Construction method for pipe-following drilling micro pile of slewing drilling machine

A technology of pipe drilling and rotary drilling rig, which is applied in excavation, soil protection, foundation structure engineering, etc. It can solve problems such as subsidence not exceeding 15mm, uplift and deformation of subgrade soil, poor foundation treatment effect, etc., and achieve construction technology Easy, eliminate hole collapse and improve pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Describe the present invention in detail below with reference to accompanying drawing:

[0026] Concrete steps of the present invention are as follows:

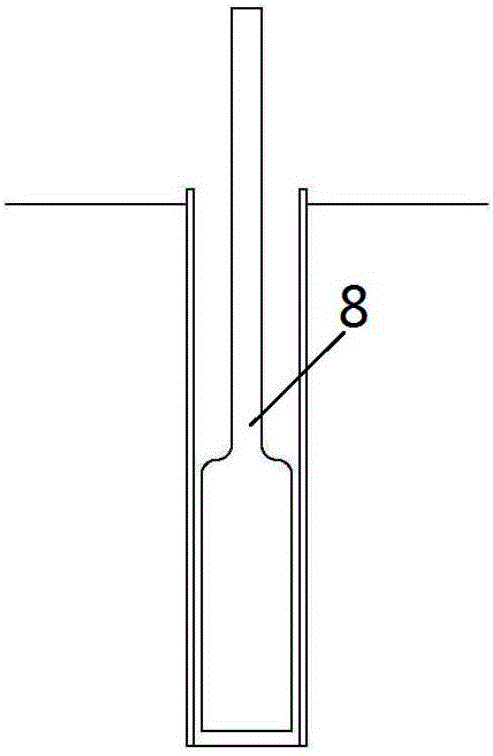

[0027] 1) Install the drilling rig in place on the working platform, and the drilling rig adopts a rotary drilling rig. Adjust drill rod, drill bit position, angle and design parameter to be consistent; After getting ready, start drilling with rotary drill drill rod, core pipe and drill bit 8 (see figure 1 );

[0028] 2) Set up a water pool near the drilling rig. The water pool needs to be plastered with cement mortar or other effective anti-seepage measures to avoid the impact of circulating water seepage on the foundation soil. The positive circulation method is used to cool the drill bit and remove slag with circulating water; each time the footage is 0.8-1.2m, the core tube is used to take the soil core and core out of the borehole.

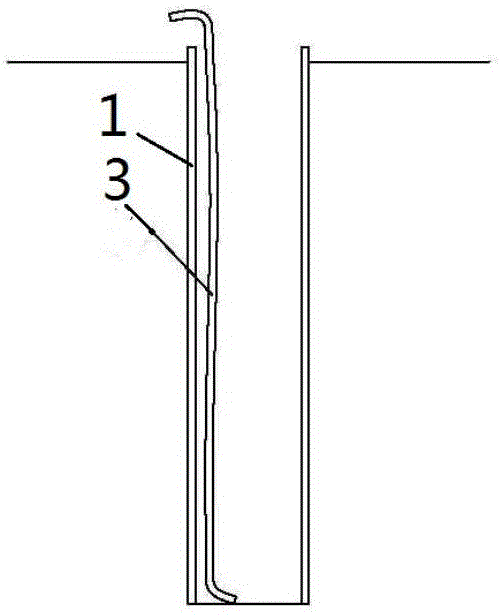

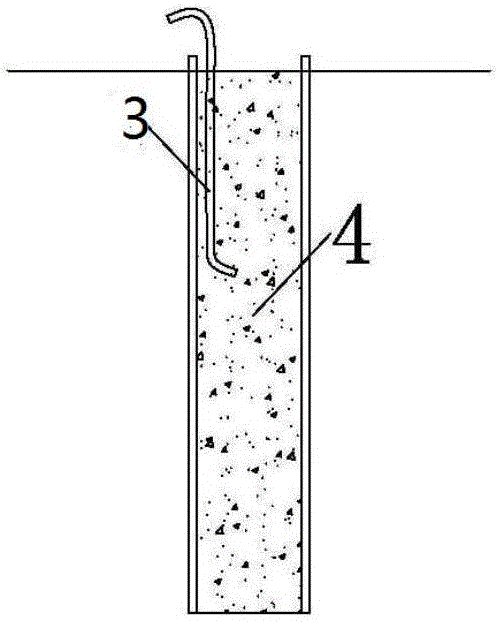

[0029] 3) With the drilling of the drilling rig, every time 0.25-0.5m is drill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com