Embedded type fiber bragg grating strain transducer for surface grooved-type road and manufacturing method for embedded type fiber bragg grating strain transducer

A strain sensor, fiber grating technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problem of poor cooperative deformation ability between the sensor and the road surface, and achieve the effect of good cooperative deformation ability, good road conditions, and good adaptation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

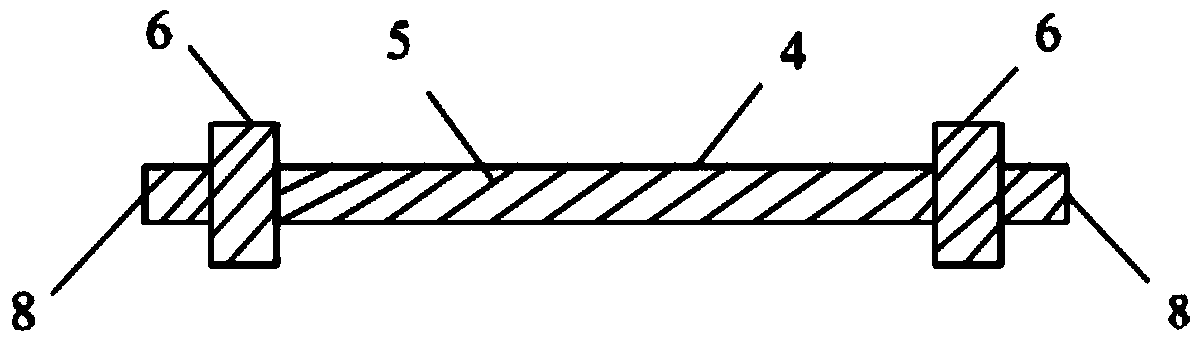

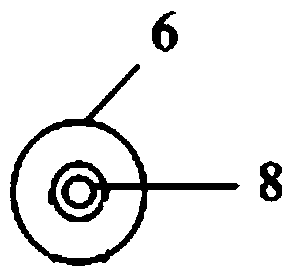

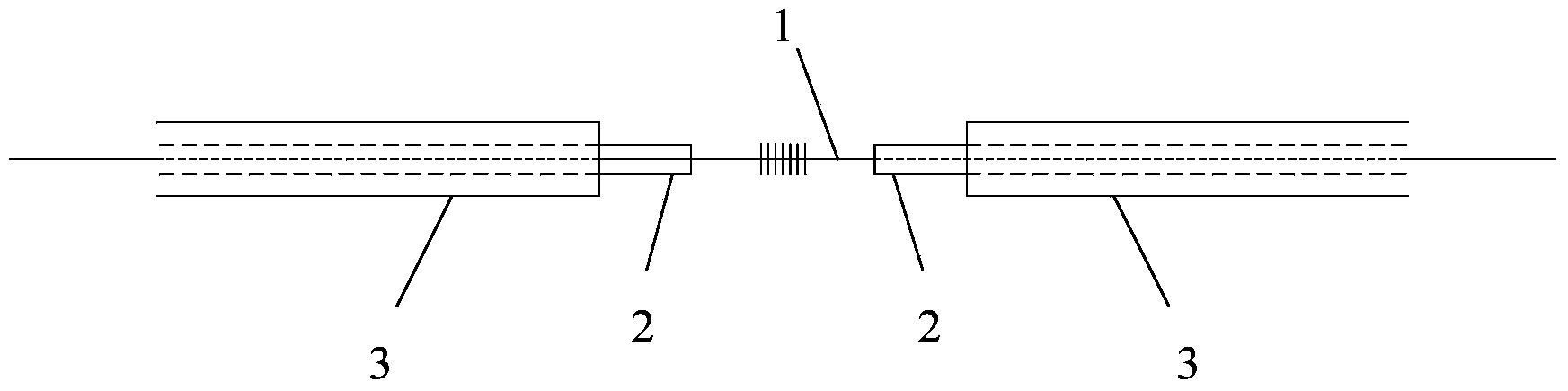

[0034] The present invention will be further described below in conjunction with the accompanying drawings. A road-use embedded fiber grating sensor packaged in a surface grooved steel casing, as shown in Figure 1, figure 2 , image 3 , there is a bare optical fiber 1, the tail fiber part of the bare optical fiber except the grating section is inserted into the white sleeve 2, and the white sleeve 2 is inserted into the armored cable 3, and the initially encapsulated optical fiber is sleeved into the steel sleeve 4, and the steel sleeve 4 Grooves 5 are engraved on the surface, end expansion heads 6 are provided at both ends, epoxy resin adhesive 7 is poured into the gap between the armored cable 2 and the steel casing 4, and the two ends of the steel casing 4 are sealed with plugs 8 .

[0035] During the sensor packaging process, when the epoxy resin adhesive is poured, the iron stand 9 is needed, and the sensor is fixed by the sensor fixing clip 10 on the iron stand 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com