Thin-wall steel combined column partially filled with ultra-high toughness cement-based composite material

A technology of ultra-high toughness and composite materials, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of low tensile strength, self-heavy composite columns, long construction period, etc., achieve simple overall structure, convenient node connection, shorten The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

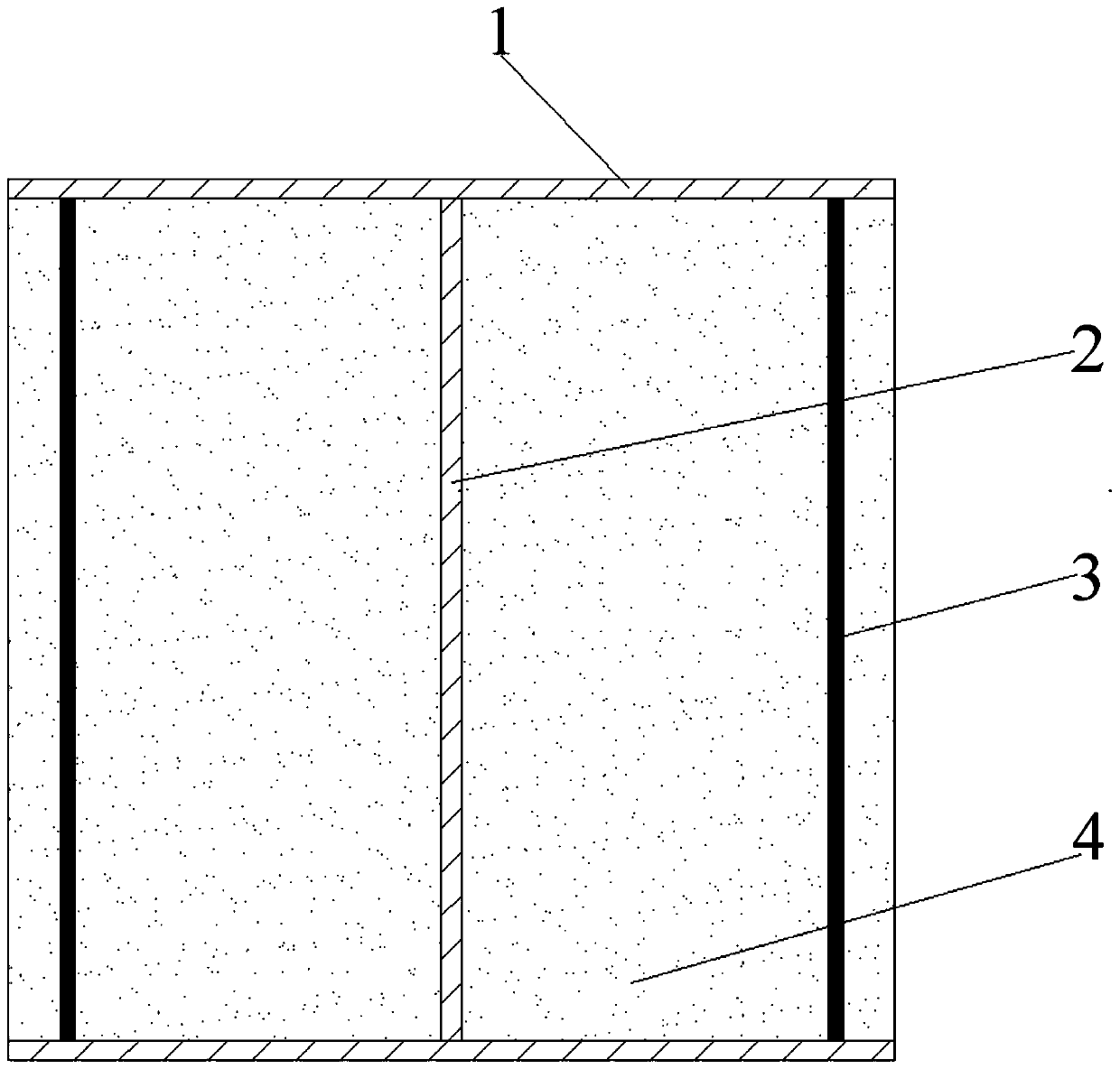

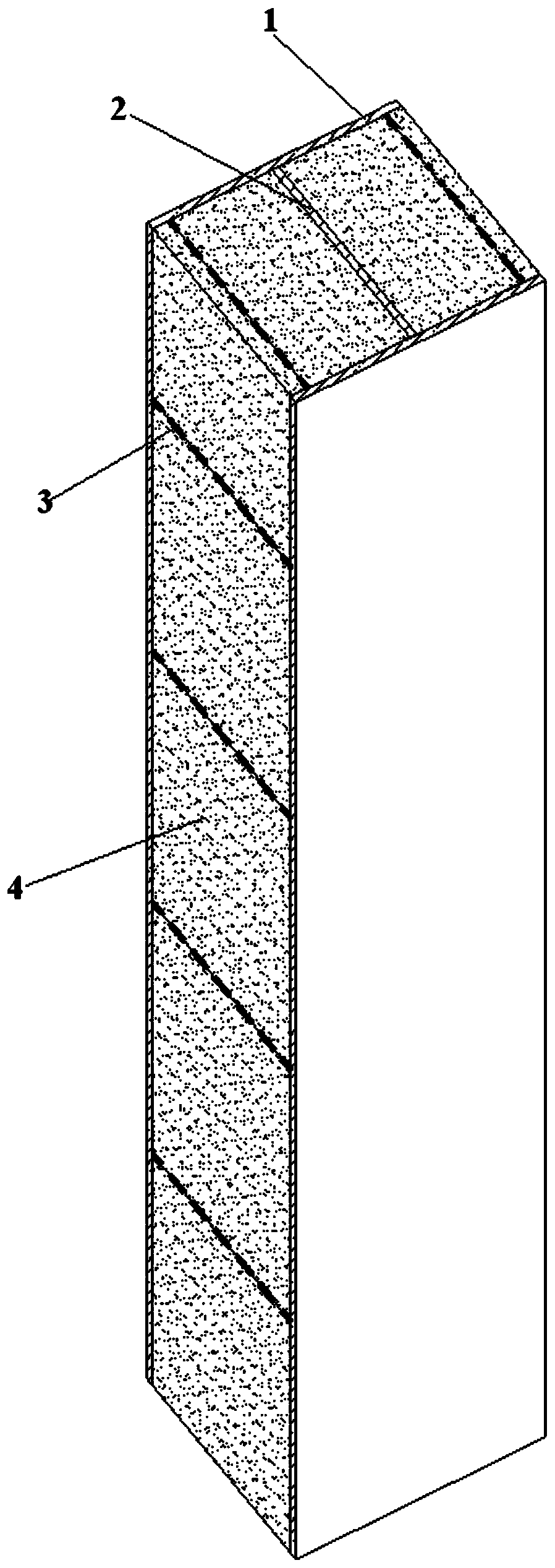

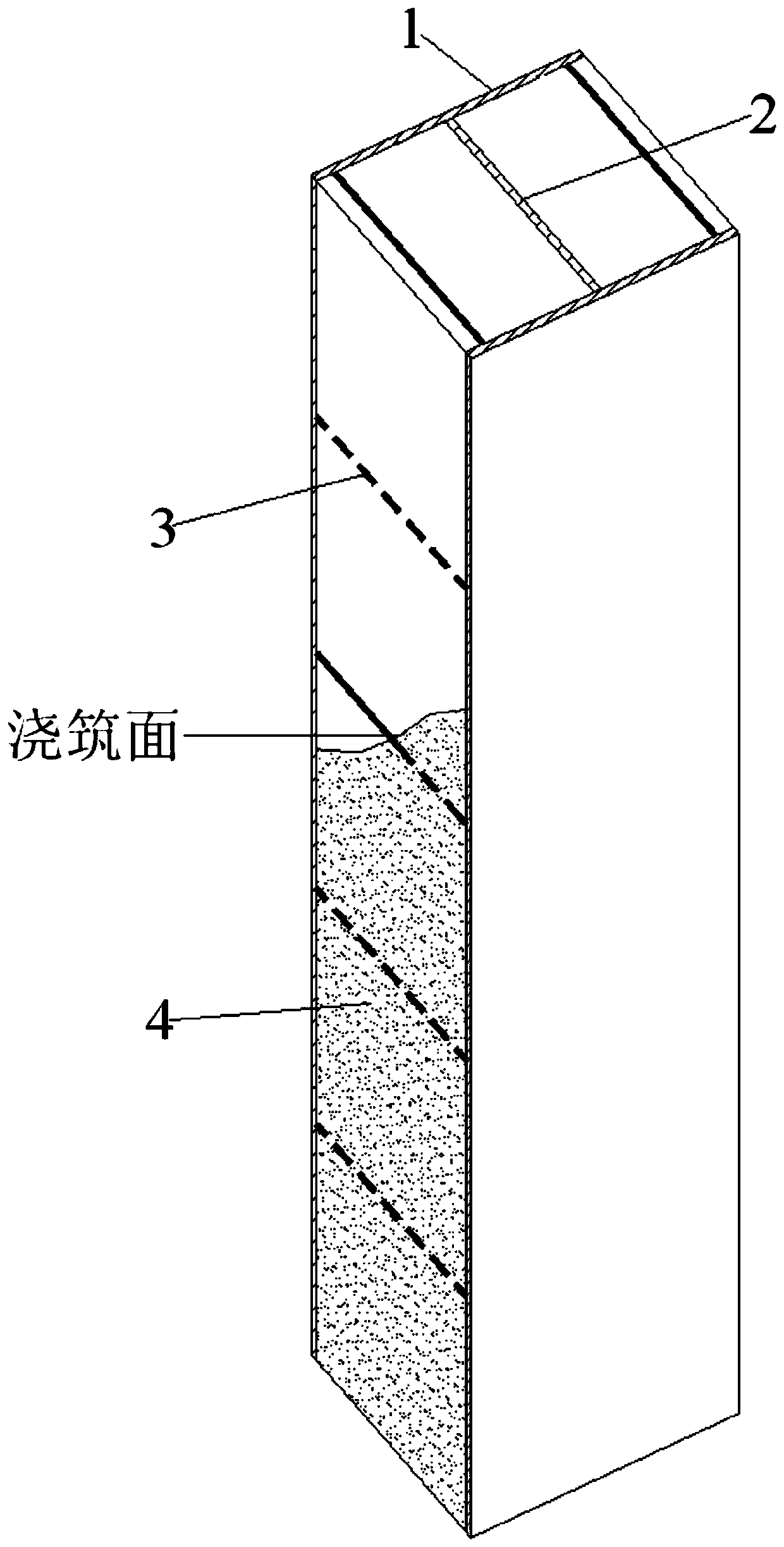

[0038] see image 3 , the present invention is a thin-walled steel composite column partially filled with ultra-high toughness cement-based composite materials, the thin-walled steel composite column is a square column with a side length of 450mm, and the column height is 3.0m; the tie bar 3 is a steel rod with a diameter of 14mm, and the The thin-walled flange plate 1 and the thin-walled web plate 2 are both Q345 grade steel with a thickness of 6mm. The thin-walled flange plate 1 and the thin-walled web plate 2 are welded into an H shape, and the The super-high toughness cement-based composite material 4 is filled in between.

[0039] The specific construction process is as follows:

[0040] S1. The thin-walled flange plate 1 and the thin-walled web plate 2 are welded by electrode arc welding with fillet welds to form an H-shaped thin-walled steel column;

[0041] S2. Arrange the tie rods 3 inside the thin-walled flange plate 1 at fixed intervals. The method adopted is to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com