Manufacturing method for low-sag soft-aluminum-wire optical fiber composite overhead phase line

A technology of optical fiber composite and manufacturing method, which is applied in the direction of cable/conductor manufacturing, power cable with shielding layer/conductive layer, power cable, etc., and can solve the problem of large sag of optical fiber composite overhead phase line, general self-damping performance, and corrosion resistance. Low performance and other problems, to achieve the effect of not easy to freeze, smooth surface and good self-damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail according to the examples below.

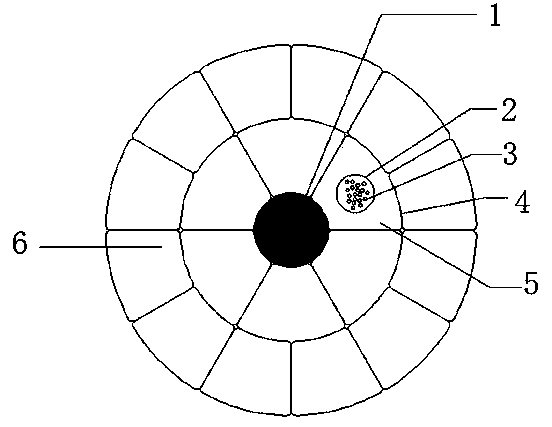

[0013] refer to figure 1 , the present invention a kind of manufacturing method of low sag, soft aluminum type line optical fiber composite overhead phase line, comprising:

[0014] 1) First set the optical fiber 3 in the stainless steel casing 2;

[0015] 2) The outer surface of the stainless steel sleeve 2 is extruded with a fan-shaped aluminum cladding layer 5 to make an optical fiber unit 4;

[0016] 3) Then simultaneously twist the fan-shaped annealed aluminum wire 6 and the optical fiber unit 4 outside the carbon fiber composite core 1;

[0017] 4) Finally twist at least one layer of fan-shaped annealed aluminum wire 6 on the outermost layer.

[0018] Such as figure 1 As shown, a low sag, soft aluminum type fiber composite overhead phase line is composed of a carbon fiber composite core 1, a conductor and an optical fiber unit 4, and a conductor and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com