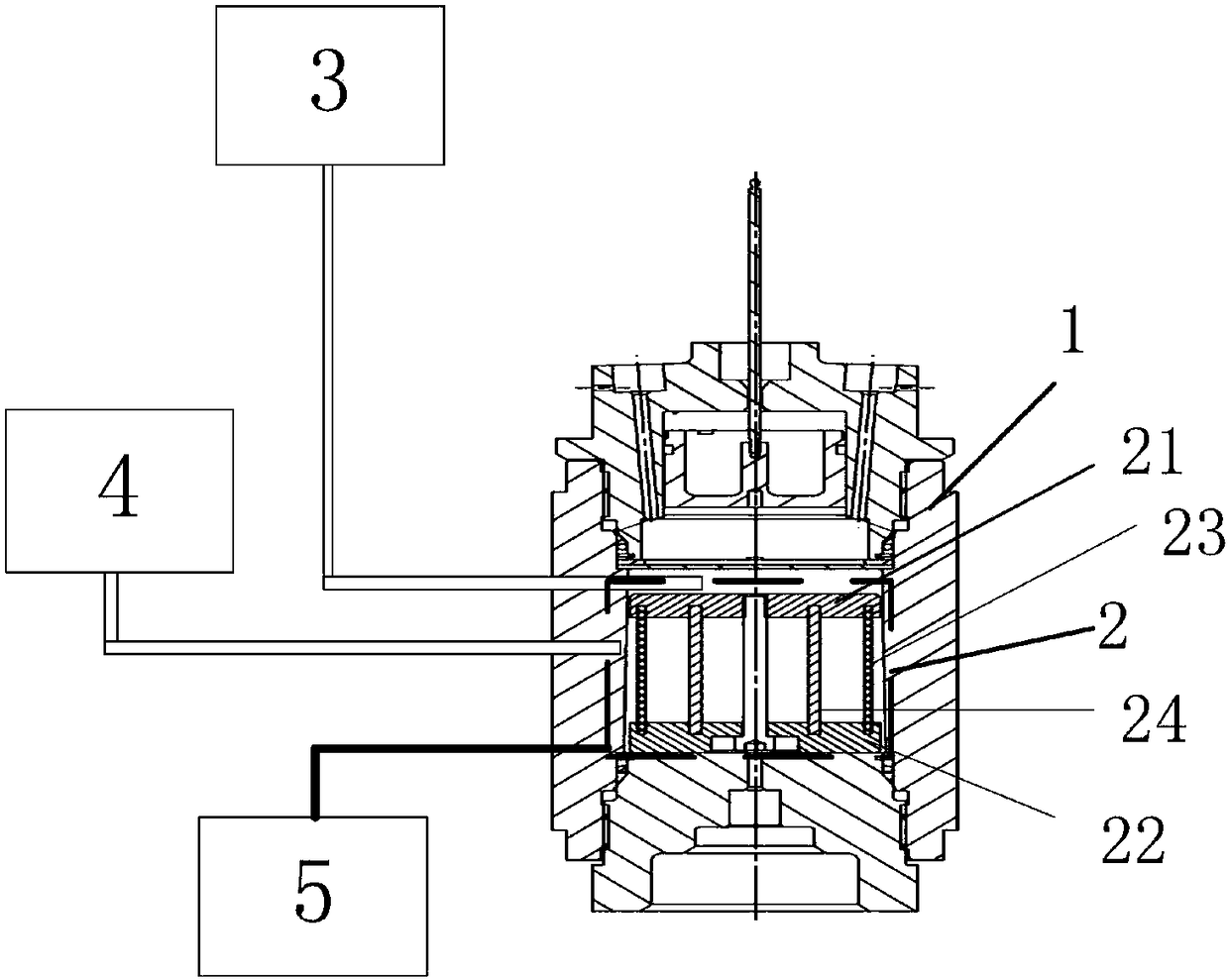

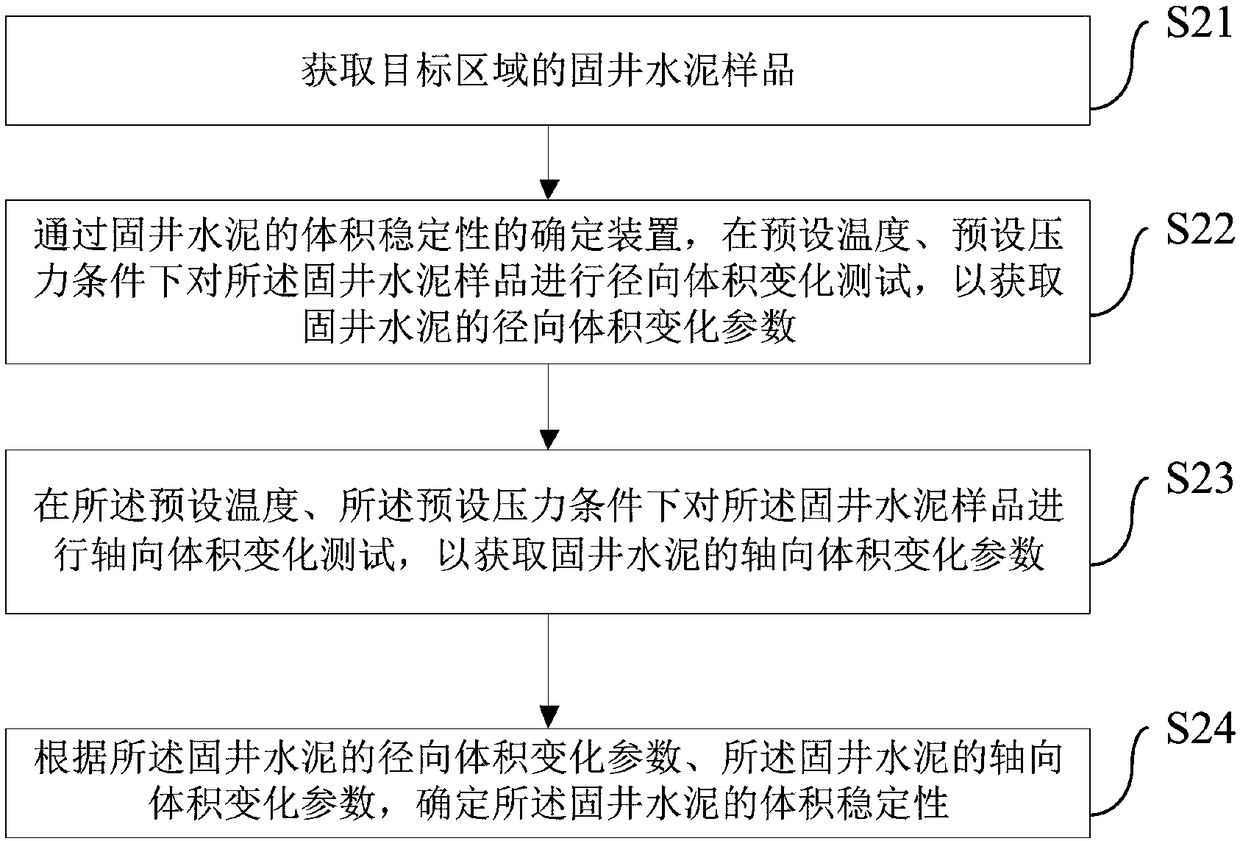

Determination device and method for volume stability of well cementing cement

ActiveCN108533209AAccurate volume stabilityFix stability issuesConstructionsMaterial strength using tensile/compressive forcesVolume variationWell cementing

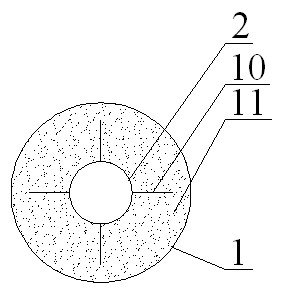

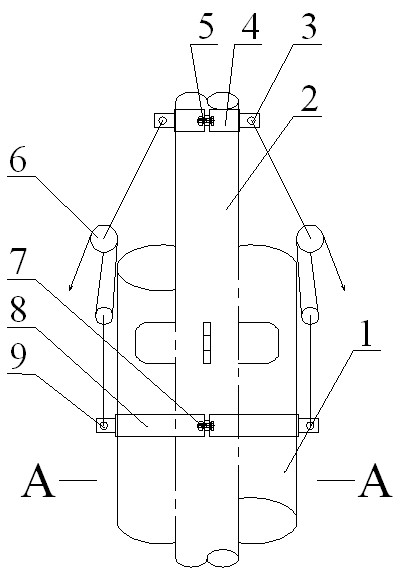

The embodiment of the invention provides a determination device and method for the volume stability of well cementing cement. The determination device comprises a reaction kettle, a radial shrinkage expansion ring, a heater, a pressurizer and a volume change parameter tester; the radial shrinkage expansion ring comprises a first casing pipe and a second casing pipe, an elastic material casing pipeserves as the first casing pipe, a steel casing pipe serves as the second casing pipe, and an annulus between the first casing pipe and the second casing pipe is used for containing well cementing cement samples; the heater and the pressurizer are used for providing the preset temperature and the preset pressure correspondingly; and the volume change parameter tester is used for detecting the radial volume change parameter of the well cementing cement. According to the determination device and method, the radial shrinkage expansion ring is arranged to obtain the radial volume change parameterof the well cementing cement, then the radial volume change parameter of the well cementing cement is utilized to comprehensively evaluate the volume stability of the well cementing cement, and thusthe technical problem that in an existing method, determination of the volume stability of the well cementing cement is incomplete and poor in accuracy is solved.

Owner:PETROCHINA CO LTD

Jacking pipe construction method for trimming deviation by reverse jacking of steel pipe casing

ActiveCN111609212AAvoid destructionReduce construction costsPipe laying and repairPipe elementsArchitectural engineeringSteel casing pipe

The invention relates to a jacking pipe construction method for trimming deviation by reverse jacking of a steel pipe casing. A construction person can clean soil in a steel casing pipe from one sideof a receiving well and enters the steel casing pipe for dismounting a machine head and dismounting a deviated concrete pipe, through the steel casing pipe, the constructor is protected, when the machine head and the concrete pipe are dismounted, the danger caused by collapse of the construction position is not prone to happening, a new concrete pipe is jacked from the receiving well to be connected with an original concrete pipe in a seam abut joint manner, according to an existing axis precision, burying is continuously carried out until the concrete pipe extends out of the receiving well, the position between the steel casing pipe and the concrete pipe is filled with the concrete, the concrete pipe is supported, construction of the last segment of jacking pipe close to the receiving well is finished, a jacking pipe system is adopted in the construction method for finishing pipeline deviation rectifying, the damage to the environment due to the fact that traditional jacking pipe deviation rectifying construction adopts a method of ground excavating for deviation rectifying can be avoided, construction cost of earth excavation and site recovering can be saved, construction operation is easy, the process saves time, and the method is efficient and safe.

Owner:GUANGDONG DACHENG CONSTR GRP

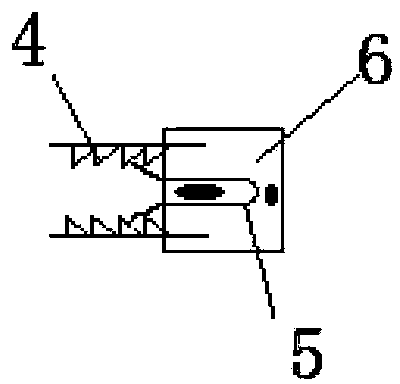

Angle-adjustable steel structural connecting piece

ActiveCN106759886AReduce weightImprove versatilityBuilding constructionsPhotovoltaic energy generationSheet steelSelf locking

The invention discloses an angle-adjustable steel structural connecting piece. The angle-adjustable steel structural connecting piece comprises a steel pipe, a steel connecting plate and a steel plate sleeve, wherein the steel connecting plate is connected with the steel pipe, and the steel connecting plate sleeve is installed in the steel connecting plate in a sleeving mode; a self-locking threaded rod capable of adjusting the height and pushing a steel plate casing pipe to rotate through height changing is connected to the steel plate casing pipe through a top rod, one end of the self-locking threaded rod is installed on the steel pipe, and angle-changing screw holes are fixedly formed in the steel connecting plate; and horizontal spring bolts, which rotates along the steel casing pipe and are capable of being fastened to the angle-changing screw holes, with different angles are installed on the steel plate casing pipe. Through height changing of a self-locking bolt, the top rod is driven by the angle-adjustable steel structural connecting piece to push the steel plate sleeve for rotating, so that the horizontal spring bolts with different angles are fastened to hole sits of the angle-changing screw holes with different angles, and thus the steel pipe sleeve is accurately fixed to the steel connecting plate; due to the fact that the small angle-adjustable steel structural connecting piece is small in mass, through implementation installation of the angle-adjustable steel structural connecting piece, a hoisting technique is simplified, installation efficiency is improved, and construction difficulty is relieved.

Owner:江门市堡城科技有限公司

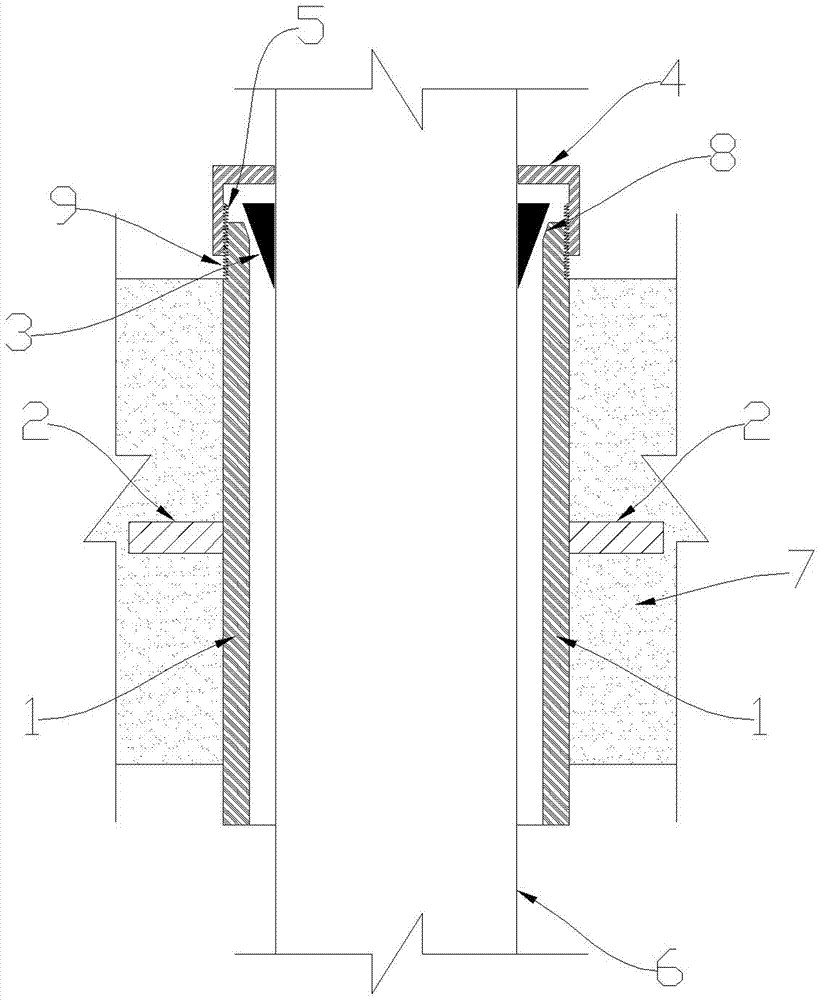

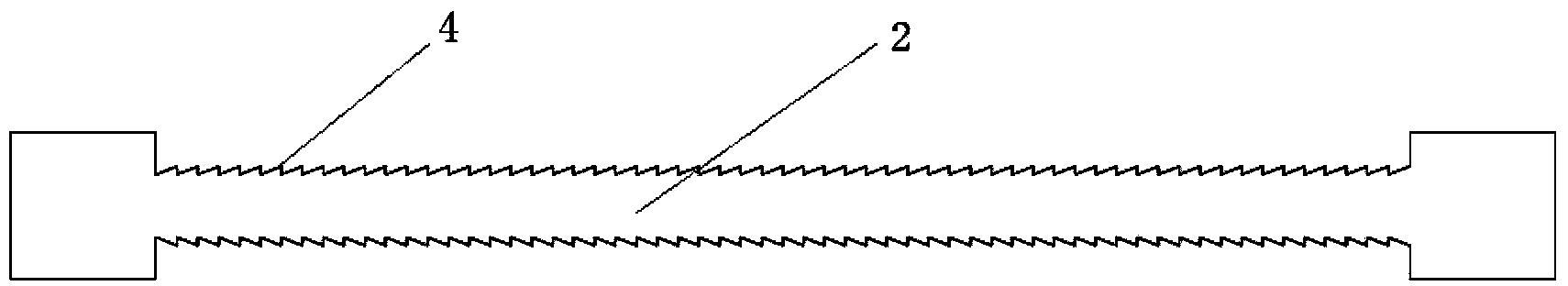

Self-waterproof casing pipe convenient to install

The invention relates to a self-waterproof casing pipe convenient to install. The self-waterproof pipe convenient to install is mainly used for waterproof use of pipelines penetrating water pool walls in the field of building engineering and can also be used for waterproof use of pipelines penetrating roofs or building surfaces or wall surfaces. The self-waterproof casing pipe convenient to install is mainly composed of a steel casing pipe, a steel water stop ring, a waterproof rubber ring and a waterproof cover. According to the main work principle and the installation method, when concrete is poured to the wall of a water pool, the steel casing pipe and the steel water stop ring are embedded in concrete, when the concrete reaches certain strength, the pipeline needed for penetrating penetrates the steel casing pipe, then the waterproof rubber ring is arranged on the pipeline in a sleeving manner from top to bottom, the conical face of the waterproof rubber ring is tightly attached to the oblique face of the steel casing pipe, then the pipeline penetrates a hole in the waterproof cover from top to bottom, the waterproof cover is screwed, the upper surface of the waterproof rubber ring is pressed step by step through the waterproof cover, the waterproof rubber ring moves downwards step by step, the conical face of the waterproof rubber ring and the oblique face of the steel casing pipe are pressed tightly, and installation work is finished.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

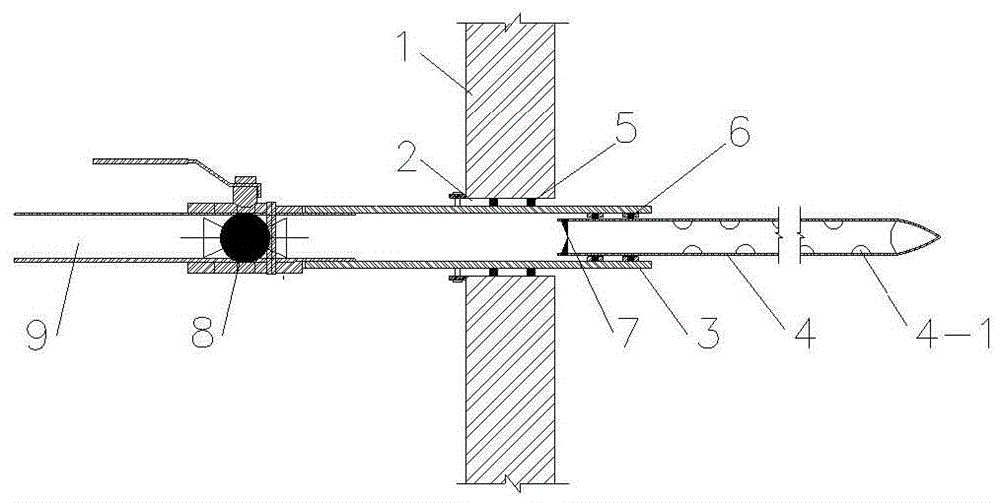

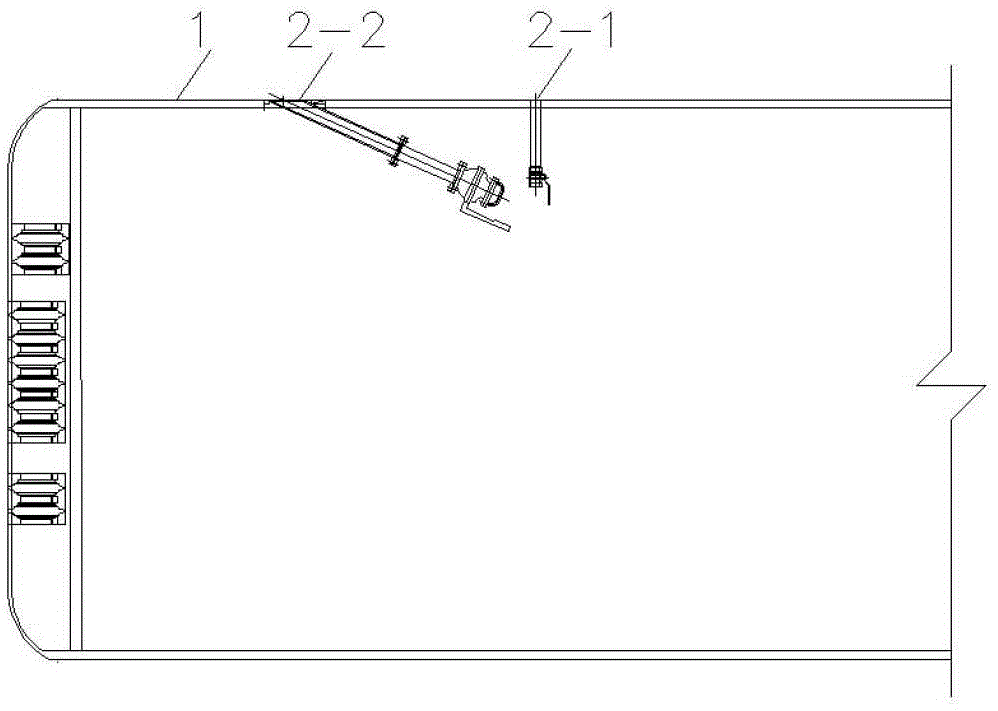

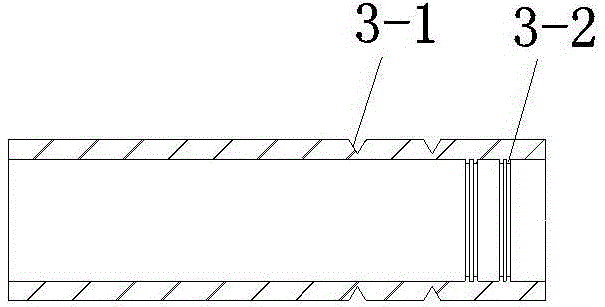

Device used for grouting reinforcement from interior of shield tunneling machine to peripheral stratum

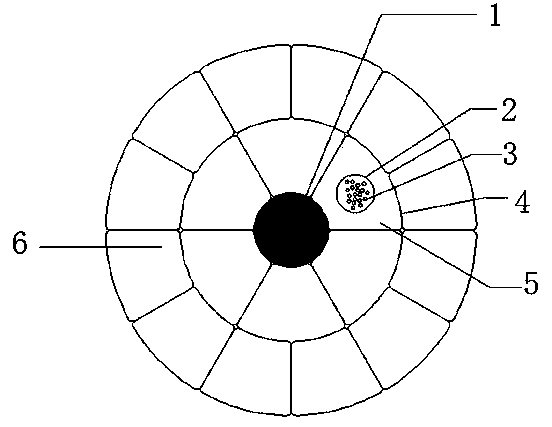

ActiveCN105649655ASimple structureEasy to install and disassembleUnderground chambersTunnel liningTrappingEngineering

The invention relates to a device used for grouting reinforcement from the interior of a shield tunneling machine to a peripheral stratum. A steel casing pipe is stricken into the stratum in front of a reserved hole through the reserved hole in a shield body of the shield tunneling machine, and a perforated steel grouting pipe connected in the steel casing pipe is used for carrying out grouting reinforcement on the peripheral rock stratum of the shield body. Meanwhile, the peripheral stratum within different ranges can be reinforced through perforated steel grouting pipes with different lengths, and thus the purposes of carrying out grouting reinforcement from the interior of the shield tunneling machine to the peripheral stratum, controlling the settlement deformation of the stratum, performing supporting, and reducing shield trapping and construction safety risks are achieved. While the stratum is reinforced through grouting, a water closing ring and a backflow-prevention rubber pad are adopted, it can be effectively prevented that grout flows back into the shield tunneling machine body in the grouting process, and it is ensured that construction is safe and environmentally friendly.

Owner:YSD RAIL TRANSIT CONSTR CO LTD +1

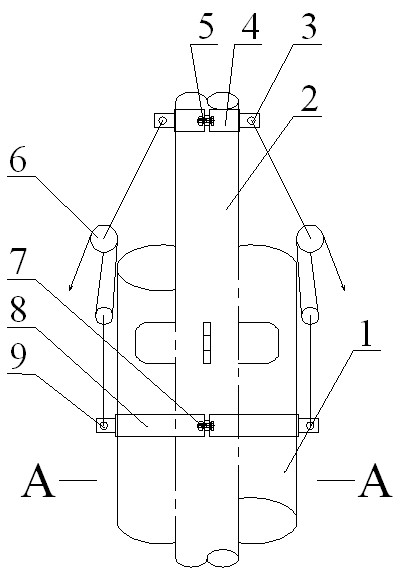

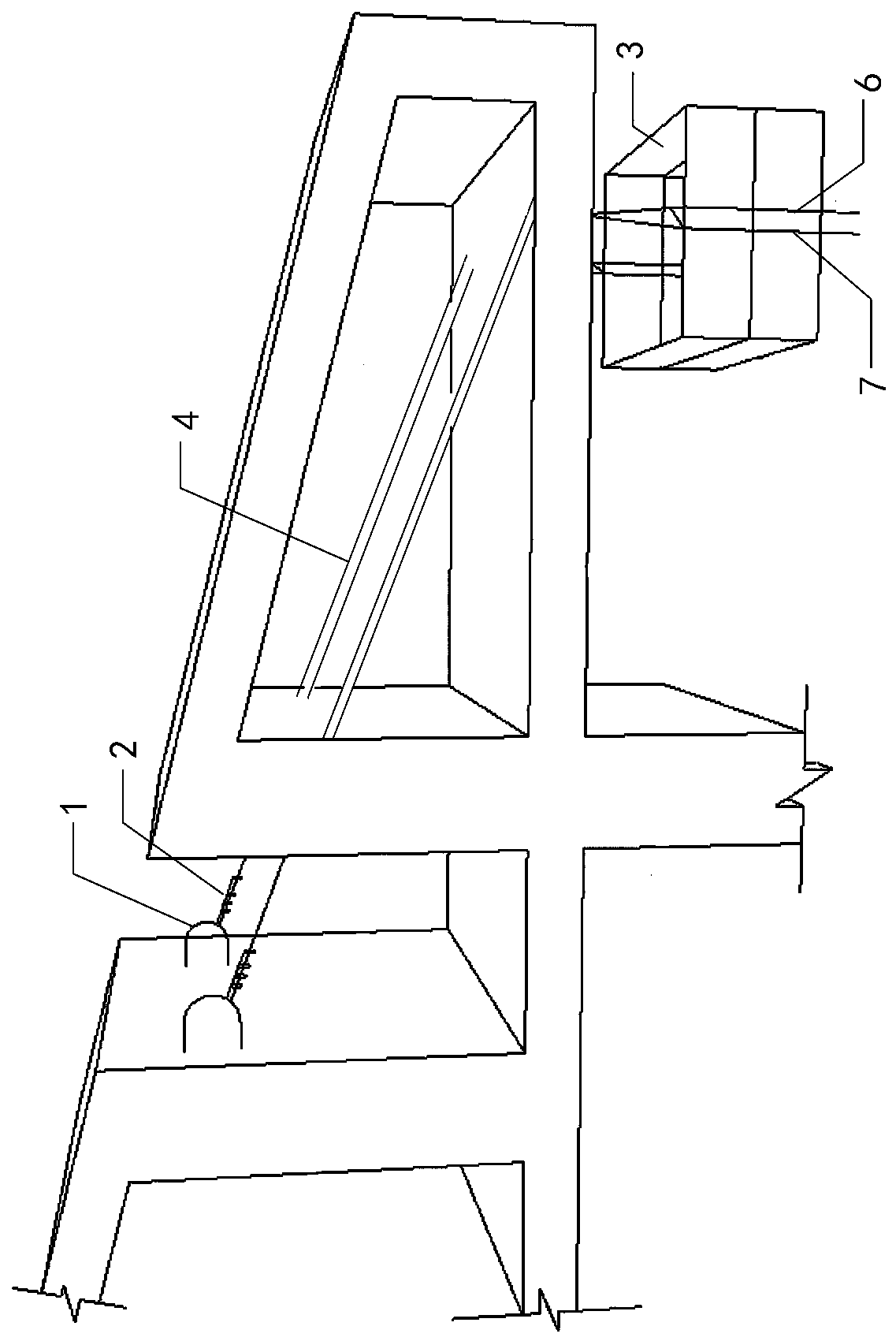

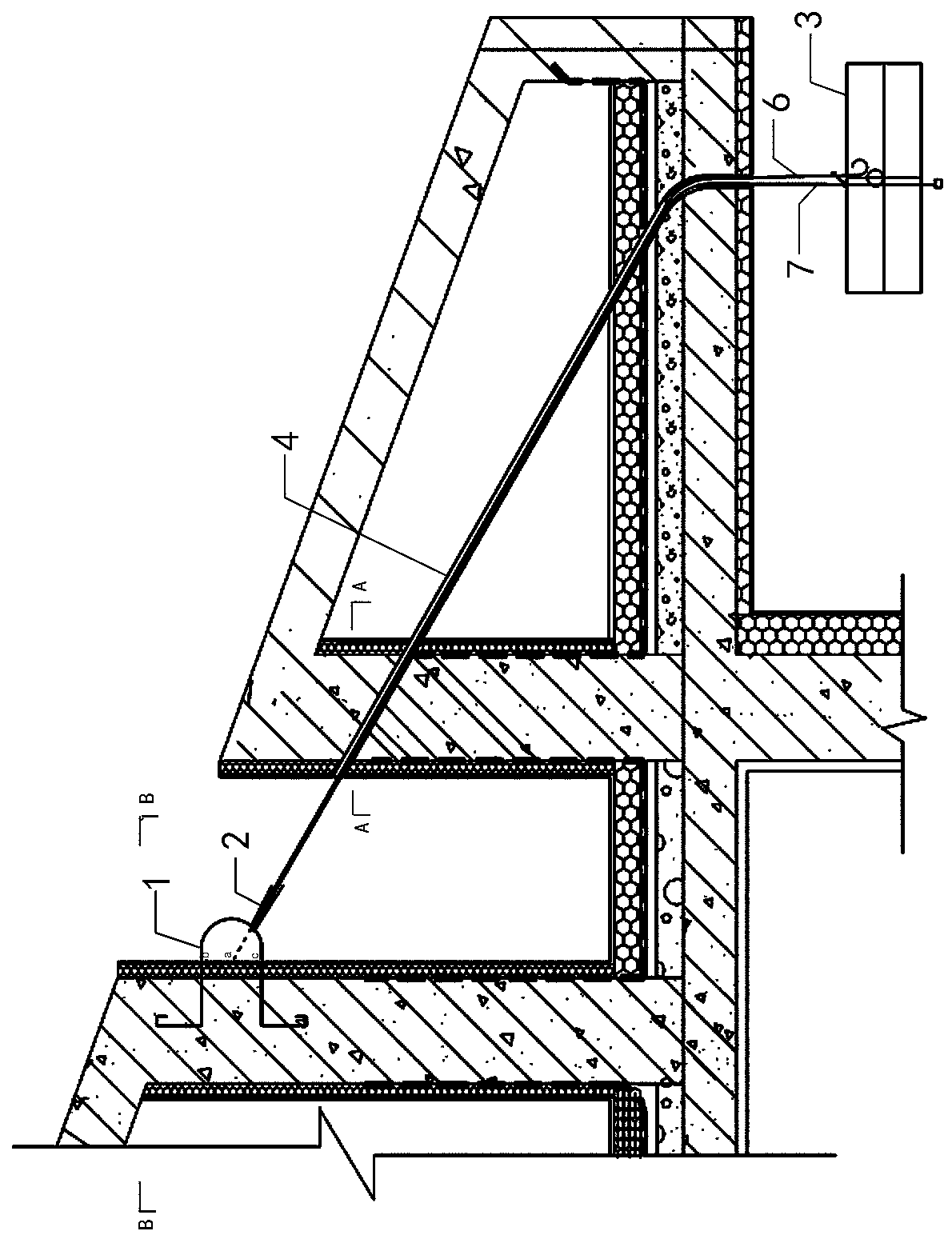

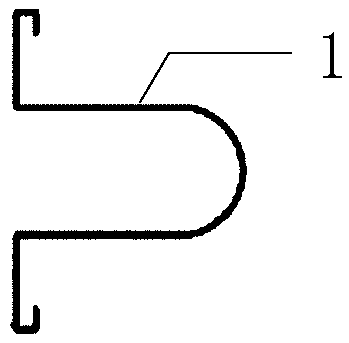

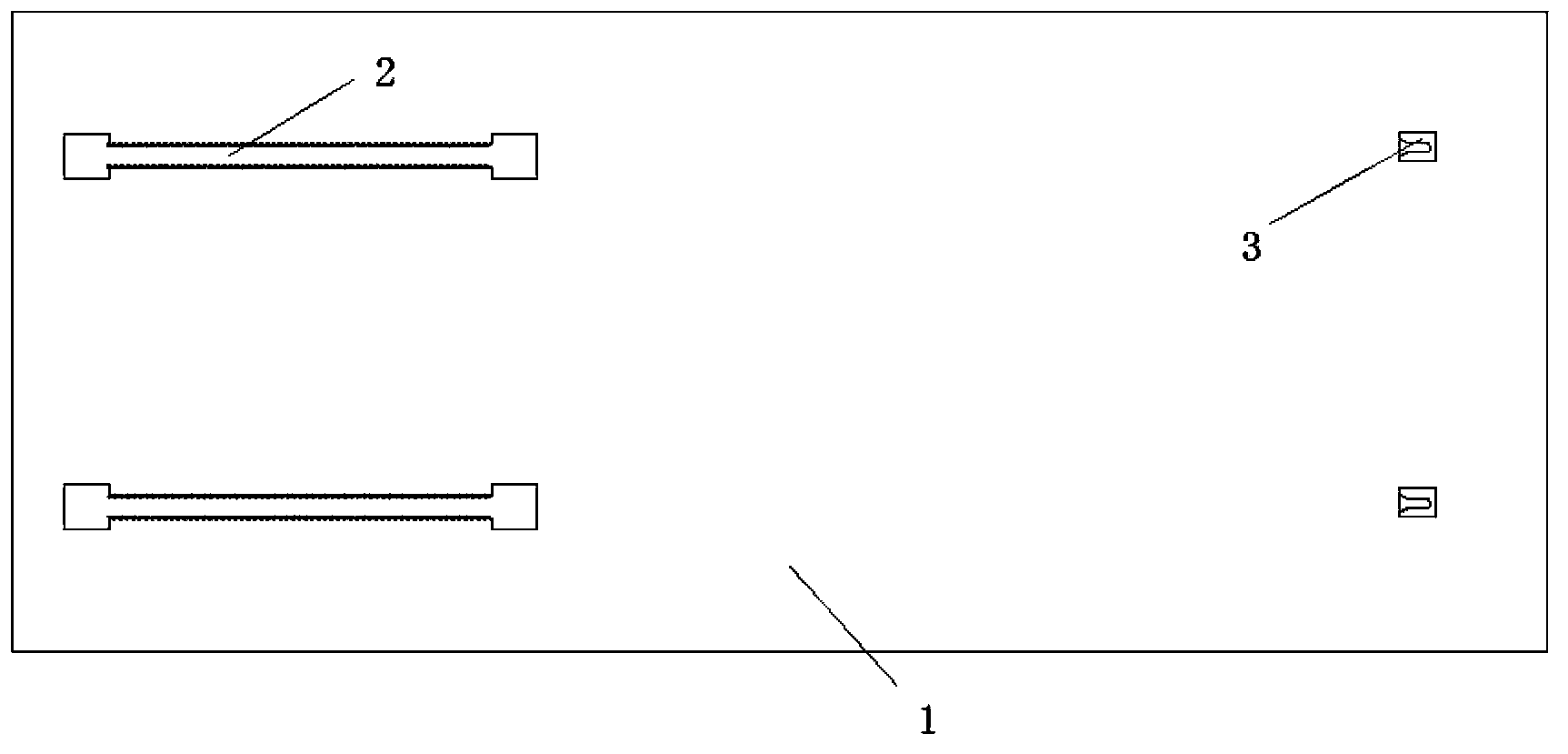

Support-free balance-weight-free hanging basket hanging structure and construction method thereof

PendingCN110158937AAvoid destructionAvoid damageBuilding support scaffoldsEavesArchitectural engineering

The invention discloses a support-free balance-weight-free hanging basket hanging structure and a construction method thereof, and relates to the field of building structure construction. The support-free balance-weight-free hanging basket hanging structure is used for a roof structure with an inclined roof and the periphery with overhanging eaves, the system comprises two hanging systems arrangedin a spaced manner, each hanging system comprises an anchorage ring embedded in the roof wall, a steel casing pipe embedded between the parapet wall and an overhanging plate, an anti-friction hose inserted in the steel casing pipe, a lifting steel wire rope and a safety rope, and the lifting steel wire rope and the safety rope are inserted into the anti-friction hose in a penetrating manner. Theproblems that a hanging basket for hanging outer eave decoration needs to erect a frame or need a balance weight when the roof is the inclined roof and the periphery is provided with the outer overhanging eaves, the structure is complex, the construction is tedious, and the construction difficulty is large are solved.

Owner:BEIJING FOURTH CONSTR & ENG

Stainless steel casing pipe applied to local repair of pipeline

The invention discloses a stainless steel casing pipe applied to local repair of a pipeline. The stainless steel casing pipe comprises a stainless steel pipe and an auxiliary silica gel ring arranged outside the stainless steel, wherein the stainless steel pipe is formed by rolling a first rectangular stainless steel plate; two clearances are formed in a direction parallel to a long side of the first rectangular stainless steel plate; buckles are welded on positions, which correspond to the clearances, on the other side of the first rectangular stainless steel plate; two ends of the clearances are rectangular; an inner side opening and an outer side opening are formed in each rectangle; each inner side opening is used for allowing the buckle to be buckled in each clearance; each outer side opening is used for allowing the buckle to be popped from the clearance when the pipeline exceeds the use range; the inner side of each clearance is of a one-way gear structure; each buckle comprises a gold-plated steel wire; each one-way gear and each gold-plated steel wire are connected to be used as a one-way opening; the one-way opening can only slide in one way, the stainless steel pipe does not retract after being stretched; the silica gel ring is arranged between the stainless steel pipe and the pipeline, is used as a liner and plays a role of sealing. The stainless steel casing pipe disclosed by the invention is low in price.

Owner:TSINGHUA UNIV

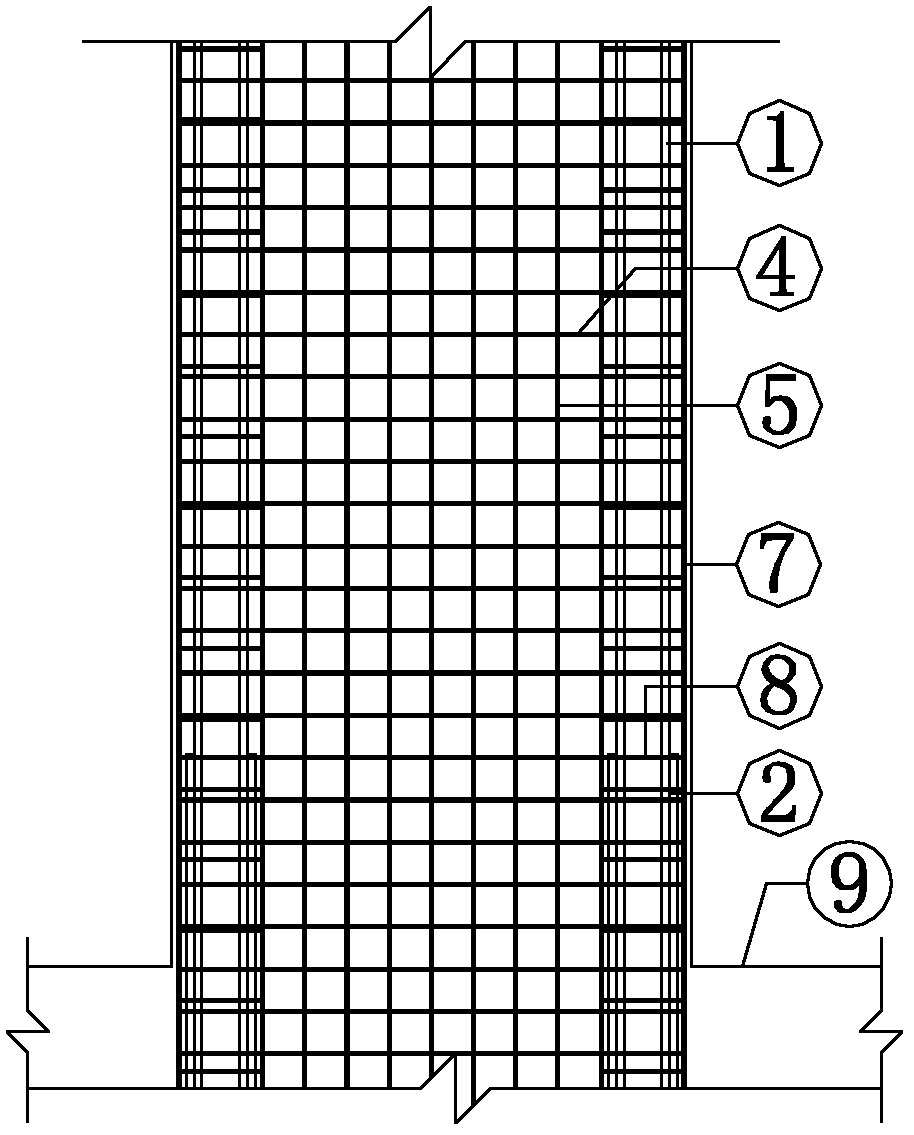

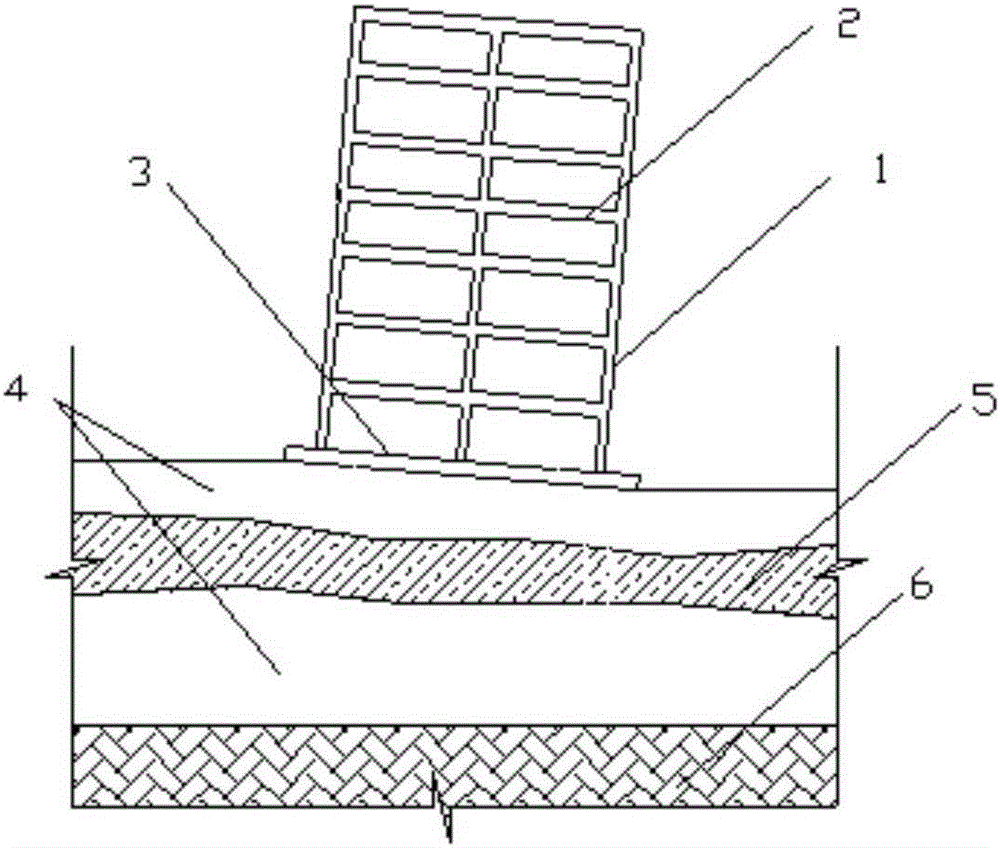

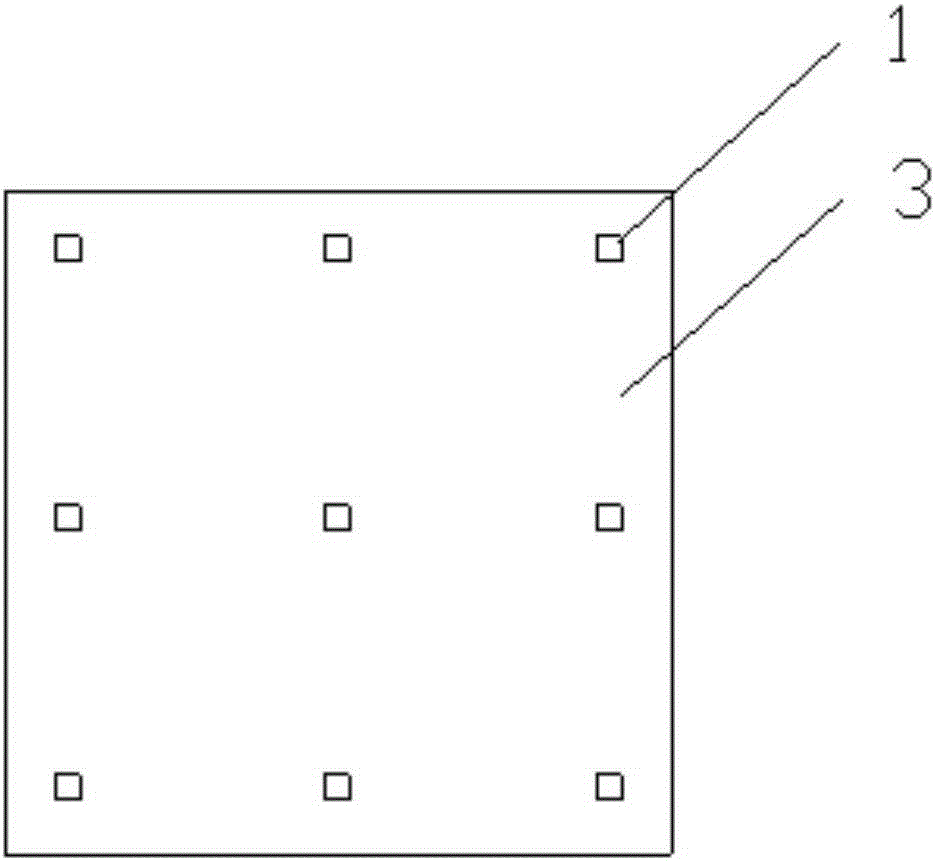

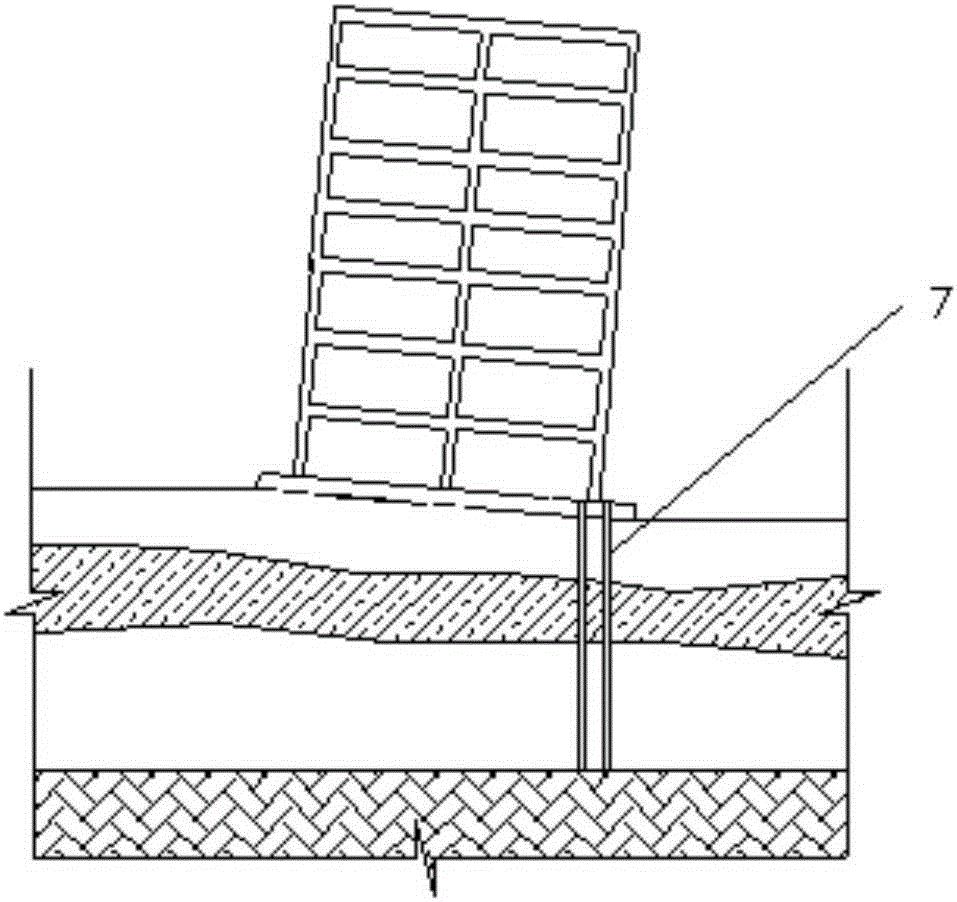

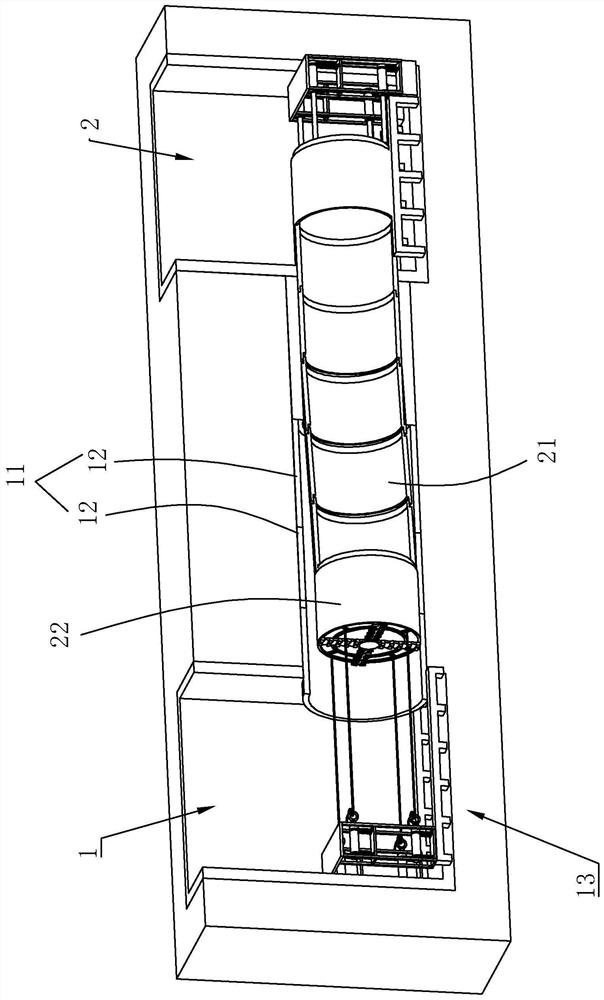

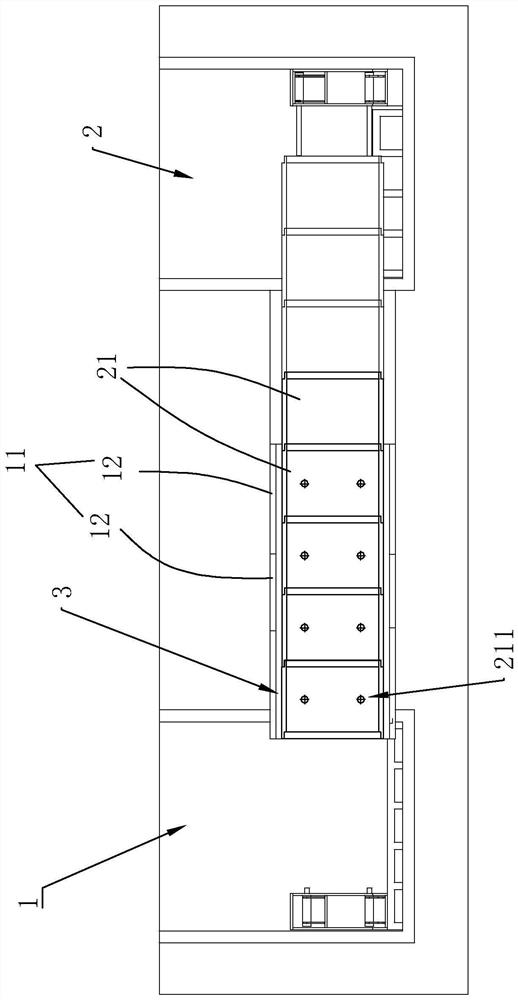

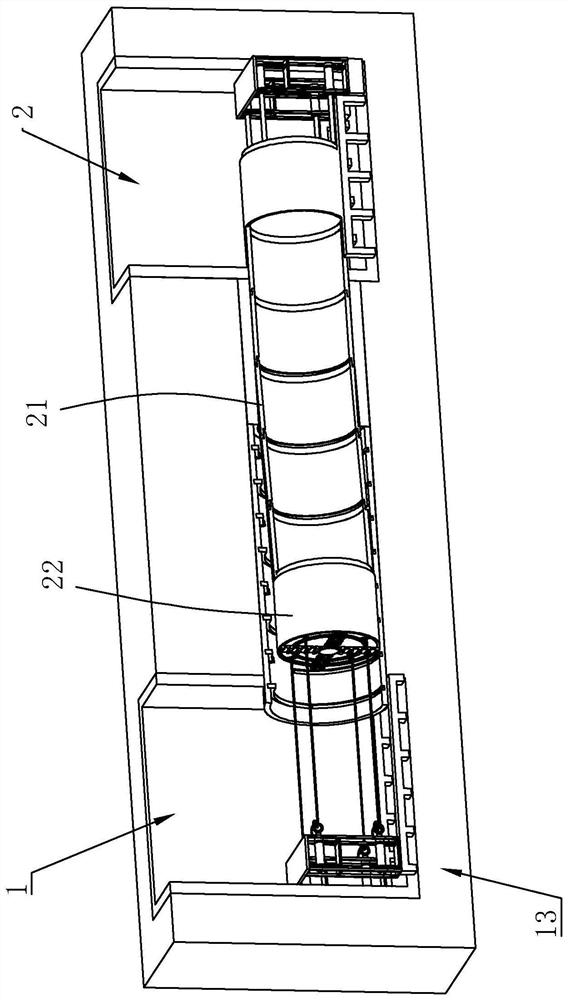

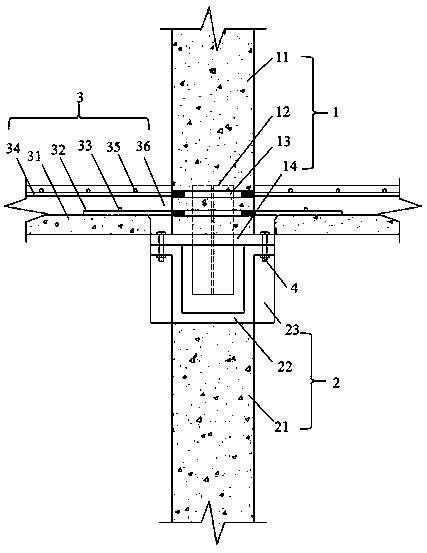

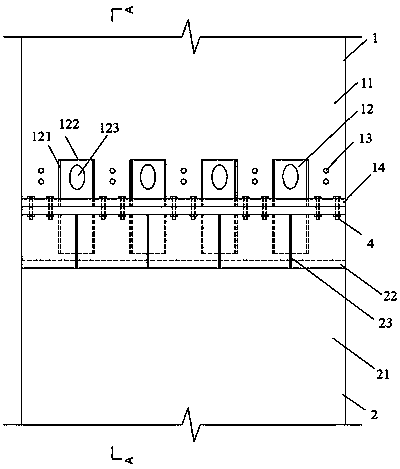

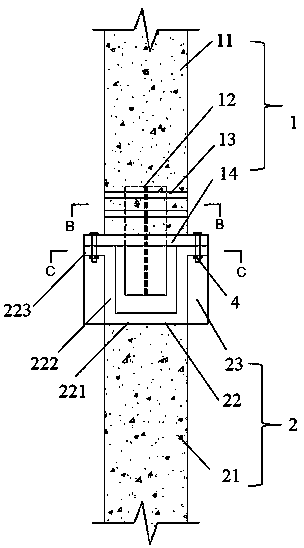

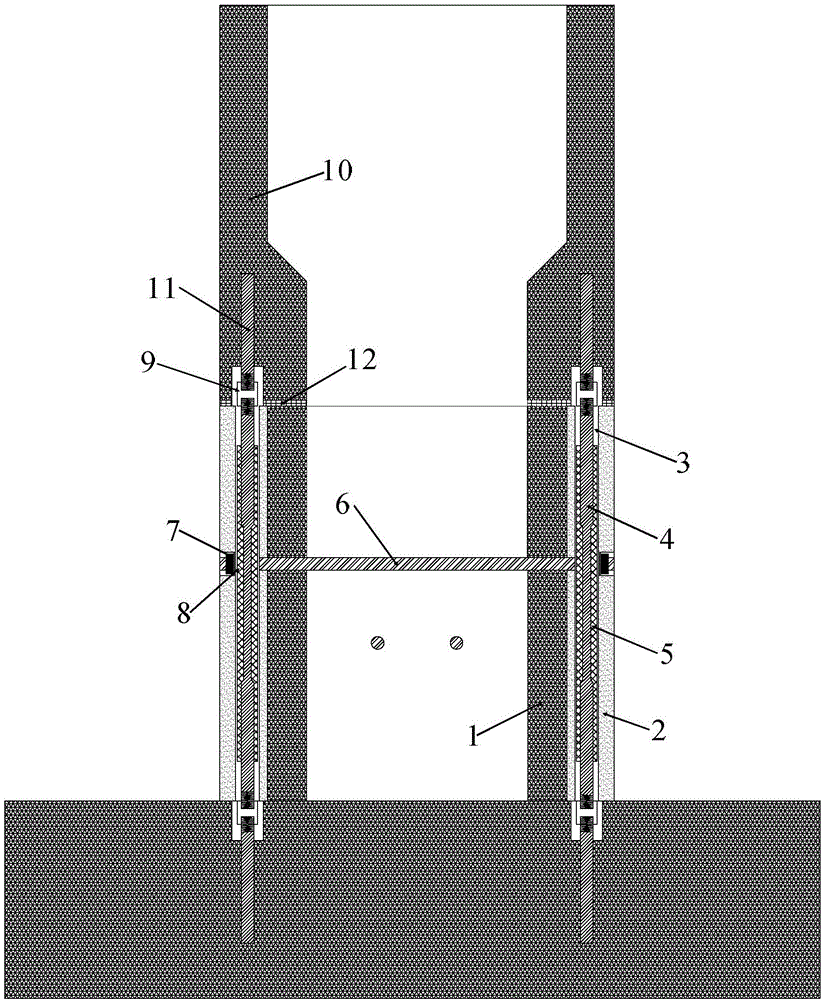

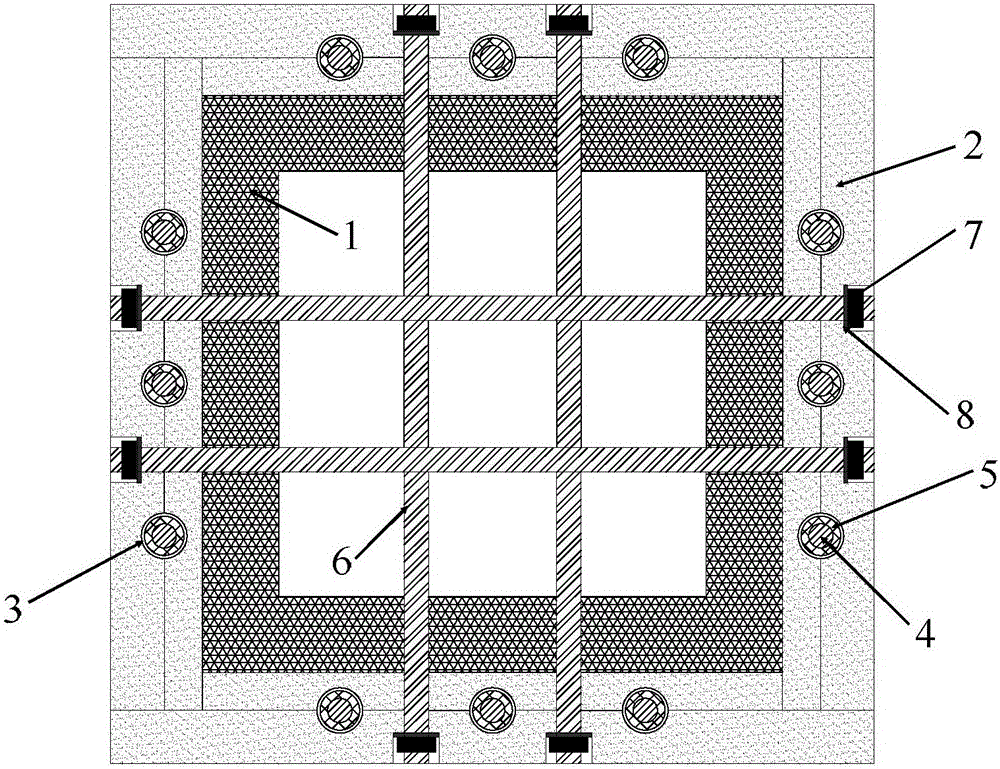

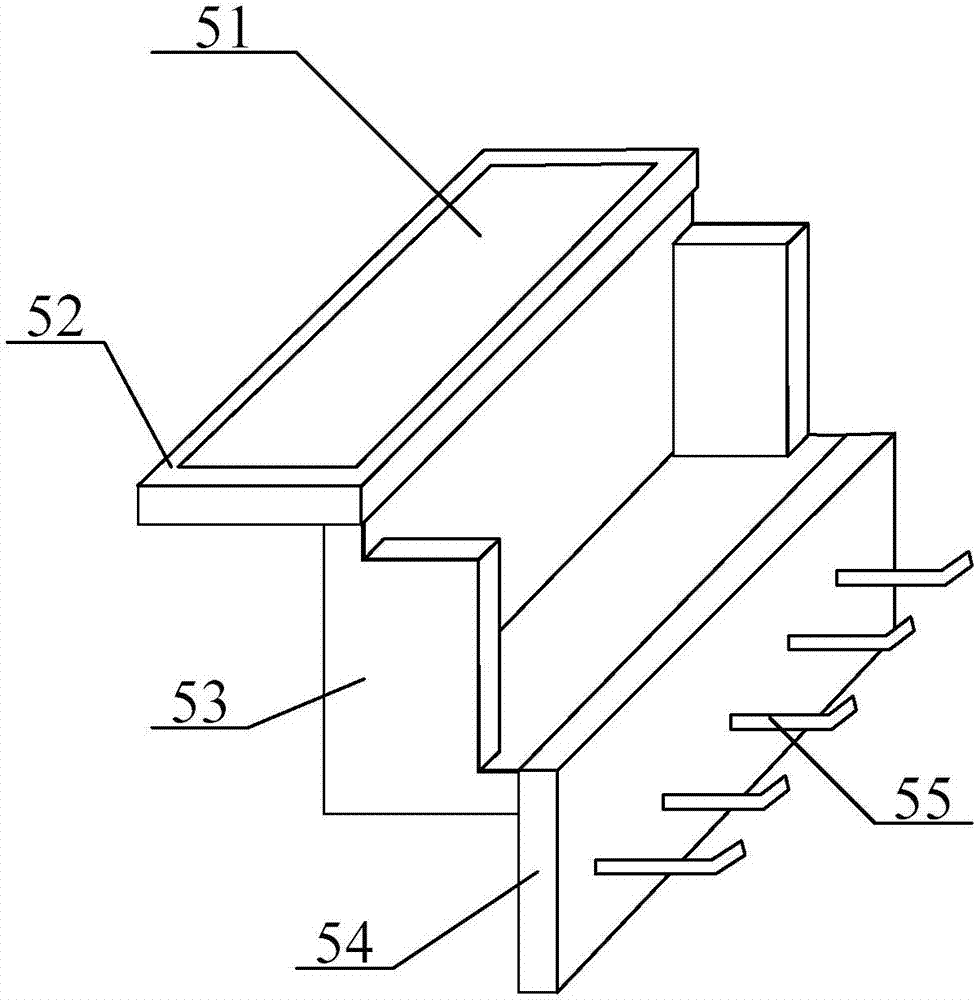

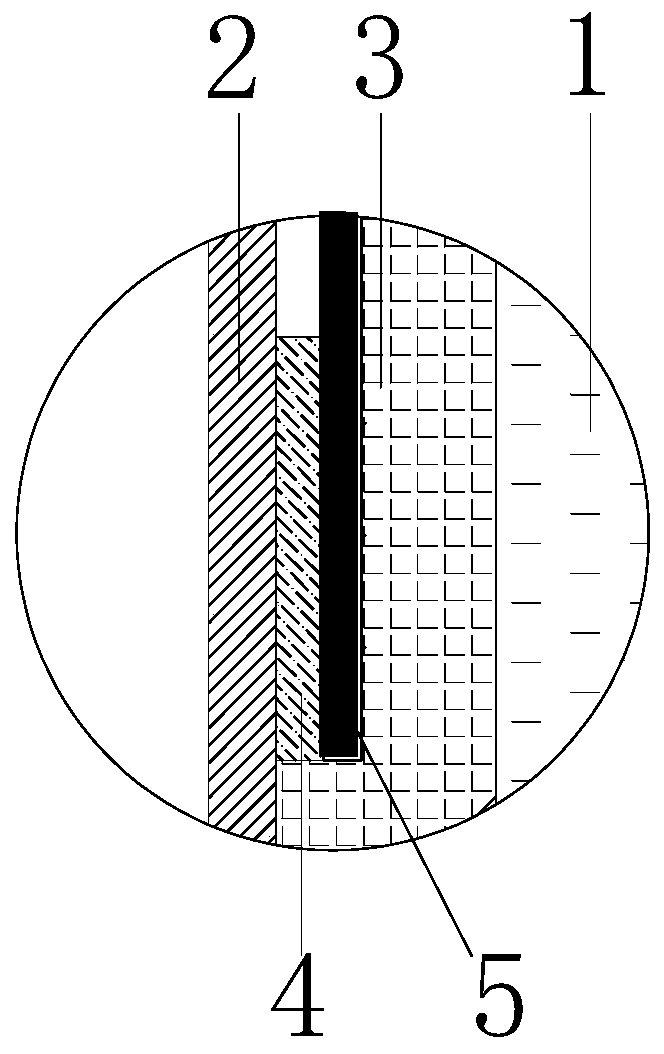

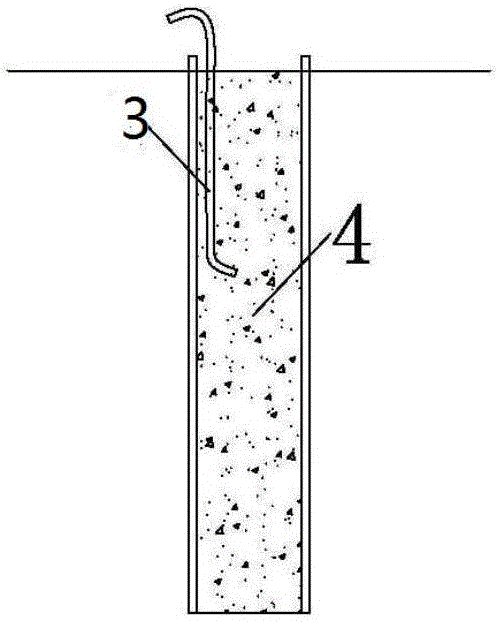

Bolting plug-in vertical prefabricated shear wall and superimposed sheet joint structure and construction method thereof

The invention relates to a bolting plug-in vertical prefabricated shear wall and superimposed sheet joint structure and a construction method thereof, which are characterized in that the bolting plug-in vertical prefabricated shear wall and superimposed sheet joint structure includes a lower prefabricated shear wall 2, an upper prefabricated shear wall 1 inserted to the top of the lower prefabricated shear wall 2, and floors 3 supported on both sides of the top of the lower prefabricated shear wall 2; the upper prefabricated shear wall 1 includes an upper prefabricated reinforced concrete wall11, H-shaped steel 12 pre-buried in the upper prefabricated reinforced concrete wall 11, a pre-buried steel casing pipe 13, and an end plate 14 arranged at the lower end portion of the upper prefabricated reinforced concrete wall 11; and according to the bolting plug-in vertical prefabricated shear wall and superimposed sheet joint structure and the construction method thereof, the connection isfast and reliable, the construction is convenient, the shear bearing capacity is high, seismic ductility and integrity are good, and the bolting plug-in vertical prefabricated shear wall and superimposed sheet joint structure with refrained concrete at the joint part and the construction method thereof are provided.

Owner:FUJIAN UNIV OF TECH

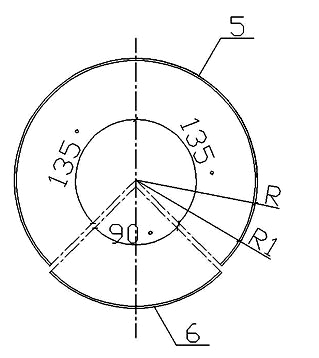

Pier energy dissipation and anti-crushing structure with replaceable composite boards internally provided with steel bar dampers

ActiveCN105735110AQuick changeMake full use of the property of cracking but not breakingBridge structural detailsFiberPre stress

The invention discloses a pier energy dissipation and anti-crushing structure with replaceable composite boards internally provided with steel bar dampers. According to the structure, the replaceable Ultra High Performance Concrete (UHPC) internally provided with steel bar dampers are used for improving the energy dissipation capacity of a dry joint section spliced pier under excitation of an earthquake effect and preventing a bottom section from being crushed. Each of the four edges of a vulnerable region, namely the bottom section of the dry joint section spliced pier is provided with two UHPC boards, prestress is applied through finish rolled threaded reinforcing steel bars to combine the UHPC boards and the bottom section into a whole, and a hole channel is reserved between every two adjacent UHPC boards and used for containing the corresponding steel bar damper composed of a flexible steel core bar and a round steel casing pipe. By the adoption of the structure, the character that UHPC is cracked but not broken due to the mixture of steel fibers is used for preventing the inner bottom section from being crushed under excitation of the earthquake effect, the steel bar dampers in the hole channels are prevented from being rusted by the utilization of the character that the UHPC structure is compact, and the steel bar dampers are used for improving the energy dissipation capacity of the pier under excitation of the earthquake effect.

Owner:SOUTHEAST UNIV

Pier energy dissipation and anti-crushing structure internally provided with steel bar dampers and viscous-elastic material

ActiveCN105735109AQuick changeMake full use of the property of cracking but not breakingBridge structural detailsPre stressEngineering

The invention discloses a pier energy dissipation and anti-crushing structure internally provided with steel bar dampers and a viscous-elastic material. According to the structure, each of the four edges of a vulnerable region, namely the bottom section of a dry joint section spliced pier is provided with two UHPC boards, a viscous-elastic material layer is arranged between the bottom section of the pier and each UHPC board, prestress is applied through finish rolled threaded reinforcing steel bars to combine the UHPC boards and the bottom section into a whole, and a hole channel is reserved between every two adjacent UHPC boards and used for containing the corresponding steel bar damper composed of a flexible steel core bar and a round steel casing pipe. The steel bar dampers in the hole channels are prevented from being rusted by the utilization of the character that the UHPC structure is compact, and the steel bar dampers and the viscous-elastic material layers are used for improving the energy dissipation capacity of the pier under excitation of an earthquake effect. The pier energy dissipation and anti-crushing structure is used for treating the dry joint section spliced pier, it can be guaranteed that the pier is good in energy dissipation capacity under excitation of the earthquake effect, the bottom section is prevented from being severely crushed, and the pier can be rapidly repaired by replacement of the UHPC boards, the steel bar dampers and the viscous-elastic material layers after an earthquake.

Owner:SOUTHEAST UNIV

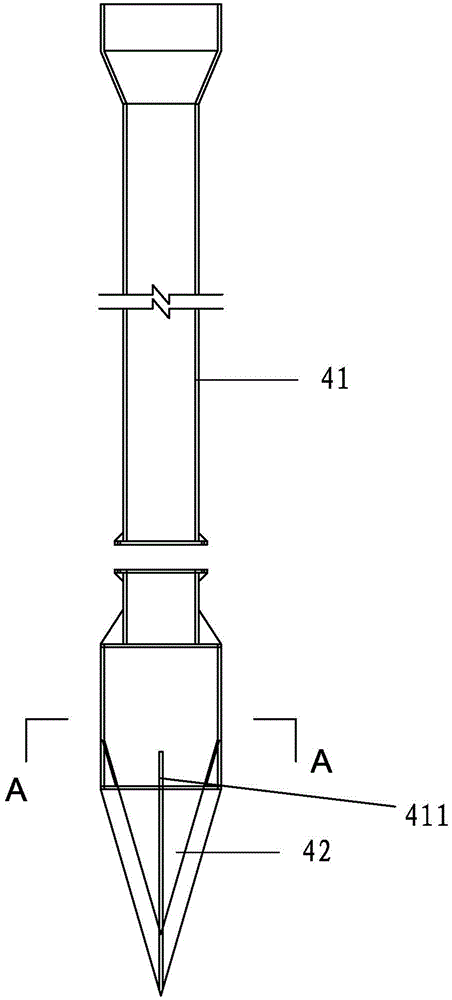

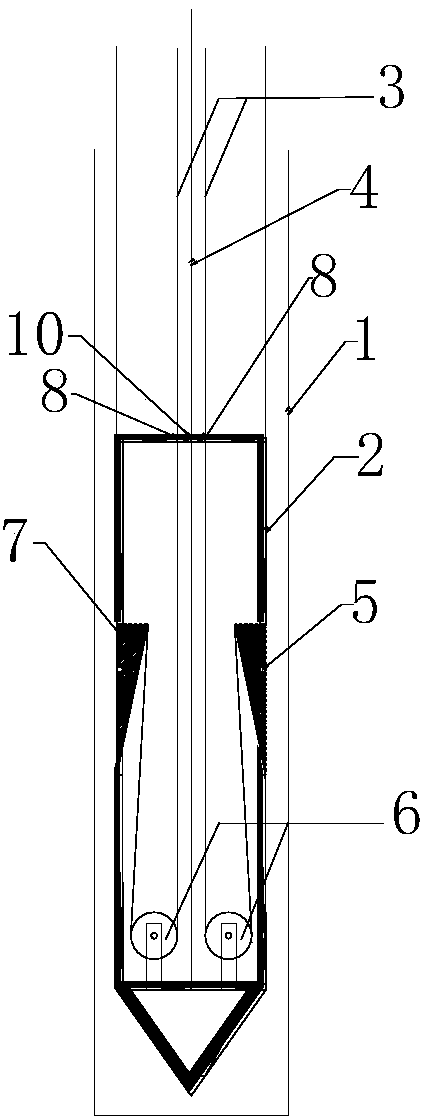

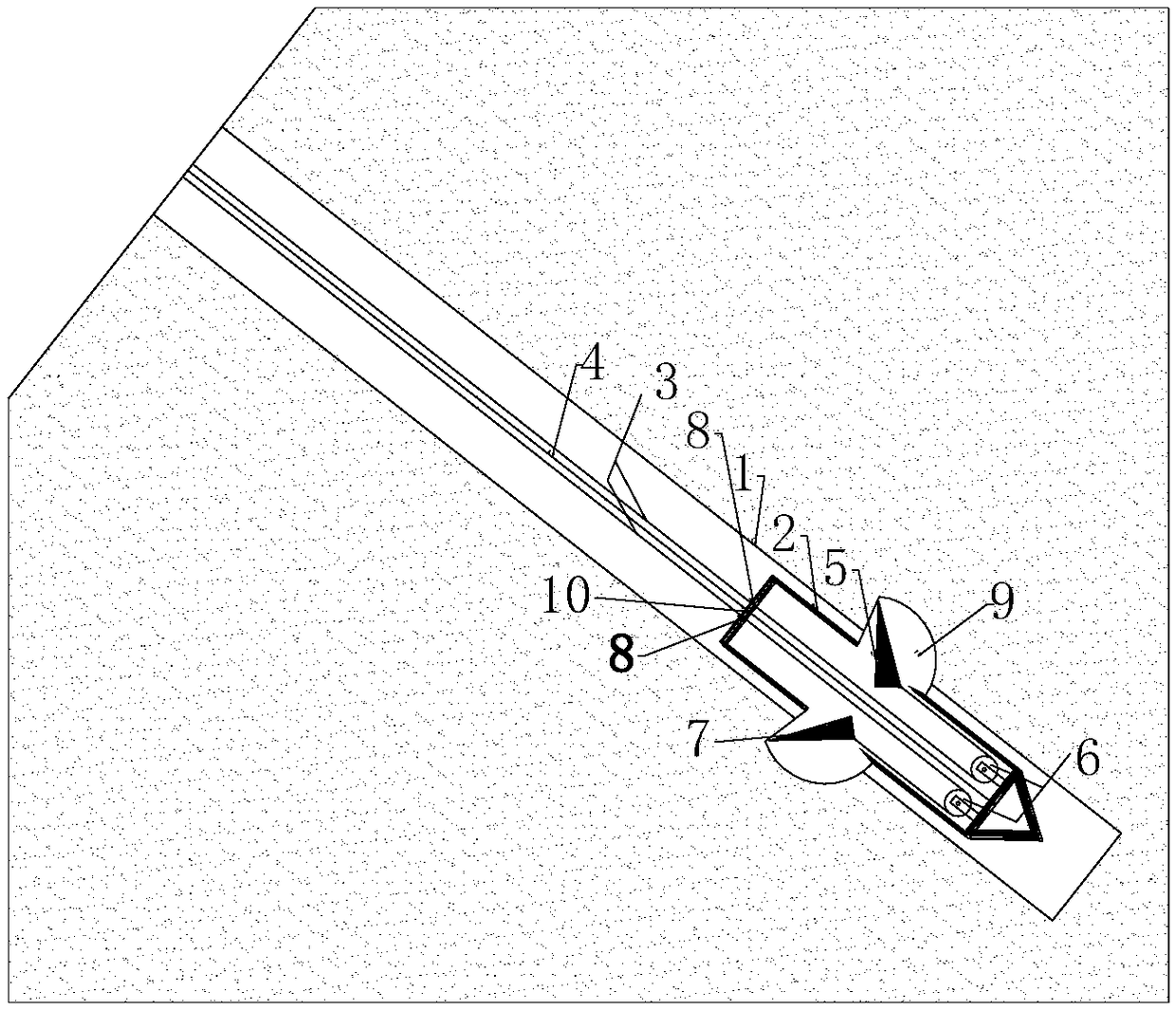

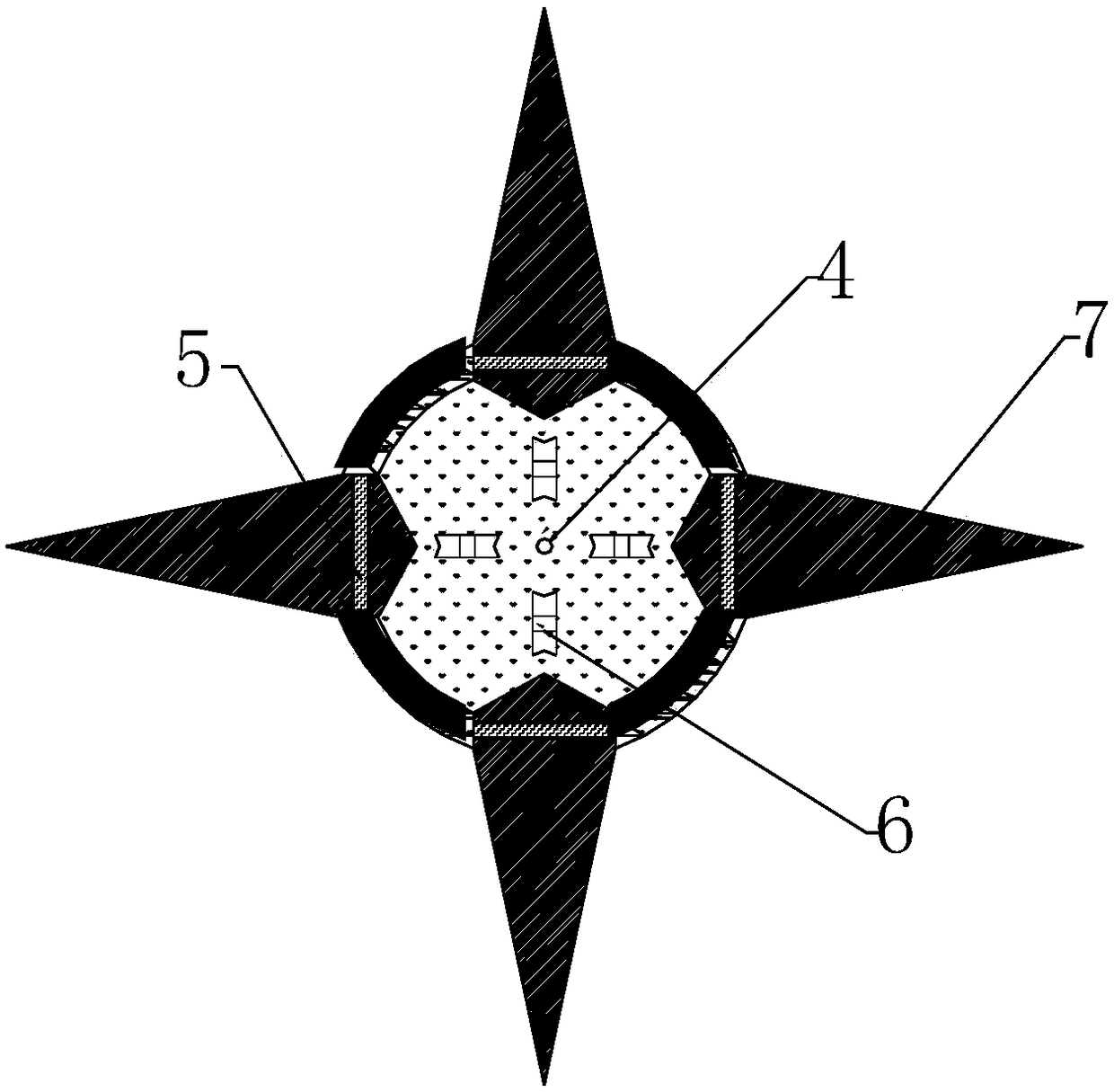

Rapid pre-stressed anchor cable capable of being recycled and construction method thereof

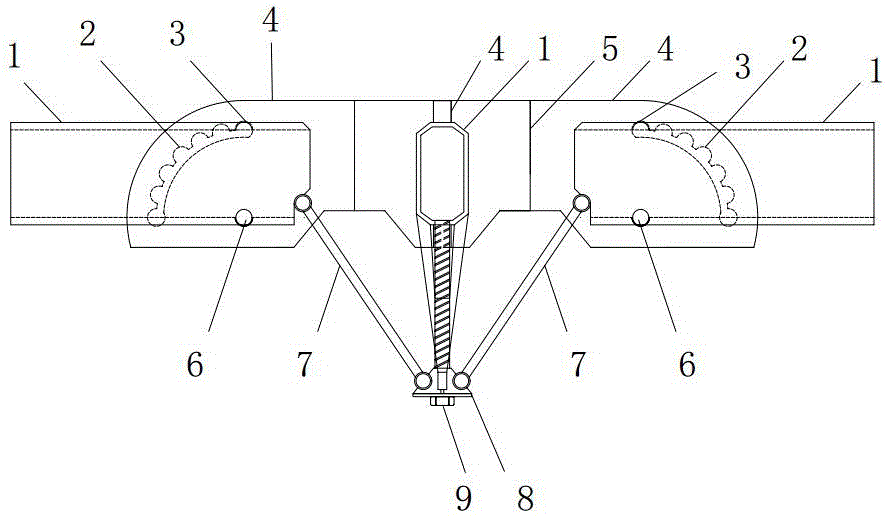

The invention provides a rapid pre-stressed anchor cable capable of being recycled and a construction method thereof. The anchor cable comprises a steel casing pipe and an expansion structure which issymmetrically distributed; a conical head is arranged at the bottom of the steel casing pipe, openings symmetrically distributed are formed in the side walls, the expansion structure comprises a fixed pin, a fixed pulley and an expansion head, the fixed pin and the expansion head are arranged in the openings in the side wall of the steel casing pipe, the two ends of the fixed pin are fixedly connected with the steel casing pipe, the expansion head is rotatably connected with the steel casing pipe through the fixed pin, the fixed pulley is fixed to the upper end of the conical head, one end ofa stress steel strand is connected with the expansion head, the other end of the stress steel stand winds around the fixed pulley to penetrate the steel casing pipe, one end of a non-stress steel stand is connected with the conical head, and the other end of the non-stress steel stand penetrates the steel casing pipe. Grouting is not needed, after mounting in-place operation, tension is achieved,after the supporting task is finished, the cable can be completely recycled, the effect on later-period building of the surrounding buildings is avoided, the construction period can be effectively shortened, resource waste is reduced, and the cable is suitable for the soft rock area and is particularly suitable for the emergency rush repair engineering and the temporary supporting engineering with the strict time need.

Owner:DALIAN JIAOTONG UNIVERSITY

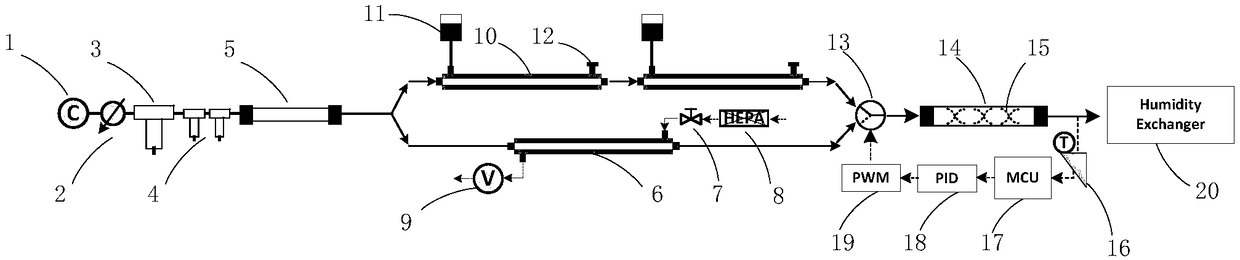

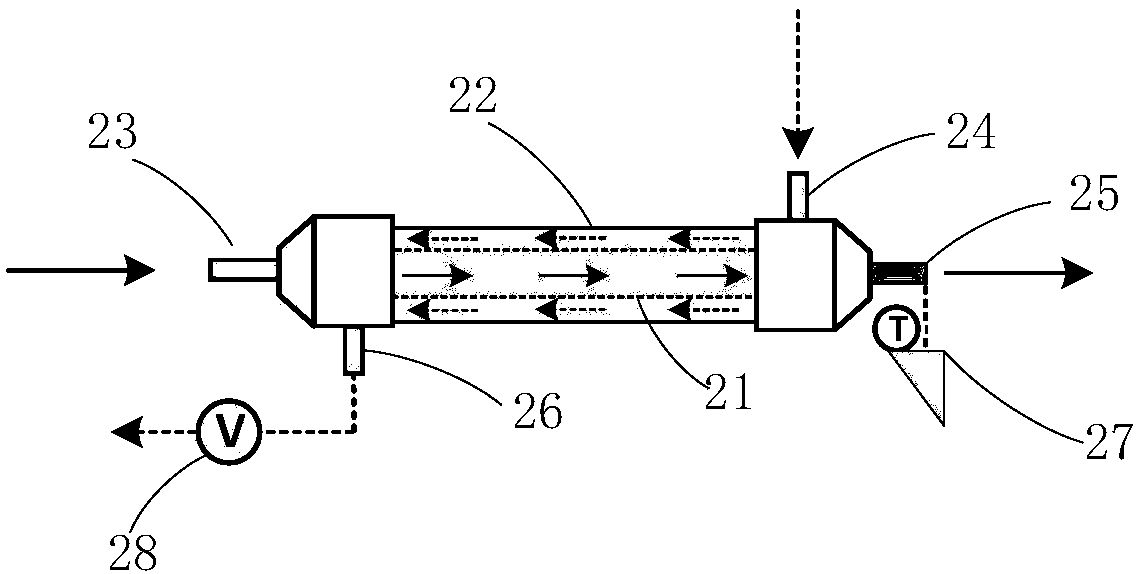

Quick particle humidity control device and control method thereof

InactiveCN108376001AReduced Humidity Switching Response TimeFacilitated DiffusionHumidity controlParticulatesMicrocontroller

The invention relates to a quick particle humidity control device and a control method thereof. The device comprises a clean air generating unit, an air flow drying channel, an air flow humidifying channel, an air flow mixing unit, a humidity measuring and adjusting unit and a particle humidity exchange unit. The air flow drying channel consists of a Nafion drying tube, a high-efficiency filter, aneedle valve, and a vacuum pump. The air flow humidifying channel includes a Nafion humidification tube, a deionized water storage tank, and a plug. The air flow mixing unit includes a three-way solenoid valve, a mixing tube, and a blade. The humidity measuring and adjusting unit includes a humidity sensor, a microcontroller, a PID algorithm processing unit, and a pulse width modulation drive circuit. The particle humidity exchange unit includes a microporous liner tube, a stainless-steel casing pipe, a humidity sensor, and a vacuum pump. According to the invention, humidity control of the sampling particle is realized during the online particle measuring process and the relative humidity is adjusted randomly between 10% to 90%; and the humidity switching response time is lower than 60 seconds.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

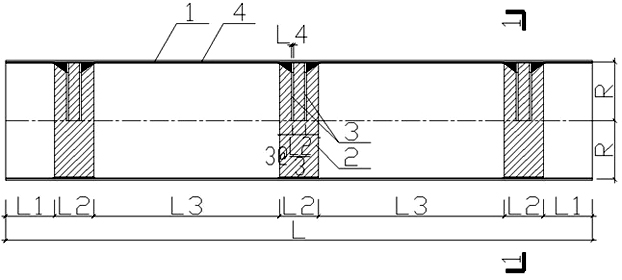

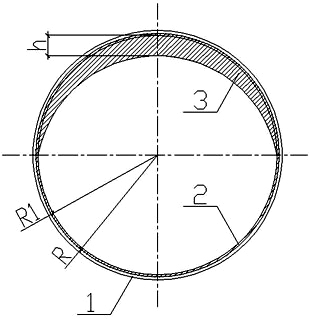

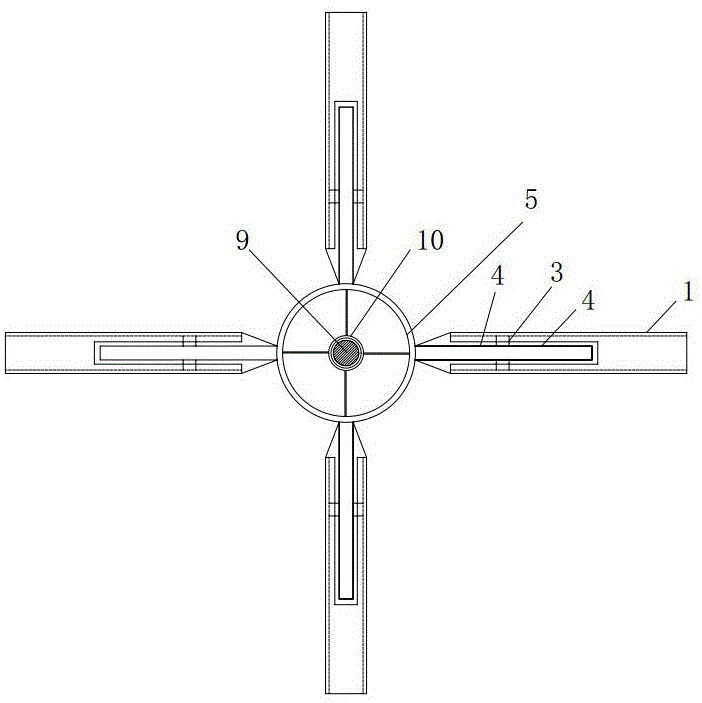

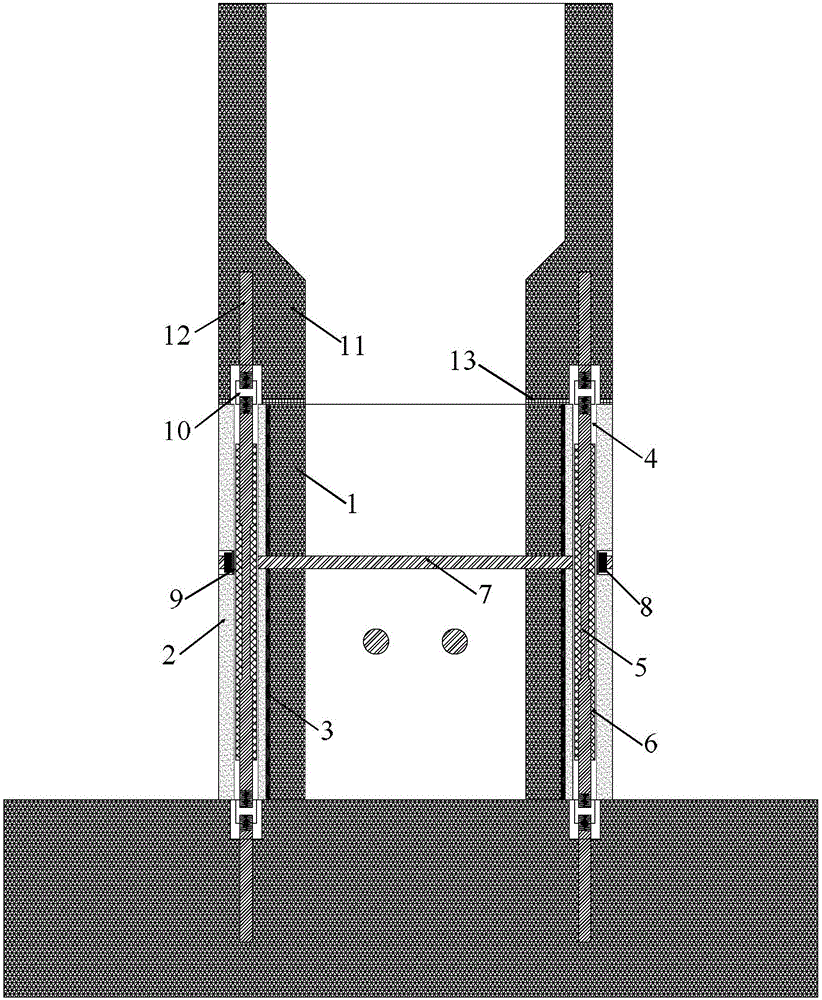

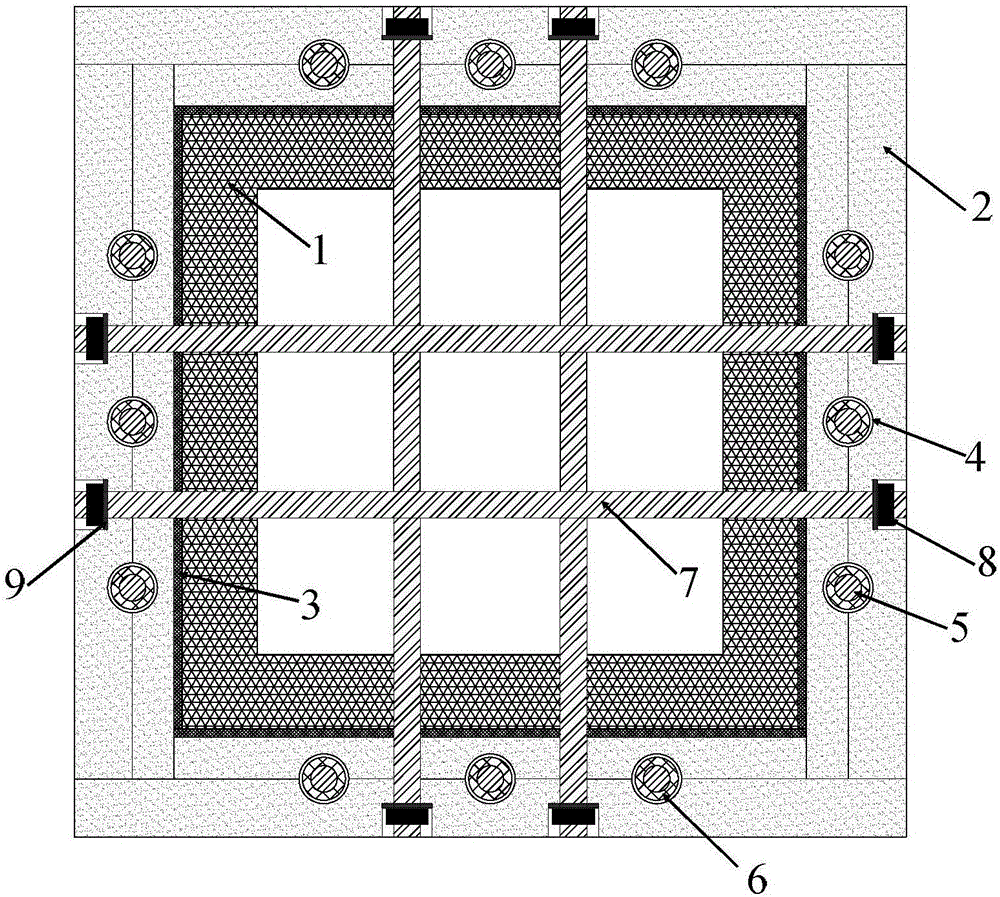

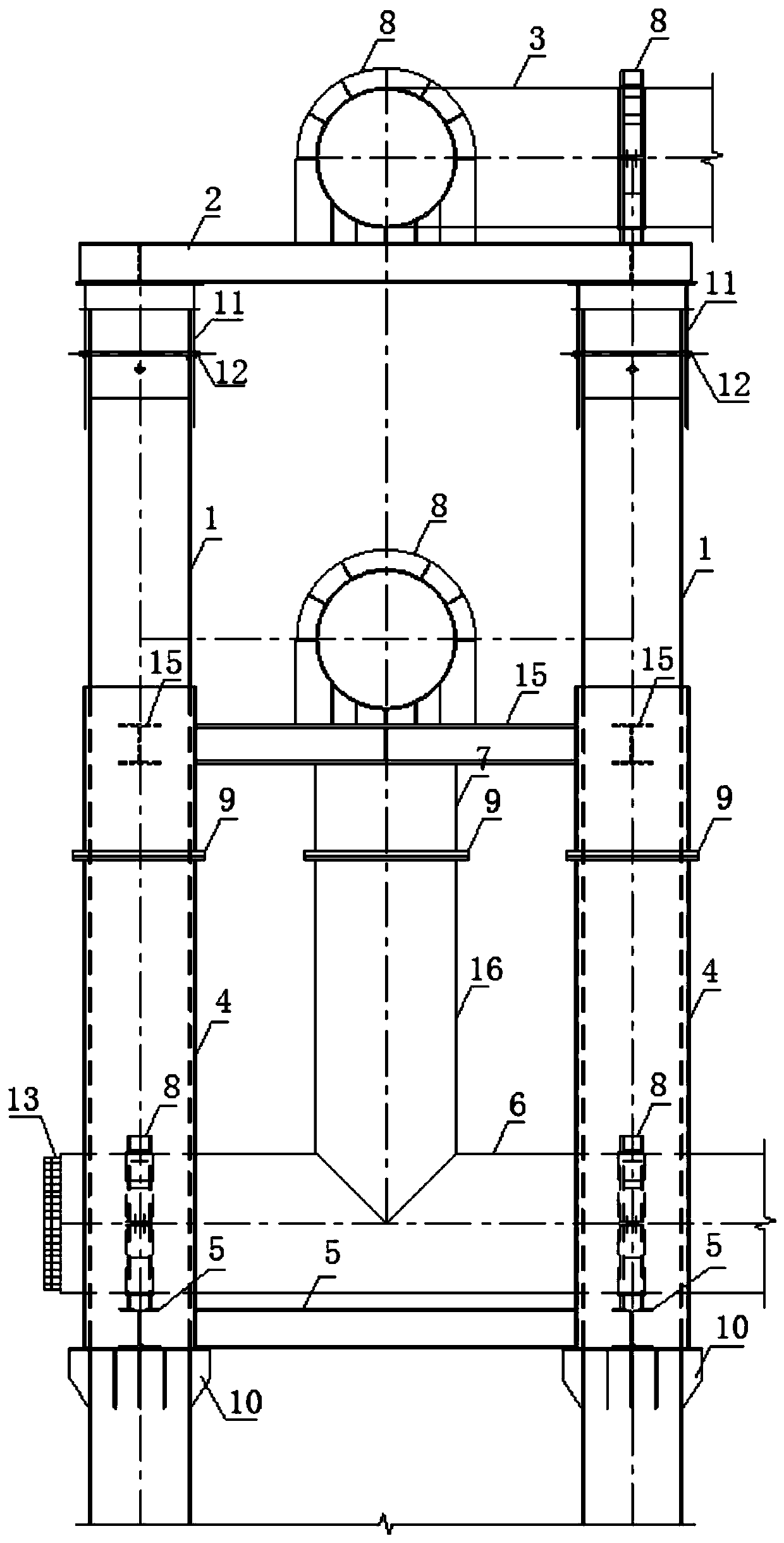

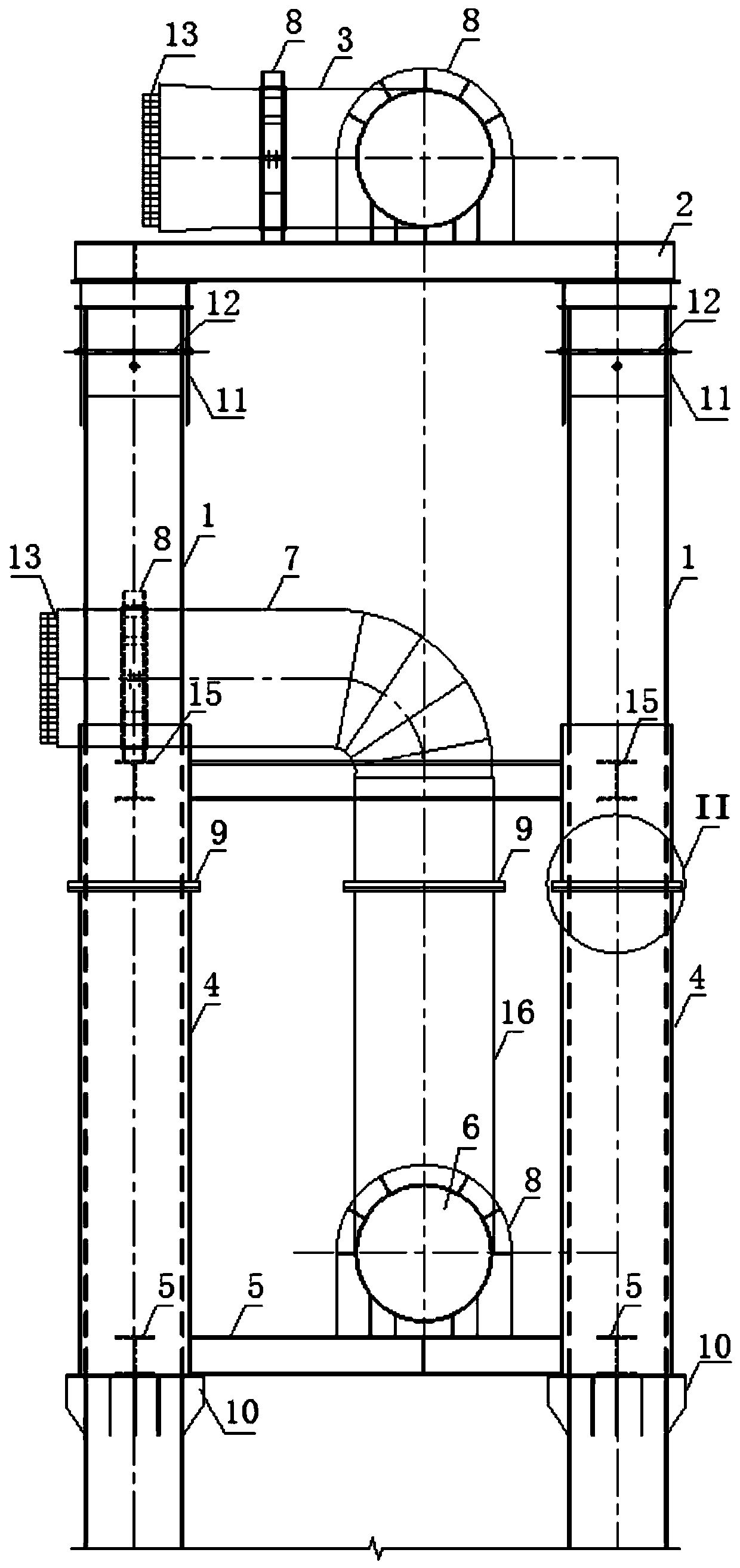

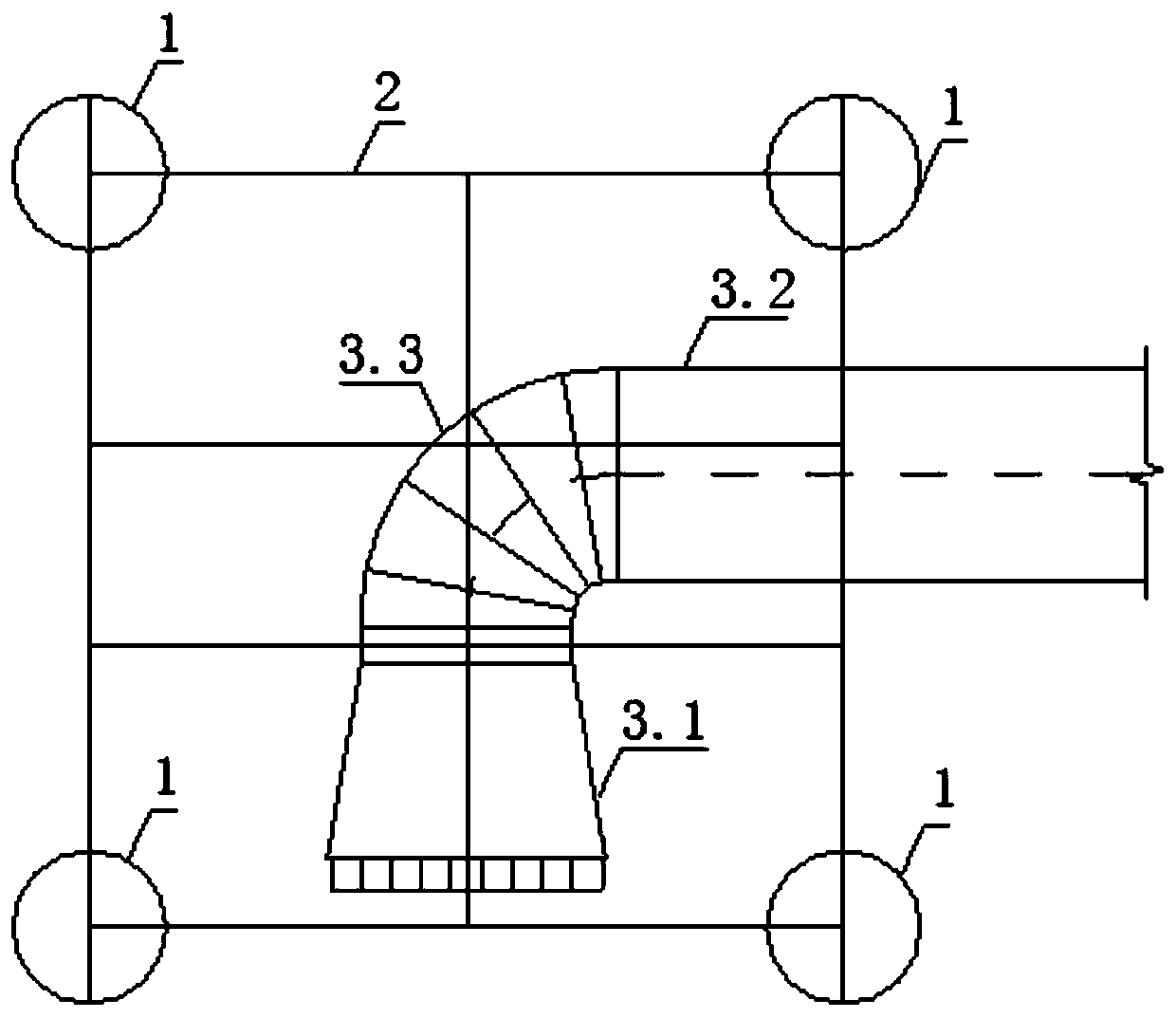

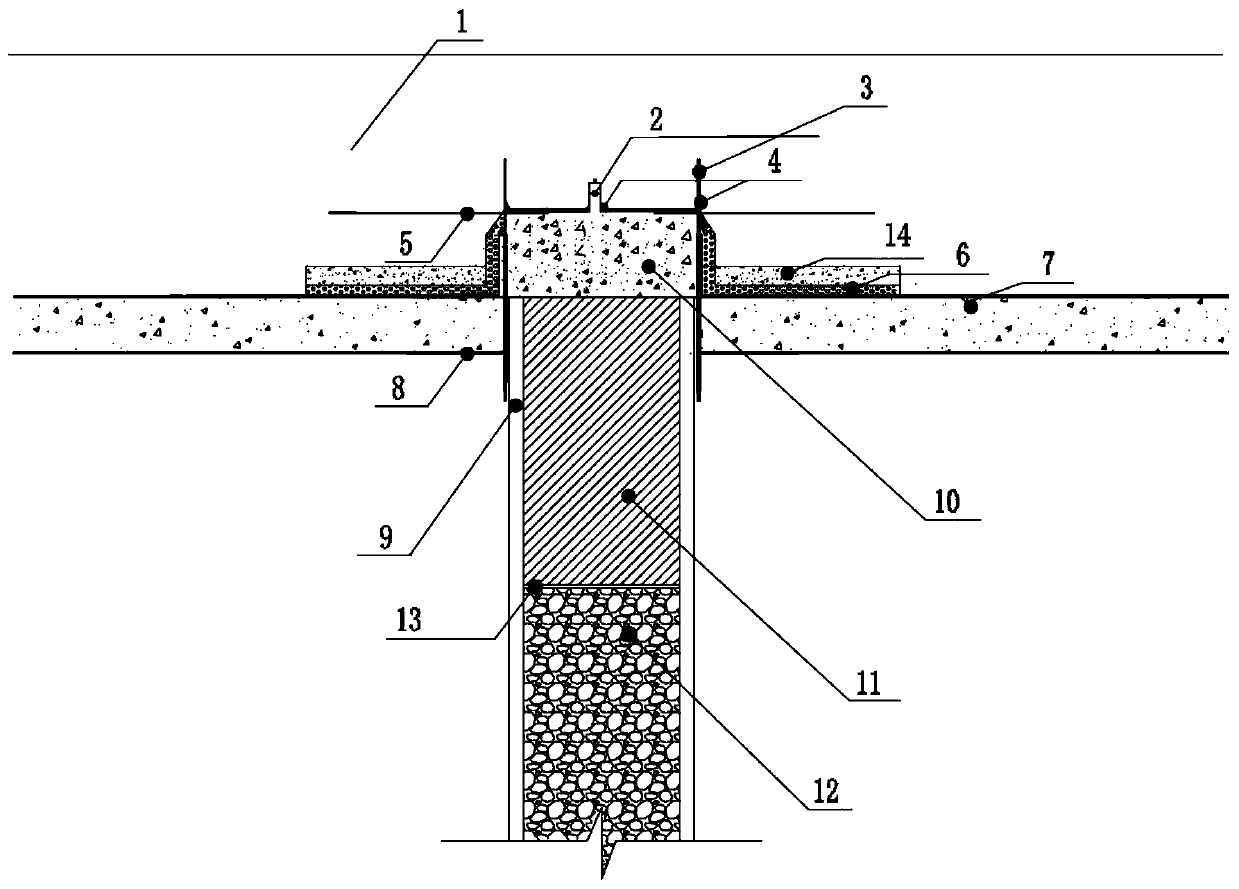

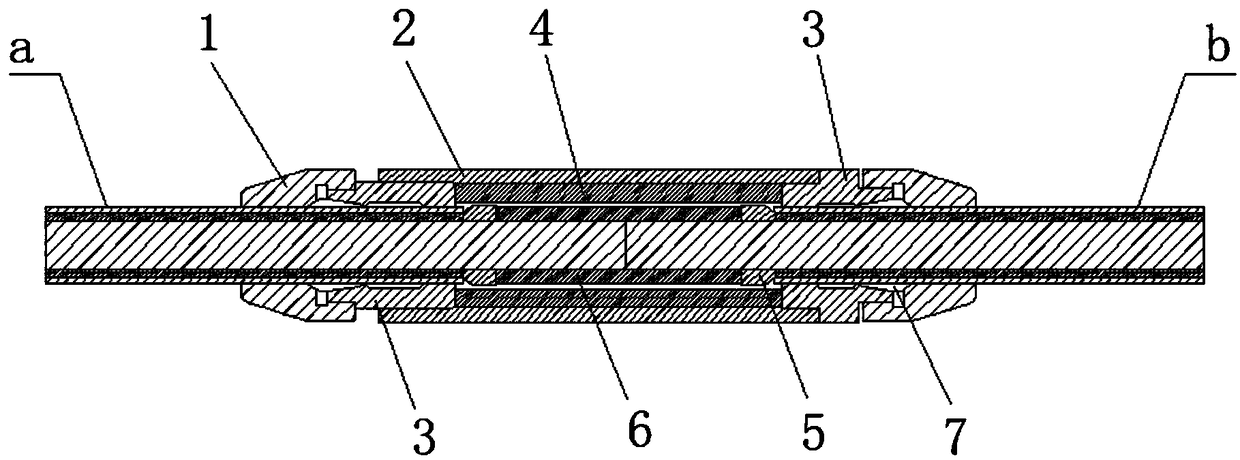

Assembly type steel pipe casing reinforced concrete combined joint and mounting method

ActiveCN105888080AImprove reliabilityIncreased shear capacityConstruction materialReinforced concreteRebar

The invention relates to an assembly type steel pipe casing reinforced concrete combined joint and a mounting method, and belongs to the technical field of structure engineering. The traditional column beam has problems that the welding quality is unstable and the construction time is long due to existence of a steel tube welding link in a construction process. The invention greatly solves the problem. The assembly type steel pipe casing reinforced concrete combined joint comprises a high-strength outer-coating steel tube, a reinforced steel bar limiting plate, high-strength reinforced steel bars, conversion spacing casings and a common outer-coating steel tube, wherein the conversion spacing casings are arranged at the upper end and the lower end of the common outer-coating steel tube, the conversion spacing casing at the upper end of the common outer-coating steel tube is connected with the high-strength outer-coating steel tube, and the conversion spacing casing at the lower end of the common outer-coating steel tube is connected with the high-strength outer-coating steel tube; the high-strength reinforced steel bars penetrate through the whole common outer-coating steel tube, the upper ends and the lower ends of the high-strength reinforced steel bars are communicated with the interior of the high-strength outer-coating steel tube, the high-strength reinforced steel bars are connected with the conversion spacing casings, and the upper ends and the lower ends of the high-strength reinforced steel bars are connected with the reinforced steel bar limiting plate. The assembly type steel pipe casing reinforced concrete combined joint and the mounting method is applied to building column beams in a building structure.

Owner:QINGDAO UNIV OF TECH

Thermal treatment method for high-grade steel casing pipe with reasonable deep processing properties

InactiveCN102392115AReduce wearExcellent screw qualityFurnace typesHeat treatment furnacesMaterial distributionSteel casing pipe

The present invention discloses a thermal treatment method for a high-grade steel casing pipe with reasonable deep processing properties. The method is characterized in that the method includes the following process steps: a, Steel pipe material distribution. Misaligned material distribution is carried out by means of steel pipe misalignment; b, Quenching furnace heating. The temperature of the heating section is 960 plus or minus 10 DEG C, the temperature of the soaking section is 910 plus or minus 10 DEG C, and the moisture retention period of time is 50 minutes; c, Water quenching. The external eruption flow rate is greater than or equal to 3000m3 / h, the internal eruption flow rate is greater than or equal to 1000m3 / h, the water quenching period of time is greater than or equal to 30 minutes, and an internal nozzle is 130mm long; and d, Tempering furnace heating. The temperature of the heating section is 695 plus or minus 5 DEG C, the temperature of the soaking section is 695 plus or minus 5 DEG C, and the moisture retention period of time is 45 minutes. The thermal treatment method can control the mechanical properties of a high-grade steel casing pipe to be within a proper deep processing range, so that a screwdriver experiences less abrasion during the threading of the steel pipe, both the thread quality and the thread screwing quality are good, and the qualification rate for the first inspection is high.

Owner:烟台宝钢钢管有限责任公司

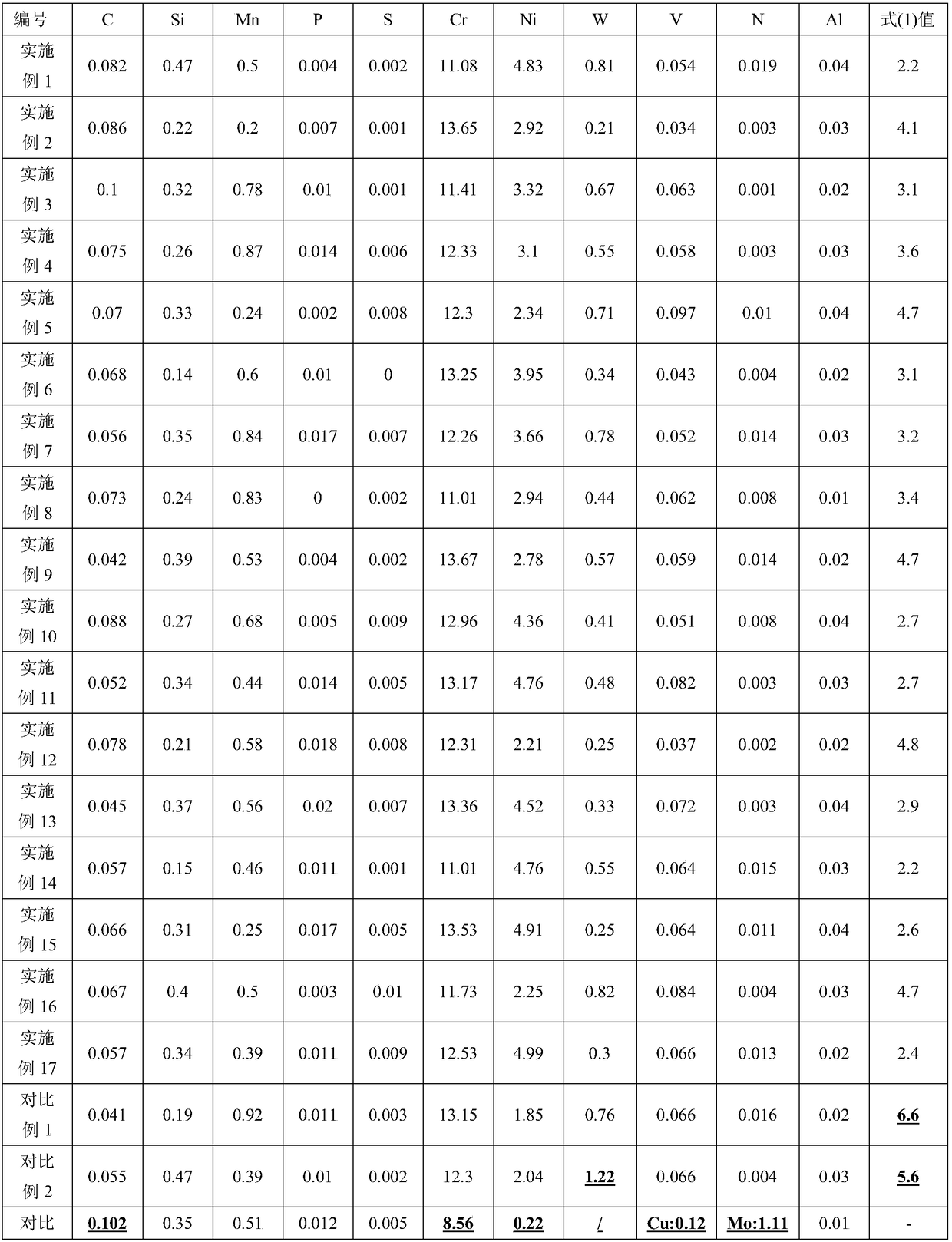

High-temperature oxygen corrosion resistant stainless steel, high-temperature oxygen corrosion resistant stainless steel casing pipe and manufacturing method of high-temperature oxygen corrosion resistant stainless steel casing pipe

The invention discloses high-temperature oxygen corrosion resistant stainless steel. The high-temperature oxygen corrosion resistant stainless steel is prepared from the following chemical elements inpercentage by mass: 0.04-0.10% of C, 0.1-0.5% of Si, 0.20-1.0% of Mn, 11.0-14.0% of Cr, 2.0-5.0% of Ni, no more than 0.02% of N, 0.2-1.0% of W, 0.03-0.1% of V, 0.01-0.04% of Al, and the balance of Feand other unavoidable impurities. The high-temperature oxygen corrosion resistant stainless steel is provided with a single tempering martensite structure, the surface of the high-temperature oxygencorrosion resistant stainless steel is provided with a passivation film, and the passivation film contains Cr and Ni. The invention further discloses a high-temperature oxygen corrosion resistant stainless steel casing pipe. The yield strength of the high-temperature oxygen corrosion resistant stainless steel casing pipe is the 90-110 ksi steel grade, the impact toughness of the high-temperature oxygen corrosion resistant stainless steel casing pipe is greater than or equal to 80 J, and the high-temperature oxygen corrosion resistant stainless steel casing pipe resists corrosion of co-existence of O2 and CO2 under the environment of 500 DEG C or above.

Owner:BAOSHAN IRON & STEEL CO LTD

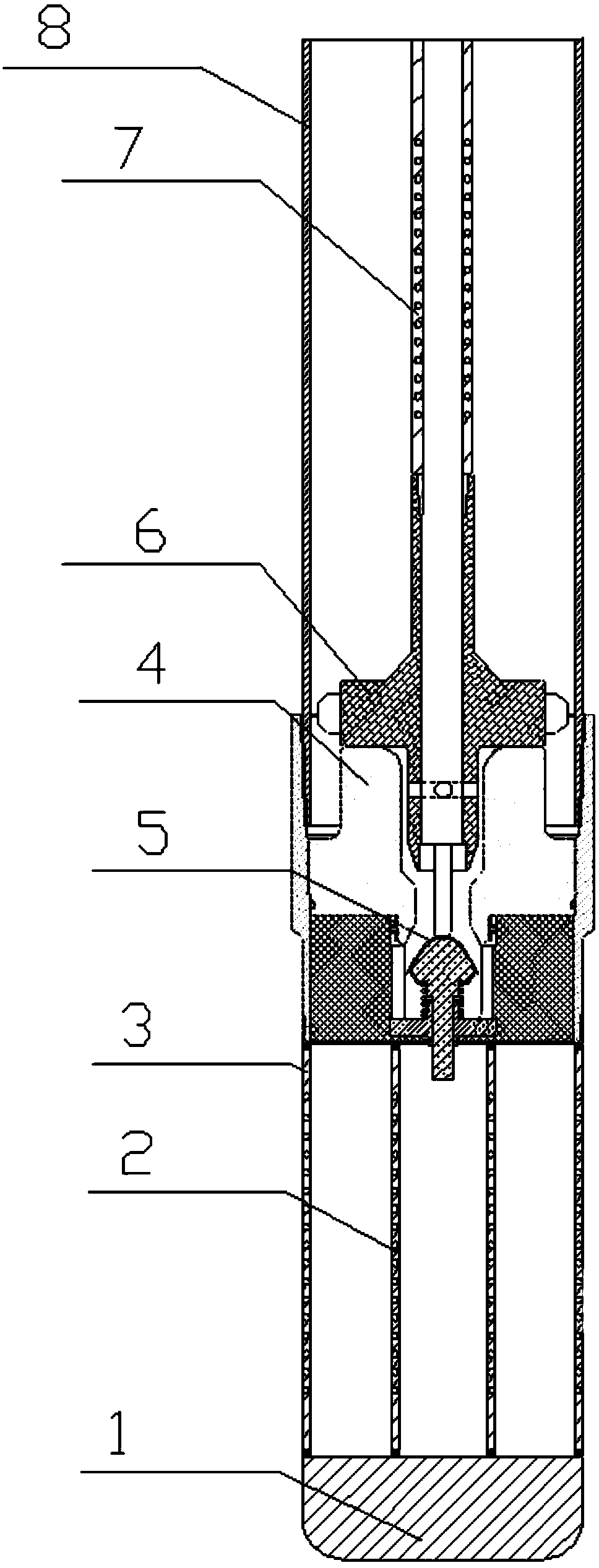

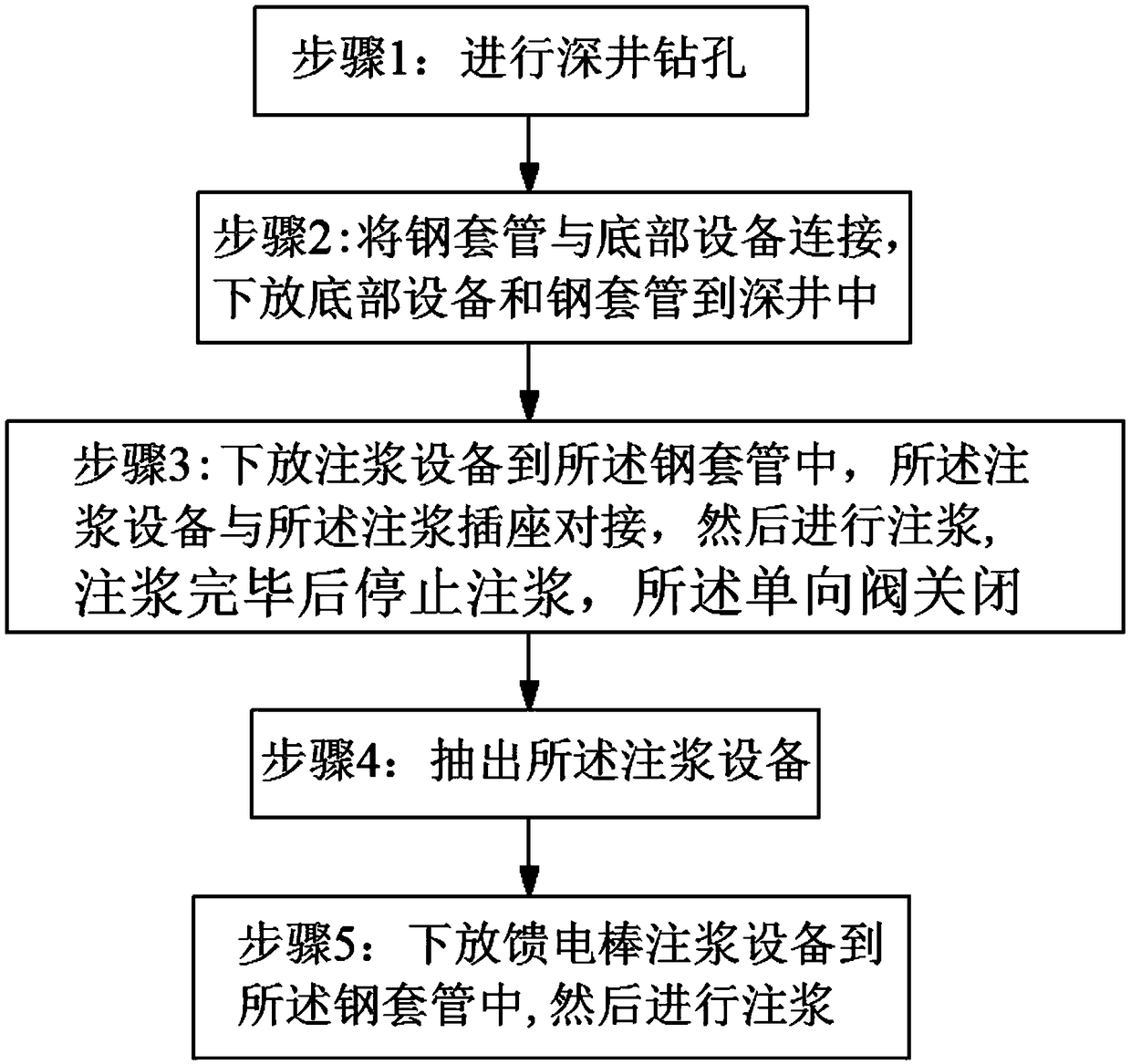

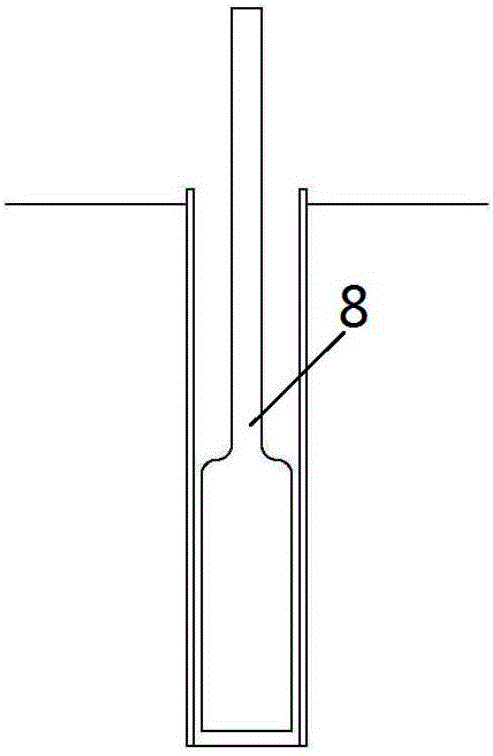

Bottom grout injection system and method suitable for deep well grounding electrode feed bar

PendingCN109295976AAvoid failureGrouting successfulFoundation engineeringConnection contact member materialSteel casing pipeSteel columns

The invention relates to a bottom grout injection system suitable for a deep well grounding electrode feed bar. The grout injection system comprises a bottom steel column, an inner layer floral tube,an outer layer floral tube, a grout injection inserting base, a one-way valve, a centralizer containing plug, a grout injection pipe and a steel casing pipe; when the grout injection system starts grout injection, through the pressure of the centralizer containing plug, the one-way valve is started, water on the outer pipe of the steel casing pipe is supplemented into the steel casing pipe in time, and the phenomenon that when the feed bar is drained to the ground, due to temperature rise, water is evaporated, and a feed system fails is avoided.

Owner:GUANGDONG KENUO SURVEYING ENG CO LTD +2

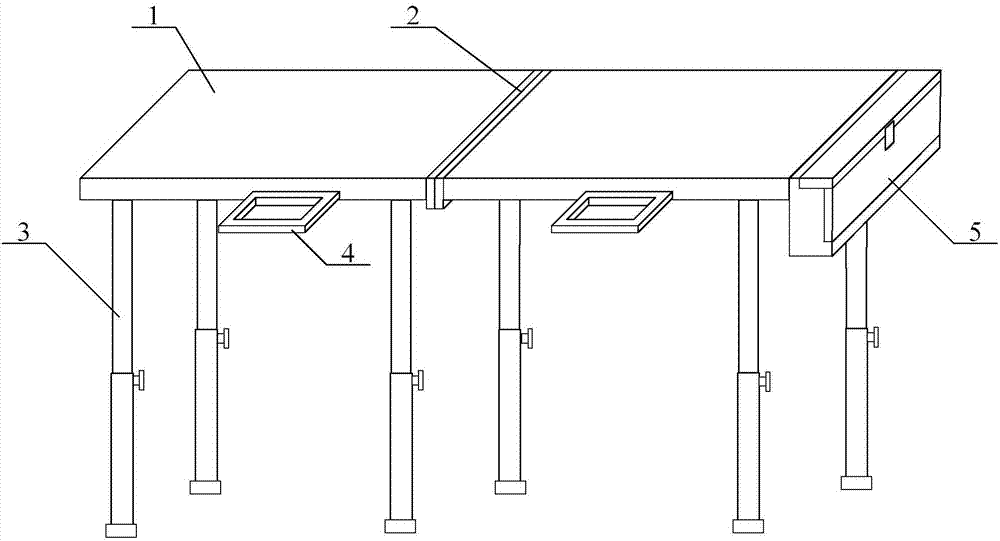

Multifunctional design table

InactiveCN107296391AEasy to foldSmall footprintWork benchesTablesSoftware engineeringSteel casing pipe

The present invention provides a multifunctional design table, which includes a workbench, a folding board, an adjustable support rod device, a handle and a tool storage device, the folding boards are installed on the right part and the left part of the workbench respectively, and the The folding boards are connected with hinges between the folding boards, the adjustable support rod device is installed at the four corners of the lower part of the workbench, the handles are respectively installed in the middle of the workbench, and the tool storage device is installed On the right side of the workbench. The beneficial effects of the present invention are as follows: the specific use of PE plastic handles for the handle is conducive to convenient carrying; the specific use of stainless steel sleeves for the telescopic rod is conducive to better folding and convenient portability; through multiple hooks The setting is conducive to improving the function of the clothing design platform.

Owner:TIANJIN TF SUNNY GARMENT

Adjustable multilayer water taking head for river water taking, and mounting method

PendingCN110397114AReduce riskReduce difficultyDrinking water installationSurface layerSteel casing pipe

The invention relates to an adjustable multilayer water taking head for river water taking, and a mounting method. The adjustable multilayer water taking head for the river water taking comprises a plurality of steel pipe piles, steel corbels which are arranged at the bottoms of the steel pipe piles, a plurality of steel casing pipes which sleeve the steel pipe piles and are located on the steel corbels, and a plurality of steel sleeves which sleeve the steel pipe piles and are located at the tops of the steel pipe piles; a steel platform is together supported by the multiple steel pipe piles;a top layer water taking head is fixed to the steel platform; each steel casing pipe comprises an upper casing pipe and a lower casing pipe; a first transverse beam is mounted between every two adjacent upper casing pipes; a second transverse beam is mounted between every two adjacent lower casing pipes; a bottom layer water taking head is fixed to the second transverse beams; and a middle layerwater taking head is fixed to the first transverse beams. According to the adjustable multilayer water taking head for the river water taking, it is guaranteed that water with the surface layer sand content being relatively low can be taken by the water taking heads in different seasons, the adjustable multilayer water taking head for the river water taking adapts to change of erosion and deposition of a river, and the safety of the water taking is ensured.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Method for preventing casing pipe from being fractured in underground well new construction hydrological drilling

ActiveCN110607995AResolve the breakEasy to operateDrilling rodsSealing/packingEngineeringLarge deformation

The invention discloses a method for preventing casing pipe from being fractured in underground well new construction hydrological drilling. The method comprises the following specific steps of anti-fracture casing pipe manufacturing, drilling, anti-fracture casing pipe lowering, anti-fracture casing pipe grouting, in-situ sweep hole drilling, performing casing pipe pressure withstand testing, andhigh-pressure blowout prevention valve installing at an orifice after the pressure withstand testing reaches a design requirement, wherein a drill bit is drilled and extended to a final hole depth through in-situ trepanning, and the anti-fracture casting pipe is provided with a short section plastic pipe and a long section plastic pipe. According to the method, a mode that a conventional steel casing pipe and a hole wall surrounding rock is separated in a large deformation section of the surrounding rock is adopted, when the surrounding rock occurs large-amplitude transformation fracture, theconventional steel casing pipe is not affected; and the method is convenient to operate, and can effectively prevent the fracture problem of the hydrological drilling anti-fracture casing pipe undera coal mine.

Owner:CHINA UNIV OF MINING & TECH

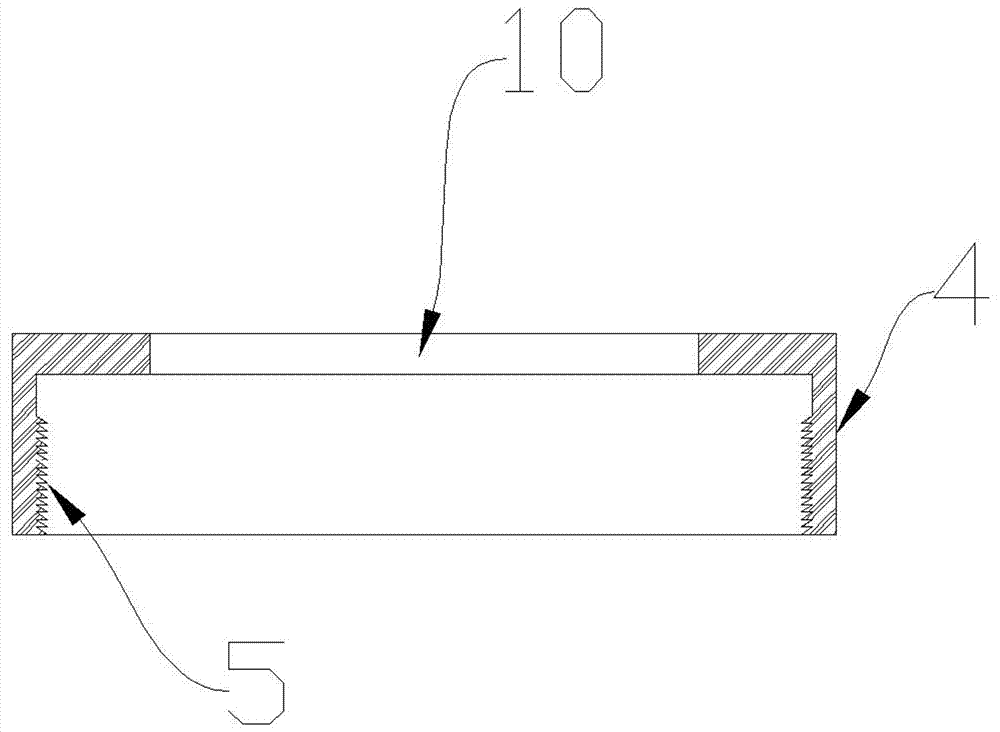

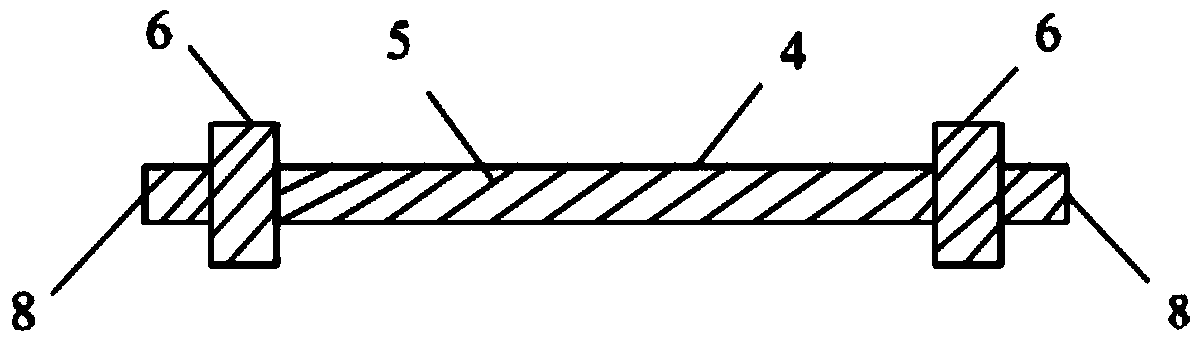

Embedded type fiber bragg grating strain transducer for surface grooved-type road and manufacturing method for embedded type fiber bragg grating strain transducer

The invention discloses an embedded type fiber bragg grating strain transducer for a surface grooved-type road and a manufacturing method for the embedded type fiber bragg grating strain transducer. The strain transducer is composed of a bare fiber and encapsulating materials, and is characterized in that a casing pipe is arranged outside the pigtail part of the bare fiber, an armor cable is arranged inside the casing pipe, a steel casing pipe is arranged outside the armor cable, the two ends of the steel casing pipe are provided with end expanding heads respectively, and the surface of the steel casing pipe is provided with a plurality of surface grooves. The strength of the strain transducer can meet the conditions of a long road engineering serving period, an adverse serving environment and the like; the surface grooves in the steel casing pipe and the end expanding heads can be used for enhancing the connecting force between the sensor and road face materials and improving the collaborative deformation capacities of the transducer and the road face, and therefore the measuring errors caused by modulus differences of the transducer and the road face are reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Manufacturing method for low-sag soft-aluminum-wire optical fiber composite overhead phase line

InactiveCN103426550AExtended service lifeNo significant effect on strengthPower cables with screens/conductive layersCable/conductor manufacturePhysical chemistrySteel casing pipe

The invention discloses a manufacturing method for a low-sag soft-aluminum-wire optical fiber composite overhead phase line. The method comprises the following steps that 1) optical fibers are arranged in a stainless steel casing pipe; 2) a fan-shaped aluminum cladding layer is extruded on the outer surface of the stainless steel casing pipe to form an optical fiber unit; 3) fan-shaped soft aluminum wires and the optical fiber unit are simultaneously intertwisted outside a carbon fiber composite core; 4) and at least one layer of fan-shaped soft aluminum wires are intertwisted on an outermost layer.

Owner:HENAN KOSEN CABLE

Construction method for pipe-following drilling micro pile of slewing drilling machine

InactiveCN104963332AAvoid disturbanceAvoid the risk of deformationRailway tracksExcavationsDiseaseSlag

The invention discloses a construction method for a pipe-following drilling micro pile of a slewing drilling machine. The drilling machine is installed in place, and the orientations and angles of a drill pipe and a drill bit are adjusted to be uniform with design parameters; after preparation, drilling starts to be performed; a direct cycle method is adopted, and circulating water is utilized for cooling the drill bit and removing slag; a wall-protecting steel casing pipe follows and is pressed synchronously every time drilling is performed by 0.25 m-0.5 m, and the distance between the wall-protecting steel casing pipe and the bottom of a hole is smaller than or equal to 0.5 m; every time drilling is performed by 1 m-2 m, the angle of the drill pipe is checked one time; after reaching a designed depth, the drill pipe and a drilling tool are taken out; fine aggregate concrete or cement mortar is injected into the wall-protecting steel casing pipe; after the concrete or the cement mortar is solidified, the pipe-following drilling micro pile for reinforcing roadbeds of existing high-speed railways is formed. Soil body disturbance of the roadbed can be avoided to the maximum degree, and roadbed additive deformation caused by regulation of project construction is prevented. Construction can be performed under the driving conditions of the existing high-speed railways, and normal operation of existing lines is not affected; the construction method is suitable for performing disease regulation on roadbed deformation occurring on the existing high-speed railways.

Owner:HUBEI UNIV OF TECH

Combined plugging device of high-water-pressure precipitation well and plugging method

PendingCN110820780ASolve technical problems that are difficult to blockReduce the chance of leaksProtective foundationWater stopSteel casing pipe

The invention provides a combined plugging device of a high-water-pressure precipitation well. The combined plugging device comprises a downcast pipe well, a waterproof casing pipe, an upper water stop ring, a lower water stop ring and a screwed plug. The top of the downcast pipe well is sleeved with the waterproof steel casing pipe, so that the upper end of the waterproof steel casing pipe is higher than foundation trench soil. The lower water stop ring is in contact with the foundation trench soil. The upper water stop ring is fixedly connected with the waterproof casing pipe. The screwed plug is fixed to the middle of the upper water stop ring. The invention further provides a plugging method of the device. The plugging method comprises the steps that the downcast pipe well is firstly sleeved with the waterproof steel casing pipe, so that the lower water stop ring is in contact with a foundation trench; and a plain concrete cushion layer is poured, waterproof material construction is carried out on the face layer of the plain concrete cushion layer, construction of a waterproof protection layer is carried out, a thick steel plate is welded to the middle of the upper water stop ring, the screwed plug is used for mechanical plugging, and later concrete pouring is completed. Procedures are simple, time and labor are saved, the seepage prevention effect is good, and a second defense line for solving seepage of an underground structure is formed.

Owner:TIANJIN 20 CONSTR

Welded connector of mineral insulated fireproof cable

PendingCN108899665AThe effect of high-efficiency insulation and fire protectionElectric connection structural associationsConnections effected by permanent deformationSteel casing pipeMaterials science

The invention discloses a welded connector of a mineral insulated fireproof cable. The welded connector comprises a stainless steel casing pipe body, two locking nuts, two aluminium-oxide ceramic rings, two semi-circular aluminium-oxide ceramic shells, and two compression cones. The two locking nuts are arranged at the two ends of the s stainless steel casing pipe body coaxially at equal diameters; the two aluminium-oxide ceramic rings sleeve two cable wire cores; the two semi-circular aluminium-oxide ceramic shells sleeve the outside of the connection part between the two cable wire cores; and the two compression cones are connected between the stainless steel casing pipe body and the locking nuts in a sealing manner. The compression cones, the stainless steel casing pipe body, the aluminium-oxide ceramic rings, and the locking nuts are arranged coaxially. According to the invention, the stainless steel casing pipe body serves as a main protection body and insulation protection of theexposed part of the connection part of the wire cores is realized by combining the aluminium-oxide ceramic shells, so that a high-efficiency insulation fireproof effect is realized.

Owner:博侃电气(合肥)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com