Self-waterproof casing pipe convenient to install

A waterproof casing, a fast technology, applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of time-consuming, no self-waterproof function, and unsatisfactory waterproof effect.

Inactive Publication Date: 2017-07-25

JINGMEN CHUANGJIA MACHINERY TECH CO LTD

View PDF9 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The currently used casings for pipes passing through the pool wall do not have the self-waterproof function, and need to be waterproofed separately. The waterproof effect is not ideal, and it is labor-intensive and time-consuming.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0007] SUMMARY OF THE INVENTION The specific embodiments of the present invention have been described in detail and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

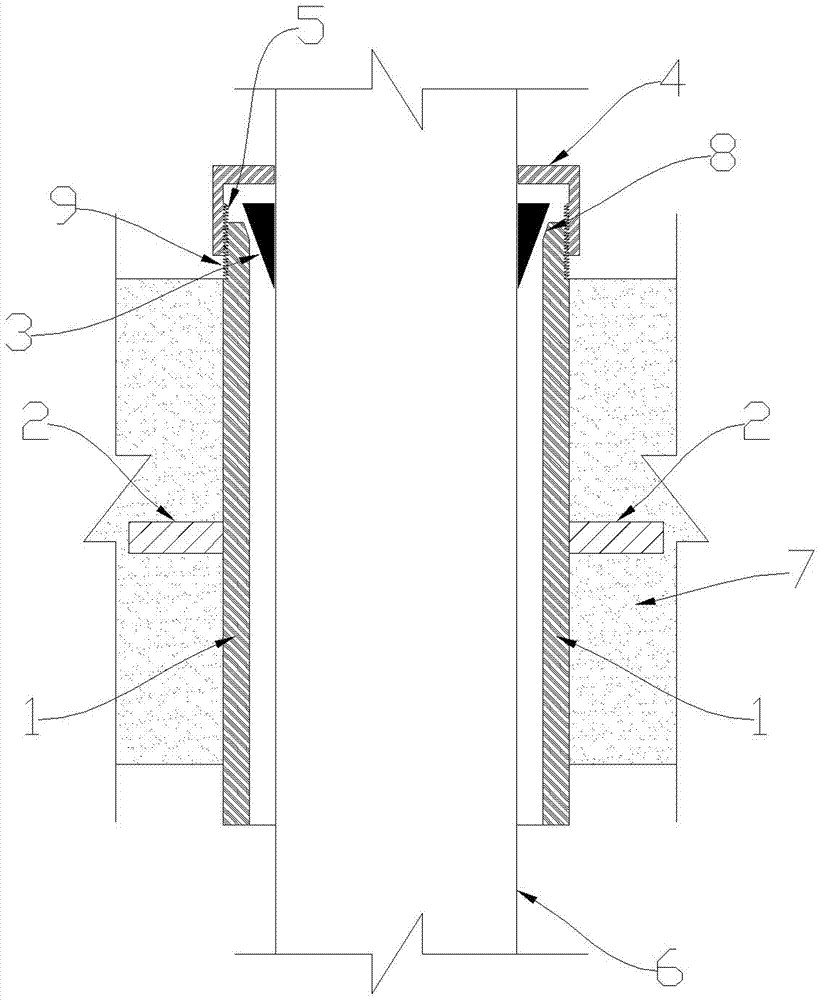

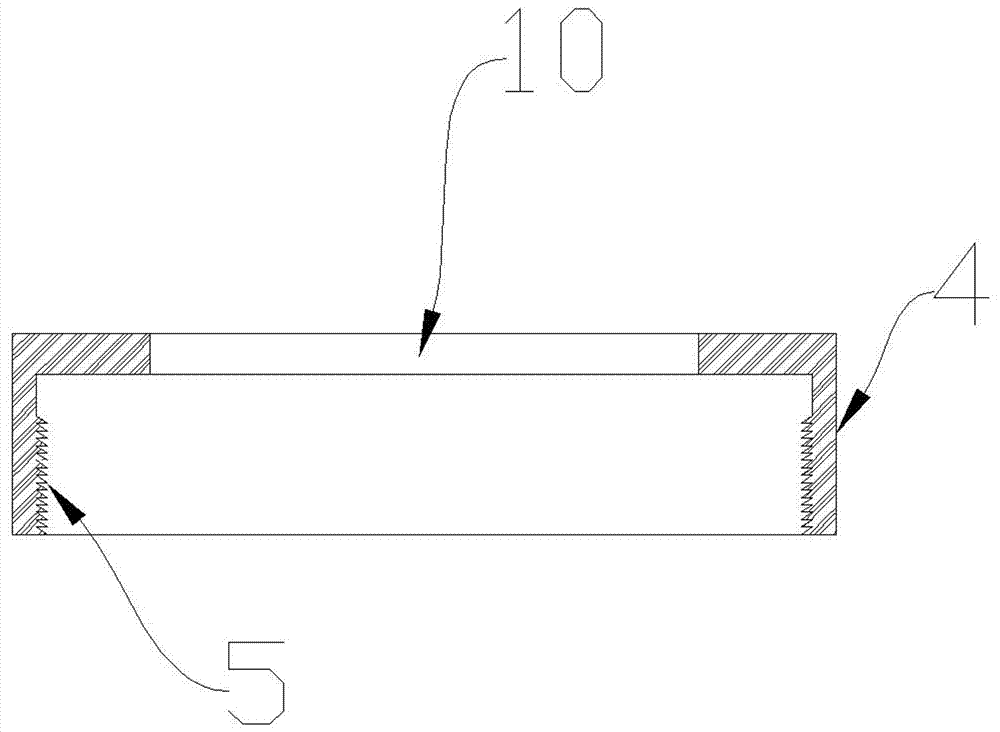

The invention relates to a self-waterproof casing pipe convenient to install. The self-waterproof pipe convenient to install is mainly used for waterproof use of pipelines penetrating water pool walls in the field of building engineering and can also be used for waterproof use of pipelines penetrating roofs or building surfaces or wall surfaces. The self-waterproof casing pipe convenient to install is mainly composed of a steel casing pipe, a steel water stop ring, a waterproof rubber ring and a waterproof cover. According to the main work principle and the installation method, when concrete is poured to the wall of a water pool, the steel casing pipe and the steel water stop ring are embedded in concrete, when the concrete reaches certain strength, the pipeline needed for penetrating penetrates the steel casing pipe, then the waterproof rubber ring is arranged on the pipeline in a sleeving manner from top to bottom, the conical face of the waterproof rubber ring is tightly attached to the oblique face of the steel casing pipe, then the pipeline penetrates a hole in the waterproof cover from top to bottom, the waterproof cover is screwed, the upper surface of the waterproof rubber ring is pressed step by step through the waterproof cover, the waterproof rubber ring moves downwards step by step, the conical face of the waterproof rubber ring and the oblique face of the steel casing pipe are pressed tightly, and installation work is finished.

Description

technical field [0001] The invention is mainly used for waterproofing pipelines passing through pool walls in the field of construction engineering, and can also be used for waterproofing pipelines passing through roofs, floors or walls. Background technique [0002] The currently used casings for pipes passing through the pool wall do not have the self-waterproof function, and need to be waterproofed separately. The waterproof effect is not ideal, and it is labor-intensive and time-consuming. Contents of the invention [0003] The present invention overcomes the above-mentioned defects, and it has good waterproof effect and quick and convenient installation; it is mainly composed of a steel casing (1), a steel water stop ring (2), a waterproof rubber ring (3), and a waterproof cover (4); the steel sleeve The upper part of the pipe (1) has an external thread (9), the inner side of the upper end of the steel sleeve (1) has an inclined surface (8), the steel water stop ring ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L5/02

CPCF16L5/02

Inventor 彭宝安

Owner JINGMEN CHUANGJIA MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com