Full casing pipe soil taking vibration construction method for squeezed and expanded cast-in-place pile

A construction method and technology for cast-in-place piles, which are applied in the fields of earthwork drilling, sheet pile wall, foundation structure engineering, etc. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

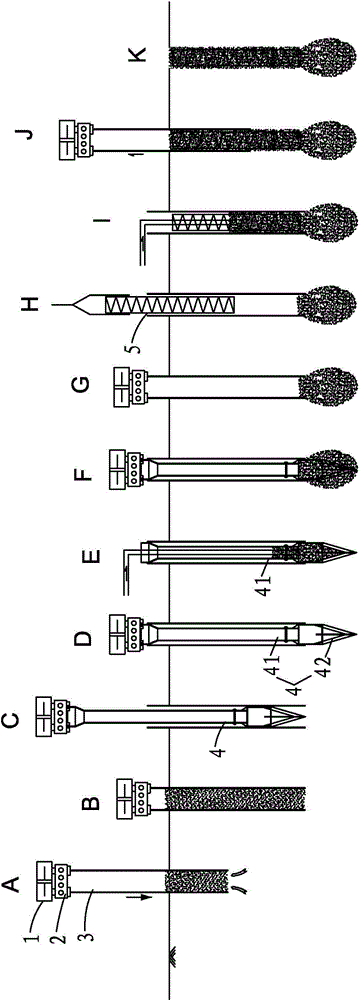

[0023] see Figure 1-3 , a construction method of vibrating extruded and expanded cast-in-place piles with full-casing soil extraction, comprising the following steps:

[0024] A. The steel casing 3 sinks into the soil under the high-frequency vibration of the high-frequency vibrating hammer 1 through the holder 2, and the foundation soil gradually enters the steel casing 3; Stones can be removed by down-the-hole hammer, blasting or manual chiseling.

[0025] B. (2) The steel casing 3 is sunk to the design elevation, and the soil layer in the steel casing 3 is taken mechanically or manually; The equipment is fetched.

[0026] C. Put a special reamer 4 in the steel casing 3;

[0027] D. The special reamer 4 is connected to the high-frequency vibratory hammer 1 to carry out vibratory reaming on the inner bottom of the steel casing 3;

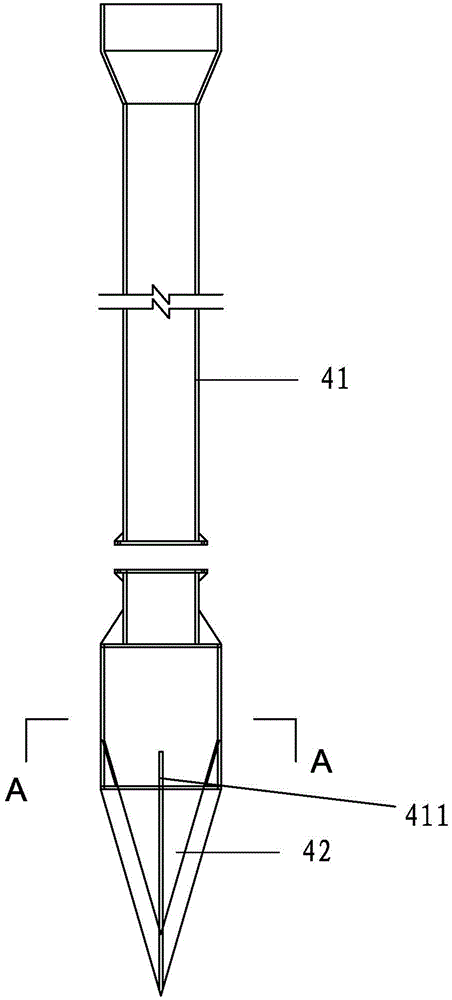

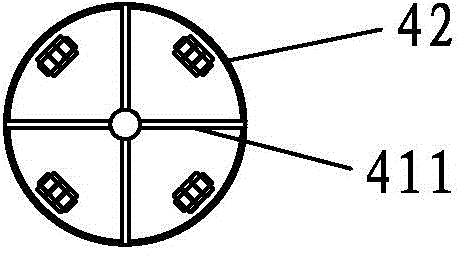

[0028] Described special-purpose reamer 4 comprises a tubular body 41 and four flaps 42, and described tubular body 41 is a hollow structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com