Patents

Literature

383results about How to "Increase ampacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

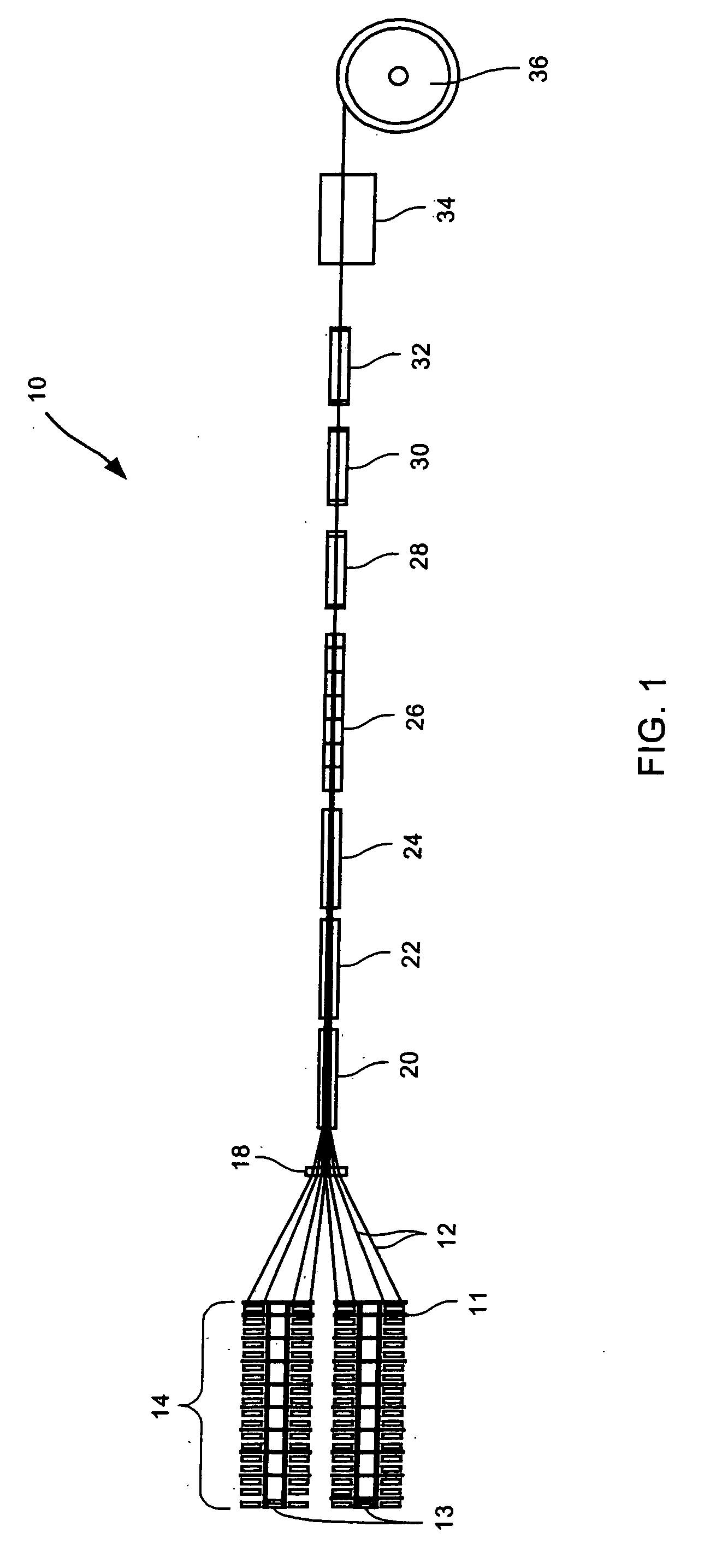

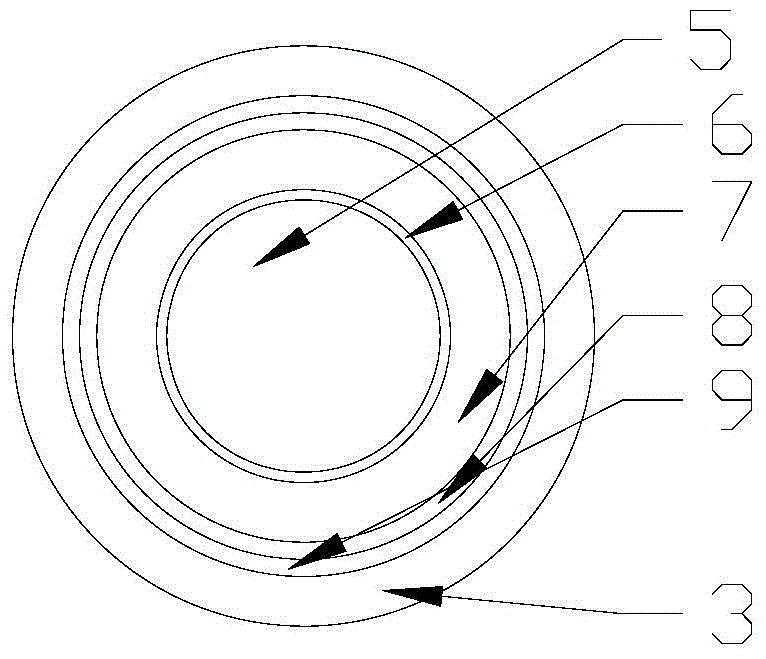

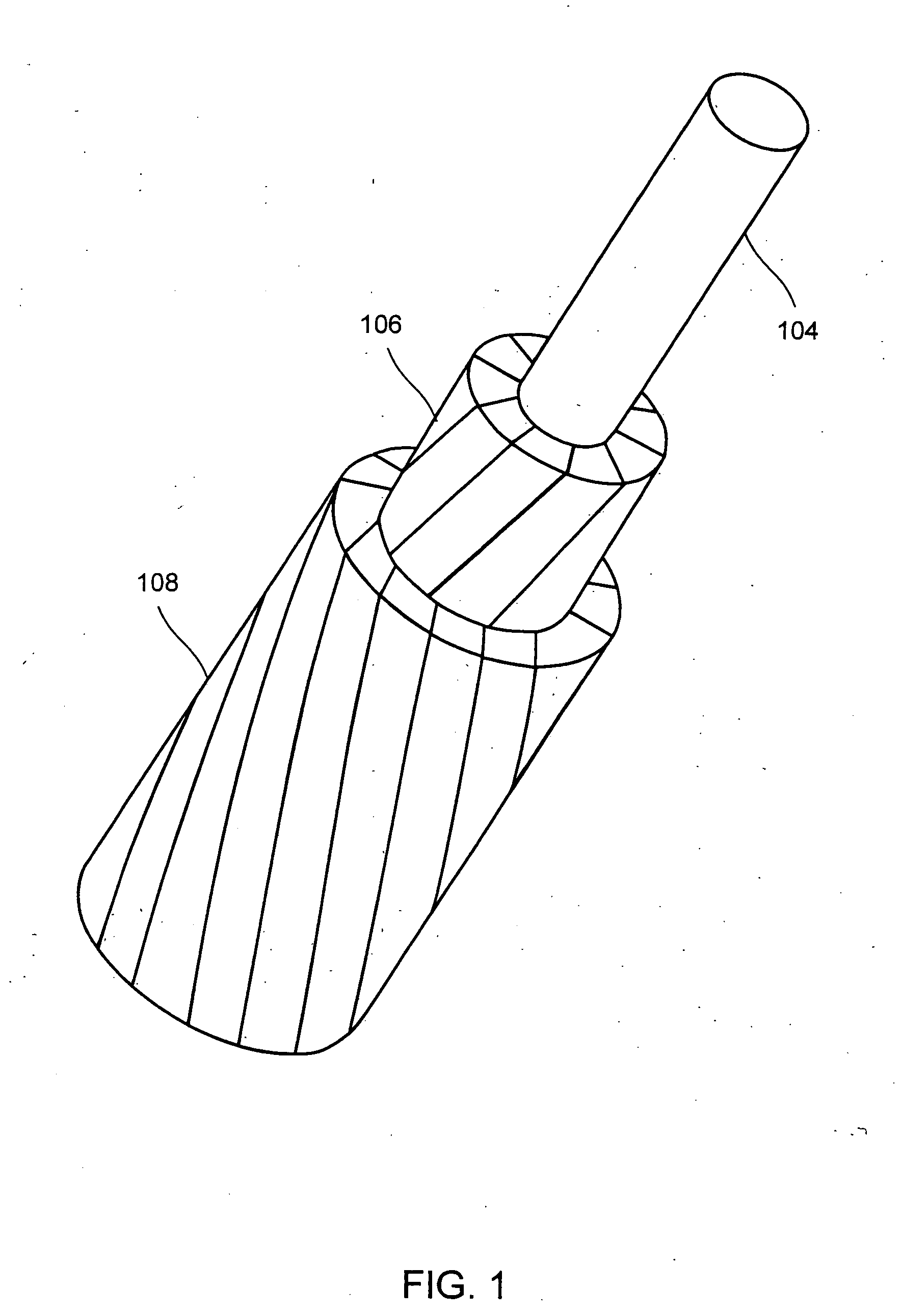

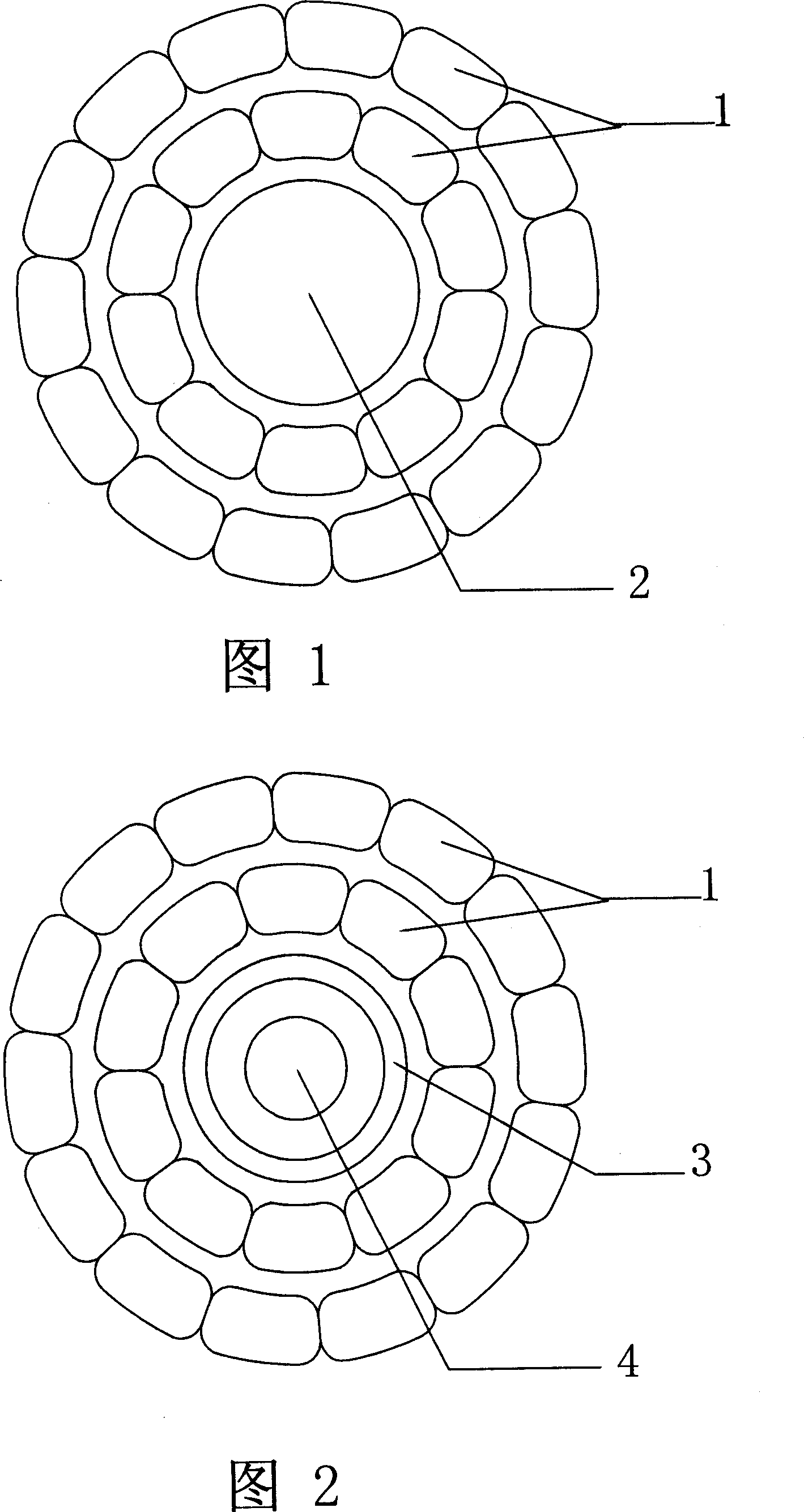

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7179522B2Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsElectrical conductorThermal expansion

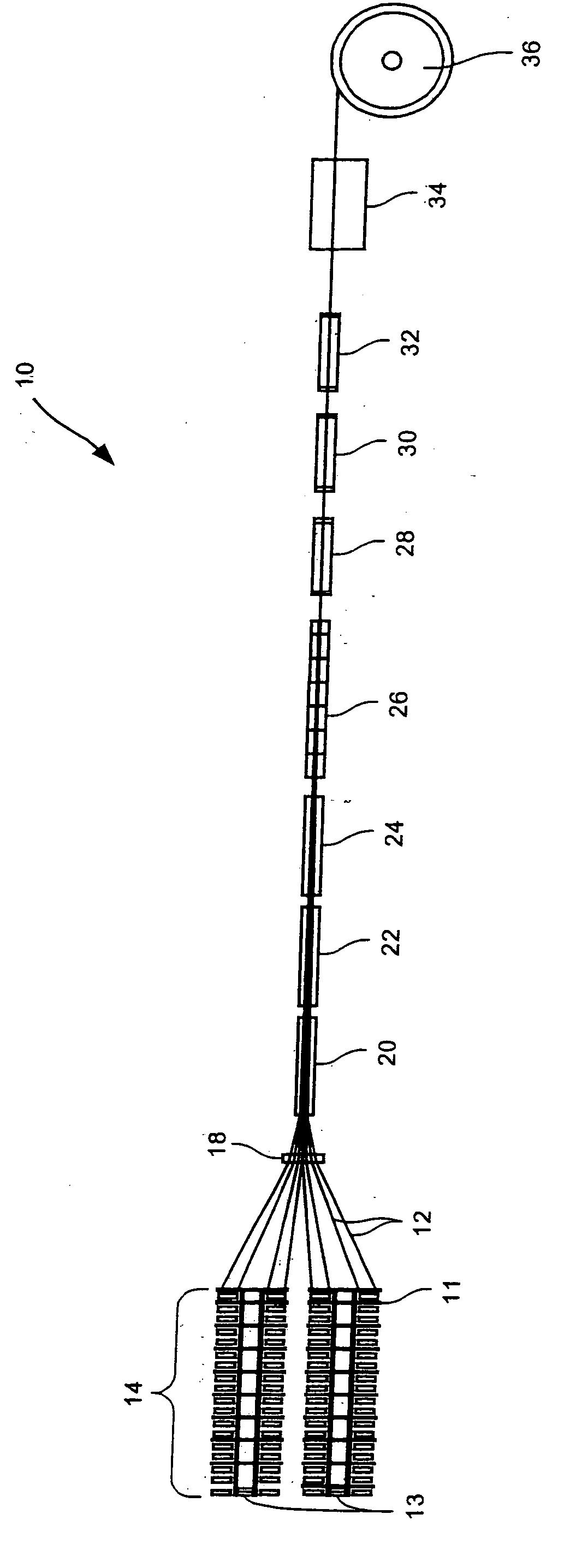

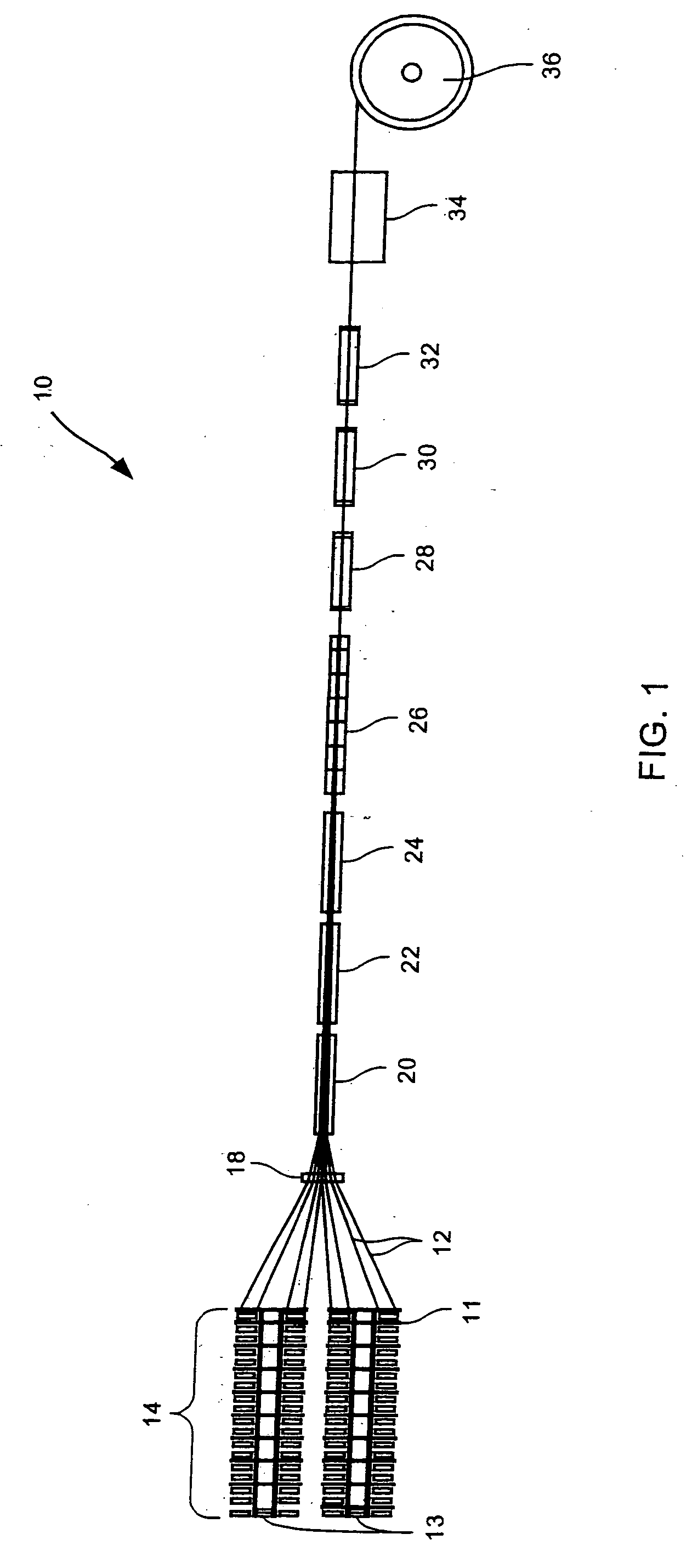

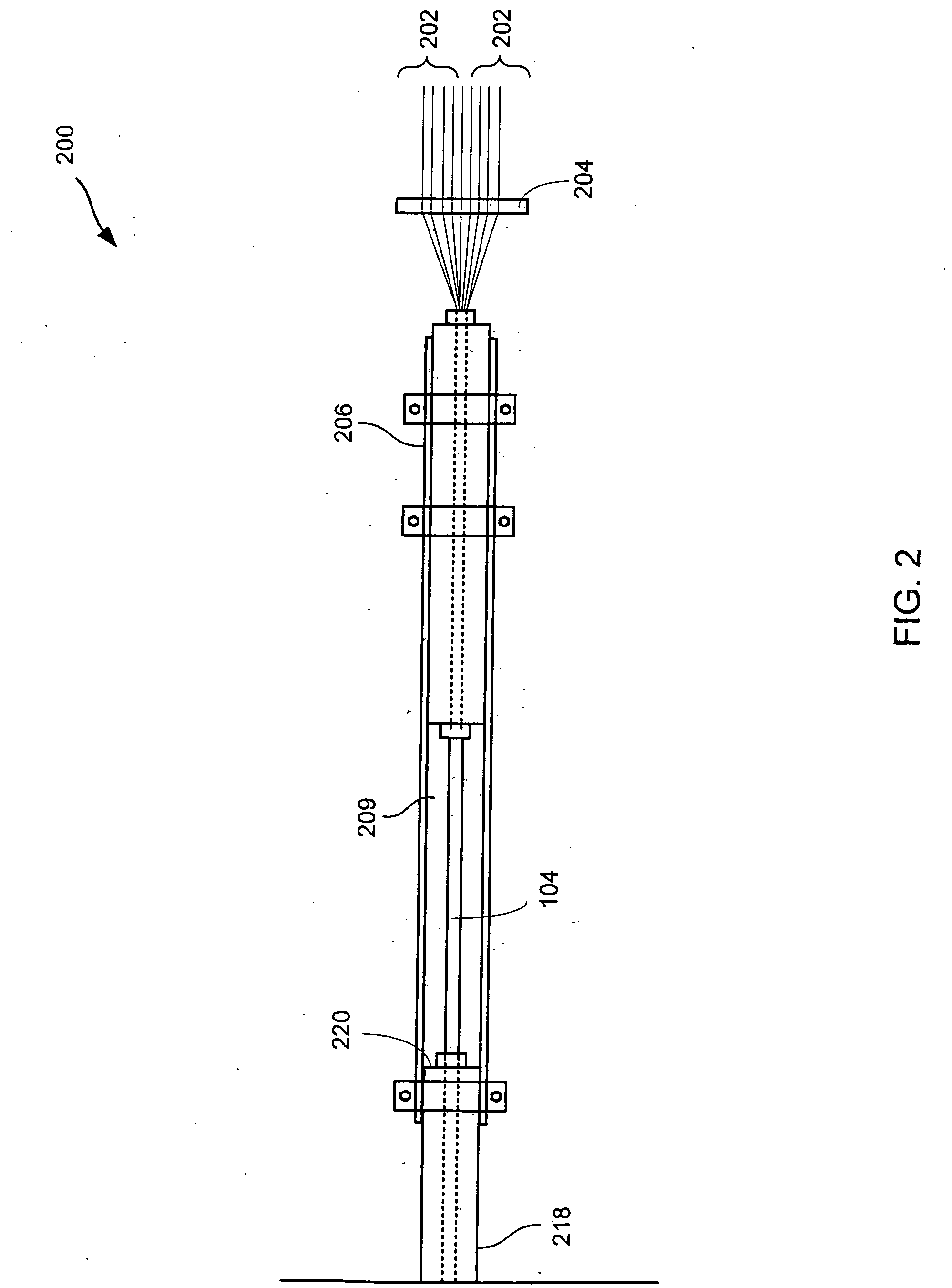

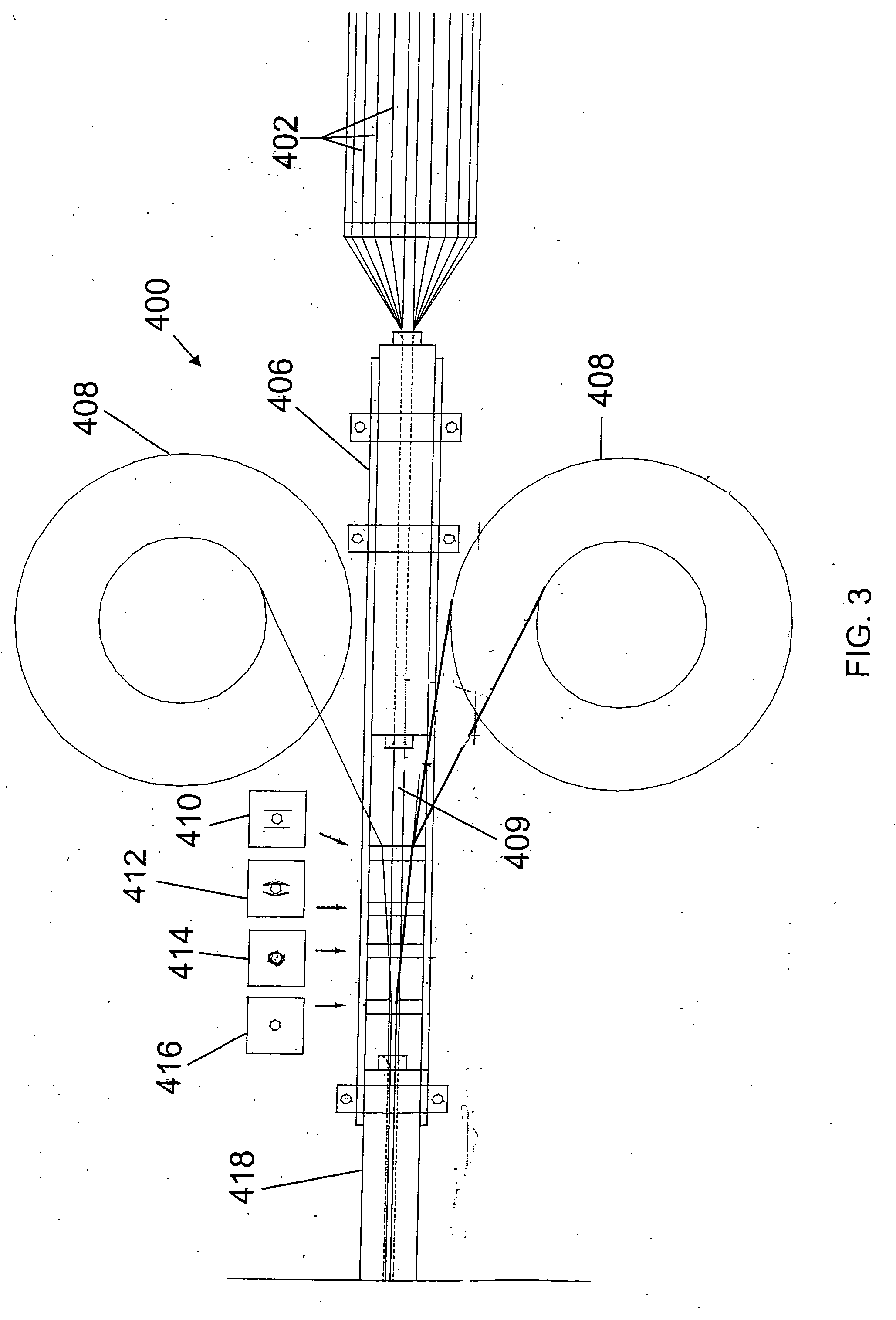

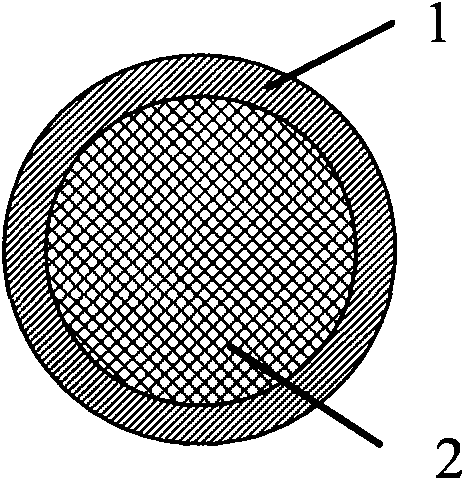

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050129942A1Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsProduction rateElectrical conductor

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

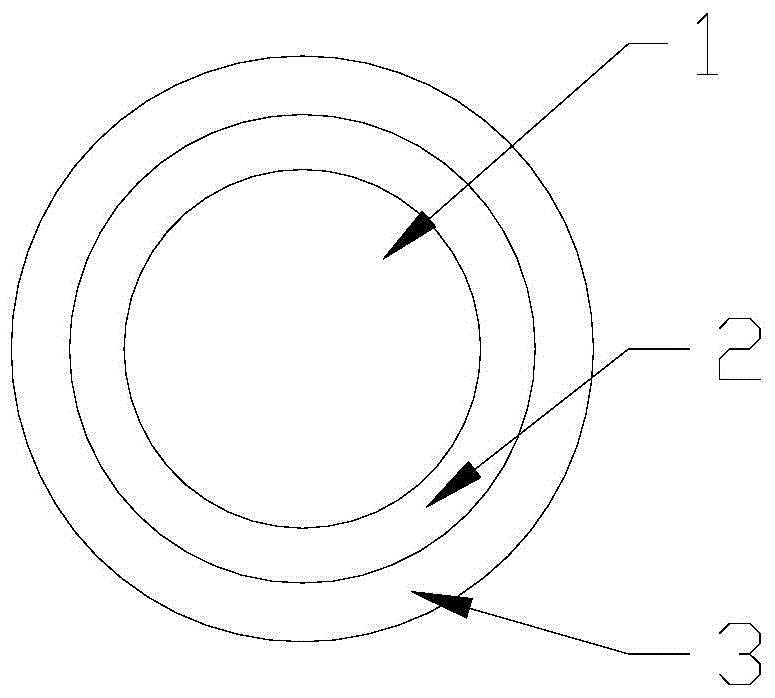

Aluminum conductor composite core reinforced cable and method of manufacture

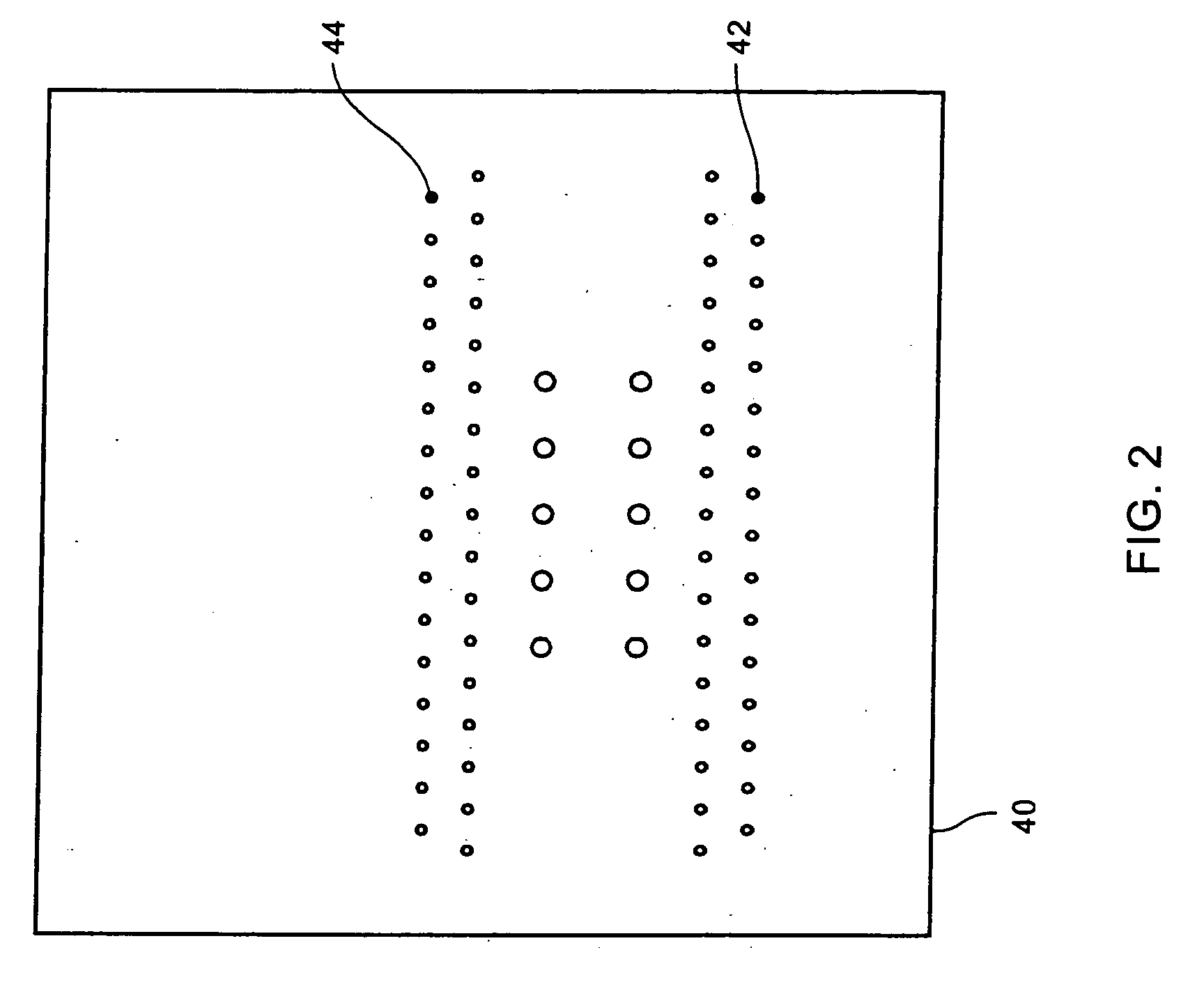

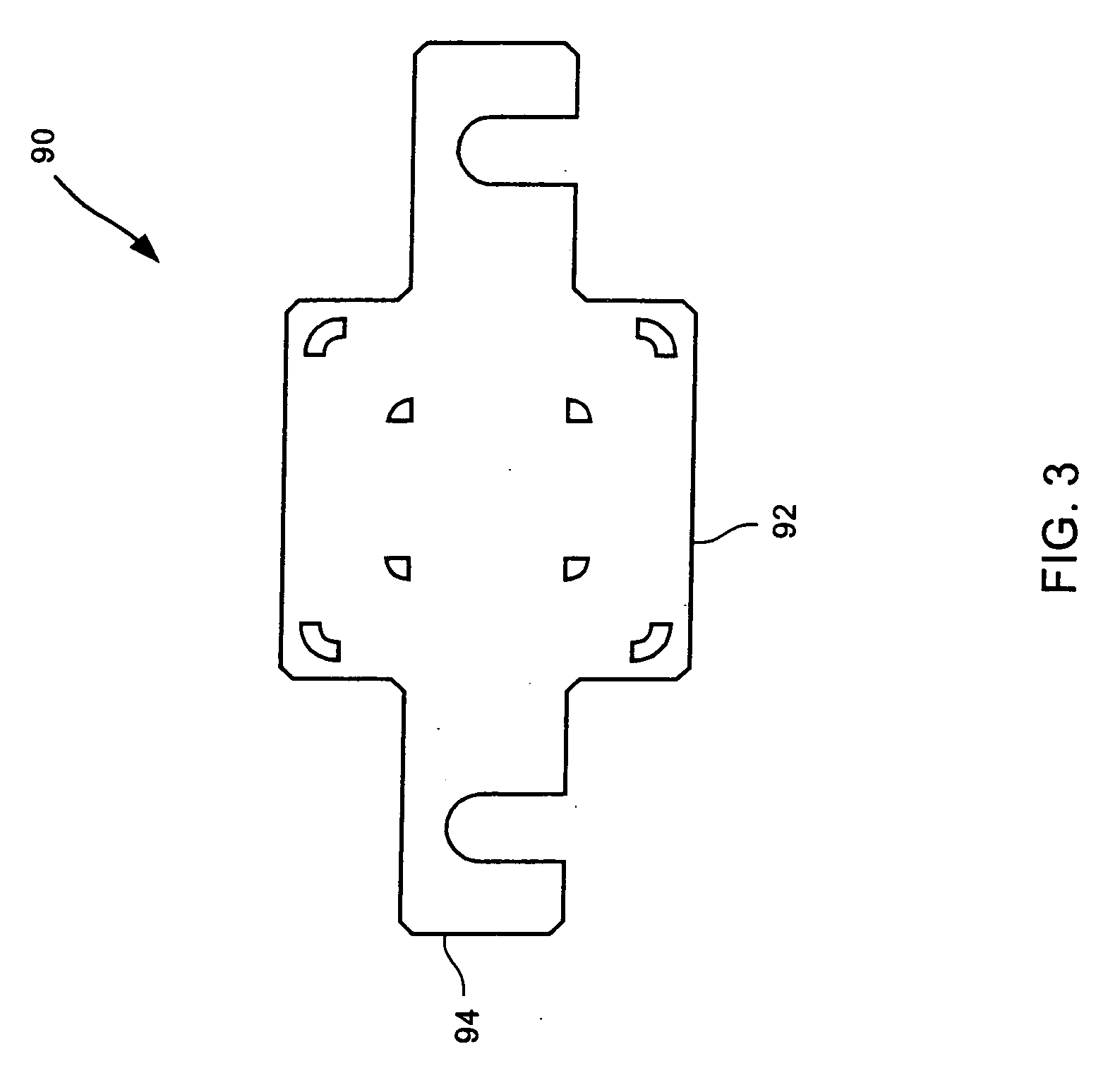

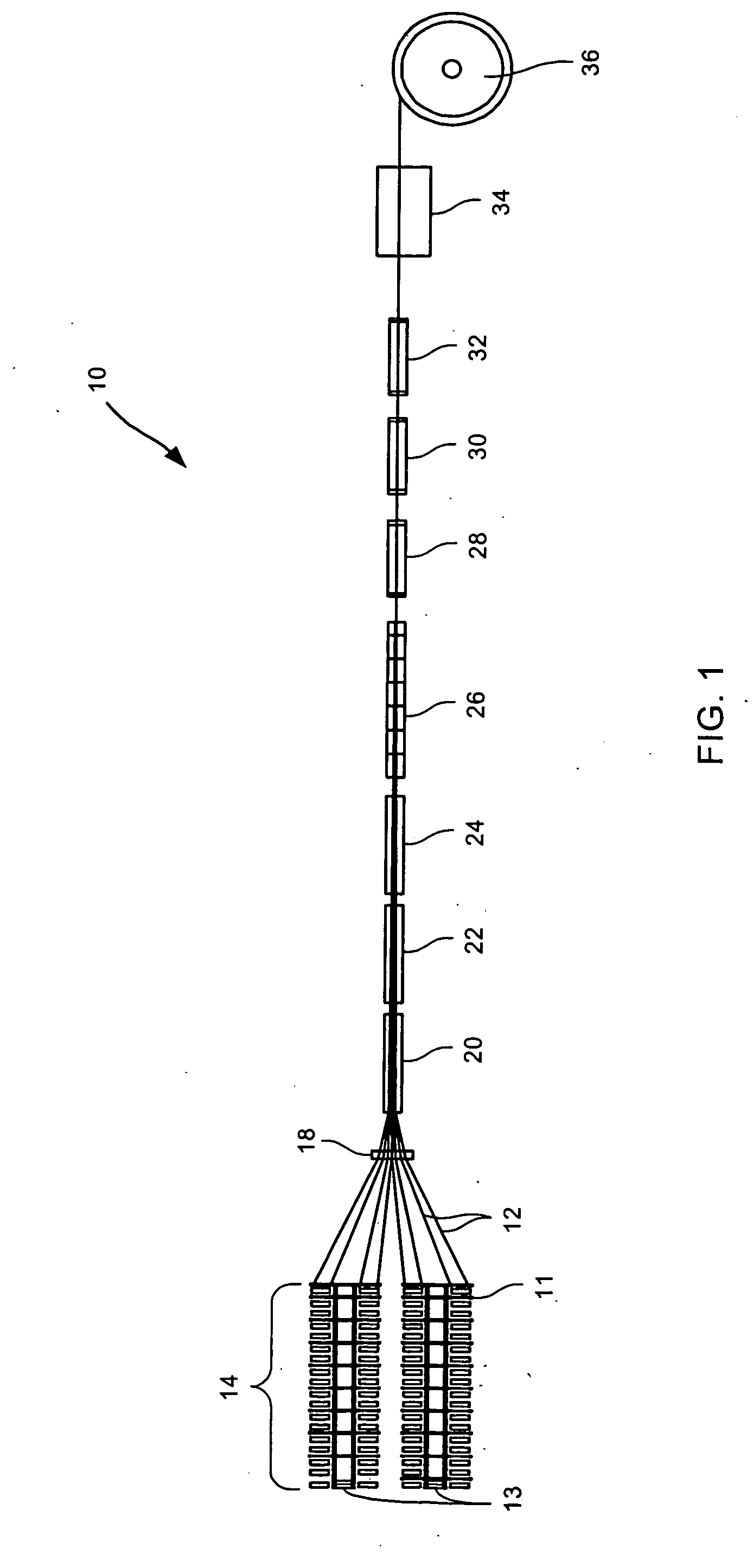

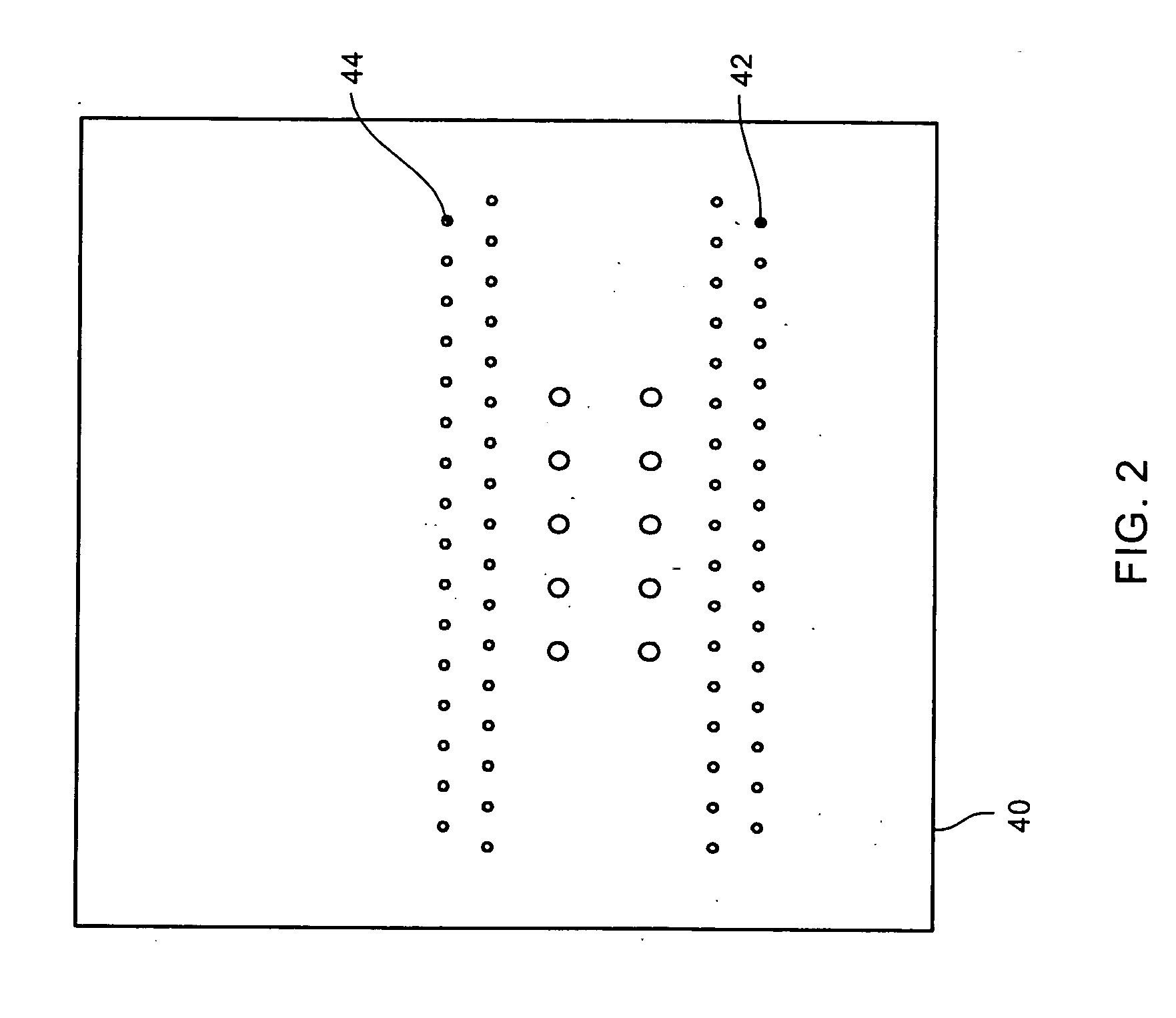

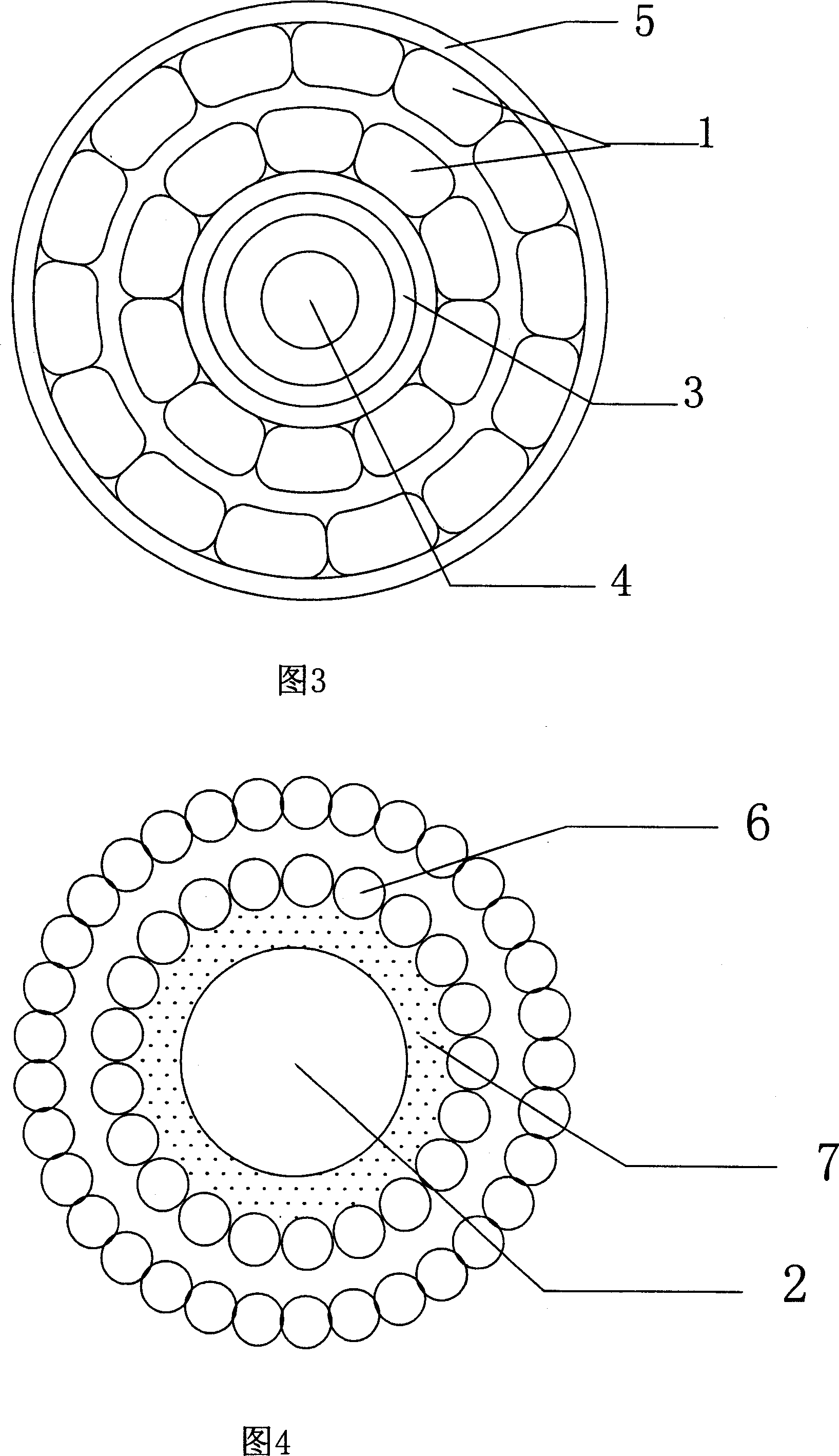

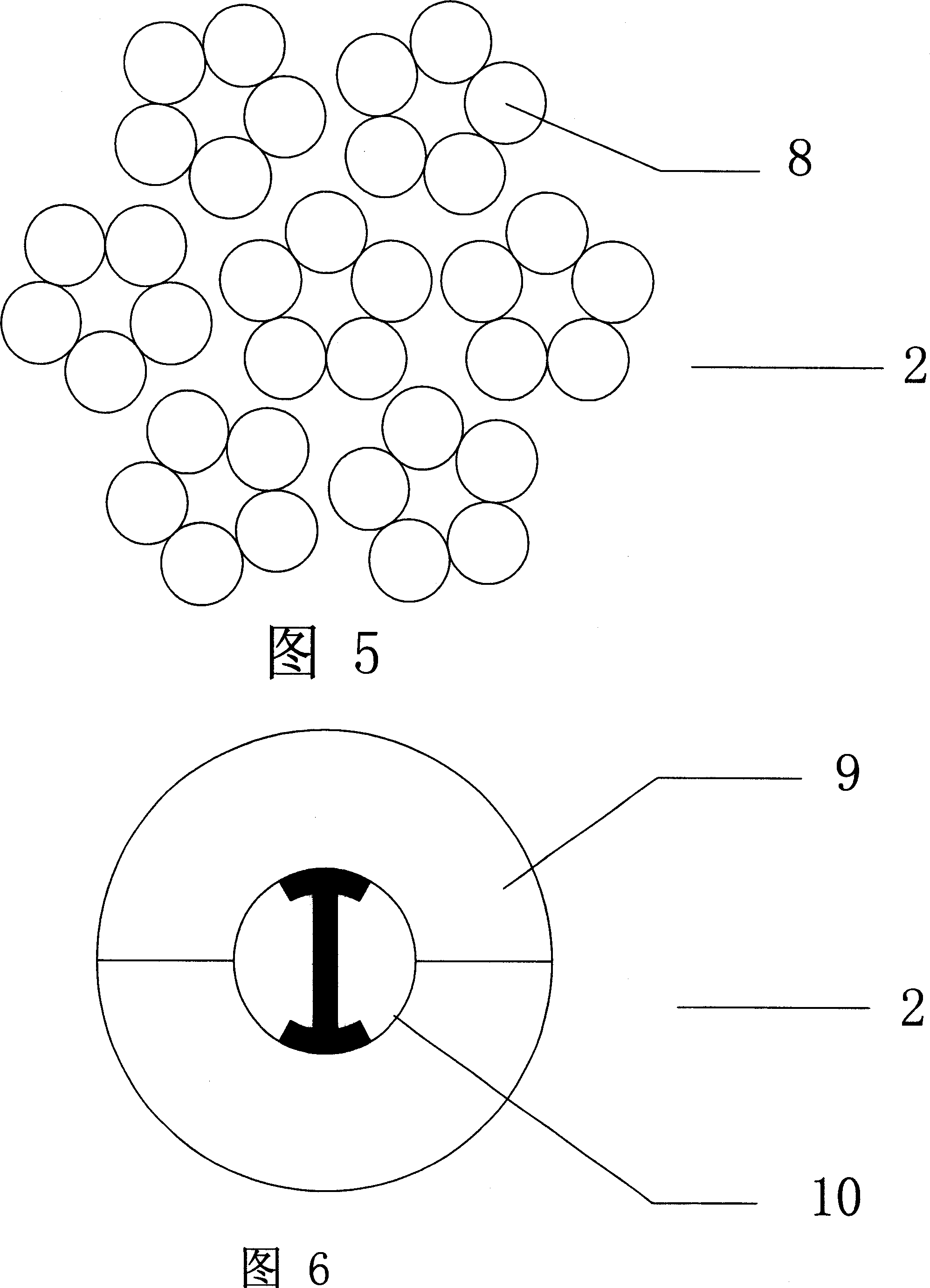

InactiveUS20040131834A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about -45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

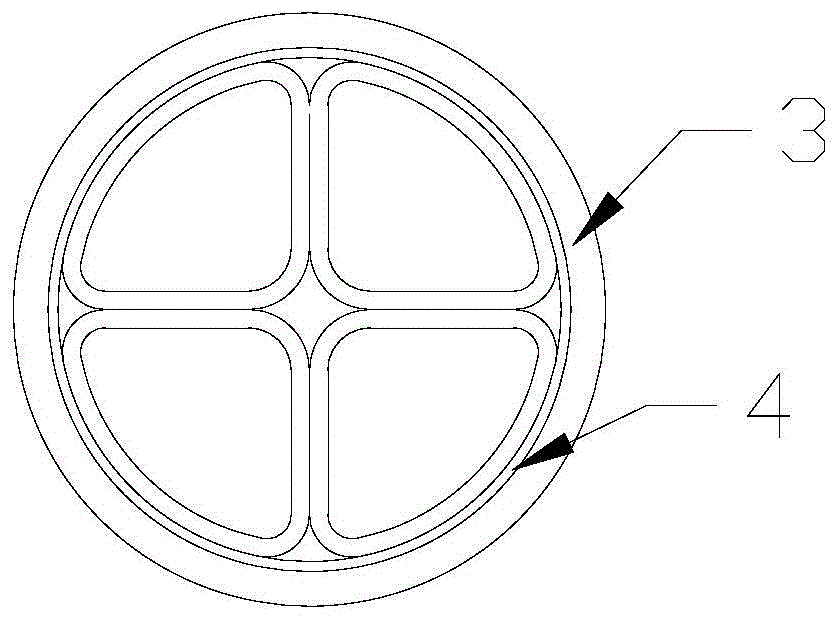

Aluminum conductor composite core reinforced cable and method of manufacture

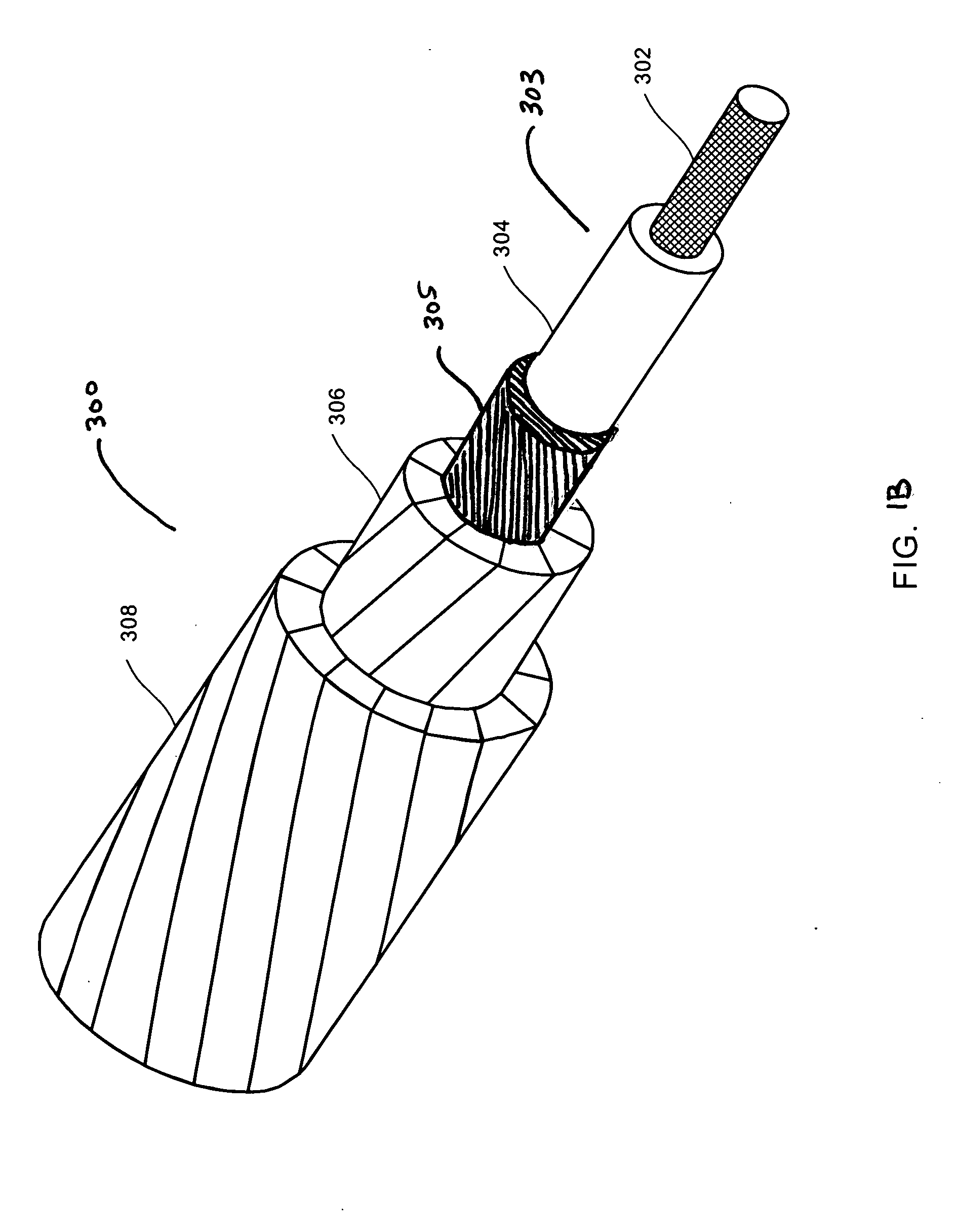

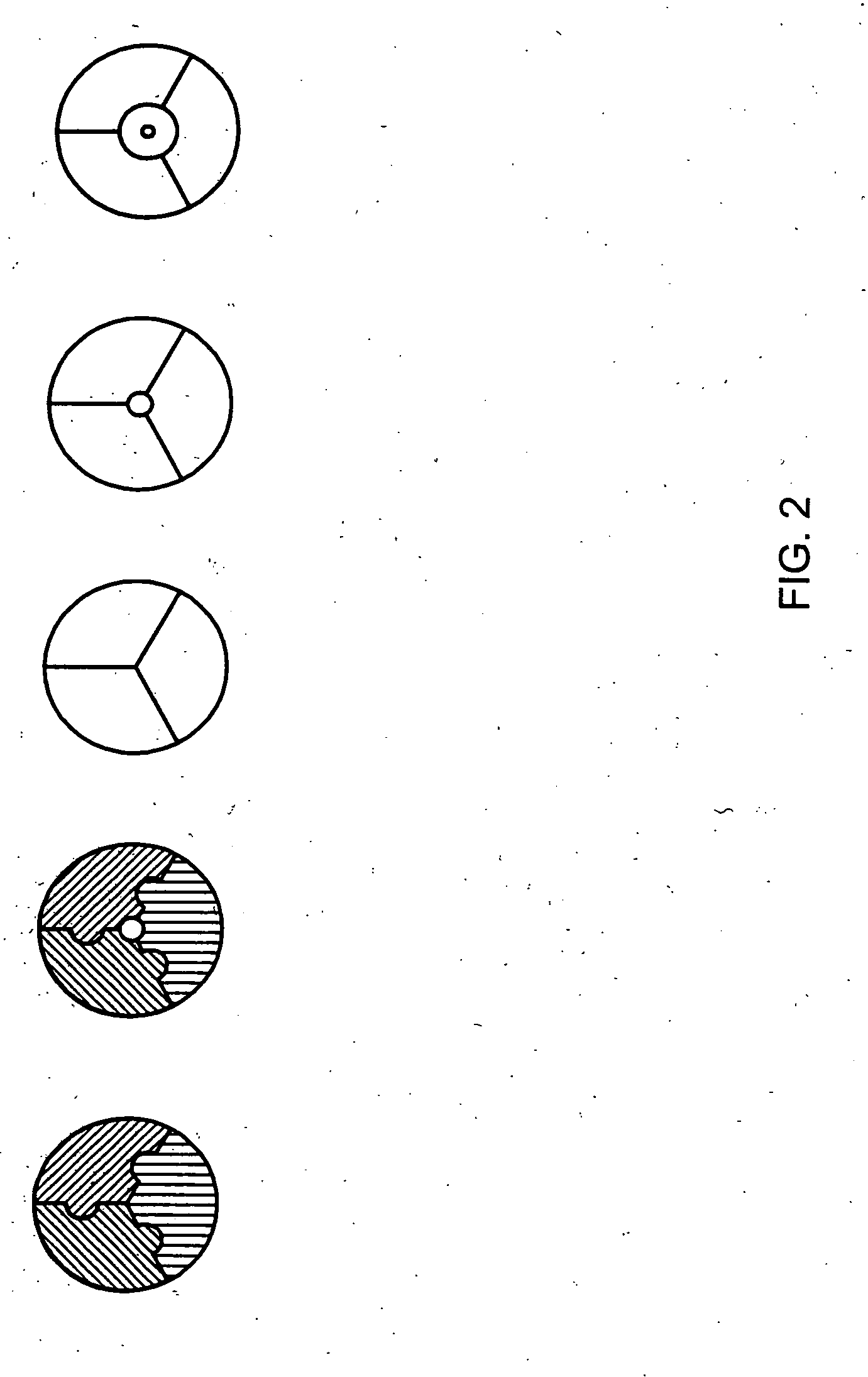

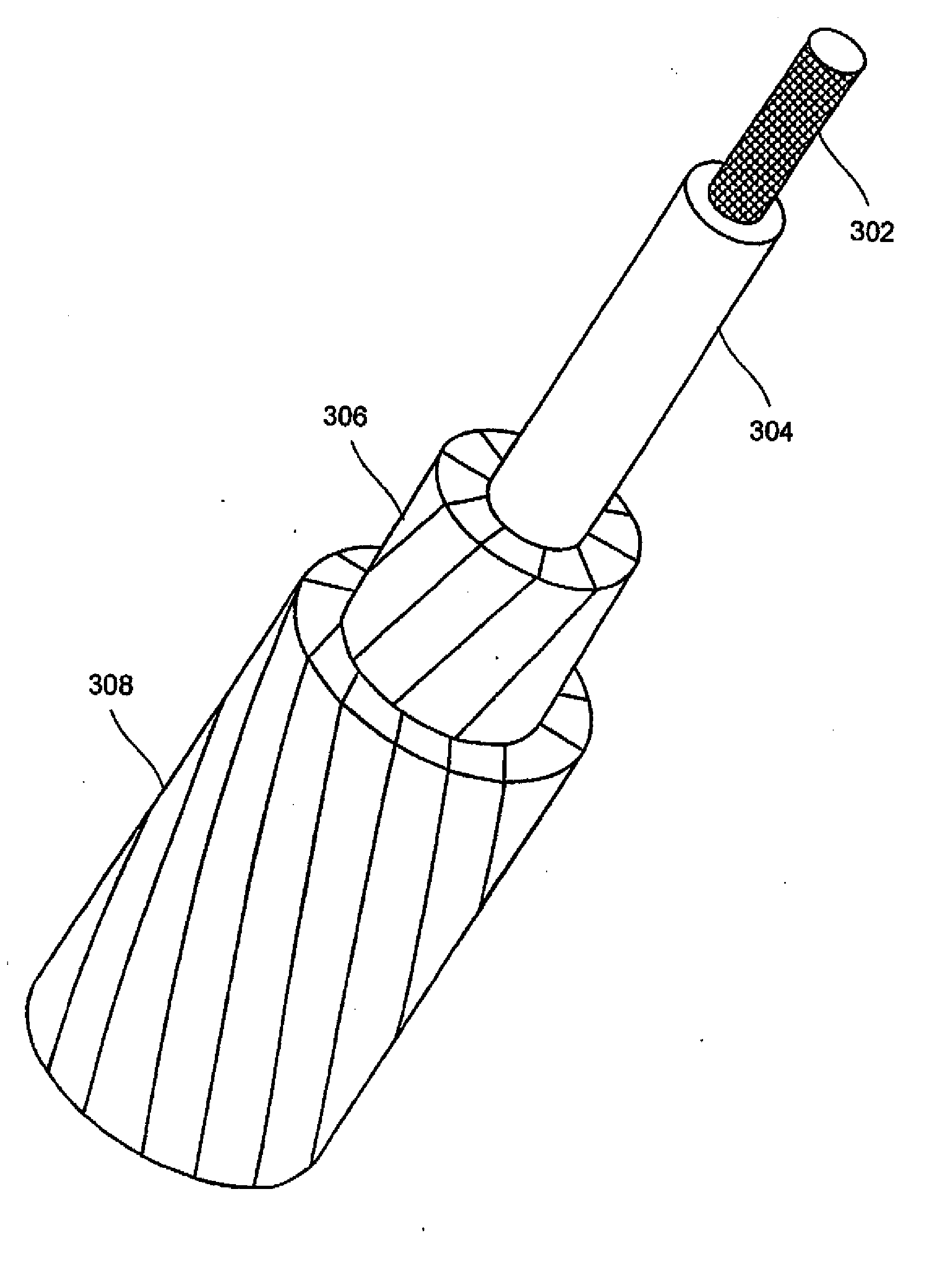

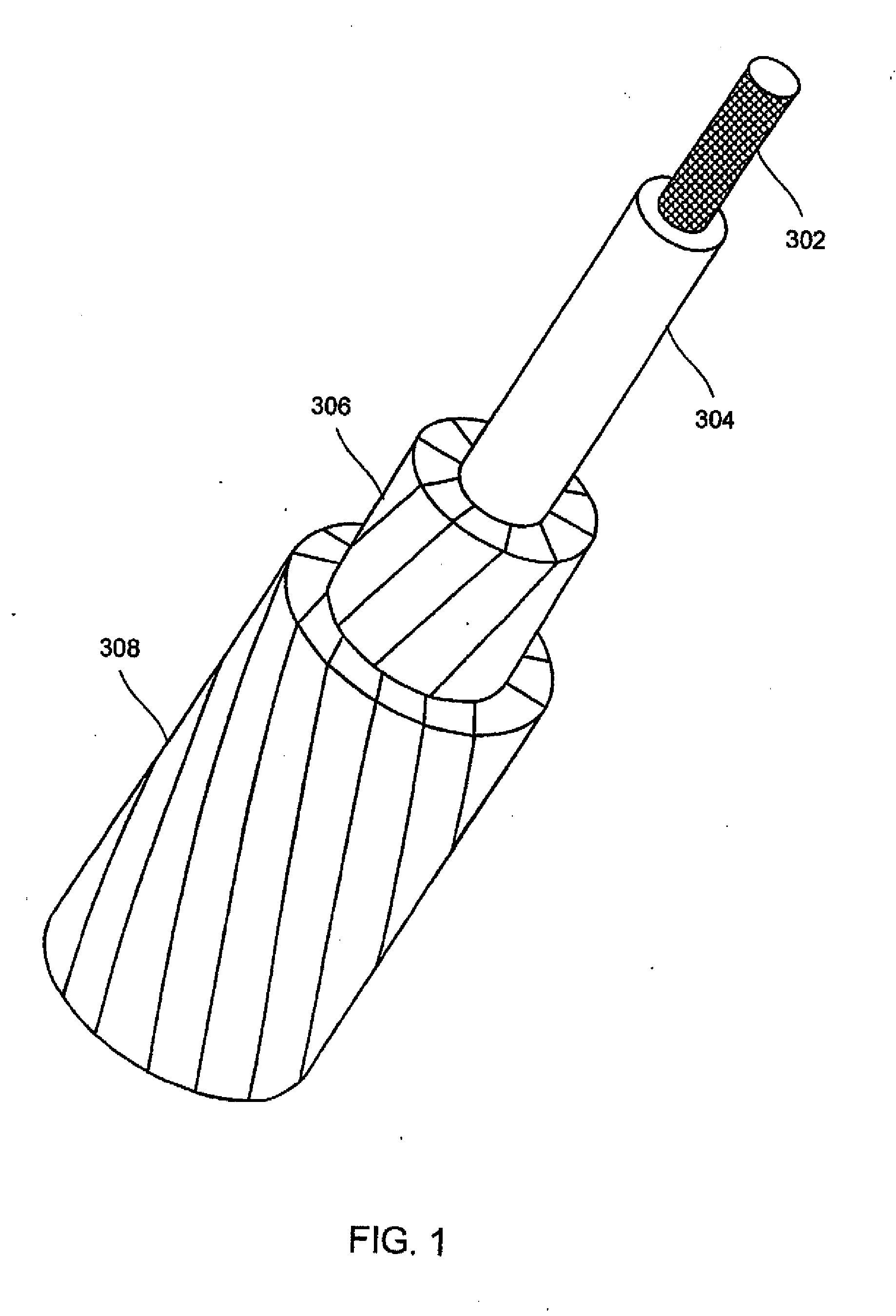

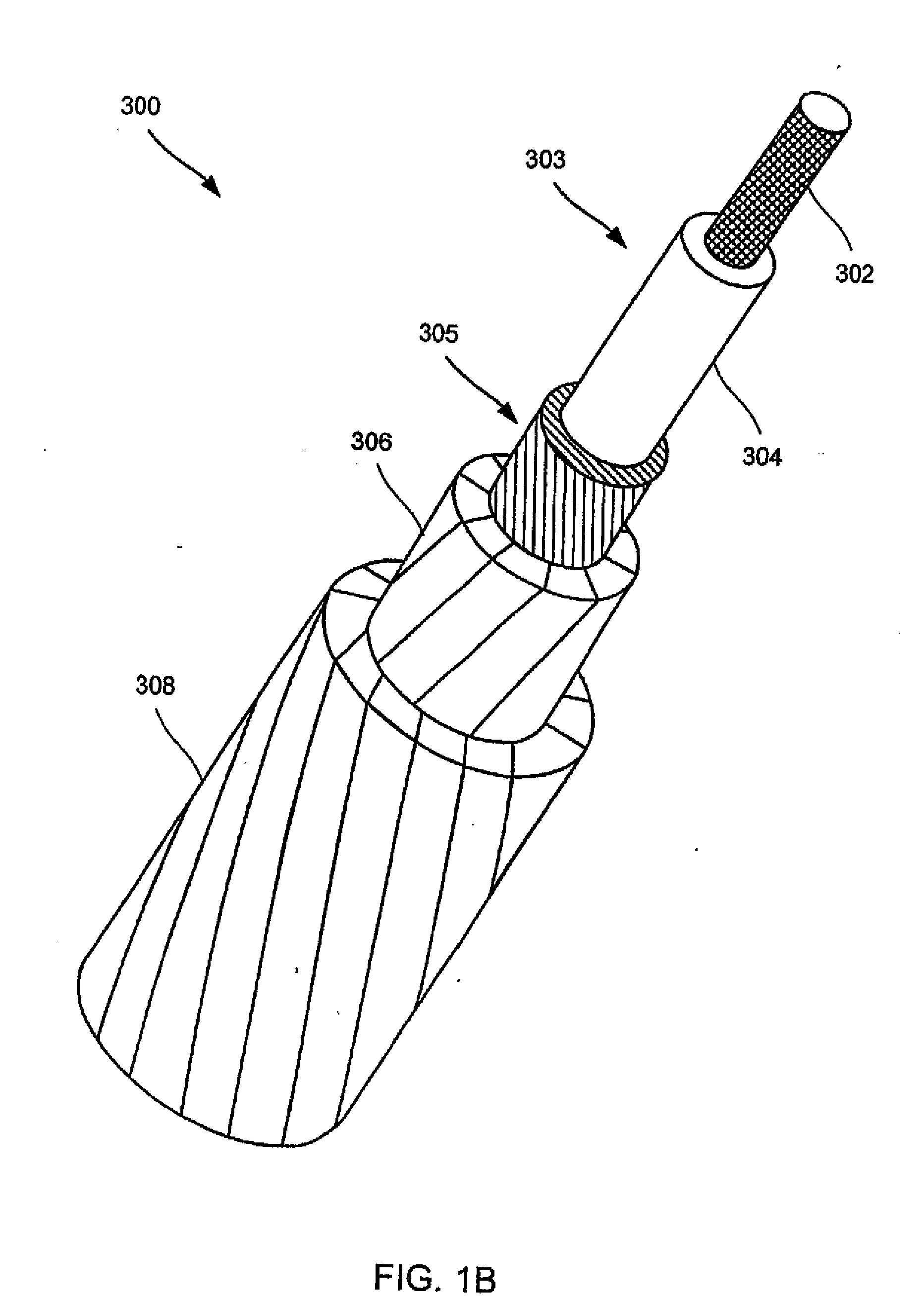

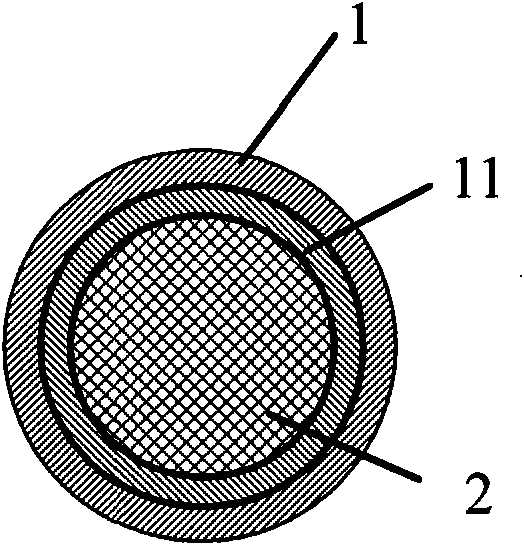

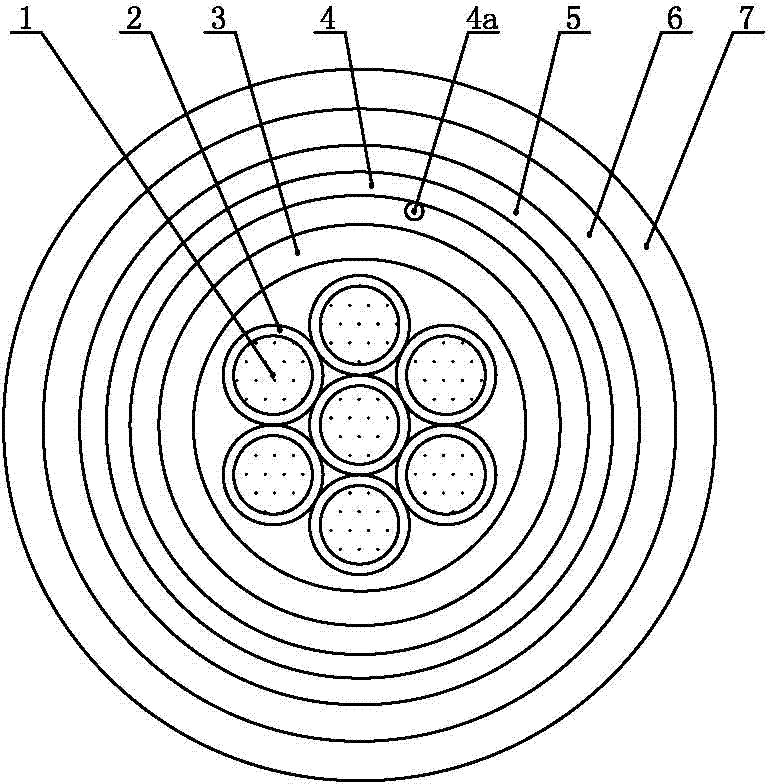

InactiveUS20070128435A1Change in weightMaintain stable propertiesMaterial nanotechnologyNon-insulated conductorsProduction rateFiber type

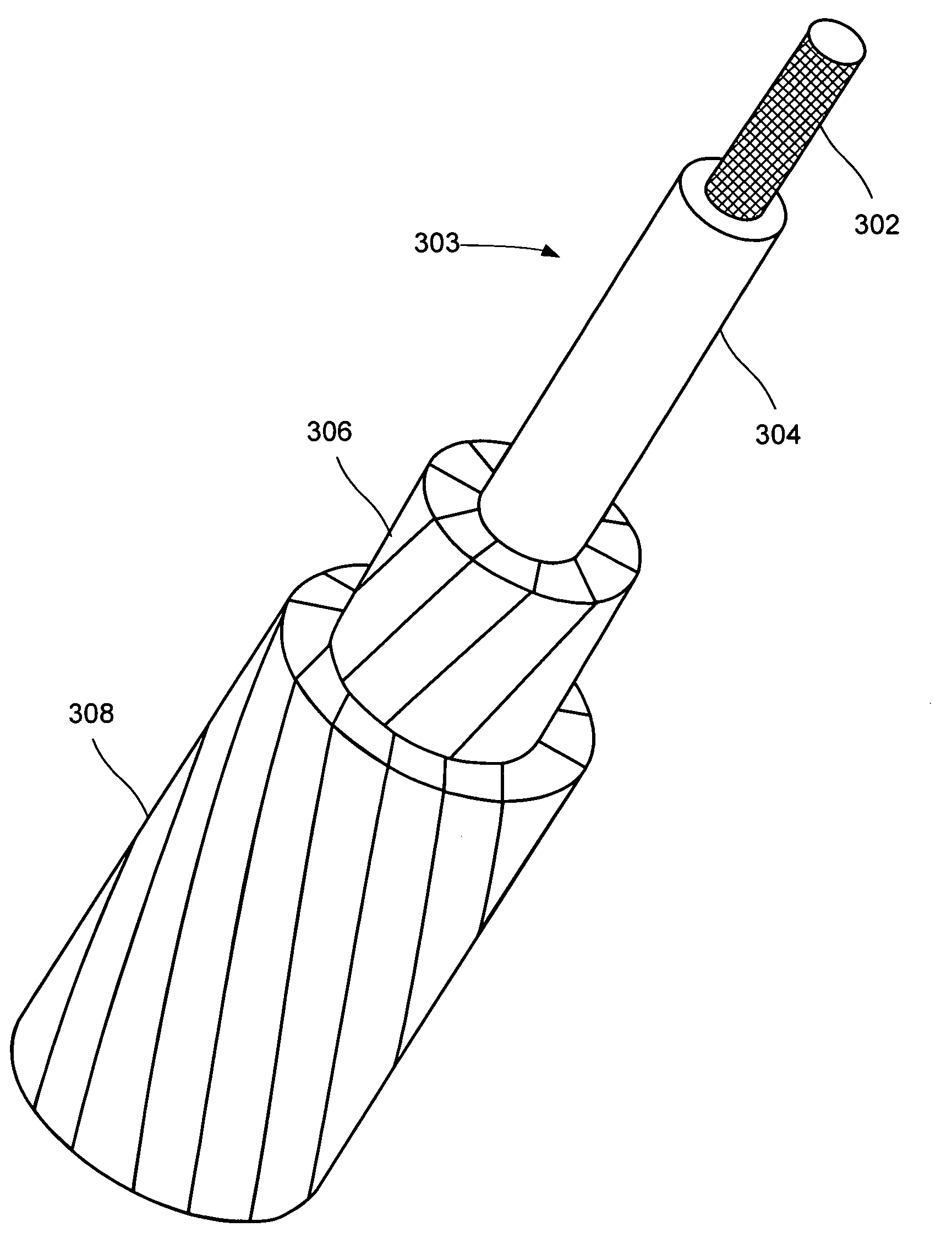

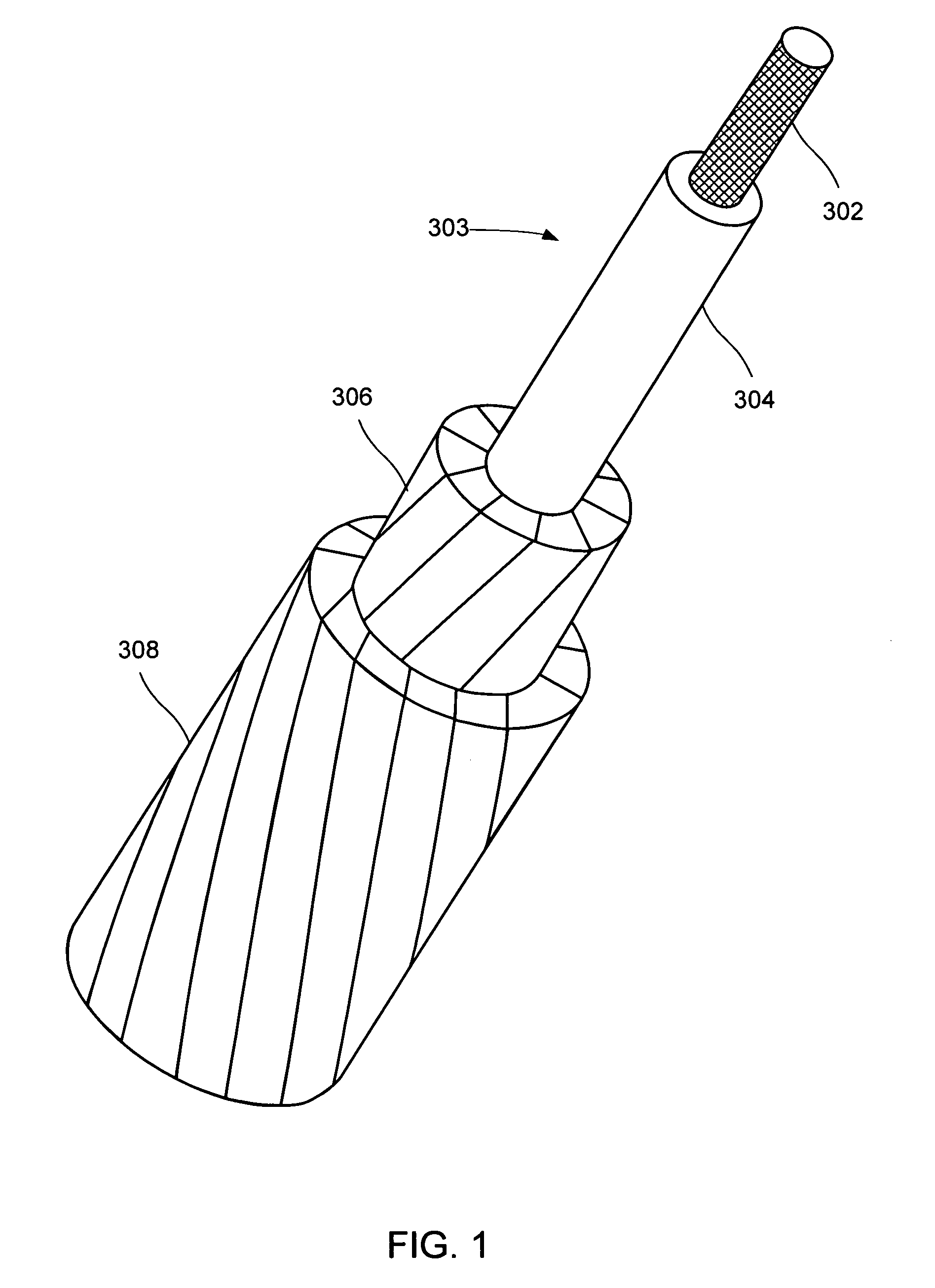

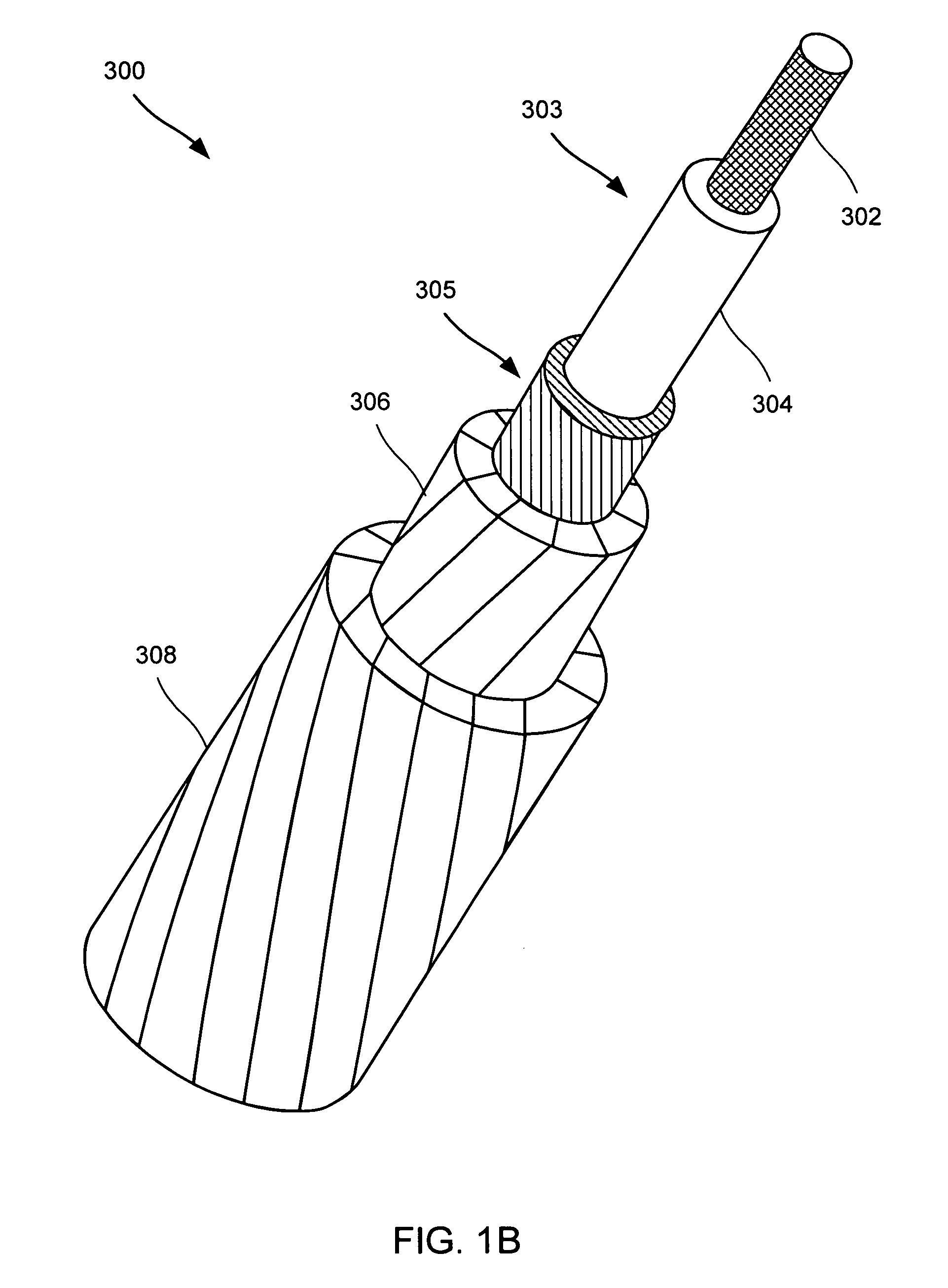

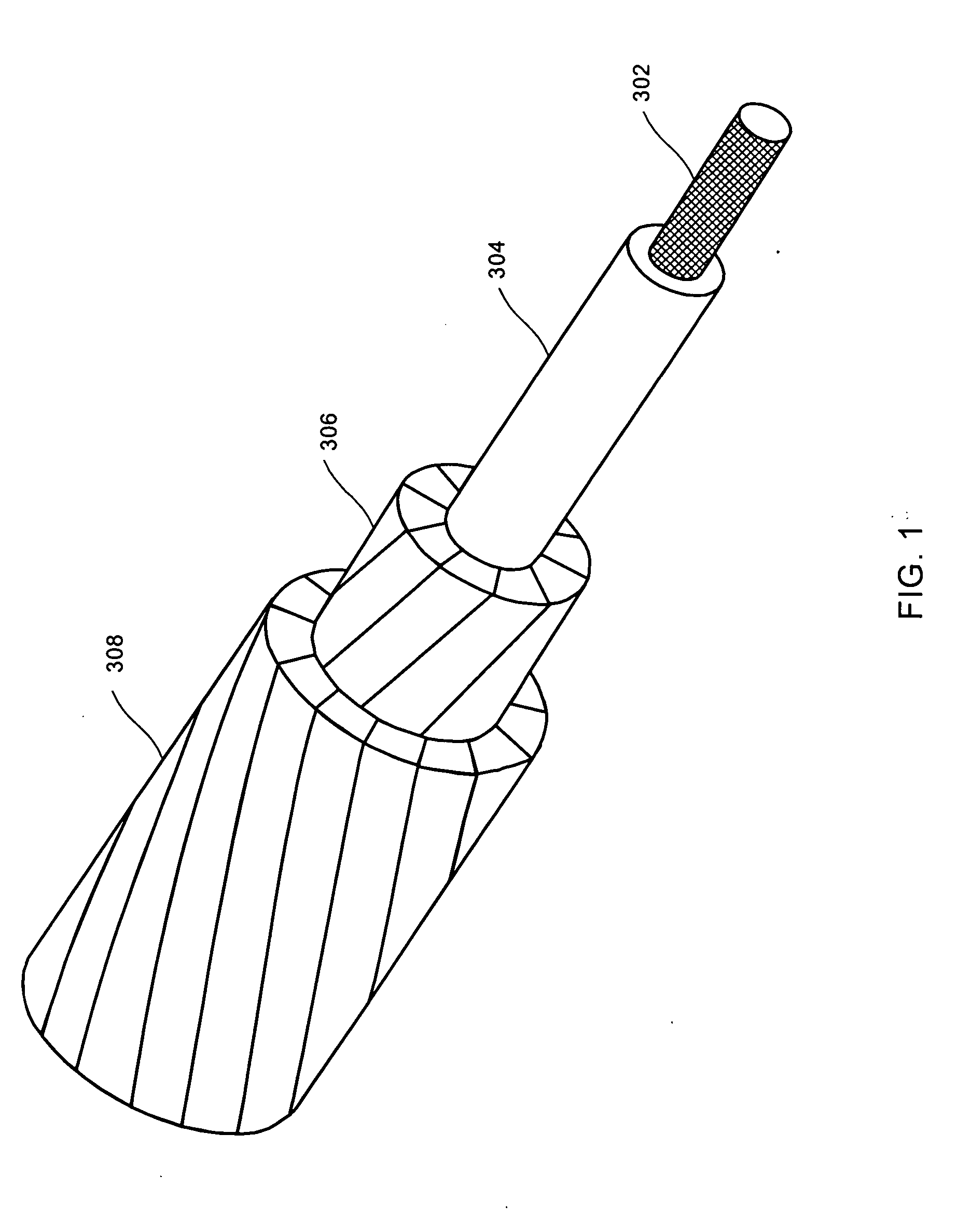

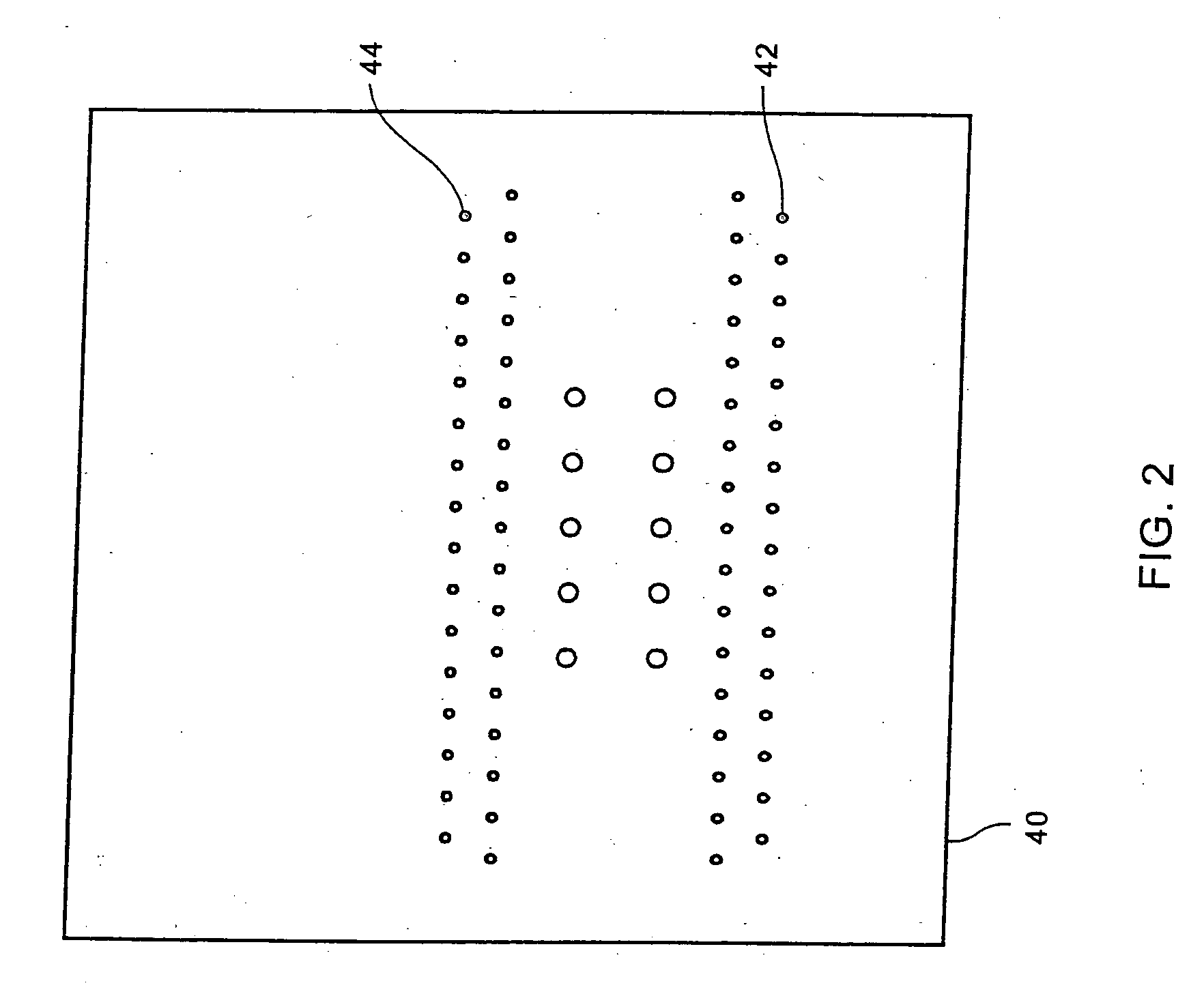

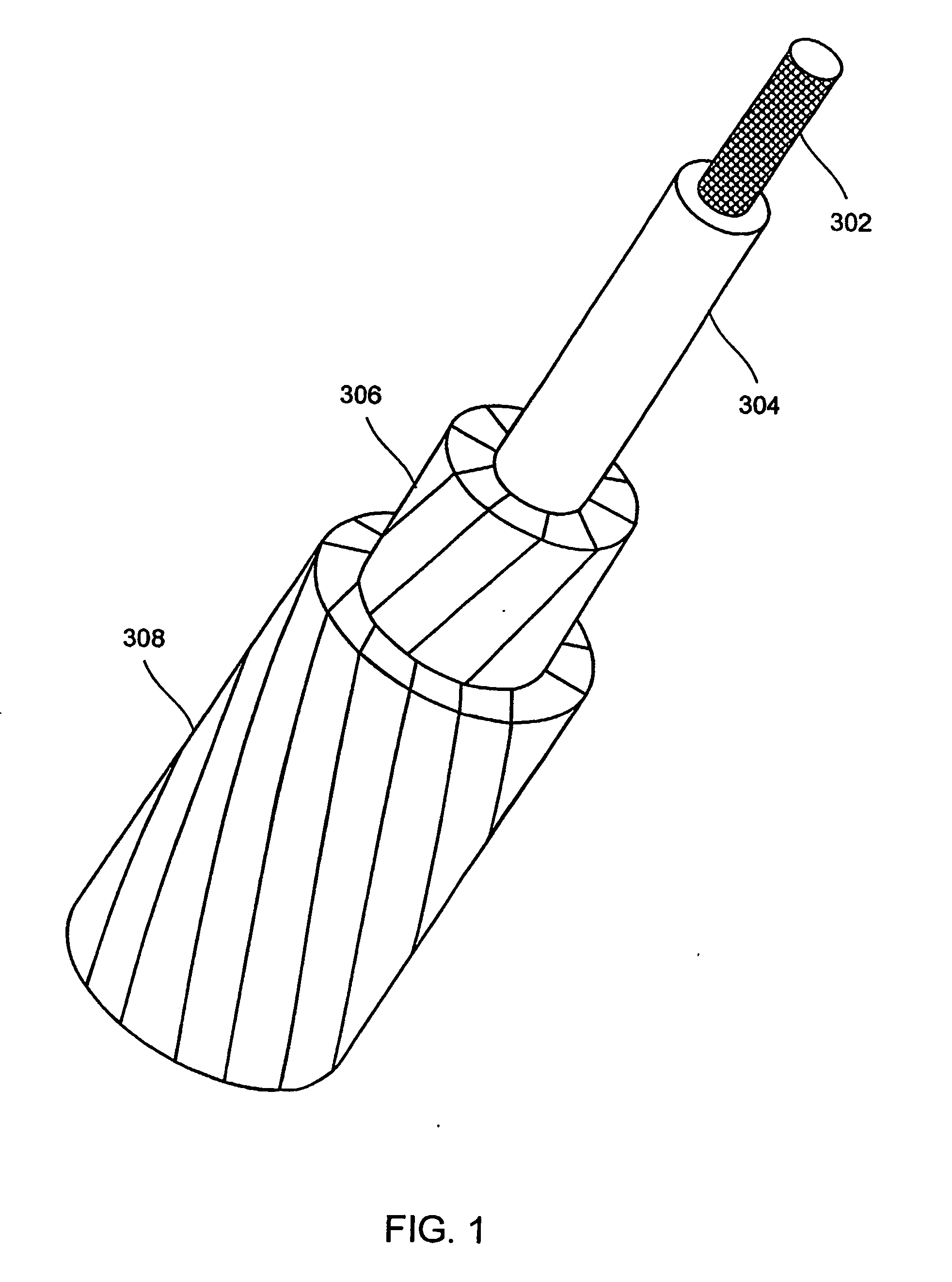

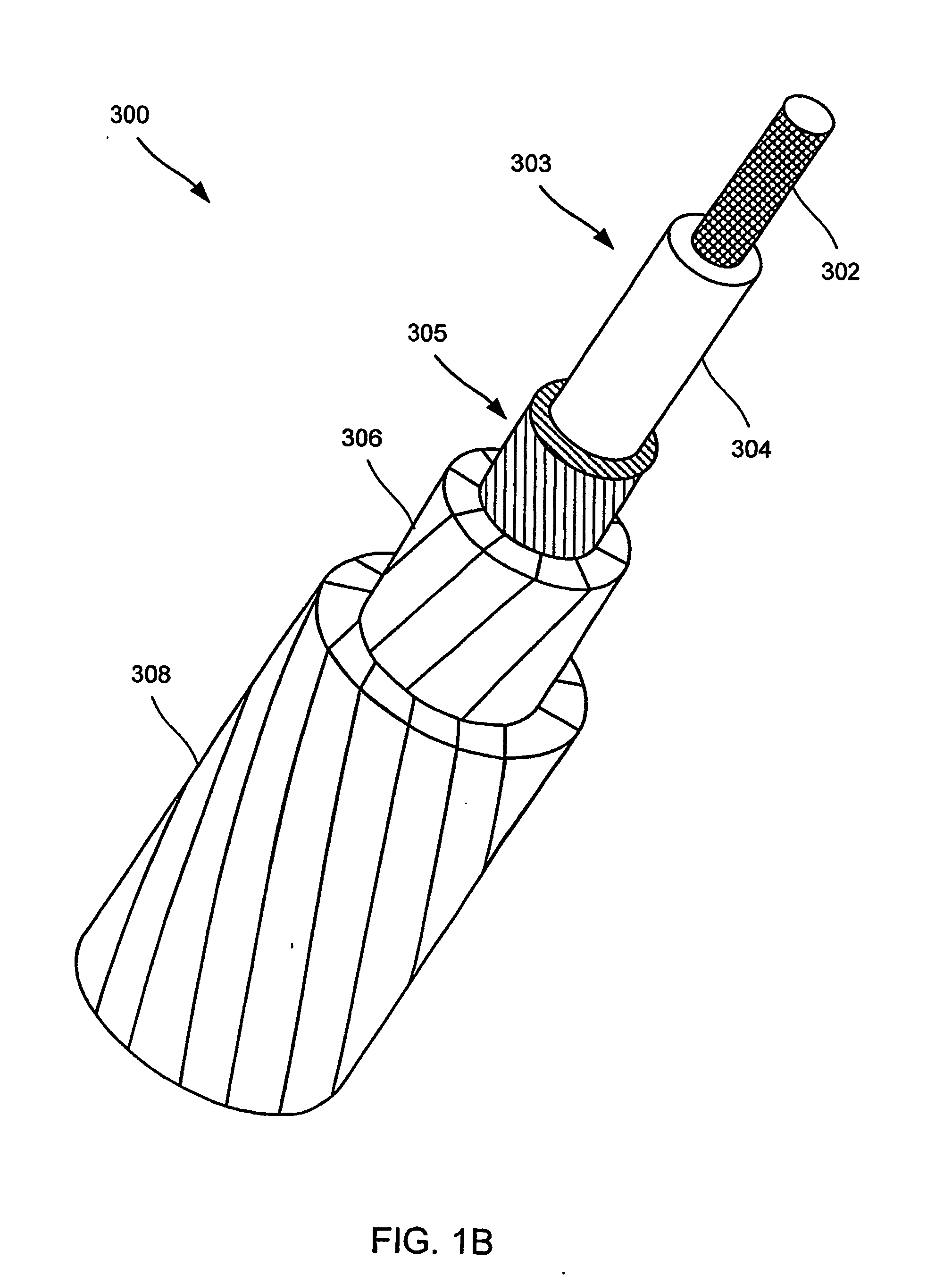

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC 303 cable (300) has a composite core surrounded by an outer film (305) and at least one layer of aluminum conductor (306). The composite core (303) comprises a plurality of fibers from at least one fiber type in one or more matrix materials. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

Composite core for an electrical cable

InactiveUS20100163275A1Change in weightMaintain stable propertiesMaterial nanotechnologyNon-insulated conductorsProduction rateElectrical conductor

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable (300) has a composite core and at least one layer of aluminum conductor (306). The composite core (303) comprises a plurality of fibers from at least one fiber type in one or more matrix materials. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20040131851A1High strengthIncrease ampacityNon-insulated conductorsApparatus for heat treatmentElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about 45° C. to about 230° C., at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about -0.7x10<-6 >m / m / ° C. to about 6x10<-6 >m / m / ° C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 60 ft / min.

Owner:CTC GLOBAL CORP

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20050227067A1Increase ampacityMaintain stable propertiesNon-insulated conductorsApparatus for heat treatmentElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable having a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises at least one longitudinally oriented substantially continuous reinforced fiber type in a thermosetting resin matrix having an operating temperature capability within the range of about 90 to about 230° C., at least 50% fiber volume fraction, a tensile strength in the range of about 160 to about 240 Ksi, a modulus of elasticity in the range of about 7 to about 30 Msi and a thermal expansion coefficient in the range of about 0 to about 6×10−6 m / m / C. According to the invention, a B-stage forming process may be used to form the composite core at improved speeds over pultrusion processes wherein the speeds ranges from about 9 ft / min to about 50 ft / min.

Owner:CTC GLOBAL CORP

Graphene-containing high heat conduction polyvinyl chloride sheath material for cable, and cable

ActiveCN105017676AImprove thermal conductivityIncrease ampacityPlastic/resin/waxes insulatorsCvd graphenePlasticizer

The invention discloses a graphene-containing high heat conduction polyvinyl chloride sheath material for a cable, and a cable with the graphene-containing high heat conduction polyvinyl chloride sheath material. The graphene-containing high heat conduction polyvinyl chloride sheath material reduces electric energy transmission loss. The graphene-containing high heat conduction polyvinyl chloride sheath material comprises, by mass, 100 parts of polyvinyl chloride resin, 0.05-3 parts of a heat conduction agent, 8-9 parts of an auxiliary heat conduction agent, 20-25 parts of a plasticizer, 0.1-0.5 parts of an anti-oxidant, 2.2-2.9 parts of a stabilizing agent, 0.5-3 parts of a lubricant and 37-53 parts of a filler. The cable sheath layer comprises polyvinyl chloride resin, a heat conduction agent, an auxiliary heat conduction agent, a plasticizer, an anti-oxidant, a stabilizing agent, a lubricant, a filler, a fire retardant and a pigment assistant. Compared with the existing sheath material, through cooperation of the heat conduction agent and the auxiliary heat conduction agent, the graphene-containing high heat conduction polyvinyl chloride sheath material has higher heat conductivity of 0.3W / mk or more and good heat dispersion effects, and reduces electric energy transmission loss or improves a cable current-carrying capacity.

Owner:江苏中超电缆股份有限公司

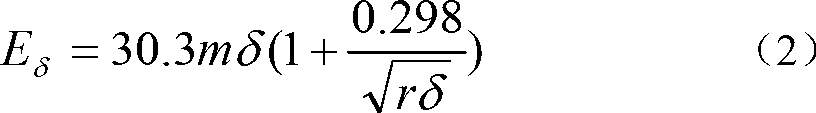

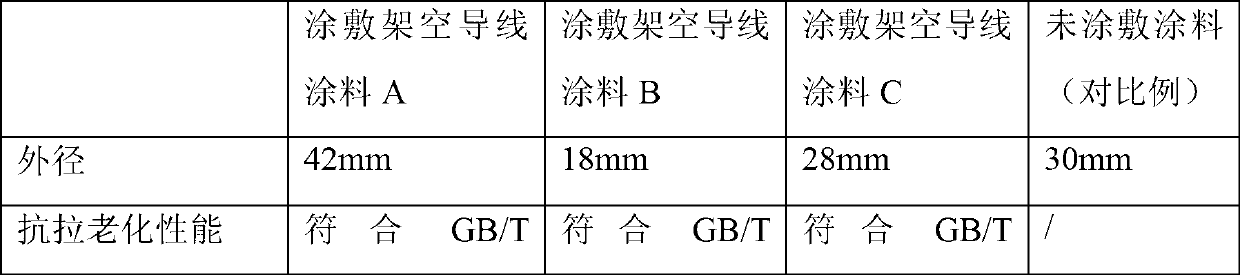

Coating for improving performance of overhead conductor comprehensively

ActiveCN102977700AImprove anti-aging propertiesImprove self-cleaning performanceInsulated cablesPolyurea/polyurethane coatingsVinyl etherEngineering

The invention relates to the technical field of overhead conductors of electric transmission lines, in particular to a coating for improving the performance of an overhead conductor comprehensively. The overhead conductor coating comprises the components in percentage by weight as follows: 38-59% of FEVE (fluoro ethylene-vinyl ether) fluorocarbon resin, 30-50% of an organic solvent, 10-20% of a curing agent and 1-12% of an auxiliary agent. The coating has good ageing resistance and self-cleaning performance as well as a high heat radiation coefficient. The surface condition of a common steel-core aluminium twisted wire is improved comprehensively through the application of the coating, so that the carrying capacity, the ant-icing performance and the corona characteristic of a common steel-cored aluminium strand are improved.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

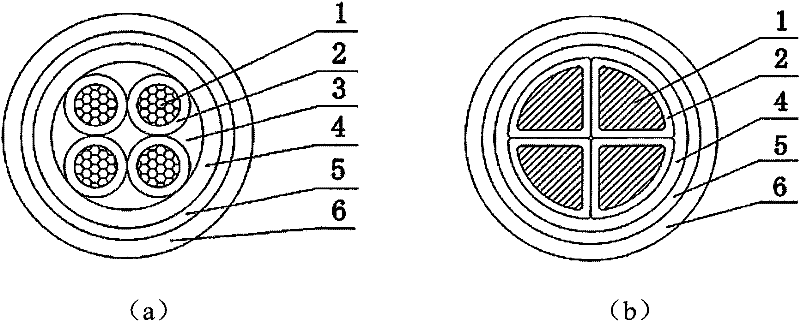

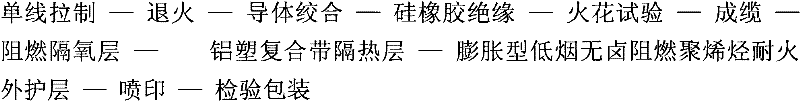

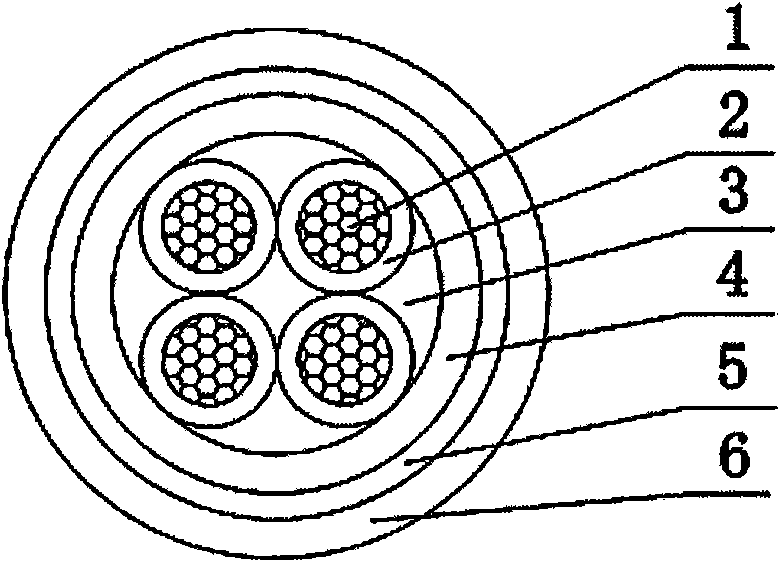

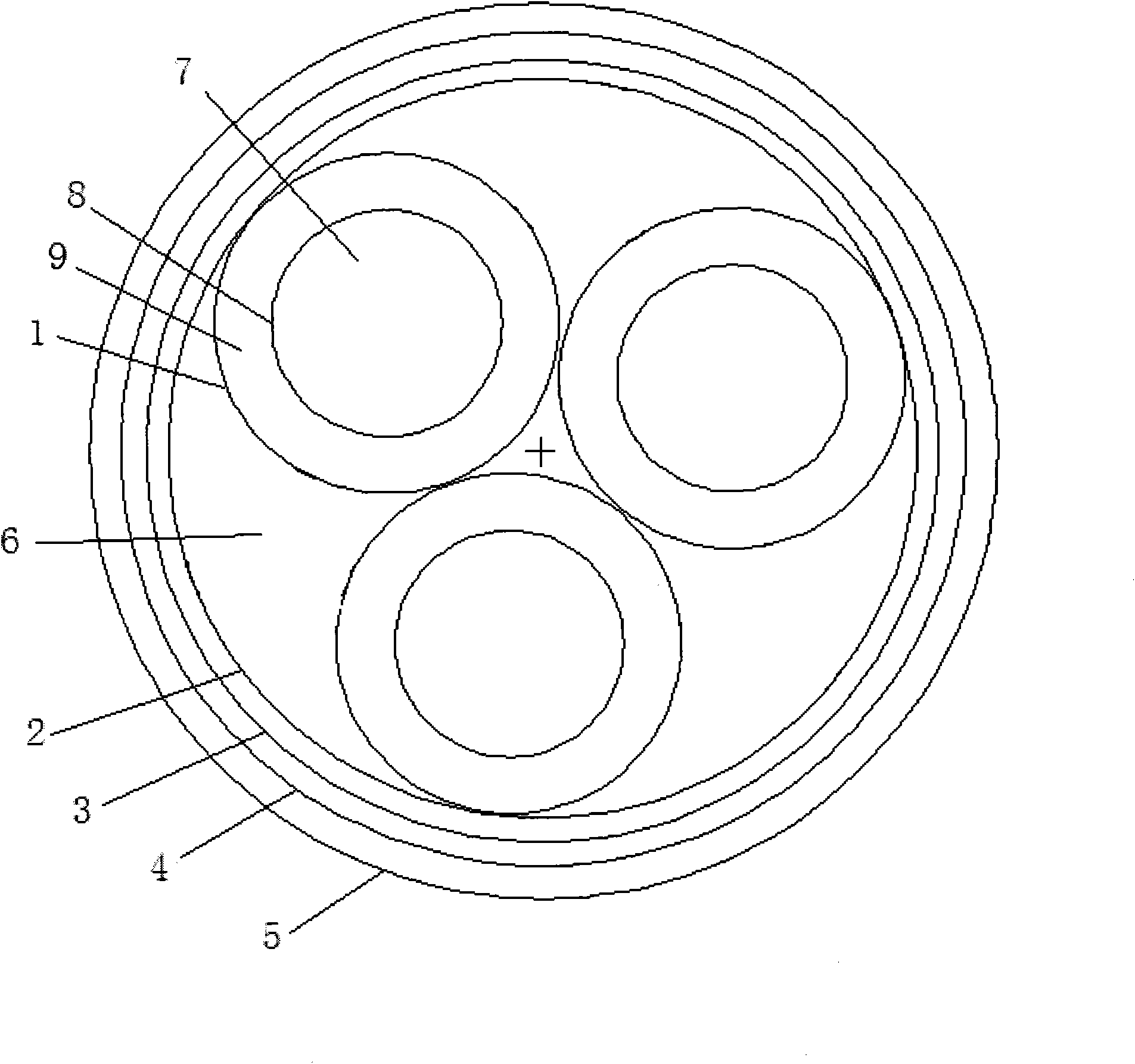

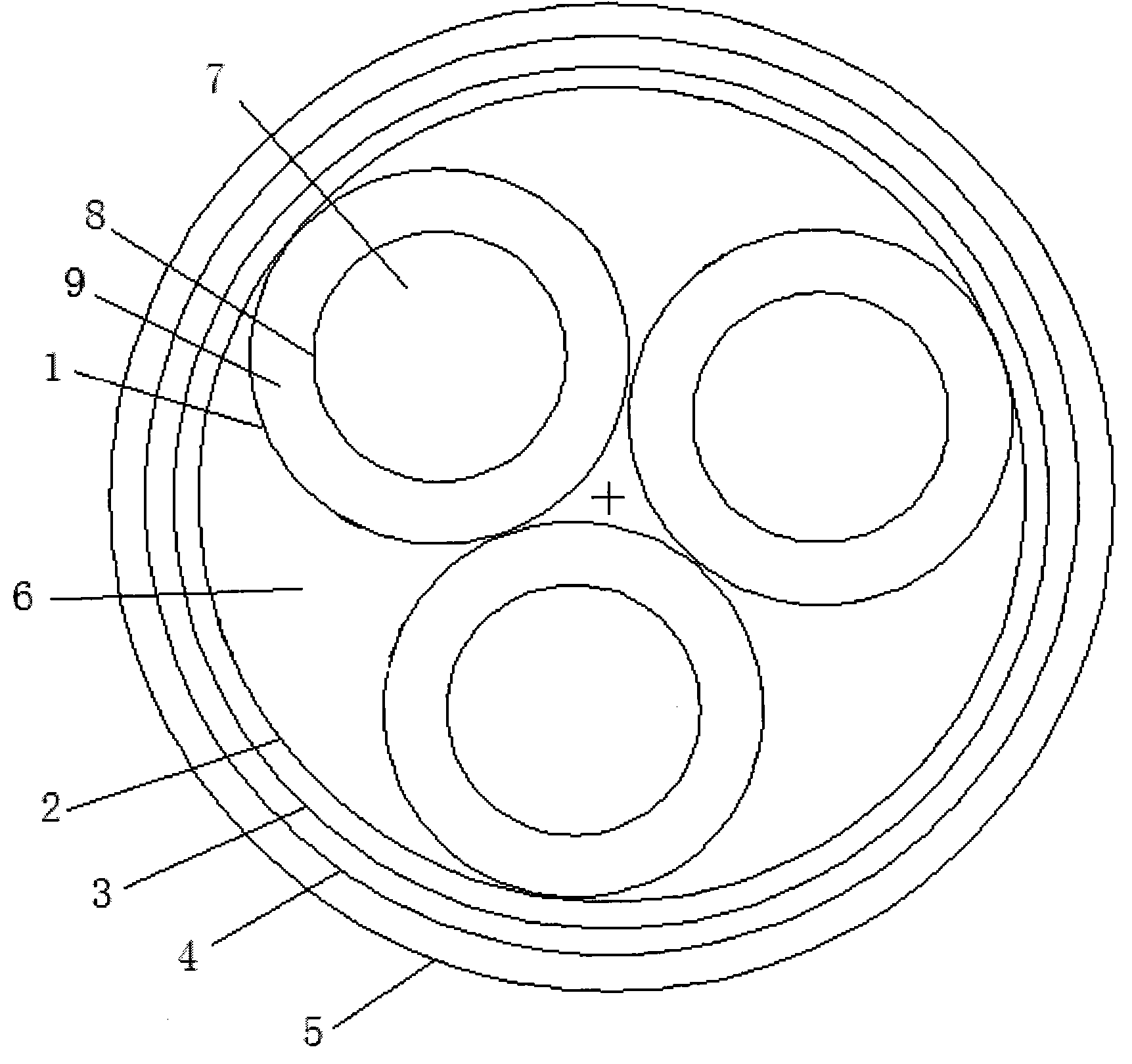

Expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and method thereof

InactiveCN102306513AEasy to processImprove mechanical propertiesFlexible cablesCable/conductor manufactureEnvironmental resistanceInsulation layer

The invention relates to an expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and a method thereof. The cable is characterized in that: each core sequentially consists of conductors, a silicon rubber insulating layer, a filler, a flame retardant oxygen separation layer, an aluminum-plastic composite tape insulation layer and an expansion type fire-resistant outer protective layer made of low-smoke halogen-free flame retardant polyolefin from inside to outside, and adopts a fire-resistant cable structure formed by combining the expansion type fire-resistant outer protective layer made of the low-smoke halogen-free flame retardant polyolefin, the aluminum-plastic composite tape insulation layer and the silicon rubber insulating layer; and a flame retardant oxygen separation layer structure is formed by a halogen-free high-flame retardant material coated with metal hydrates. The preparation method comprises the following steps of: drawing single lines, performing annealing, twisting the conductors, insulating silicon rubber, cabling, and preparing the flame retardant oxygen separation layer, the aluminum-plastic composite tape insulation layer and the expansion type refractory outer protective layer made of the low-smoke halogen-free flame retardant polyolefin. The cable provided by the invention is easy to process, the external diameter of the cable is smaller than that of the traditional cable by 2 to 4 millimeters, and the structure can be obviously lightened.

Owner:南洋电缆集团有限公司

Nylon composite material special for electric wire and cable jacket and preparation method thereof

ActiveCN102020842AImprove heat resistanceImprove light aging resistanceInsulated cablesInsulated conductorsPropanoic acidPhenol

The invention provides a nylon composite material special for an electric wire and cable jacket, which is prepared from the following components by mass percent: 86-100% of nylon 6, 0.1-2.0% of main antioxygen, 0.1-2.0% of auxiliary antioxygen, 0.1-2.0% of lubricant release agent, 0.1-2.0% of light stabilizer, 0.1-2.0% of lubricant, 0.1-2.0% of nucleating agent and 0.3-2.0% of tackifier, wherein the main antioxygen is a hindered phenol antioxygen, the auxiliary antioxygen is thiodi-propionic acid diester or phosphite ester, the lubricant release agent is calcium stearate, the light stabilizer is a hindered amine light stabilizer, the lubricant is ethylene double hard ester amide (EBS), silicone powder or a compositor of the ethylene double hard ester amide (EBS) and silicone powder, the nucleating agent is nano talcum powder, and the tackifier is nylon 6 containing reactive groups. The nylon composite material has the advantanges of simple formula and cheap, easily available components and low cost, and the electric wire and cable jacket prepared from the nylon composite material can prevent white ants and mousse, has abrasion resistance and corrosion resistance, is durable in use and is non-toxic and environment-friendly.

Owner:辰东意普万新材料(广东)有限公司

Special tensile dragging control cable and method for manufacturing same

ActiveCN102360603AHigh tensile strengthImprove electrical performanceFlexible cablesMetal/alloy conductorsCopper conductorEnvironmental resistance

The invention discloses a special tensile dragging control cable. An insulating wire core consists of a plurality of multi-stranded zinc-coated soft steel wires, a tin-coated oxygen-free copper wire and an insulating extruded layer; a plurality of insulating wire cores are stranded into a cable core; a filling layer which consists of hemp ropes is filled in a clearance of the cable core; the cable core is wound with a tear-resistant polypropylene belt in an overlapping mode and extruded with a tensile wear-resistant polyurethane elastic outer sheath; the outermost layer of the cable is a braided zinc-coated steel wire outer sheath layer; each insulating wire core consists of the plurality of multi-stranded zinc-coated soft steel wires which serve as reinforcing cores and the tin-coated oxygen-free copper wire which serves as a copper conductor; and the insulating extruded layer is made of ethylene-propylene-diene monomer compound rubber. The special tensile dragging control cable has the characteristics of high tensile strength, high flexibility, high tear resistance, oil resistance, aging resistance, external environment weather resistance and the like, has excellent functions ofhigh bending winding capacity, dragging resistance, environment friendliness and the like, and is applicable to equipment such as a winding drum, a port machine and an excavator; and the service lifeof the dragging cable is greatly prolonged.

Owner:ANHUI SIAIT CABLE GROUP

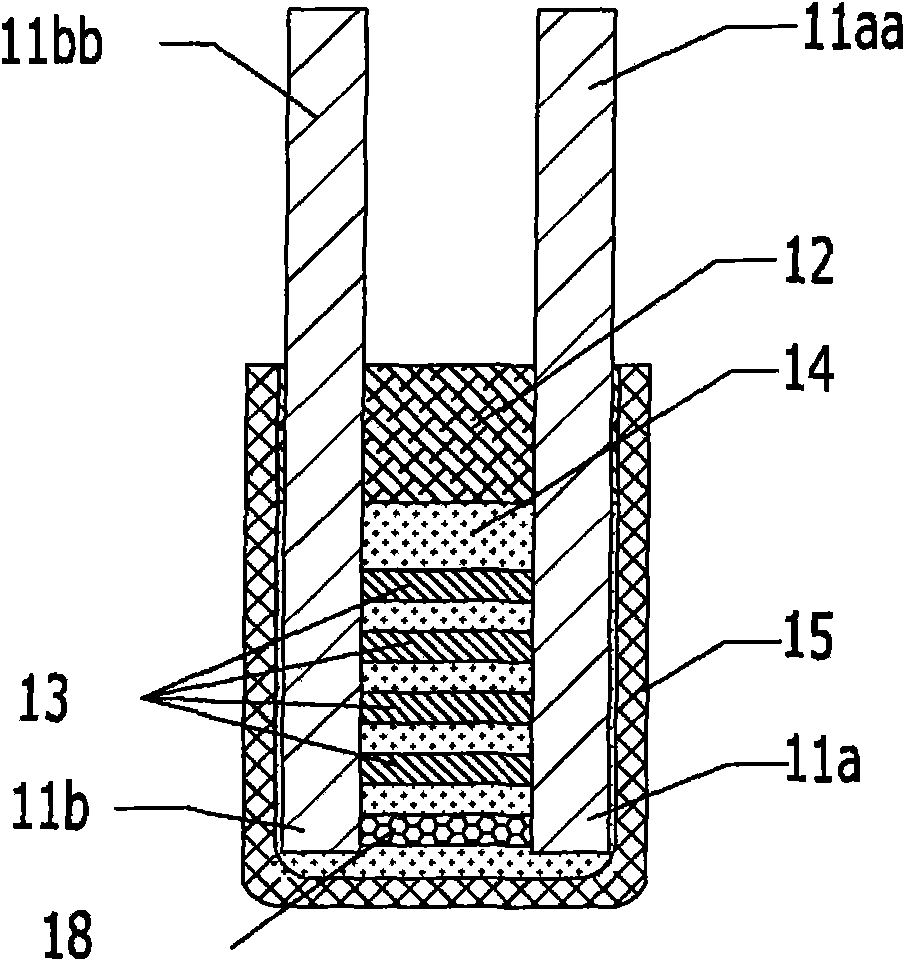

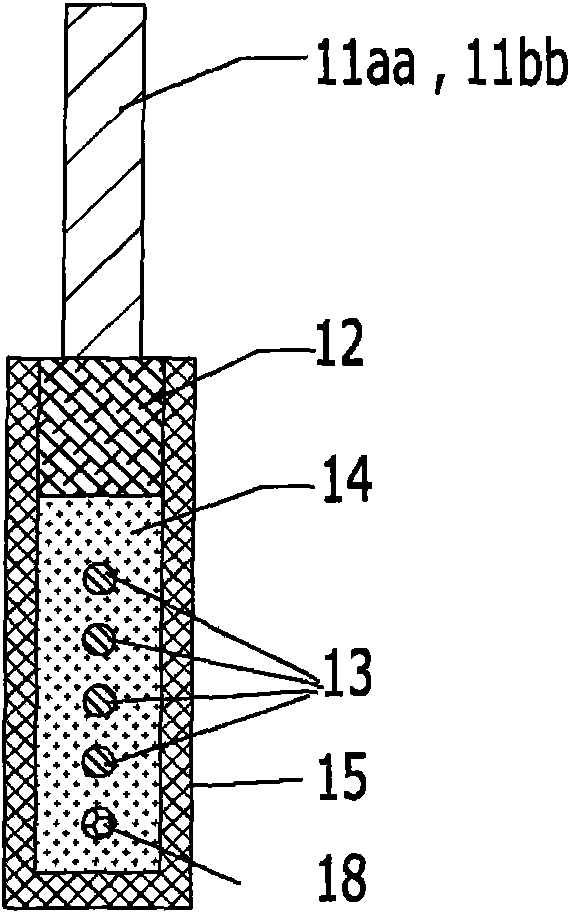

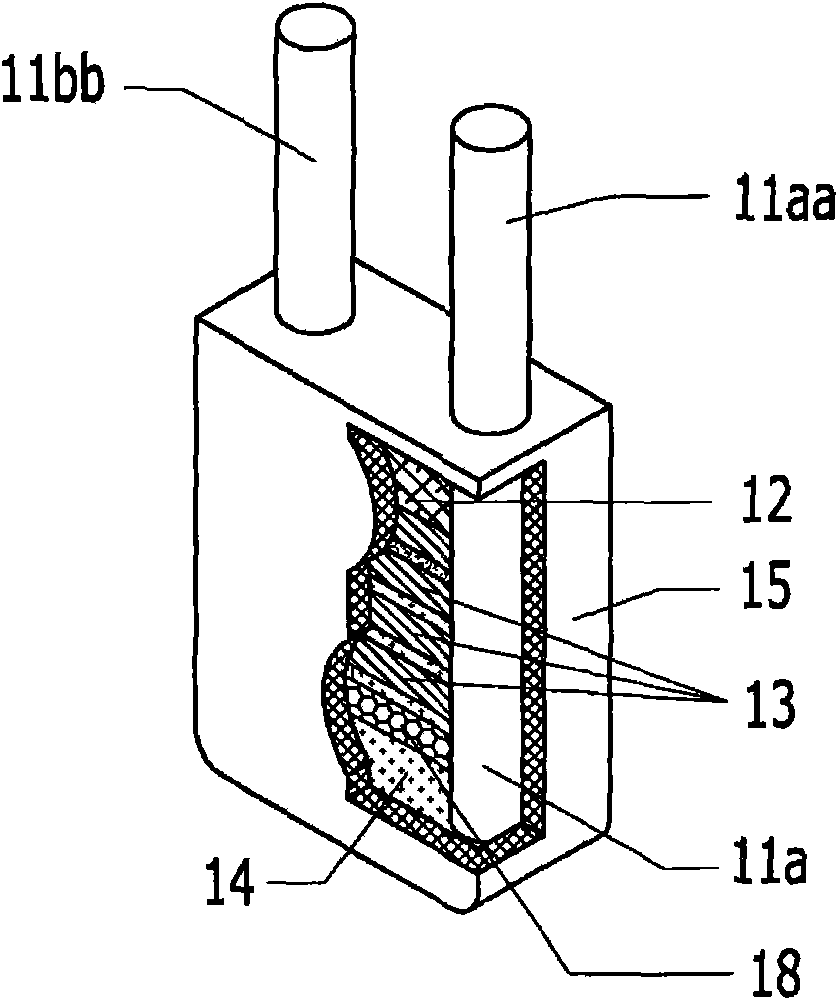

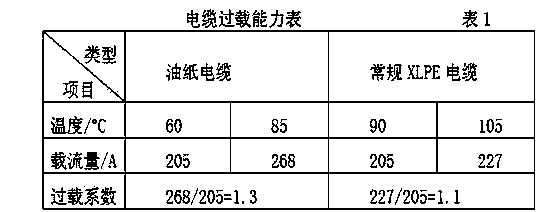

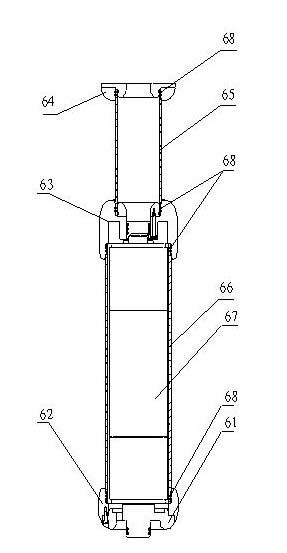

Alloy type thermal fuse with high ampere capacity

InactiveCN101859665AImprove protectionExcellent protection effect High protection effect High ampacityHeating/cooling contact switchesPower batteryMetal electrodes

The invention relates to an alloy type thermal fuse with high ampere capacity, which can act as a protective action to devices, such as a power accumulator and the like, with the properties of large current. When the devices, such as a power battery and the like, are in an abnormal temperature rise state, the alloy type thermal fuse can be automatically switched off so as to prevent the occurrence of the accidents of explosion or fire and the like of the devices, such as the power accumulator and the like, because of overtemperature. Because the alloy type thermal fuse and the devices with the properties of the large current run in series, the alloy type thermal fuse must bear large current. In order to solve this problem, a plurality of alloy wires with low melting point (containing two alloy wires with low melting point) are welded between two metal electrodes with favorable weldability in parallel, and the periphery of each alloy wire with low melting point is also provided with a fusing assistant material, so that the condition that each alloy wire with low melting point is quickly and completely retracted to the electrodes can be promoted after each alloy wire with low melting point is heated and fused, thereby switching off the large current safely.

Owner:XIAMEN SET ELECTRONICS

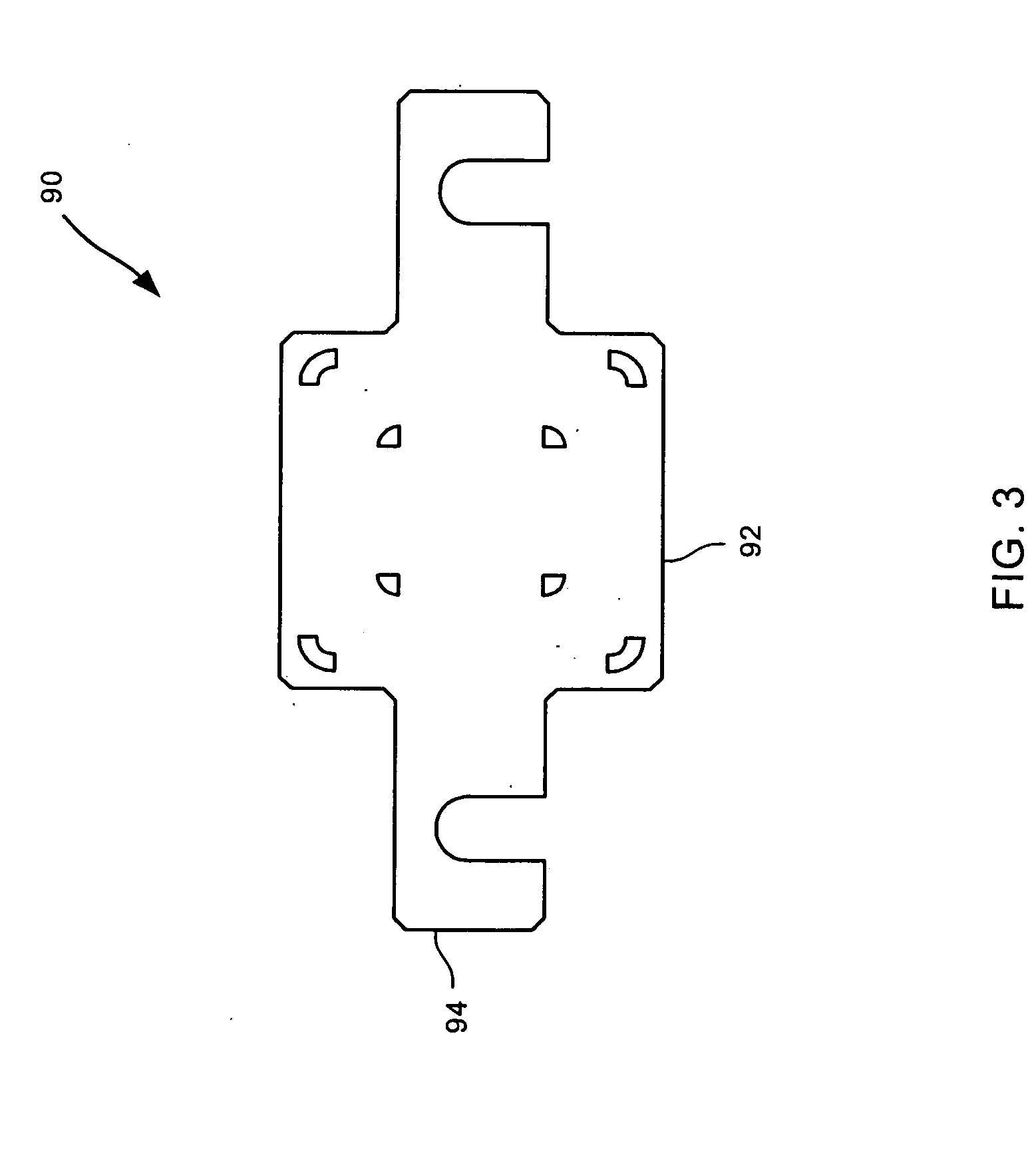

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS20060051580A1Increase ampacityNon-insulated conductorsSynthetic resin layered productsElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable and method of manufacture. The composite core comprises a plurality of longitudinally extending fibers embedded in a resin matrix. The composite core comprises the following characteristics: tensile strength ranging from about 250 to about 350 Ksi; a tensile modulus of elasticity ranging from about 12 to about 16 Msi; and a coefficient of thermal expansion less than or equal to about 6×10−6 cm / cm·° C. The composite core is further manufactured according to a one or more die pultrusion system, the system comprising tooling designed in accordance with the processing speed, selection of composite core fibers and resin and desired physical characteristics of the end composite core.

Owner:CTC GLOBAL CORP

Optical fibre composite electric power seabed oil-filled cable

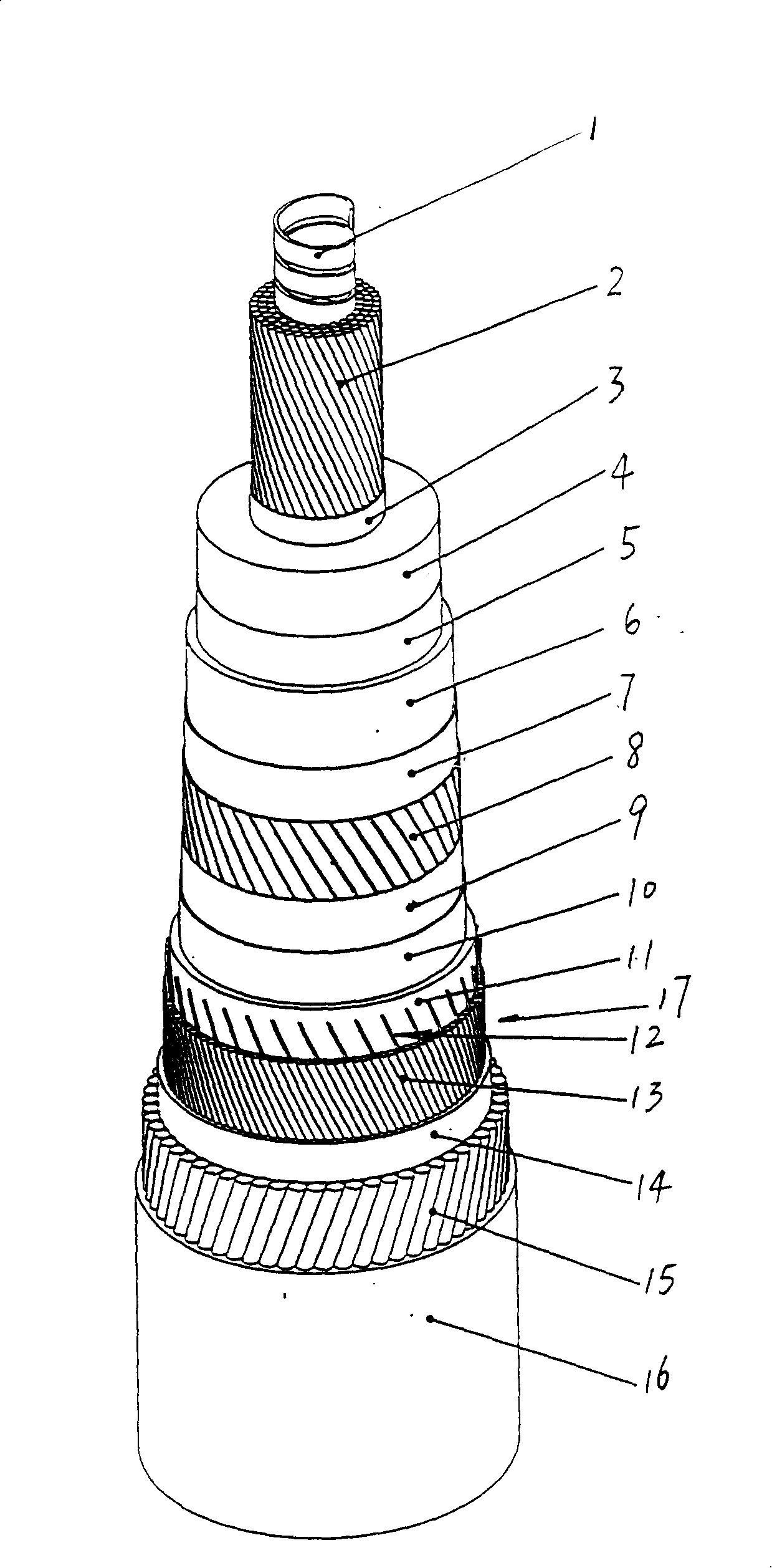

InactiveCN101211680ASafe and reliable protection performanceIncrease ampacityCommunication cablesSubmarine cablesOcean bottomFilled cable

The invention discloses an optical fiber composite power seabed oil-filled cable, which is characterized in that a light unit layer is arranged in a defending layer. The light unit layer is twisted by an optical fiber and polyethylene filled bar at interval. A metal protecting layer comprises a lead protecting layer, wherein a return feeder layer is arranged outside the lead protecting layer. The return feeder layer is assembled by a flat copper line. A lining layer is arranged between the lead protecting layer and the return feeder layer. The return feeder layer is arranged in the metal protecting layer so as to improve the short circuit current of the metal protecting layer and help to improve the current carrying amount of the cable at the same time. The invention has the advantages of higher electrical performance and sufficient mechanical intensity by combining the seabed optical fiber cable and seabed power cable.

Owner:上海电缆厂集团有限公司

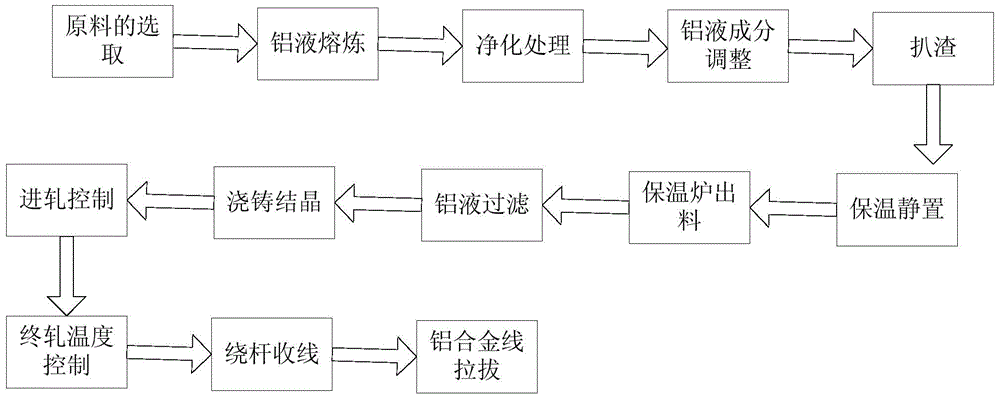

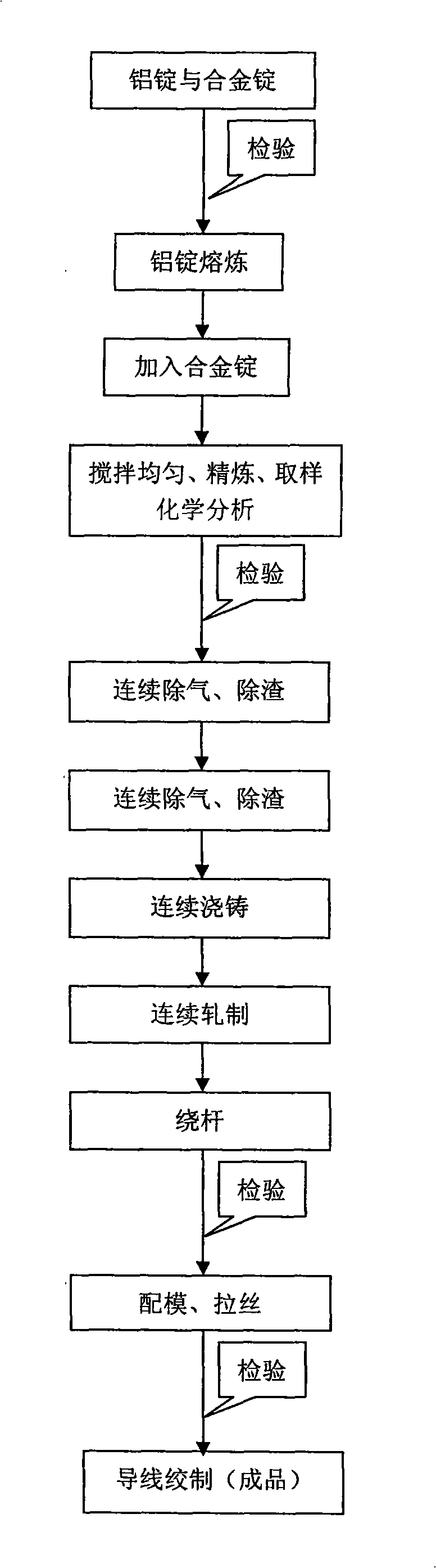

High-conductivity heat-resistance aluminum alloy wire and preparation method thereof

InactiveCN104831127AImprove heat resistanceImprove conductivityMetal/alloy conductorsSilicon alloyChemical element

The invention relates to a high-conductivity heat-resistance aluminum alloy wire and a preparation method thereof. The high-conductivity heat-resistance aluminum alloy wire comprises the chemical elements by weight percent: 0.03-0.06% of zirconium, 0.07-0.10% of silicon, 0.14-0.25% of iron, 0.03-0.06% of ytterbium, 0.01-0.04% of boron, not more than 0.02% of total amount of titanium, manganese, chromium and vanadium, and the balance of aluminum. The preparation method comprises the following steps: respectively weighing raw materials including aluminum ingots, aluminum-silicon alloy, aluminum-iron alloy, aluminum-ytterbium alloy and aluminum-boron alloy at a mass ratio of (6000-7000): (50-95): (15-55): (18-20): (40-85): (35-90); melting each raw material, performing purification regulating elements of an aluminum solution, slagging off, preserving the heat, standing, filtering the aluminum solution, casting and crystallizing; rolling ingot-casting-formed aluminum alloy ingots to form aluminum alloy wires, drawing the rolled aluminum alloy wires to form high-conductivity heat-resistance aluminum alloy wires. According to the prepared high-conductivity heat-resistance aluminum alloy wire, the electric conductivity is larger than 61% IACS, the tensile strength is larger than 160MPa, and the heat resistance is good; furthermore, the production technical steps are simple; by utilizing electric wires and cables produced by the aluminum alloy wires, the operation speed of a circuit can be improved, and the carrying capacity is improved.

Owner:WUXI HUANENG ELECTRIC CABLE

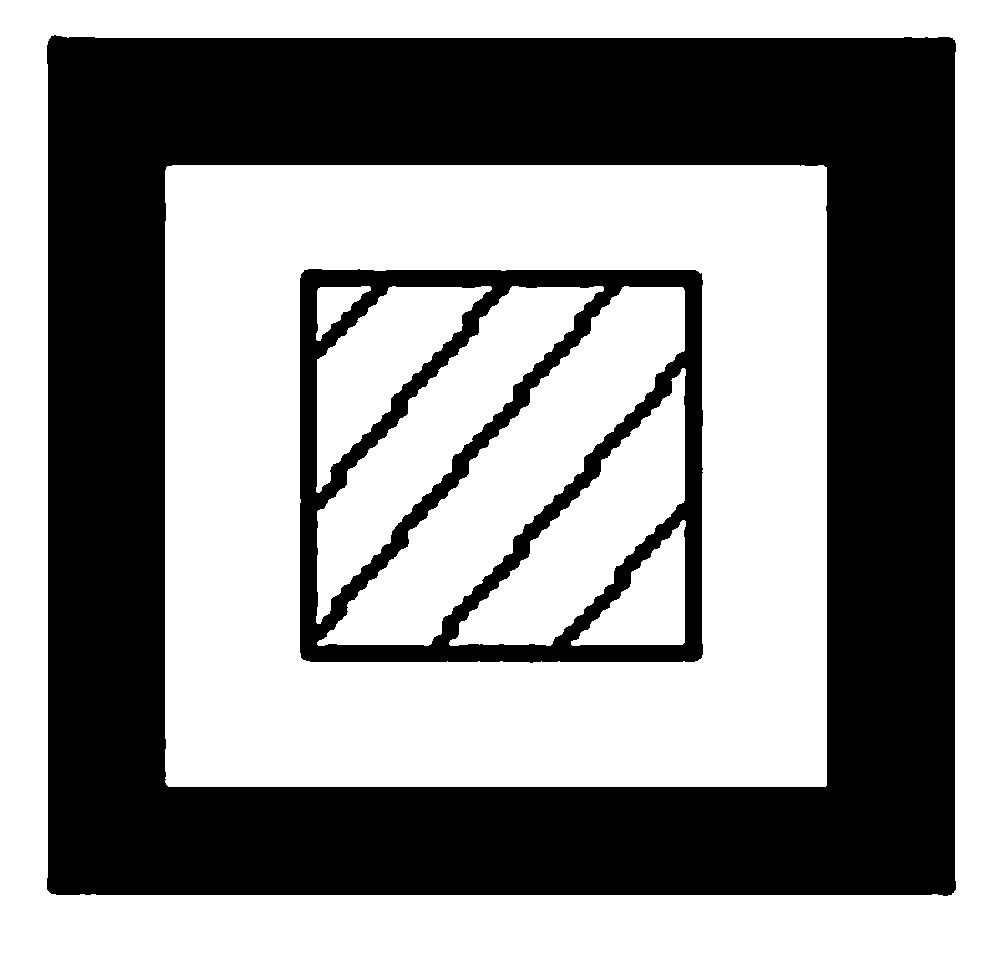

Fireproofing and heat resistant environmental-friendly power cable

InactiveCN101834029AEvenly distributedReduce the temperaturePlastic/resin/waxes insulatorsPower cables with screens/conductive layersElectricityPower cable

The invention discloses an environmental-friendly power cable which comprises a core wire, an aluminum tape layer lapping outside the core wire and steel-tape armoring arranged outside the aluminum tape layer, wherein the gap between the core wire and the aluminum tape layer is provided with silicon carbide mineral composite fillers, a polyethylene inner sheath is arranged between the aluminum tape layer and the steel-tape armoring, and a polyethylene outer sheath is arranged outside the steel-tape armoring. The invention has the advantages of good heat radiation property, long service life, strong flame retarding property, electricity saving, no toxicity and environmental protection.

Owner:无锡市黄浦电线电缆有限公司

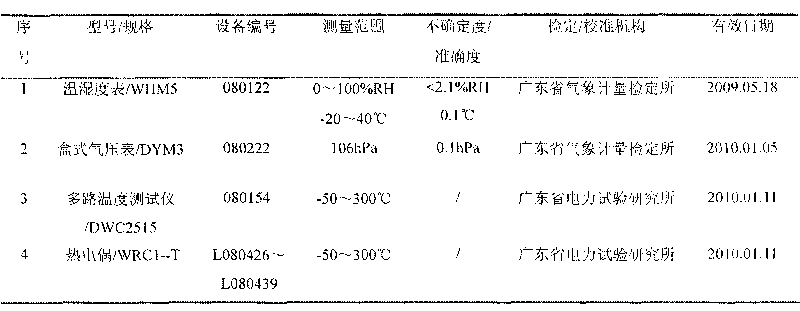

High-strength heat-resistant aluminum alloy single line and wire for smart power grid and processing process of single line

ActiveCN105369073AHigh strengthImprove the safety of useConductive materialInsulated cablesSmart gridPower grid

The invention discloses a high-strength heat-resistant aluminum alloy single line and wire for a smart power grid and a processing process of the single line. The high-stretching-rate high-strength heat-resistant aluminum alloy single line is prepared from, by weight percent, 0.05%-0.15% of Zr, 0.01%-0.30% of Y or La, 0.15%-0.30% of Fe, 0.01%-0.40 of Si, 0.01%-0.50% of Mg, 0.10% or less of other impurity elements and the balance aluminum. The strength of the wire formed by stranding single lines can be greatly increased, the draw-weight ratio can be increased, and the use safety of the wire can be improved; meanwhile, the operating temperature of the wire is greatly increased, the operating temperature of the wire is increased to 150 DEG C from conventional 70 DEG C, and therefore the carrying capacity is greatly improved; and the use requirements of high-capacity and large-span extra-high-voltage lines can be met.

Owner:FAR EAST CABLE +2

Aluminum alloy conductor for extra-high voltage

ActiveCN105420556AHigh strengthImprove conductivitySingle bars/rods/wires/strips conductorsConductive materialSolid solutionObserved Survival

The invention provides an aluminum alloy conductor for an extra-high voltage. The aluminum alloy conductor for the extra-high voltage comprises the following components in percentage by weight: 0.4-0.7% of Mg, 0.35-0.65% of Si, 0.2-0.4% of Cu, 0.1-0.3% of Fe, 0.05-0.15% of Zn, 0.3-0.6% of B, 0.01-0.1% of Zr, 0.05-0.25% of Y, 0.04-0.2% of Ce, less than or equal to 0.1% of other impurities and elements and the balance being Al; and a preparation method of the aluminum alloy conductor for the extra-high voltage comprises the steps of raw material treatment; smelting; alloying; boronizing; refining; casting; solid solution heat treatment; rolling; drawing; and aging treatment. The aluminum alloy conductor for the extra-high voltage has the tensile strength of 269.27MPa and the electric conductivity of 63% IACS; in addition, the aluminum alloy conductor for the extra-high voltage has the strength survival rate of larger than 93% after being subjected to a test operation, namely heating at the temperature of 300 DEG C for 2 hours.

Owner:STATE GRID CORP OF CHINA +1

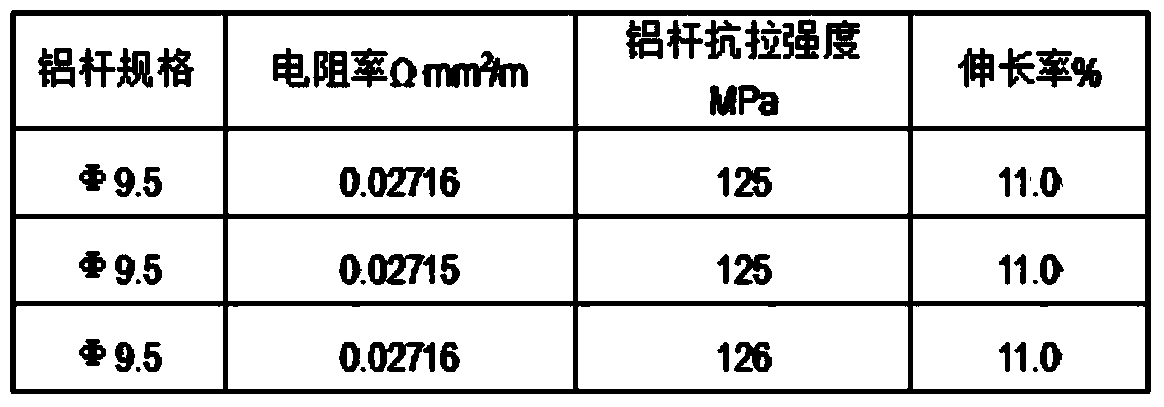

High-conductivity hard aluminum wire and preparing technology thereof

ActiveCN103854807AGuaranteed tensile strengthImprove conductivityNon-insulated conductorsCable/conductor manufactureCarrying capacityAtmospheric pressure

The invention discloses a high-conductivity (63 percent IACS) hard aluminum wire and a preparing technology thereof. The preparing technology of the high-conductivity hard aluminum wire comprises the following steps that firstly, a high-conductivity aluminum rod is prepared in a continuous casting and rolling mode; secondly, the high-conductivity aluminum rod is drawn into high-conductivity aluminum wires which are drawn through various dies, wherein the coefficient of elongation of the last die is controlled within 1.35-1.50, and the coefficients of elongation of the other dies are controlled within 1.30-1.40; thirdly, a plurality of high-conductivity aluminum wires are twisted, the pay-off tension is controlled in the twisting process, the control air pressure is smaller than or equal to 3 kilograms, the tensile strength of the manufactured single hard aluminum wire is larger than or equal to 160 MPa, and the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C. The tensile strength of the manufactured single hard aluminum wire in an overhead conductor is larger than or equal to 160 MPa, the conductor resistance is smaller than or equal to 0.027366 Omega*mm<2> / m when the temperature is 20 DEG C, the tensile strength of the hard aluminum wire is kept, the conductivity of the hard aluminum wire is increased to 63 percent IACS, and the conductivity is increased by 3.28 percent compared with the stipulated conductivity of a hard aluminum wire in common GB / T17937-2009. The high-conductivity hard aluminum wire is used in the overhead conductor, the loss of the circuit electric energy can be greatly reduced, the circuit operation cost is reduced, and the carrying capacity of the wire can be obviously improved.

Owner:FAR EAST CABLE +2

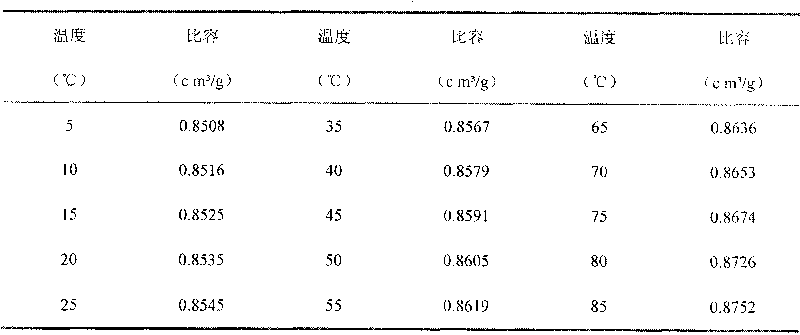

Cable low heat resistance protection medium and preparing method thereof

ActiveCN101764384AReduce thermal resistanceIncrease thermal resistanceCable installations on groundAlkalinityElectrical conductor

The invention discloses a cable low heat resistance protection medium with high water content, high stability, low heat resistance, environment protection and effective prevention of termite damage, and a preparation method thereof. The filling medium is prepared by mixing bentonite, fine quartz sand, water and cement, and using a small amount of tartaric acid and sodium sesquicarbonate as additives. As accounted by 100% of mass fraction, the filling medium is preferably prepared by 54%-57% of bentonite, 24%-28% of fine quartz sand, 14%-16% of water, 2.5-3.5% of cement, 0.24%-0.26% of tartaric acid and 0.24%-0.26% of sodium sesquicarbonate. Before condensation, the filling medium has the advantages of better initial liquidity, moderate alkalinity, low bleeding rate and the like. After condensation, compared with traditional material, the filling medium has the advantages of high water content and high stability, and enables the surroundings of the cable to maintain low heat resistance for long term, the heat resistance is smaller than that of soil, and the hardness is higher, therefore the current carrying amount of the cable is improved, or the running temperature of the cable conductor is reduced.

Owner:广州骏拓电力科技有限公司

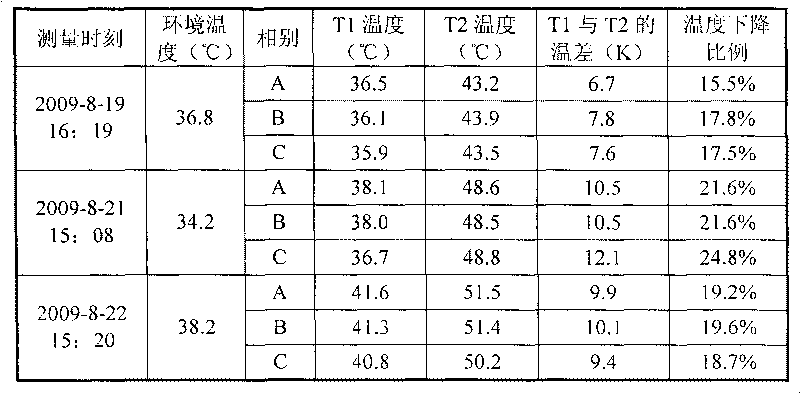

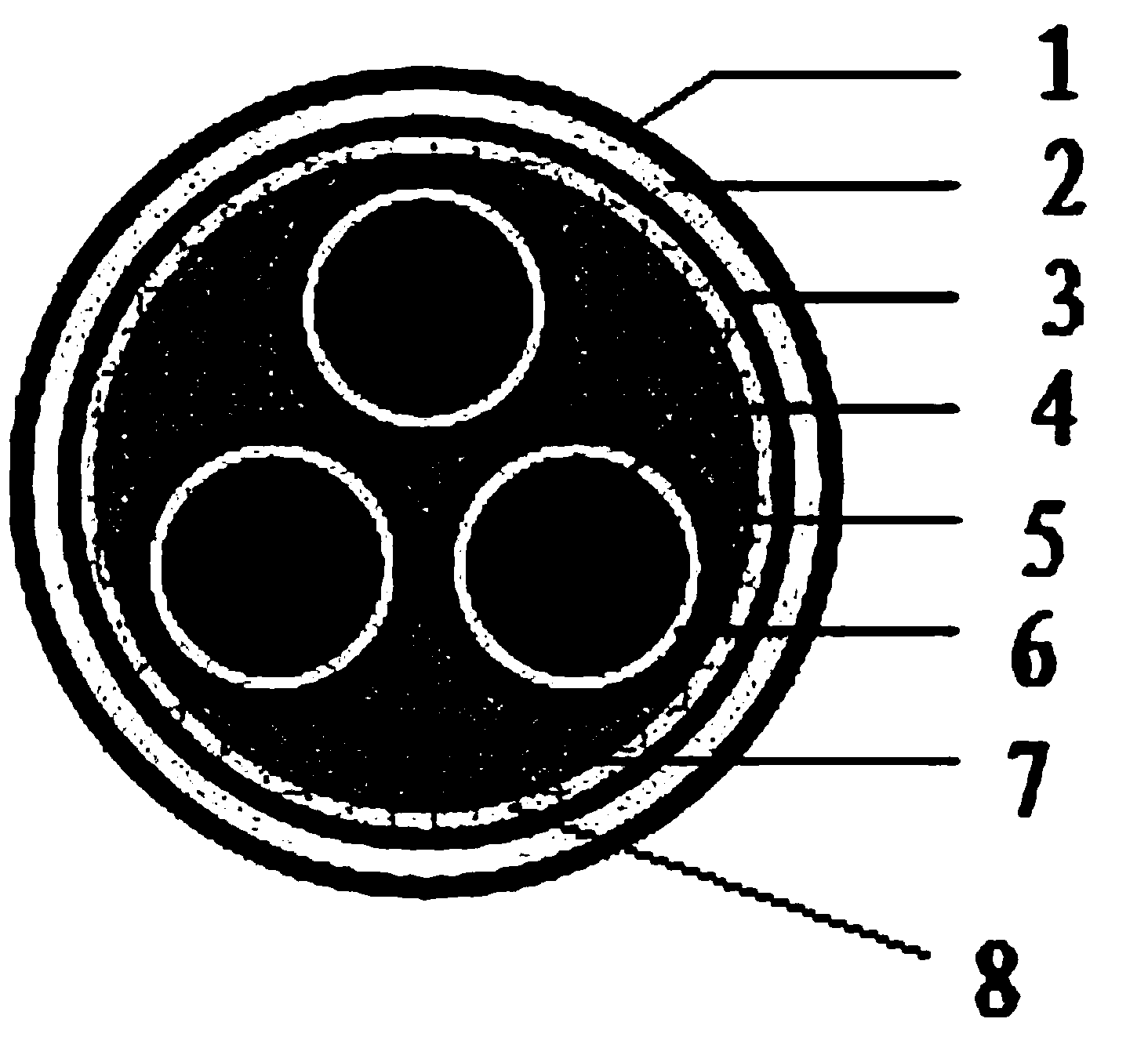

Phase-change temperature-control type high-voltage cable

InactiveCN104036866AImprove thermal stabilityAchieve strong heat conduction self-cooling functionPower cables with screens/conductive layersInsulated cablesTemperature controlEngineering

The invention discloses a phase-change temperature-control type high-voltage cable, and relates to the technical field of cables. The cable comprises an inner cable core and an outer cable layer, the inner cable core sequentially comprises a cable core body, an insulating layer and a shielding layer from inside to outside, the outer cable layer sequentially comprises a wrapping layer, an inner protective layer, an armor layer and an outer protective layer from inside to outside, a filling layer is disposed between the inner cable core and the outer cable layer, and the filling layer is made of a composite phase-change material. The cable saves energy, is environmentally friendly, achieves automatic temperature control, improves heat dissipation through the phase-change material, improves current-carrying performance, the overload capacity and heat stability, and prolongs service life.

Owner:STATE GRID CORP OF CHINA +1

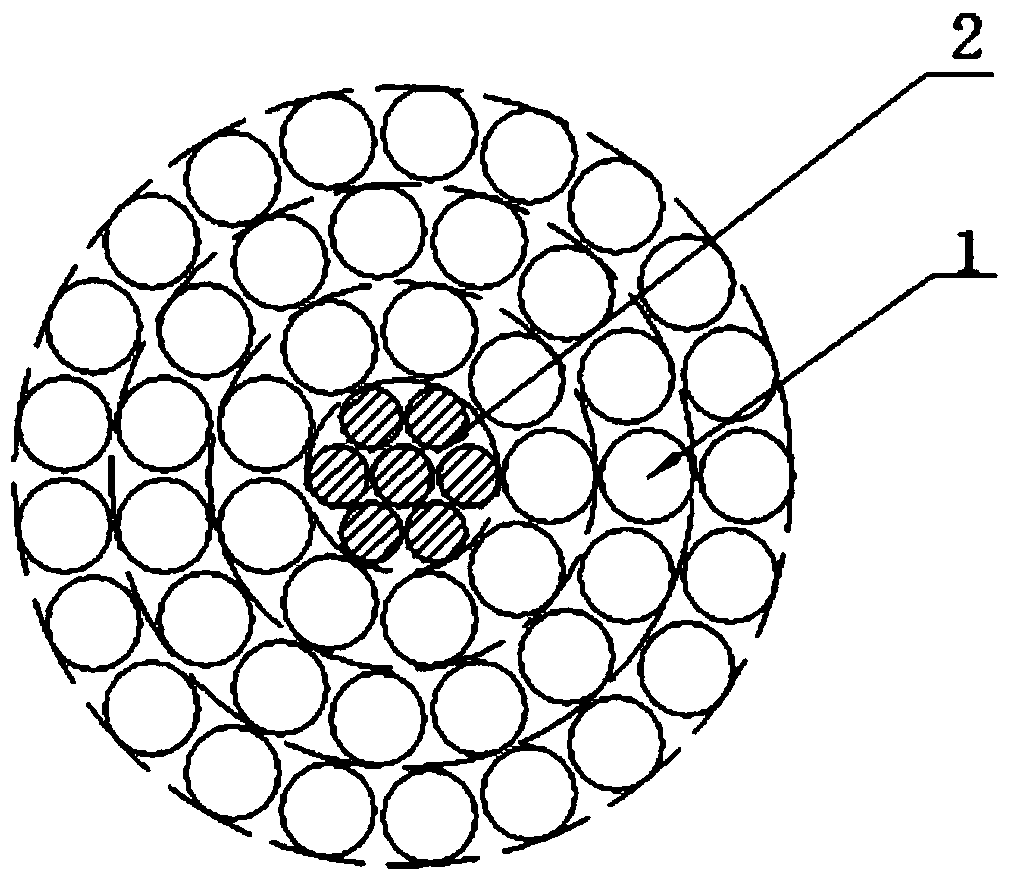

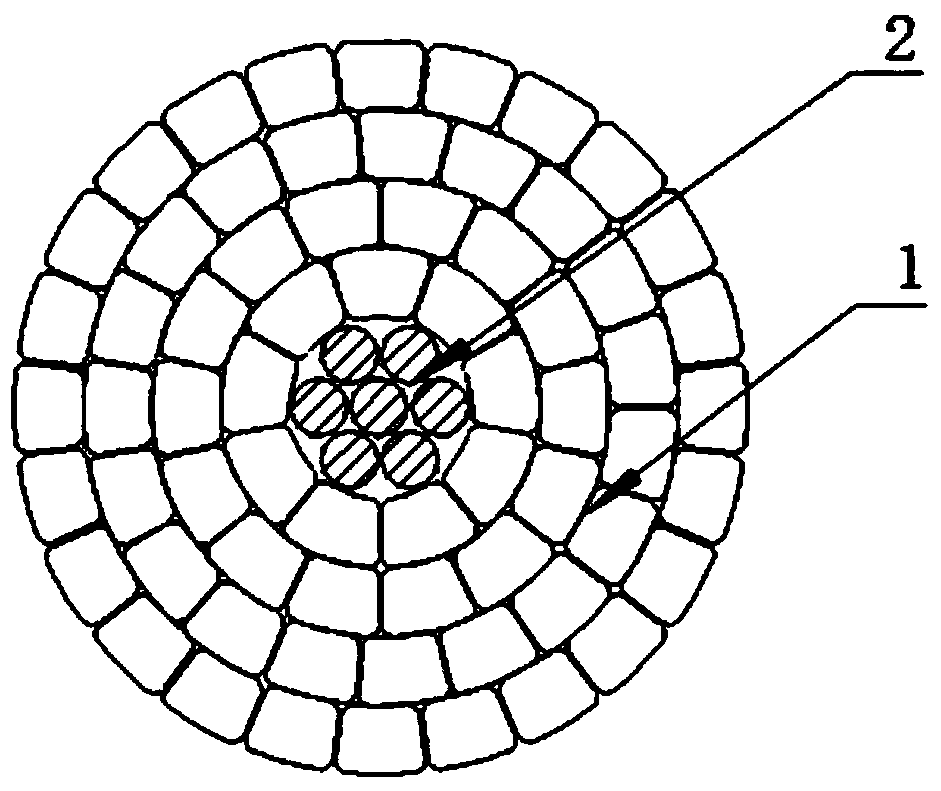

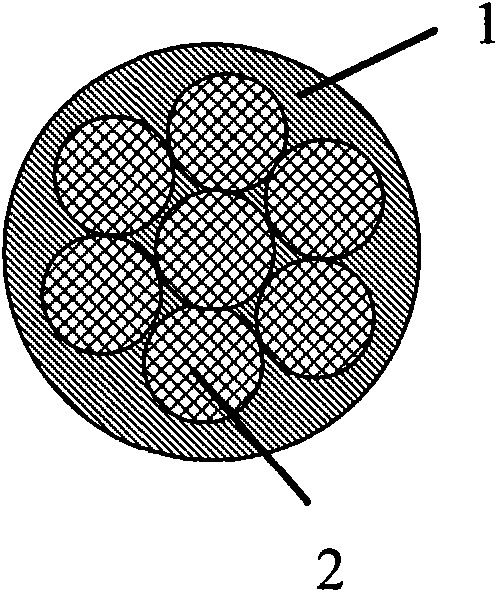

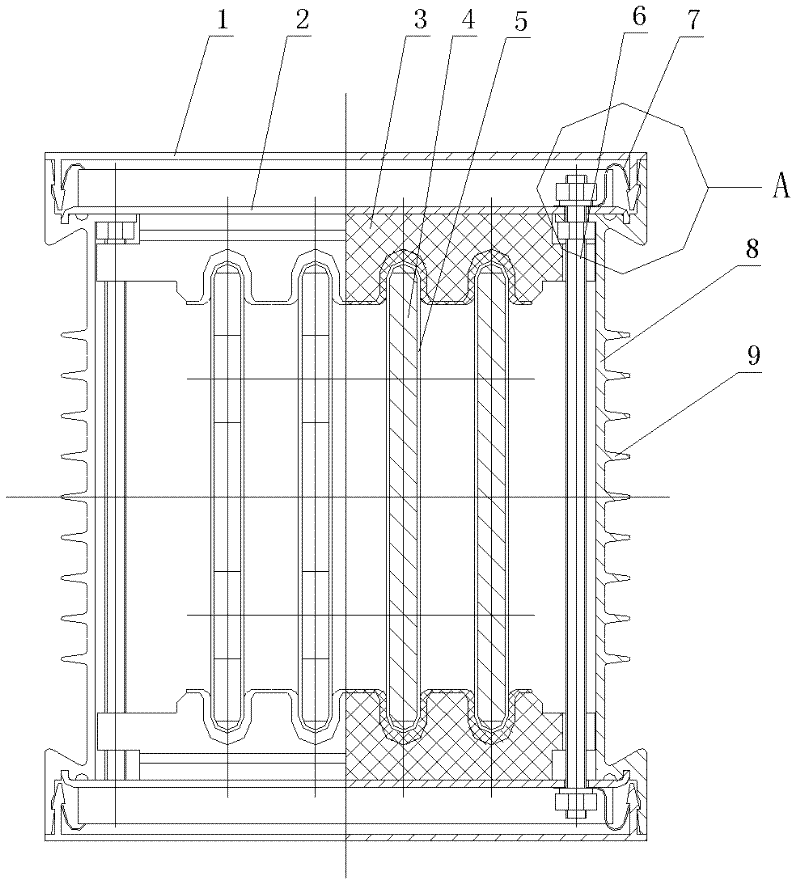

Reinforced cable core and manufacturing method thereof

InactiveCN101727998AExtended service lifePrevent Galvanic CorrosionNon-insulated conductorsConductive materialCarrying capacityElectrical conductor

The invention discloses a reinforced cable core and a manufacturing method thereof. The reinforced cable core comprises a fiber reinforced core and a metallic sheath, wherein the fiber reinforced core is coated by the metallic sheath. The reinforced cable core of the invention not only has the advantages of low density, low expansion coefficient, high tensile strength and the like, but also has the functions of improving the current carrying capacity of a cable, shielding an inner fiber composite structure to avoid the electrical erosion between a fiber and an aluminum conductor, protecting the surface of a fiber composite material and reducing the mechanical performance loss caused by surface damage. Compared with reinforced cable cores with other structures, which are formed by only fiber composite cores, the reinforced cable core of the invention not only plays a role of bearing but also can further improve the current carrying capacity of the cable.

Owner:SHANGHAI ELECTRIC CABLE RES INST

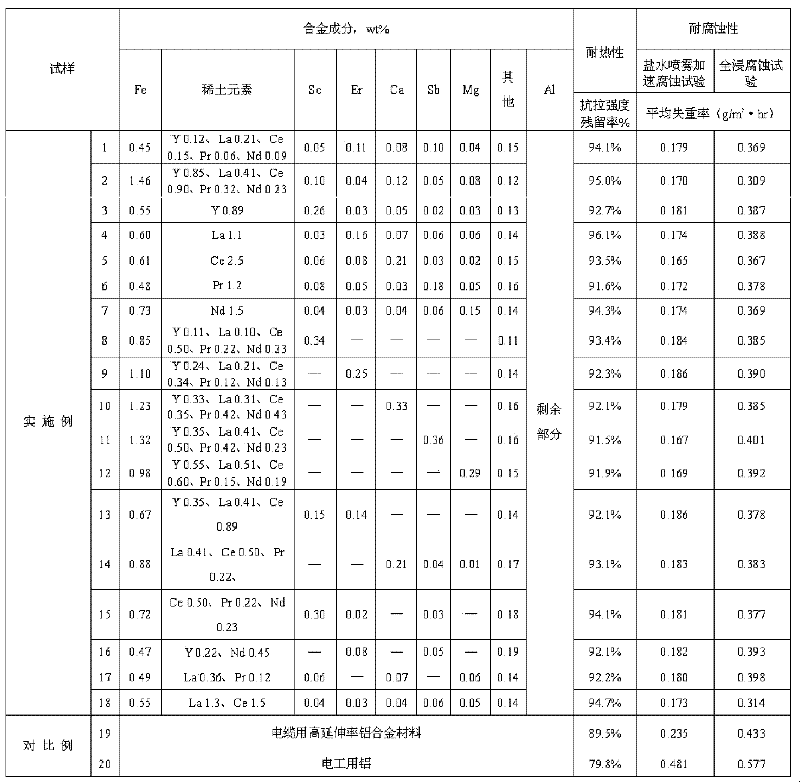

Rare earth high iron aluminum alloy conductor material

ActiveCN102262913AImprove performanceEasy to stretchMetal/alloy conductorsRare-earth elementElectrical conductor

The invention discloses a rare earth high-iron aluminum alloy conductor material, which comprises 0.4 to 1.5 weight percent of Fe, 0.3 to 1.3 weight percent of rare-earth element, 0.01 to 0.4 weight percent of one or several of Sc, Er, Ca, Sb and Mg and the balance of aluminum and inevitable impurities. The aluminum alloy material has various performance indexes of a high-elongation aluminum alloy material for a cable and has excellent heat resistance and corrosion resistance; therefore, the material has higher current carrying capacity.

Owner:于贵良 +1

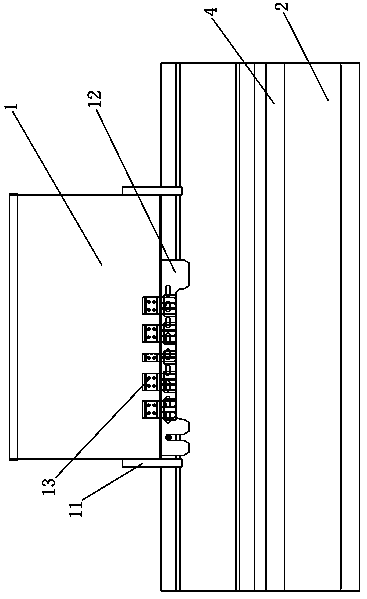

Intelligent copper-aluminum composite conductor bus groove

InactiveCN102361294AImprove antioxidant capacityReduce contact resistanceSingle bars/rods/wires/strips conductorsOpen bus-bar installationsVoltage dropMonitoring system

The invention relates to an intelligent copper-aluminum composite conductor bus groove, which consists of a box body and buses, wherein the box body consists of two aluminum-magnesium alloy side plates and upper and lower aluminum-magnesium alloy cover plates; the buses are arranged in the box body and uniformly distributed between upper and lower insulating brackets at intervals; each bus is a copper-aluminum composite bus of which an outer layer is copper and an inner core is aluminum; the area of the copper section of the outer layer is 20 percent of that of the whole section; and an insulating layer is coated outside the copper-aluminum composite bus. The intelligent copper-aluminum composite conductor bus groove is simple in structure, low in impedance, low in voltage drop, low in energy consumption, low in cost and high in using reliability; a temperature monitoring system and an electric leakage monitoring system which are arranged on the bus groove can automatically detect the temperature of the bus groove during operation and the leakage current of a power supply line, perform out-of-limit alarming and guarantee the safety of a power supply system; and the bus groove is intelligent, low-cost and energy-saving and has a wide application prospect.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

Corrosion-proof vibration-proof wire

InactiveCN101145413AHigh tensile strengthSmall outer diameterInsulated cablesInsulated conductorsBreaking strengthElectrical conductor

The invention relates to an improvement of anti-corrosion and anti-vibration overhead power transmission cables for overhead power transmission lines and is characterized in that the reinforced inner core of the twisted cable is a fiber resin-molded elongated body and has a 0.5-8 mm distance to the innermost conductor of the twisted cable. The inventive wire has the advantages of self-damping vibration protection function, reduced weight of the reinforced core molded from resin mixed with carbon fiber and / or basalt fiber (50-70 percent of the steel-core anti-corrosion and anti-vibration cable core), increased tensile strength (up to 2000-6000MPa), maximum applied stress up to 60 percent of breaking strength, reduced base number or altitude of towers, larger construction span, large current capacity (about doubled), reduced construction cost (by 10-20 percent), and increased service life (by 20-30 years).

Owner:FAR EAST COMPOSITE TECH

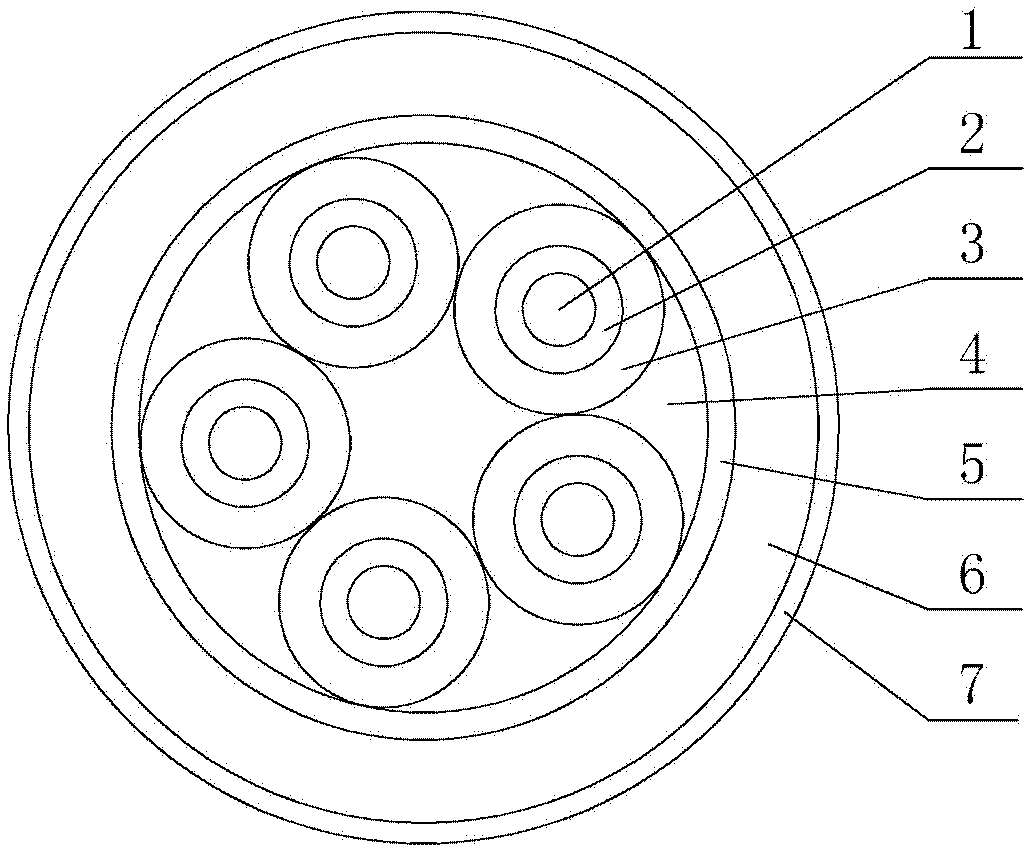

Hydrocarbon-ageing-resistant control cable for petrochemical unit and manufacturing method of hydrocarbon-ageing-resistant control cable

InactiveCN103578633AReduce the temperatureInsulation effectFlexible cablesCable/conductor manufactureCopper conductorPolyester

The invention relates to a hydrocarbon-ageing-resistant control cable for a petrochemical unit and a manufacturing method of the hydrocarbon-ageing-resistant control cable. The manufacturing method includes the steps that an insulating layer is evenly extruded on the periphery of each stranded copper conductor to form a control cable insulated wire core; a plurality of control cable insulated wire cores are stranded to form a control cable core. The periphery of the control cable core is sequentially wrapped by a flame-retardant fireproof longitudinal wrapping tape, an aluminum foil composite shielding tape, a hydrocarbon-ageing-resistant inside liner, a nylon inner sheath and a hydrocarbon-ageing-resistant outer sheath. The aluminum foil face of the aluminum foil composite shielding tape faces inwards and the inner side of the aluminum foil face of the aluminum foil composite shielding tape is provided with copper wire current steering wires. The components of the inside liner and the components of the outer sheath respectively comprise, by weight, 15 parts of PVC-SG2, 5 parts of NBR3305, 3-7 parts of adipic acid propylene glycol polyester,2-3 parts of epoxidized soybean oil, 0.6-1 part of barium stearate, 1-1.5 parts of lead sulfate tribasic, 0.05-0.1 part of diphenol propane, 3-5 parts of antimonous oxide, 0.1-0.5 part of chlorinated paraffin-52 and 0.3-0.5 part of dicyclopentadienyl iron. The hydrocarbon-ageing-resistant control cable is capable of resisting hydrocarbon ageing, small in external diameter and light in weight.

Owner:JIANGSU YUANYANG DONGZE CABLE

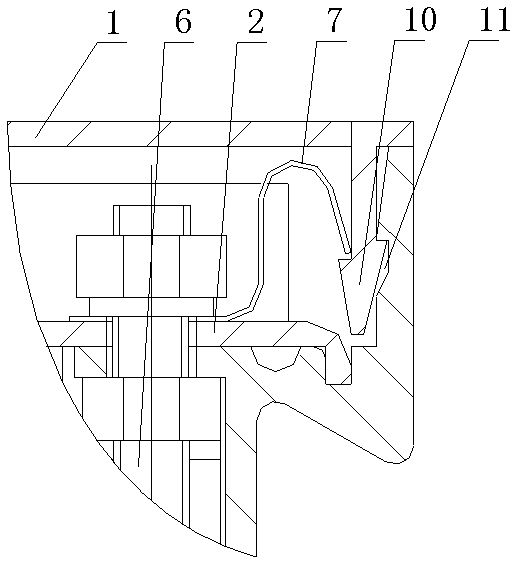

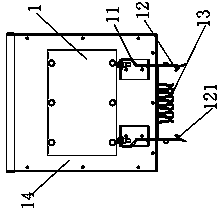

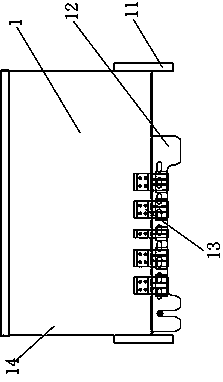

Intensive busway

InactiveCN103515897APrecise positioningImprove sealingCooling bus-bar installationsPartially enclosed bus-bar installationsCopperElectrical and Electronics engineering

The invention discloses an intensive busway. The intensive busway comprises a plug box, a busway housing and a plurality of buses, wherein the plug box is arranged at the upper end of the busway housing; the buses are arranged inside the busway housing; the plug box comprises a box body, two pairs of guiding plates, a fixing plate and a plurality of pin assemblies; a pair of guiding plates are arranged at two ends of the box body respectively; the fixing plate is arranged at the bottom of the box body; the pin assembly comprises a pin, a pair of reeds and a pair of pin copper sheets; the busway housing comprises a pair of H sectional materials and a pair of U sectional materials; the H sectional materials are connected through the U sectional materials; the number of the buses is equal to the that of the pin assemblies. The intensive busway is good in sealing performance, large in heat dissipating area, low in cost, easy in operation and high in yield.

Owner:XIANGRONG ELECTRIC GRP

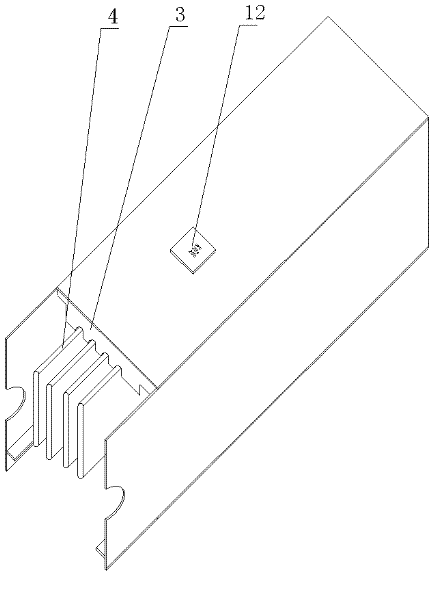

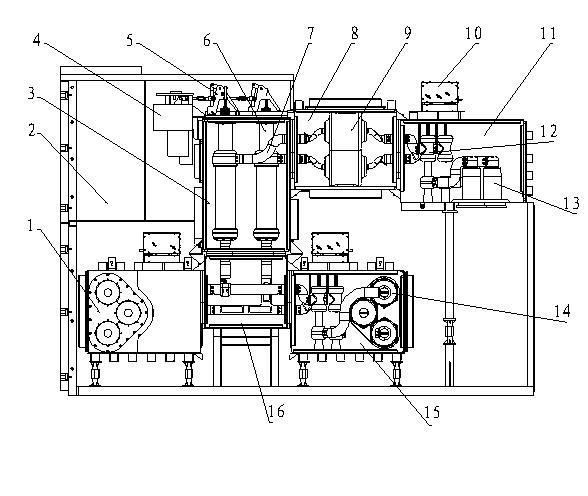

126-kv cabinet type gas-insulated metal-closed switching equipment

ActiveCN102255258AReduce manufacturing costShorten the manufacturing cycleBus-bar/wiring layoutsSwitchgear arrangementsSulfur hexafluorideLaser cutting

The invention discloses 126-kV cabinet type gas-insulated metal-closed switching equipment and solves the problems that: the 126-kV cabinet type gas-insulated metal-closed switching equipment in the prior art is large in size; final assembly and check are required in a user field; gas tightness is relatively difficult to guarantee; environmental pollution is easy to occur during switching on or off of an electric main loop by using a sulfur hexafluoride breaker; and pressure resistance capacity is relatively lower. The 126-kV cabinet type gas-insulated metal-closed switching equipment is characterized in that: six compartments have a square box shape formed by laser-cutting and laser-welding non-magnetic stainless steel plates which are 4 mm thick; sulfur hexafluoride gas of which the pressure is 0.1 to 0.2 MPa is filled into all compartments; all compartments realize insulating transition connection by using a disk type bus insulating sleeve component of which the diameter is smaller than 300 mm; a vacuum arc-distinguishing chamber polar column is arranged in a vacuum breaker compartment; and double-sheet splicing buses which realize communication of the main loop are arranged in the six compartments. The 126-kV cabinet type gas-insulated metal-closed switching equipment has the advantages of good gas tightness, high mechanical strength, low manufacturing cost and good environmental benefit, solves the insulating problem under the condition of low gas pressure and improves the operating safety of the equipment.

Owner:沈阳华利能源设备制造有限公司

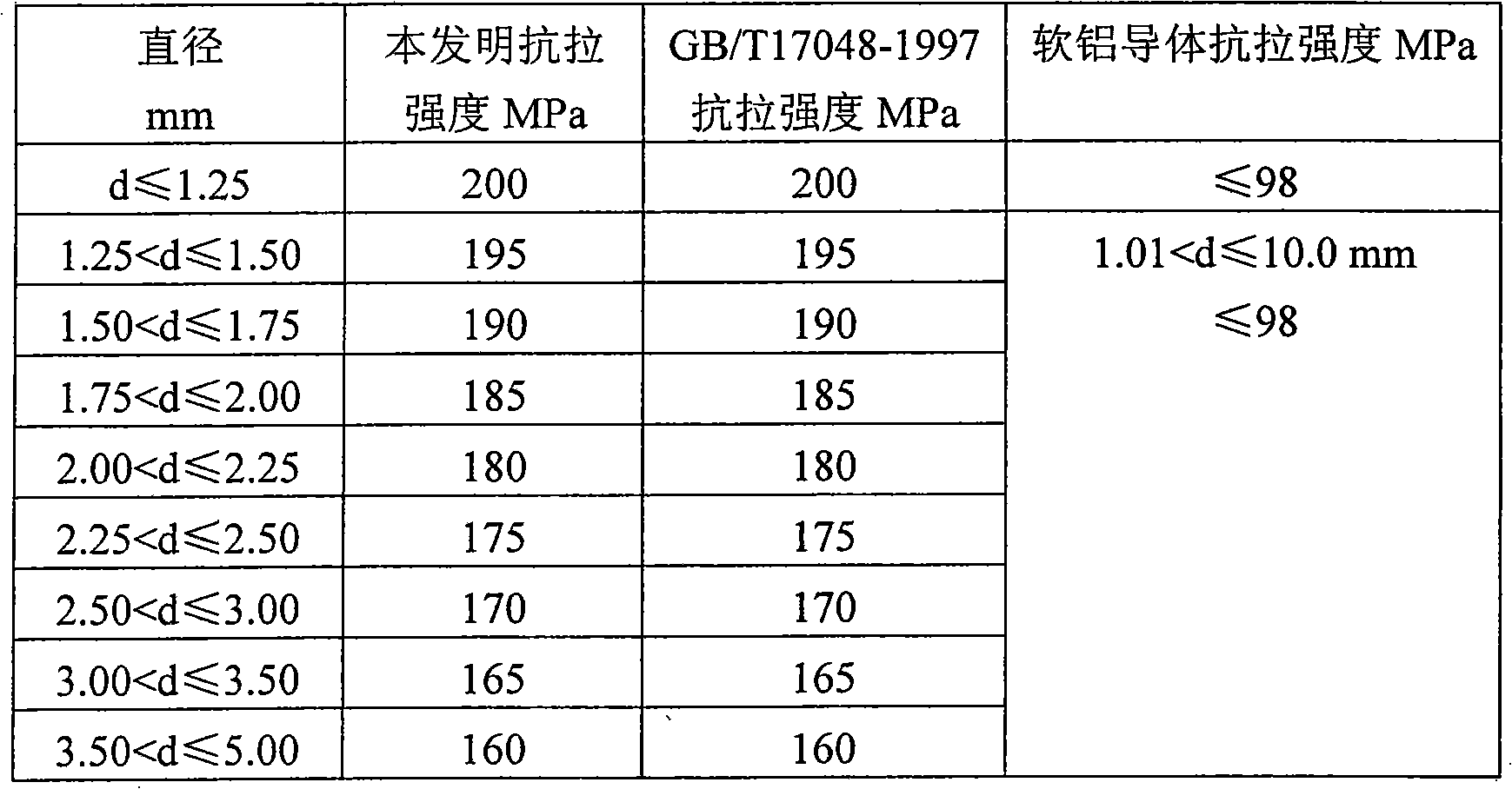

Aluminum conductor for overhead conductor

ActiveCN101345098AImprove delivery capacityImprove conductivityMetal/alloy conductorsHeavy metalsElectrical conductor

The invention relates to improvement to an aluminium conductor used for overhead leads, which is characterized in that: during electrical aluminium ingot melting, according to the content of silicon, heavy metal and iron in the raw material, lanthanum-rich rare earth aluminium alloy, boron or aluminium boron alloy, iron or aluminium iron alloy are respectively added or not added into the raw material; the weight percentage of silicon in the aluminium is controlled to be not more than 0.05wt%, the weight percentage of heavy metal in the aluminium is controlled to be not more than 0.01wt% and the weight percentage of iron in the aluminium is controlled to be between 0.12-0.16wt%; according to wire drawing, the aluminium conductor with the resistivity of 27.300-27.650n Omega question mark m and the tensile strength of 160-200MPa is obtained. Therefore, not only the tensile strength of the hard aluminium conductor is kept, but also the conductivity of the aluminium conductor is improved; the main technical index is obviously better than that of the hard aluminium conductor of national standard GB / T17048-1997; the aluminium conductor of the invention is used for the overhead leads and can obviously improve the high-carrying flux.

Owner:FAR EAST CABLE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com