Welded connector of mineral insulated fireproof cable

A fire-resistant cable and mineral insulation technology, which is applied in the direction of conductive connection, electrical component connection, connection with permanent deformation, etc., can solve problems such as inability to withstand high temperature, affecting cable insulation performance, and large mud viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

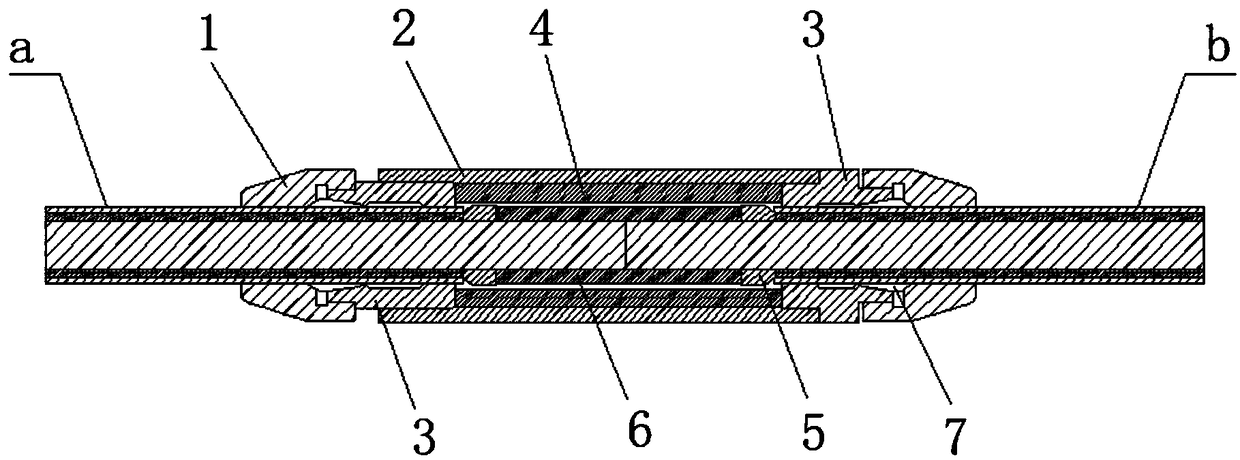

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] Such as figure 1 As shown, the welded connector of the mineral insulated fireproof cable consists of a stainless steel sleeve body 2 coaxially arranged, two lock nuts 1, two alumina ceramic rings 5, two semicircular alumina ceramic shells 4, Two compression cones 7, two glands 3 and a copper connecting pipe 6 are formed.

[0020] A gland 3 sleeved on the wire core is installed between the stainless steel sleeve body 2 and the compression cone 7, and the end of the compression cone 7 facing the gland 3 is formed with a first chamfer, the angle of which is α, and the compression cone 7. A second chamfer is formed at the end facing the lock nut 1, the angle of which is β, and a first chamfer matched with the first chamfer is formed at the end of the gland 3 facing the compression cone 7. The angle of the first chamfer is γ, the end of the lock nut 1 facing the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com